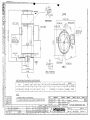

Download ho(v)-4-2 side thrusters

Transcript

OWN

DESCRIPTION

DATE REV NO

APPD

CHKD

' SUBMITTED TO OWNER FOR APPROVAL.

2004

07.05

ISSUED FOR WORKING.

*APPgoVfrD BV

x |4gU£E

g

A//)

£ S BH s

STAMP AREA

BH

{1 )S

r.TAERSK WILLOW

MSSB (US)

.S

m

IMO 9303546

DAE 4437

PROJ. NO.

PROJECT

4437/38/41

FOR CONST.

D FOR REVISION

A.P MOLLER 45',000 M2 PURE CAR/TRUCK CARRIER

APPD BY

TITLE

7

CHKD BY

(H.S. BAEK)

CTEL: 4264)

OWN BY

V/D OF

SIDE THRUSTER

KTE & HYUNDAI

DEPT.

SCALE

HULL OUTFITTING DATE

2004.07.05 AS SHOWN

DESIGN TEAM

E-1012

DWG

REV NO.

DV4040001

DSME :nui>goMM«umi:*

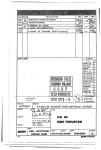

MESSRS :

DAEWOO SHIPBUILDING & MARINE

ENGINEERING CO., LTD

SHIP NO. : DSME / H4437-8 , H4441

TITLE :

SPECIFICATION

OF

THREE PHASE INDUCTION MOTOR

1400KW x 6P x 6600V - BOW THRUSTER

/\H Y U N D A I

HEAVY INDUSTRIES CO., LTD

ELECTRO ELECTRIC SYSTEMS

FOR FINAL

APPROVED BY

K.J.KANG

CHECKED BY

FOR FINAL

2 05.09.12

r

K.S.KIM

FOR WORK NG

04.11.25

FOR APPROVAL

0 04.06.23

NO.

CHECKED BY

DESCRIPTION

DATE

CHECKED BY

CHANGE OF ALTERATION

DESIGNED BY

1 04.11.25

NO.

DATE

K.S.KIM

—

REVD BY

CHKD BY

REVISIONS

RM-W230-049-3

K.S.KIM

K.S.KIM K.J.KANG

CLASS

DNV

CHKD BY

DATE

2004-03-12

APPD BY

DWG. NO.

APP - 4RPH093-095

A4(210mm x 297mm)

Y U N D A

I

DATA SHEET

RFQ. No.

Three Phase Induction Motor

ieavy Industries Co.. Ltd.

I Project No. I4RPH093-5

DSME / H4437-8.H4441

reject Name

1400

6600

A T I NG

KW 6

60 Hz

GENERAL DATA

Rev. No.

[

Item No.

Q'ty

0 1

l Set/Ship

TECHNICAL DATA

IEC.DNV

BOW THRUSTER

630

HLA7 636-66Y

losure-Protection Degree

TEAAC - IP 44

is t rue t ion-Cooling Method

V10

- IC511

INDOOR

at ion

NON-HAZARDOUS.NON-SEISMIC

:a Classification

iulation Class

75 °C

ip. RiseCResi stance method)

ent Temperature

45

°C

LP TO 1000 METER

It i tude

90

i liditv

S2 / 1.0 (30 Min.)

tv-Service Factor

COLD: 2 / HOT: 1

iber of consecutive starts

NEMA DESIGN B

lectrical Design

DIRECT

upling Method

laft Extension

SINGLE

Type

ANTI-FRICTION

6226C3 / 7322B

D.E / N-D.E No.

aring

Lubrication

GREASE

ternal Thrust

NOT APPLICABLE

licable Standard

ignation of Driven Machine

ne No.

ACCESSORIES

Rotor Type

Starting Method

Current

Torque

Rated

Starting

Rated

Starting

Break Down

100 % Load

(*)

(*)

(*)

Efficiency

100 % Load

O.SSO

Power Factor

Rated Speed

Load GD2 (**)

Motor GD2

Direction of Rotation

Location of Main Terminal Box

Paint Colour (Munsell No.)

Motor Weight (Approx.)

1187

rpm

kg275

kg-m2

REFER TO OUTLINE DWG

REFER TO OUTLINE DWG

10 GY 8/4

5100

kg

Sound Pressure Level - mean value,

measured at 1 meter distance from moVibration

Witness Test

WINDING TEMP. DETECTOR (PT 100 ohm):2EA/PHASE

SPACE HEATER : 220V, 630W. 1 PHASE

SQUIRREL CAGE

AUTO T/R 65% TAP

146.5

600

1148.8

kg-m

90

200

95.0

- dB(A)

3.8 mm/sec. (Peak)

DNV

SUBMITTAL DRAWING

** SPARE PART ***

BEARING (6226G+7322B)

OUTLINE DIMENSION DRAWING NO.

MAIN TERMINAL BOX DRAWING NO.

ACC'Y TERMINAL BOX DRAWING NO.

ACC'Y T/B WIRING DIAGRAM AWG. NO.

GENERAL ASSEMBLY DRAWING NO.

MAIN NAME PLATE DRAWING NO.

SPARE PART LIST DRAWING NO.

1 SET / SHIP

Rs = 0.97%, Rr - 2.77%, Xm = 16.97%

Starting Power Factor : 23.2%

Starting Current at Auto TR 65% TAP : 371.4 A

Starting KVA at Auto TR 65% TAP : 4245.7 KVA

ite : Others not mentioned in this specification

shall be in accordance with HHI standard.

\bove technical data are only design values and shall

)e guaranteed with tolerance of applicable standard.

-W230-119-1

(*) : Value at f u l l voltage starting.

Date

Prepared

K.S.KIM

20040623

(**) : Referred to Motor Shaft

Checked

HM-070565

3M-049656

3M-025056

4M-047000

2M-070472

4M-052647

4M-056186

Checked

Approved

K.S.KIM

K.J.RANG

A4(210mm X 297mm)

lo

|o

II

I DETAIL OF UFTING LUG l

MAIN T/BOX

3 n»

5? S-

tlo 4

OU_

B"J°

»J S

o

l

.or

THREE PHASE INDUCTION SQUIRREL CAGE ROTOR MOTOR

OQ

:g

TYPE

OUTPUT

POLE

VOLTS

FREQ.

HLA7

636-66Y

1 400 KW

6P

6600V

60 HZ

PROT.

IP44

INS CUSS

F

SYN. RPM

MOUNT

TOTAL WIGHT

1200RPM

V 10

5100 KG

BEARING

N-D.E

D.E

6226C3

7322B

NOTE

oo

zo:

QUJ

Si

W

VW

WW

REV

60S

12.5S

3.2S

DESCRIPTION

Q'TY

1. THIS MOTOR IS DESIGNED TO BE OPERATED IN ARROW DIRECTION.

2. EXTERNAL THRUST ; NOT APPLICABLE

0.4S

2004.11.22 REV. OF OWNER COMMENT

REV. OF ROTATION (C.W -> C.C.W)

DATE

CONTENTS

K.J. KANG

K. S. KIM K.J. KANC 18-83

K. S. KIM

REVO BY CHKD BY CHKD BY APPDBY

K. S. KIM

K. S. KIM

APPO

CHKD

CHKD

DSND

BY

BY

BY

BY

K. J. KANG

K. S. KIM

MATERIAL

UNIT

SCALE

PROJEC'N

KIM KVANG SDC DATE

DIMENSION

SUBJECT

WEIGHT

PART NO.

HLA7 636-66Y

NON SCALE

TITLE

Angle)

2004-06-23

REF. NO

HYUNDAI

HEAVY INDUSTRIES CO., LTD.

INDUSTRIAL 1C POWER SYSTEMS

REMARK

NO.

OP PRO) T \ FILE •»

S/AX1-15)

OUTLINE DIMENSION DWG.

DWG NO

Sheet No.

HM— 070565

Revision No.

of

2

THIS DRAWING IS PROPRIETARY TO HHI. NO PART OF THIS DRAWING

MAYBE REPRODUCED WITHOUT THE PERMISSION OF HHI.

e säe

HEAVY INDUSTRIES CO., LTD

HYUNDAI

O

ro

on

o

en

en

C/)

fc

CD

O

X

>

O

O

THIS DRAWING IS PROPRIETARY TO HHI. NO PART OF THIS DRAWING

MAYBE REPRODUCED WITHOUT THE PERMISSION OF HHI.

a 240

HEAVY INDUSTRIES CO.. LTD.

HYUNDAI

REV

DATE

CONTENTS

REVO BY CHKD BY CHKD BY APPD BY

a

I I

o

z

l

o

z

Q

Q

o:

o

o:

2

\

(NCMCMrOrOIO1<J-'<J-Tj-lfilOlOCOCOCO

*~

T-

CM

T-

££££££5^££££££

w w

l l l l l l l l l l l l l l l l l l

o o o o o o o o o o o o o o o o o o o o o o o o

l

NOTE

1) WT11.12,13/41,42,43 ; Winding temp, sensor (U) - Pt 100 ohm

2) WT21,22.23/51,52,53 ; Winding temp, sensor (V) - Pt 100 ohm

3) WT31.32,33/61,62,63 ; Winding temp, sensor (W) - Pt 100 ohm

4) SH11.12; Space heater

WTD SETTING POINT (AMBIENT TEMP. : 4-5'C)

WINDING

ALARM

TRIP

130 T 140 *C

DESCRIPTION

APPD BY

H. H. LEE

UNIT

CHKD BY

J. S. PARK

SCALE

NONE

PROJEC'N

3 *TC(3rd Angle)

DATE

2004.06.23

CHKD BY

DSND BY

KIMKWANGSOO

MATERIAL

DIMENSION

Q'TY

MM

HYUNDAI

HEAVY INDUSTRIES CO., LTD.

INDUSTRIAL äc. POWER

SYSTEMS

WEIGHT

PART NO.

REMARK

NO.

CAD PROJ 1 \ FILE

SUBJECT

TITLE

WIR-DIAG\4K047000

ACC'Y TERMINAL BOX

WIRING DIAGRAM

Sheet No.

REF. NO

DWG NO

4M-047000

Revision No.

of

lUONflAH

o

-n

ro

-f^

-j

O

Ul

col

p

Z

o

an

x

(/>

7;

O

'"D

5m

m

~TD

co

a

3

o_

Ol

o

o

c

o

ui

to

x

| T;

o

o

ISl

o

o

o

p

73

m

to

o

O

O

2

s

l

m

5

70

m

o

OIS

O

ERIA

bo

o

o

-(i

01

c

l/)

ro

o

o

i

É

m

o

O

«L

m

m

CO

CO

m

O

m

0

m

CO

o

TI

(/)

M

T)

TI

m

Hl

«=3

J_

DRAWING IS PROPRIETARY TO HEECO. NO PAWOFTHIS DRAWING

MAYBE REPRODUCED WITHOUT THE PERMISSION OF HHI.

o

HEAVY INDUSTRIES CO.,

o

01 OJ

LTD.

1

2

l

1

I

3

4

|

SPARE PART LIST FOR INDUCTION MOTOR

G

SPEC

G

1050KW x 6P STERN THRUSTER

QUANTTITY

ITEM

NO

NAME

OF

PARTS

OUTLINE

DIMENSION

F

—-

ROLLER

BEARING

1

42

Q

o

IT)

CM

IS

'

WORKING

PER

MOTOR

1

O

"*-

SPARE

PER

SHIP

REMARK

PER

SHIP

1

F

NU228M

1

s

E

E

U

50

—

ANGULAR

CONTACK

BALL

BEARING

2

D

O

0

^•a

CM

o

1

1

#7322B

1

D

IS

Q

C

C

B

B

Q'TY

MATERIAL

DESCRIPTION

APPD BY

K. J. KANG

CHKD BY

K. S. KIM

UNIT

MM

SCALE

NONE

DIMENSION

WEIGHT

PART NO.

siiR.irrr

NO.

REMARK

BRG-AS02\4R0561 87

MILL.

A CHKD BY

DSND BY

KIMKWANGSOO

PROJEC'N

3 rd Angle

DATE

2004.06.23

A HYUNDAI

*-

^

1

HEAVY INDUSTRIES CO.,

LTD.

INDUSTRIAL & POWER SYSTEMS

2

1

1

A

SPARE PART LIST

REF. NO

DWG NO

3

Sheet No.

4M-056187

I

4

Revision No.

I

of

0

A . rui •&«•*•

A HYUNDAI

MOTOR TYPE

:

HLA7 634-64Y

1050

RATED TORQUE :

863.0

GD2 OF MOTOR :

160

2

GD OF LOAD

:

300

250

kg.m

kg.m2

2

66.3

£

l

I

l_

i

I

'

kg.m

!

I

L

!

_|

i

I

[

J

i,

!

i

I

1

!

r1

§

1.

!.

,

!

i

i

r

1

i

1

i

!

r

r

r

i

!

!

l

l

1648.0

A

!D :

i•"

l

!

V

!

[

J

!

I

'

i

L

i

I

L

!

U

i

\

l

1

1l

:

;

:

i

!

1

L

1

0

(}

L

1

1

~i i 1 i '

NOT E :

REMARK.

L

1

111!

10

i

i

r

\

-~r — -

i

lp

.

1

; /: \

L

O

O

T-

1

mn

O

O

r-.J

50

LTtrci....

i

i

U -

: ./ !

-__ jT3 _i

i

i

- 700

L

._ r; _ . iA

_Y

§* 100 p.

L

'

'

A ' ^P"

p&-H

\>--L^_i_l_—J^- +

i

i

j

j

r

r

440

O

O

r'"j

L

|

t

— . . }.... —

;

:

'_'

O

TTJ-

;

P

^ 150 _ •

VOLTAGE

CURRENT IN PERCENT

^j

. _

RPM

O

O

i/}

Lc _ U ^ - - U - L - _ !

1185

::iS^

j

i

:

1

1

U-y— — 1

I-D

!

!

t

HZ

RATED SPEED

i

I

L

^ 200

•

60

P

6

RATED CURRENT :

l

I

l_

1

_|

1

I

KW

STC- 4RPM164

J

i

i

;

1

L _ _ 1

i

I

I

CURVE NO.

SPEED-TORQUE & CURRENT

CURVE

.

1

1

1

i Li 1 i i i i !i i i i

L

L

L

.

L

L

1

1

I

1

1

i i i ! i i i i i i i i. 1 i i i i 1 i

7.0 30 40 50 60 70

SPEED IN PERCENT

flO

J- '-' f<

90 100

A: SPEED-TORQUE CURVE AT RATED VOLTAGE

B: SPEED-CURRENT CURVE AT RATED VOLTAGE

C: SPEED-TORQUE CURVE AT 65 % RATED VOLTAGE

D: SPEED-CURRENT CURVE AT 65 % RATED VOLTAGE

REV.

CONTENTS

DATE

DSN

CHK

APPD

2

1

0

RM-W230-091-1

ORIGINAL ISSUE

2004-06-23

S.M.LEE

Y.S .KIM

H.H.LEE

A4(210mmx297mm)

^T

A uvri »mm

THERMAL LIMIT & TIME CURREt

CURVE

A HYUNDAI

MOTORTYPE

:

HLA7634-64Y

1050

KW

CURVE NO.

TLC- 4RPM164

6

60

P

HZ

RATED TORQUE:

863.0

kg.m

RATED SPEED

:

1185

RPM

GD2 OF MOTOR:

160

kg.m2

VOLTAGE

:

440

V

GD2 OF LOAD

66.3

kg.nr

RATED CURRENT :

1648.0

A

:

1n

3

3j

2 !

•j

-l

I

H ,-, 2

i

H "^

M •

i^

\ i

\

i \i

'"«'"'%.

j

T"

1U

n,

^^

7

S

a

'

^_

»

'

•

ii

|

X

i!

-'

S

'

'•-; v

'

i\ %.

j

i V "V

S3

M

y

tlj

v

-.

B . .J

--—

(

i

'

}

l

i

} Z~~V

i

!

!

!

i

3

T

1

fl-r—

"N

•—r—-

1

1 >

\i

*•

c.

i

t

3i

1

NOTE :

REMARK.

!

1

i

\

\

\

\

1

1l Un -1 !| i i i i

1.0

I

H

~-.

i X

|

|

2.0

i i i i

i i i i

i i i i

i i i i

3.Ü

4.0

5.0

CURRENT IN P. U

i i i i

6.0

7.0

A: THERMAL LIMIT CURVE AT HOT CONDITION

B: THERMAL LIMIT CURVE AT COLD CONDITION

C: TIME - CURRENT CURVE AT RATED VOLTAGE

D: TIME - CURRENT CURVE AT 65% RATED VOLTAGE

REV.

CONTENTS

DATE

DSN

CHK

APPD

2

1

0

RM-W230-091-1

ORIGINAL ISSUE

2004-06-23

S.M.LEE

Y.S.KIM

H.H.LEE

A4(210mmx297mm)

1

MESSRS :

DAEWOO SHIPBUILDING & MARINE

ENGINEERING C O . , LTD

SHIP NO. : DSME / H4437-8 , H4441

TITLE :

SPECIFICATION

OF

THREE PHASE INDUCTION MOTOR

1050KW x 6P x 440V - STERN THRUSTER

.

/\H Y U N D A I

HEAVY INDUSTRIES CO., LTD

ELECTRO ELECTRIC SYSTEMS

FOR FINAL

APPROVED BY

K.J.KANG

CHECKED BY

2 05.09.12

"1

NO.

FOR FINAL

CHECKED BY

04.11.25

FOR WORKING

04.06.23

FOR APPROVAL

DATE

DESCRIPTION

K.S.KIM

CHECKED BY

CHANGE OF ALTERATION

DESIGNED BY

1 04.11.25

E

O.

DATE

RM-W230-049-3

K.S.KIM

—

REVD BY

CHKD BY

REVISIONS

K.S.KIM K.J.KANG

CLASS

CHKD BY

DATE

APPD BY

DWG. NO.

K.S.KIM

DNV

2004-03-12

APP - 4RPM164-166

A4(210mm x 297mm)

Y U N D A

I

DATA SHEET

RFQ. No.

Three Phase Induction Motor

Heavy Industries Co.. Ltd.

Project Name

DSME / H4437-8.H4441

Project No. 4RPM164-6

V

1050

KW 6

440

60 Hz

R A T I N G

Rev. No.

[ 0 ]

Item No.

Q'ty

1 Set/Ship

TECHNICAL DATA

GENERAL DATA

IEC.DNV

Rotor Type

SQUIRREL CAGE

~> ilicable Standard

AUTO T/R 65% TAP

Starting Method

s ignat ion of Driven Machine

STERN THRUSTER

1648.0

Rated

rame No.

630

Current

>e

Starting

600

HLA7 634-64Y

(*)

863.0

Rated

kg-m

closure-Protection Degree

TEAAC - IP 44

90

onstruet ion-Cooling Method

Torque

Starting

(*)

V10

- IC511

ocation

Break Down (*)

200

INDOOR

95.0

NON-HAZARDOUS.NON-SEISMIC

100 % Load

ea Classification

Efficiency

sulation Class

mp. RiseCResistance method)

75 °C

0.880

100 % Load

nt Temperature

45

Ititude

LIP TO 1000 METER

Power Factor

niditv

90

1185

r pin

tv-Service Factor

S2 / 1.0 (30 Min.) Rated Speed

2

66.3

COLD: 2 / HOT: 1 Load GD (**)

kg-m2

nber of consecutive starts

160

NEMA DESIGN B

Motor GD2

kg-m2

lectrical Design

Direction of Rotation

jupling Method

DIRECT

REFER TO OUTLINE D1VG

Location

of

Main

Terminal

Box

REFER

TO OUTLINE DWG

SINGLE

laft Extension

10 GY 8/4

ANTI-FRICTION

Paint Colour (Munsell No.)

Type

NU228M / 7322B

Motor Weight (Approx.)

5500 kg

aring

D.E / N-D.E No.

Lubrication

GREASE

Sound Pressure Level - mean value,

'ternal Thrust

NOT APPLICABLE

- dB(A)

measured at 1 meter distance from mo-

E

ACCESSORIES

Vibration

Witness Test

) WINDING TEMP. DETECTOR (PT 100 ohm):2EA/PHASE

HEATER : 220V, 630W, 1 PRASE

3.8 mm/sec. (Peak)

DNV

SUBMITTAL DRAWING

*** SPARE PART ***

) BEARING (NU228M+7322B) 1 SET / SHIP

Rs = 0.82%, Rr = 2.68%. Xm = 16.61%

Starting Power Factor : 22.2 %

Starting Current at Auto TR 65% TAP : 4177.7 A

Starting KVA at Auto TR 65% TAP : 3183.8 KVA

tote : Others not mentioned in this specification

shall be in accordance with HHI standard.

Above technical data are only design values and shall

be guaranteed with tolerance of applicable standard.

I-W230-119-1

(*) : Value at f u l l voltage starting.

OUTLINE DIMENSION DRAWING NO.

MAIN TERMINAL BOX DRAWING NO.

ACC'Y TERMINAL BOX DRAWING NO.

ACC'Y T/B WIRING DIAGRAM AIVG. NO.

GENERAL ASSEMBLY DRAWING NO.

MAIN NAME PLATE DRAWING NO.

SPARE PART LIST DRAWING NO.

HM-070571

3M-045160

3M-025056

4M-047000

1M-000810

4M-052647

4M-056187

Checked

Checked

Approved

K.S.KIM

K.J.RANG

Date

Prepared

K.S.KIM

20040623

(**) : Referred to Motor Shaft

A4(210mm X 297mm)

ACC'Y T/BOX

B-PF2 1/2/

/(GLAND

l'-PF1/2s\

ZyPFI 1/4\

GLÄN.D 15c,30b/

AIR OUTLET

O

in

THREE PHASE INDUCTION SQUIRREL CAGE ROTOR MOTOR

TYPE

HLA7 634-64Y

OUTPUT

1050 KW

POLE

VOLTS

6P

440 V

FREQ.

60 HZ

PROT.

INS CLASS

SYN. RPM

IP44

F

1200 RPM

BEARING

MOUNT TOTAL WEIGHT

V 10

5500 KG

N-D.E

D.E

NU228M

7322B

NOTE

W

505

I2.5S

1. EXTERNAL THRUST : NOT APPLICABLE

Q'TY

2. THIS MOTOR IS DESIGNED TO BE OPERATED IN ARROW DIRECTION.

APPD BY

UNIT

CHKD BY

SCALE

NON SCALE

PROJEC'N

3 Ttt(3rd Angle)

2004-05-23

3.2S

WW

0.4S

DESCRIPTION

CHKD BY

DSND BY

REV. OF OWNER COMMENT

REV. OF ROTATION (C.W -> C.C.W)

REV

DATE

CONTENTS

K. S. KIU

v S. KIM

K. J. KANG

REVDBY CHKD BY CHKD BYi APPD BY

KIM KWANG SOO

MATERIAL

DATE

SUBJECT

A HYUNDAI

*-

^>

HEAVY

DIMENSION

INDUSTRIES CO., LTD.

WEIGHT

PART NO.

REMARK

HLA7 634-64Y

NO.

«(1:20)

TITLE

OUTLINE DIMENSION DWG.

REF. NO

DWG NO

Sheet No.

HM-070571

Revision No.

of

2

23

22

21

20

9

1 GREASE DRAIN ASSY

CREASE SUPPLY ASSY

CREASE DRAIN ASSY

GREASE SUPPLY ASSY

MILD STEX {SS4OO)

MILO STEt (SS400)

END COVER ASSY

UILDSTH <SS400)

FAN COVER ASSY

MILD SIEE (SS400)

7

6

~T

OUTER FAN ASSY

END SHIELD ASSY(N-O£ StOE)

BEARING ASSY(N-D.E SIDE)

END SHIELD ASSY(Di SIDE)

U1LDSTEE (SS400)

BEARING ASSY(D.E SIDE)

FIXINQ SUPPORT ASSY

MILD STCE (SS400)

AR GUIDE ASSY

INNER FAN A£SY(N-D.E SDE)

ULD SIG (SS400)

INNER FAN ASSY|D.C SIDE)

UlLDSTCI (SS<00)

ROTOR BAR ASSY

CU

ROTO« CORE ASSY

FORGING'. IEEL.

3

STATOR COIL ASSY

STATOR CORE ASSY

^Ti

WLDSTEE (SS400)

WEIGHT

OTT

APPD BT K. J. KANC

CHKD BY K. S. KIM

PROUEC"N J rt Angl«

DSHD BY KM KIMNC SCO DATE

/HYUNDAI

REVD BY

CHKO ttt APPO BY

*

i

EUCTRCAi. ENGINEERING co.. im

PART NO.

NO.

HLA7.(V10)

GENERAL ASSEMBLY

Slmt No.

1M-000810

li —

R«vl«lon No.

of

O

s

660

700

¥

TERMINAL BOX COVER

550

+• H- +

-t- I—t+ + +

+ + + + + +

+ + + + •• +

at

MAIN POWER TERMINAL

X

4i-

EARTH TERMINAL

"

4"

o

Q

in .

1

8-PF2 1/2"

173

173

OQ

zco

130

il

MAIN POWER CABLE GLAND : 8-55a

I VIEW "Z'l

0.5

OQ

600

CABLE GLAND ARRANGEMENT AREA

a:

^

REV

DATE

CONTENTS

2

REVO BY CHKD BY|Q.P CHK APPO BY

m.

DESCRIPTION

QTY

MATERIAL]

APPD BY

K.J. KANO

UNIT

Q.P CHK

K. S. KIM

SCALE

CHKD BY

DSND BY

KIM KWANG SOO

| WEIGHT |

PART NO.

* ELECTRICAL ENGINEERING CO., LTD.

|

REMARK [NO.

CAOPROJ <\F1LE t

SUBJECT

NONE

TITLE

PROJEC'N 3 «M(3rd Angle)

DATE

2003.02.18

A HYUNDAI

*•

DIMENSION

MM

| T-BOX-M\3ft045160

TERMINAL BOX ASSEMBLY

REF. NO

DWG NO

Sheet No.

3M—045160

I

Revision No.

9

of

0

IS.

TO

o

Ul

en

01

to

To

•L

g

§

3

I

R

CO

OD

O

X

O

THIS DRAWING IS PROPRIETARY TO HHI. NO PART OF THIS DRAWING

MAYBE REPRODUCED WITHOUT THE PERMISSION OF HHI.

Ø

D 240

©@©

HYUNDAI

O

O

_HEAVT INDUSTRIES CO.. LTP.

w'

o'

•vi

O

O

l

O

rr

(D

(D

Ol

fo

CD

o

o

>

ö

M

S

>

o

c/>

o

o

o

cn

X

'S.

a

?

O4

-l

Q.

o

?

o

x'

o

o

o

o

OJ

i5

-H

T!

^

>

z

o

o

^

z

en

d

ro

m

S

<D

z

01

m

ro

(/)

£,

o

3

IT

o

o

o

O)

OJ

N3

b)

Ol

\

OJ

OJ

ro

OJ

OJ

o

rr

O

O

OJ

cn

Ul

M

cn

K)

M

NJ

OJ

K)

O

O

T)

l

OJ

ro

OJ

M

,, „o wlv,,.,,,o ,0 , ROPRIETARYTO HHI.^.y PART OF THIS DRAWING

MAYBE REPRODUCED WITHOUT THE PERMSSION OF HHI.

HEAVY INDUSTRIES

-SH12

-SH11

-WT42

-WT43

-WT51

-WT52

FOR WINDING TEMP. TRIP

-WT53

-WT61

-WT62

-WT63X

-WT4K

-WT12

-WT13

-WT21

-WT22

FOR WINDING TEMP. ALARM

-WT23

-WT31

-WT32

-WT33X

-WT1K

l\r

8*1

C/)

ro

CO., LTD.

04

l

33

(t

<

cn

Ul

o

(

f

5

o

m

-Q

NJ

r°

b

KJ

O

O

o

(/>

o

o

5

O

O

O

c

CO

03

ion

o

m

T)

m

O

o

m

oo

o

T

m

o

OISN

o

in

ERIA

CO

o

uo

c

>

m

o

o

±

O

Cn

5

O

_

m

2 >

m

O

0

«i

m

o

•a

m O

0

_L

c

co

O

XI

(n

M

XI

XI

m

_L

TlWuRAWING IS PROPRIETARY TO HEECO. NO PAR^)F THIS DRAWING

MAYBE REPRODUCED WITHOUT THE PERMISSION OF HHI.

o

o

HEAVT INDUSTRIES CO., LTD.

HYUNDAI

HEAVY INDUSTRIES CO., LTD.

riYUrauui

1

2

l

I

3

4

SPARE PART LIST FOR INDUCTION MOTOR

G

G

1400KW x 6P BOW THRUSTER

SPEC

QUANTTITY

ITEM

NO

NAME

OF

PARTS

OUTLINE

WORKING

PER

MOTOR

DIMENSION

F

—-

|l[Dl

SPARE

REMARK

PER

PER

SHIP

SHIP

F

40

~~~

_|_

BALL

1

P

K

**•

|

BEARING

0

n

1

0

1

#622603

1

CM

^

E

E

M^1

iij

-\5° h

TN"

HJ *T

ANGULAR

CONTACK

BALL

BEARING

2

J>

Z

D

1

:e

d

0

o o

CM

1

#73226

1

D

Q

n

NG IS PROPRIETARY TO HHI.iKJ PARI Oh IH

RODUCED WITHOUT THE PERMISSION OF HHI.

1

T™

C

C

B

B

DESCRIPTION

Q'TY

DIMENSION

MATERIAL

WEIGHT

PART NO.

CO

US

APPD BY

K. J. KANG

UNIT

MM

CHKD BY

K. S. KIM

SCALE

N/S

PROJEC'N

3*TO(3rd Angle)

DATE

2004.06.23

A CHKD

Dl

DSND BY

KIM KWANG SOO

A

1

«;iiR.iFrrr

1

BRG-AS02\4R056186

DWG NO

I

A

SPARE PART LIST

Sheet No.

REF. NO

HEAVY INDUSTRIES CO.. LTD.

INDUSTRIAL Se. POWER SYSTEMS

2

CAD PROJ * \ FILE t

T-l-Pl 1-

A HYUNDAI

f.

NO.

REMARK

3

4M-056186

I

4

Revision No.

of

0

.

'

AHYUNDA

MOTORTYPE

:

CURVE NO.

SPEED-TORQUE & CURRENT

CURVE

HLA7 636-66Y

1400

KW

6

STC-

4RPH093

P

60

HZ

RATED TORQUE:

1148.8

kg.m

RATED SPEED

:

1187

RPM

GD2 OF MOTOR :

275

kg.m2

VOLTAGE

:

6600

V

GD2 OF LOAD :

89.0

kg.ni2

RATED CURRENT :

146.5

A

T.nn r^

_.

juu

!

1

L

1

i

9*>o £7u

/.•Jv

1

1

1

1

.

U

1

1

1

L

1

1

.

i

L

L

1

1

1

1

1

1

Ijy

i

l

1

!-D

1

I

L

!

I

1

I

L

1

I

1

I

L

1

!

- 700

L

-ij

L.

1

1

i

j

|

|

j

-

!

,

,

.y

H 500

r

f-

f>° i

I

1

te

M

i i i L l i i Å

É

sJ

r - —

f~

\-

tj

§

i

NOTE :

!

! __^_J--^"

1

!

|

i

!

!C__^

L

L

L

L

!

1

1

1

!

1

1

1

L

20

\

i

!

!/

!

1 1 1 1 1 1 1 1 1 1 ! 1 1 1 1 1 1 1 1 l_.

10

JrS

i

/

^"i

L

L

1

i

1 1 1 ! 1 1 1 L.

L

L

l

1

flO

1

0

90 100

1 1 1 1 1 1 1 1 LJ L 1

30 40 50 60 70

SPEED IN PERCENT

0

0

!

o

LU. l

i

T-

A

f

!7\

o

L

c——

i

1_ !

!

RH U

vMJ

[J

i

Ll

O

K^_

1

l

: / ^

D-J

g

!

~

!

i

Q

E

^*

nn ~

i^ 1l Uw

;

o

g

ID ;

KJ

r

i-

:

ßV PERCENT

^ 1 50 !

I

A: SPEED-TORQUE CURVE AT RATED VOLTAGE

B: SPEED-CURRENT CURVE AT RATED VOLTAGE

C: SPEED-TORQUE CURVE AT 65 % RATED VOLTAGE

D: SPEED-CURRENT CURVE AT 65 % RATED VOLTAGE

REMARK.

REV.

CONTENTS

DATE

DSN

CHK

APPD

2

1

0

RM-W230-091-1

ORIGINAL ISSUE

2004-06-23

S.M.LEE

Y.S .KIM

H.H.LEE

A4(210ninix297nmi)

T

A HYUNDAI

A

™ ™*

c TIME CURRENT

VT

^

MOTORTYPE

:

1400

HLA7 636-66Y

KW

6

CURVE N0

"

TLC- 4RPH093

60

P

HZ

RATED TORQUE:

1148.8

kg.m

RAJED SPEED

:

1187

RPM

GD2 OF MOTOR:

275

kg.m2

VC)LTAGE

:

6600

V

GD- OF LOAD

89.0

kg.m2

RßiTED CURRENT :

146.5

A

:

1M n,' ' n . •

H3 .ji

å- i

,

i

l

[

i

i

i

1

i

i f~\ 2

\

i

j

i

, .> ^\.

'•

:

H =,

*„

-J

-

5i

*i

N.

\

\

'

t

vx i

._ i x x „ _ .

i

"V

! "~v.

s^

:

m

|1J

n~" •

B^;

^^

N

"

"":

!

1

;

1

1

i

-

-_

H

[

!

i

!

i

;

1 ^^-.~~"~--^ R

i

1i \A

—it

'" •

*

1J i

1

1

3

!

—•u""~"—^. i

,f

1

-

J

i

^

Sv_

1

i

1

J

.

i

*~-^f. '

c , \=t=

\

Q

l

j

i '^--.. """--"H^

^

^

rTi

•

i

n!

-\

\

j

\

i

\

j

1| U

n -1

i l 1 i

1.0

i i i i

2.0

3.0

i i i i | i i i i | i i i i | i i i i

4.0

5.0

6.0

7.0

CURRENT IN RU

NOTE :

REMARK.

A: THERMAL LIMIT CURVE AT HOT CONDITION

B: THERMAL LIMIT CURVE AT COLD CONDITION

C: TIME - CURRENT CURVE AT RATED VOLTAGE

D: TIME - CURRENT CURVE AT 65% RATED VOLTAGE

REV.

2

1

0

RM-W230-091-1

CONTENTS

ORIGINAL ISSUE

DATE

2(J04-06-23

DSN

S.M.LEE

CHK

Y.S.KIM

APPD

H.H.LEE

A4(210mmx297mm)

CONTENTS

1. INSTRUCTION MANUAL

FOR THRUSTER CONTROL SYSTEM

BOW & STERN

2. REMOTE CONTROL SYSTEM

THRUSTER

3. HYD. PUMP STARTER &

TCT-220

LOCAL CONTROL BOX

4. SPARE PARTS & TOOLS LIST

4-1. ELECTRIC PART

5. NOTE

KTE - ü NAKASHIMA

KTE CO.,LTD.

MECHATRONICS DIVISION

w w w .kte.co .kr

INSTRUCTION

MANUAL

(VER

1.1)

KT - TCS

Thruster Control System

August 2005

KTE

KTECa,LtcL

1497-11. Songeong-Dong, Gangseo-Gu,

Busan 618-270, Korea

Tel: +82-51-265-0255 Fax : +82-51-265-0250

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

-Contents1. Introduction

1.1. Use

1.2. Basic specifications

2. System construction

2.1. The whole system construction

2.2. Terminal block diagram (1)

2.3. Terminal block diagram (2)

2.4. Terminal block diagram (3)

2.5. Hardware construction

3. Main functions

3.1. Auto blade angle control (follow up)

3.2. Change control position

3.3. Manual control

3.4. Auto load control

3.5 Communication and analog output for VDR

4. System operations

4.1. Adjusting command value

4.2. Adjusting feedback value

4.3. Setting parameter

5. Layout drawing

5.1. Front panel

5.2. External diagram

6. Operating flow charts

6.1. Normal operation

6.2. Change control position

6.3. Auto load control

7. Parameter adjust unit

7.1 LCD display

7.2 Explanations for each key

7.3 Changing over to another address

7.4 Changing value of each parameters

# Appendix : system parameter

KTE CO., LTD.

REV

PAGE : 2

OF 43

DOCU. NO :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 3

OF 43

DOCU. NO :

1. Introduction

1.1. Use

This manufacture is a private controller of the thruster which is used when a

ship enters or leaves a port, the main functions of the manufacture are to detect

control input, feedback value, and to control blade angle of the thruster with the

most optimal condition by follow up control algorithm

Control command is done by port wing, stb'd wing as well as W/H, and the

action is done with the command of related control position, which can be

changed simply by operating a button.

Each parameter which is necessary to control can be identified and changed

with parameter setting equipment.

1.2.

Basic Specifications

1.2.1. Main control panel ( Bow / Stern )

1) Standard specifications

- Supply voltage : DC 24V

- Current : 3A

- Temperature range : Ot: ~ 70 °C

- Output contact : 10A ( 250VAC ) for magnet contact

2A ( 30VDC ) for signal output

2) Main control board

- 8 bit micro-controller

- Digital dimmer

3) Input specifications

- Digital input : 20 channel

- Analog input : 7 channel

- Control dial : potentionmeter 2K ohms

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 4

DOCU. NO :

4) Output specifications

- Indication lamp

• For alarm : 12

• For information •' 7

• For indication : 9

• For pitch : bar Indication

• For current : decimal (with pitch indicating by mode switch)

- Contact output : 2 channel ( for S/V operation )

13 channel ( for signal output )

- Alarm contact output :

• System failure contactor.

• Power failure contactor.

- Analog output

• 2 Channel ( for wing analog meter )

- For VDR (Voyage Data Recorder)

• Command signal : -10V ~- -MOV

• Feedback signal : -10V ~ +10V

• Thruster run signal : On/Off contactor

• RS-485 communication

1.2.2. Wing control panel ( Bow & Stern )

1) Input specifications

- Digital input : 2 channel x 2

- Analog input : 2 channel x 2

- Control Dial : Potentiometer 2K ohms x 2

2) Output specifications

- S/W output : 2 channel ( for signal output ) x 2

- Analog output : 1 channel ( for command ) x 2

KTE CO., LTD.

OF 43

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

3) Indication lamp

• For alarm : 3 x 2

• For information : 1 x 2

• For indication : 1 x 2

• For pitch : bar Indication x 2

• For current : ammeter Indication x 2

KTE CO., LTD.

REV

PAGE : 5 OF 43

DOCU. NO :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 6

DOCU. NO :

2. System construction

2.1. The whole system construction ( Bow / Stern )

W/H PANEL

PORT WING

&SB

Terminal Board A,B

ENGINE ROOM

KTE CO., LTD.

OF 43

KTE

2.2.

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

Terminal block diagram (1)

- Bow

KTE CO., LTD.

REV

PAGE : 7 OF 43

DOCU. NO :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

2.2. Terminal block diagram (1)

- Stern

w

r*

u

AC220V 60Hz #1(3A)

CONTROL POWER SUPPLY '

OC24V (M)

BMTERY POWER SUPPLY

TERMINAL BOARD A

3

rå

La Ilif

TB2A

TB2

SSP

SSP

ssc

sss

ssc

sss

—

«-sp

c"

ȣ*

ftffi | EMSW ~|5

STT m, -c P

ai

—

1

!?

TB3

Rc

sro

•x>L

SNO

SPO Ir, LOCAL

SNO J"STAnOI4

sw

SA1

SU

>

e- SUE1

SUE2

SUEZ

EUW STOP

0^

SUE4

IB5

35

ii r

]

/ J-TI

SW1 tiov

SJJ

SW1 ±1<V

1—

sue

sue

1

J

COMI

SU3

-Q KHOKWPRÜN

SU3 -Q IWUSTDt RUN

SUS -Q READY 10 START

sus

SU« -aPOWCHAWIW«

sue

r^

SUB

SEC

SE*

SEC

SE3

SES

SES

1—

COINON

SEC

11

._ SO

J

-O Hra

PUMP U» PRESS.

-Q HEADI9t WK UM Urø.

—D **** UOroN OVERLO«

-n H«. RJUP crauwo

SE3

-D "** MOTOR

-O u** MOTOR

SE7

START FHL

STARTER ÅBN.

MOTOR «MMO

"^ TEUP MM

8«-<3

I

I

^

"P

p

^

(_<—f f

J|

-i

se«

SE»

n

11

-

3

^

"^

>

g

E

ov

s« •<_»-

,— .

tiw

L

S-0

/j=».

son ±1W

<—f^ff

ov

SCR2

L

*L

sji

S

r

SVR2

SJ>

-^

j <—(

S

^"^

SAUI

~t_f-

Æ

+15V "

SFt

sn

SF3

ST*

5FE

Sf2

5T3

SF4

-15V

W

F.G

SFE

E

S

TB4

SN1

SN1

SN2

SN2

SPI

SPI

SP2

SP3

SP3

SP4

SP4

SPS

SP9

SM

BUOCANOZ

NEUTRAL

TWU5TER «M

ft

TWU5TER STOP

Q

KUXPUIP RUN

HttMIP STOP

5

ROW BOATO

KTE CO., LTD.

PAGE : 8

OF 43

DOCU. NO :

KTE

2.3.

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

Terminal block diagram (2) - ( Bow / Stern )

TER WINAL BOARD B

1'B6

+24V

BTB1

r

1A

ov

1A

-n

n-

—1^ CON. STATION

THRUSTER ÅBN.

-a

M/U OVERLOAD

-d

T)

HYD.PUMP STOP

-a

S

THRUSTER RUN

BUZZER STOP

TJ

O

3

f

58

-

148

6A

•

8A

F.G

9A

- 11A

F.G

98

- 118

BUZZER f

°~

PITCH

T

L

IND.

o

^

—TBzl BUZZER

-i

}-a

i

°

O

i

•M5V

SIG

-15V

OV

Ml

1I

m

r~

J

)^-k

AMMETER [

11A

EM'CT STOP

- ISA

- 16B

11B

44i

B7

+24V

^i

—«S-o

BTB1

IA

-

1A

2B

-

48

38

- 5B

OV

-d

STAT. IND. Jt-T"

nU/U OVERLOAD

HYTXPUMP STOP

THRUSTER RUN

BUZZER STOP

21

S

PITCH

IND.

1

-••^ CON. STATION

-a

THRUSTER ÅBN.

SÅ

» 14A

58

- 14B

T

L

—G

iq

-a

-n

CD

°

~*n

—fBZlBUZZER

^

s

0

O

+15V

SIG

-15V

"

OV

AUMETER

F.G

9A

F.G

9B

£

EU'CY STOP

10B

113

- 11A

- 11B

"ri—Å

Ml

S

- 128

rH

- 168

æ1

4é BNR2

f

BNR1

BAB<

BAB2

KTE CO., LTD.

"Z.

m

r~

PAGE : 9 OF 43

DOCU. NO :

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

KTE

REV

PAGE : 10 OF 43

DOCU. NO :

2.4. Terminal block diagram (3) - ( Bow / Stern )

~Tw/H

POWER SUPPLY

(EWS150-24)

+S +V -V

Ø

DC24V OUTPUT

-S ACG L

N

Ø

AC220V INPUT

AEMSW

REU\Y BOARD

TB3 (36P)| |TB4 (36P)| |TB5 (20P)|

KTE CO., LTD.

CONTROL PANEL

KTE

2.5.

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 11 OF 43

DOCU. NO :

Hardware construction

2.5.1. Main control panel

1) CPU board :

This board uses 8-bit micro-controller in order to control digital input,

digital output, and analog in/out. This is composed of CPU, memory, etc.

2) Analog board :

This board is composed of hybrid. IC, analog input circuit, this includes

volume resistors to tune offset and gain for 5-channel analog inputs.

3) I/O board :

This is for digital input/output. It is consist of relay and etc.

4) Display board :

This board is located in front of the case, and composed of various

indication lamps, buttons, dial for command input, blade angle indicator,

ampere meter, etc.

5) Mother board :

This board is connected with CPU board directly. This is supply DC power

to system.

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 12 OF 43

DOCU. NO :

2.5.2. Wing control panel

1) Display & mother board :

This board is located in front of the case, and composed of various

indication lamps, buttons, dial for command input, blade angle indicator,

ampere meter, etc.

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 13 OF 43

DOCU. NO :

3. Main functions

3.1. Auto blade angle control (follow up control)

Main function of this system is to control blade angle with command value.

That is to say, this system controls blade angle automatically with command,

when follow up control algorithm is used. If feedback value becomes close to

command value, this system doesn't transmit S/V control signal constantly, but

pulse signal with constant time interval, and feedback value can reach the

objective value quickly without overflowing command value. Users have to set

parameters with parameter setting equipment in advance, and it is possible to

set parameters properly per characteristics of every ship.

The kinds and contents of related parameters are as follows.

- Follow up start gab : data to decide starting point of follow up control

(Starting point of follow up control = command value - follow up start gab)

- Follow up S/V on time : when follow up control, S/V active time

- Follow up S/V off time : when follow up control, S/V inactive time

- Dead band zone : if each parameter and data are in this range when they

are compared, they are regarded as same values,

(applied items : neutral, command & feedback, command

change over comparison)

All parameters can be identified and changed with parameter setting eqipment,

and operating method for parameter setting equipment can be referred in

another manual.

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 14 OF 43

DOCU. NO :

1) Interval time chart (when P1 is compatible)

Command position

Time

P1

P1 : follow up start position (= command position - follow up start gab)

2) Interval time chart (when P1 is too long)

Command position

Pitch

i ime

n

SN ON

S/V OFF

I

Time

T2 IT1

P1

T1 : When follow up control, S/V active time

T2 : When follow up control, S/V inactive time

P1 : follow up start position (= command position - follow up start gab)

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 15 OF 43

DOCU. NO :

3) Interval time chart (when P1 is too short)

Command position

Time

PI

P1 : follow up start position (= command position - follow up start gab)

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 16 OF 43

DOCU. NO :

3.2. Change control position

1) Change position from W/H to wing

Position can be changed to wing by pushing "CHANGE OVER" button in wing

control panel. If once button is pushed, wing control station lamp in W/H

control panel starts flickering, and buzzer starts ringing in the form of pulse,

when command value of wing control panel corresponds with feedback value,

control position is turned to wing completely and wing control station lamp

becomes steady state.

Moreover, if W/H control station button is pushed in flickering state, then all

motions are canceled and return to previous state.

Process of the motions is as follows

CONDITION

ACTION

W/H

WING

- Command :

Port 7.0

- Command :

Zero

- Position :

Port 7.0

- Push on

wing control

button

- W/H : Flickering wing lamp

- Wing : Flickering wing lamp &

buzzer on

- Push on

W/H control

button

- W/H : Wing lamp off

- Wing : Wing lamp off &

buzzer off

Cancelled

- W/H : Flickering wing lamp

- Wing : Flickering wing lamp &

buzzer on

- Push on

wing control

button

- Command :

Port 7.0

REMARK

FEEDBACK

- Position :

Port 7.0

KTE

- W/H : W/H lamp off

- Wing : Wing lamp go to steady

& buzzer off

CO., LTD.

Ack.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 17 OF 43

DOCU. NO :

2) Change position from wing to W/H

To change control position from wing condition state to W/H is equal to

previous one, and process of the motions is as follows

CONDITION

ACTION

W/H

WING

- Command : - Command :

Zero

Port 7.0

- Position :

Port 7.0

- Push on

W/H control

button

- W/H : Flickering W/H lamp &

buzzer on

- Push on

wing control

button

- W/H : W/H lamp off &

buzzer off

- Push on

W/H control

button

- Command :

Port 7.0

REMARK

FEEDBACK

Cancelled

- W/H : Flickering W/H lamp &

buzzer on

- Position '•

Port 7.0

- W/H : W/H lamp go to steady

wing lamp off &

buzzer off

- Wing : wing lamp off

KTE CO., LTD.

Ack.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 18 OF 43

DOCU. NO :

3.3. Manual control (Non-follow up control)

In this system, blade angle can be basically controlled by means of

recognizing angle that users input with CPU and controlling automatically with

follow up control algorithm, and another operation isn't necessary.

But, users must operate manually in case of not being controlled automatically

because of difficulties in CPU or related components, for manual operation,

users must pull Non-follow button in W/H control panel, when all control signals

transmitted from CPU board are blocked forcedly and users can control directly

with the button below control dial

3.4. Auto load control

This is for protecting overload in follow up operation, and controlled

automatically by PI control depend on ALC set point.

If main motor actual load is more than preset load in follow up condition, the

blade angle is automatically reduced to the angle of preset load.

Current

ALC

set point

Time

SA/ Activated

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 19 OF 43

DOCU. NO :

3.5. Communication and analog output for VDR

In this system, there are communication port(Serial / RS-485) and 2 analog

output, 1 digital output.

• Command signal : -10V ~ +10V

• Feedback signal : -10V ~ +10V

• Thruster run signal : on/off contactor

• RS-485 communication

KTE CO., LTD.

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

KTE

REV

PAGE : 20 OF 43

DOCU. NO :

4. System operations

4.1. Adjusting command value

In this system, 3 command values transmitted from W/H, port wing, st'bd wing

are used, each input value is voltage value transmitted from potentiometer

located in the inside, and converted into digital value by A/D converter.

A/D converter provides 12-bits resolution, and -10V—+10V voltage range

basically corresponds to 0 — 4095 digital value, but, there may be a few

differences due to position of potentiometer or variable resister value of circuit.

Therefore, zero and min/max value should be set in advance by means of

adjusting position of potentiometer and offset, gain resister of circuit.

Data which should be set in advance in relation to command input are position

of control dial (potentiometer), voltage, A/D conversion value, and angle. Values

set for each item and allowed tolerance of error are as follows

No

Control dial

Voltage

A/D Count

Angle

1

Port max. position

-10 V

0-10

up to 30.0°

2

Zero position

0 V

2043 ~ 2053

0

3

St'bd max. position

+10 V

4086 ~ 4095

up to 30.0°

The methods to set data are as follows

-

Stick prameter setting equipment on control unit, and input maximum angle.

Set address for parameter setting equipment to indicate A/D count value.

Put the position of control dial to port max. position

Adjust offset, gain, position of potentiometer for A/D count to be in

tolerance.

In the same way, set zero position and st'bd max. position

Set address for parameter setting equipment to indicate angle.

Identify position and angle of control dial

Save A/D count value to the address of parameter setting equipment

KTE CO., LTD.

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

KTE

REV

PAGE : 21 OF 43

DOCU. NO :

4.2. Adjusting feedback value

Adjusting feedback value is equal to that of command, and 2 positions for

data identification are added in order to heighten accuracies of data.

No

Control dial

A/D Count

Angle

01

Feedback PORT 25

0-20

Port 25 degree

02

Feedback PORT 20

309 ~ 419

Port 20 degree

03

Feedback PORT 15

809 ~ 829

Port 15 degree

04

Feedback PORT 10

1218 ~ 1238

Port 10 degree

05

Feedback PORT 5

1628 ~ 1648

Port 5 degree

06

Feedback Zero

2038 ~ 2058

Zero

07

Feedback STBD 5

2447 ~ 2467

STBD 5 degree

08

Feedback STBD 10

2857 ~ 2877

STBD 10 degree

09

Feedback STBD 15

3266 ~ 3286

STBD 15 degree

10

Feedback STBD 20

3676 ~ 3696

STBD 20 degree

11

Feedback STBD 25

4075 ~ 4095

STBD 25 degree

4.3. Setting parameter

Parameters in this system are saved at the memory in W/H control panel, and

loaded when power is supplied initially, setting and identifying each parameter

are accomplished with another parameter setting equipment.

Refer appendix if you want to know the kinds and contents of parameters in

system.

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 22 OF 43

DOCU. NO :

5. Layout drawing

5.1. Front panel

1) W/H control panel ( Bow )

BOW

©

©

THRUSTER CONTROLLER

.©

©

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

PAGE : 23 OF 43

REV

DOCU. NO :

5. Layout drawing

5.1. Front panel

1) W/H control panel ( Stern )

[ STERN

©

©

THRUSTER CONTROLLER

EM'CY STOP

MAIN MOTOR

PO

SO

-{com. STATION)-

o

£

FDUm

-f

BLADE ANGLE INDICATOR

PORT

10

STBD

5

0

]D

10

PORT

OFF

10

5

^

10

ST'BD

I ON l l PIHM .

laial

- MNAKASHIMÄJ

.©

©

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 24 OF 43

DOCU. NO :

2) Wing control panel

- port wing

o

o

o

o

o

o

O

c

c/)

H

m

o

O

o

o

o

=•!

o

o

KTE CO., LTD.

o

I—

f—

m

O

O

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 25 OF 43

DOCU. NO :

- Stb'd wing

o

o

o

O

o

O

O

o;

kJ

o

o

o

o:

Lu

c/)

Z)

o er

i

O

o

= !•=

o

O

KTE CO., LTD.

O

o

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 26 OF 43

DOCU. NO :

5.2. External diagram

1) W/H control panel ( Bow / Stern )

-THRUSTER CONTTOUfR

ANALOC BOARD

CPU BOARD

I/O BOARD

< FRONT VIEW >

' < SIDE VIEW >

MOTHER BOARD/

POWER

SUPPLY

< BOTTOM VIEW >

KTE CO., LTD.

LL

0

£

••

0

O

ü

LU Z>

<£

CL Q

LU

GC

CO

O

11

E

"g

H

LL .22

O

_J CO

=)

"Z.

*^ "c

o

2E O

CO i—

DC "oo

LU

CO rID

LU

H-

A

ÜJ

et:

<

Lu

er

v

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 28 OF 43

DOCU. NO :

2) Wing control panel ( port )

Gaf

< FRONT VIEW >

< REAR VIEW >

KTE CO., LTD.

< SIDE VIEW >

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

6. Operating flow charts

6.1. Normal operation

Feedback Value

> Command ?

Feedback Value

< Command ?

KTE CO., LTD.

REV

PAGE : 29 OF 43

DOCU. NO :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

6.2. Change Control Position

Feedback Value =

Wing Command ?

KTE CO., LTD.

REV

PAGE : 30 OF 43

DOCU. NO :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

6.3. Auto load control

Actual Current

ALC set point

KTE CO., LTD.

REV

PAGE : 31 OF 43

DOCU. NO :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 32 OF 43

DOCU. NO :

7. Parameter adjust unit

7.1 LCD display

1) Setting parameter mode

> S[00] : 00000

S[01]

: 00000

S[02]

: 00000

No :

-

"

"

"

"

"

"

DATA :

> " : Cursor which is indicate position of address

S " •' It means that each parameters are available to be set

[xx] " : It means address

00000 " : It means value of each address

No : " : This is area of inputting address

DATA : " : This is area of inputting value

2) Monitoring parameter mode

> M [00] : 00000

M[01]

: 00000

M [02] : 00000

No :

DATA :

> " : Cursor which is indicate position of address

M " : It means that each parameters are available to be monitored

[xx] " : It means address

00000 " : It means actual value of each address

No : " : This is area of inputting address

DATA : " : It is not available in this mode

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 33 OF 43

DOCU. NO :

7.2 Explanations for each key

Information

Name

Numeric "O"

Numeric T

Numeric "2"

Numeric "3"

Numeric "4"

Numeric "5"

Numeric "6"

Numeric "7"

8

Numeric "8"

Numeric "9"

It is used for setting data

ENT

It is used for entering data or address

It is used for moving cursor to increase address

It is used for moving cursor to decrease address

It is used for changing over to parameter setting mode

It is used for changing over to parameter monitoring mode

KTE CO., LTD.

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

7.3 Changing over to another address

1) Method by using "up/down" arrow key

- Press "up arrow" key to increase address

- Press "down arrow" key to decrease address

2) Method by numeric key

- Press address number that you want to move

- That number is displayed at "No" area

- Press "ENT" key to change over

7.4 Changing value of each parameters

-

It is available in "setting parameter" mode

Press address number that you want to change

That number is displayed at "No" area

Press "ENT" key to change over

Press "SET" key

Press available value for each parameter

Press "ENT" key to change value

If value is not useful, parameter will not changed

KTE CO., LTD.

REV

PAGE : 34 OF 43

DOCU. NO :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 35 OF 43

DOCU. NO :

# Appendix, system parameters

1) Setting parameter & value

Address

S [00]

Function

W/H command full scale

S [01] W/H command port 10

S [02] Not used

S [03] W/H command zero

Range

Unit

0-300

Degree x 10

0-20

A/D

-

-

2038 - 2058

A/D

-

-

4075 ~ 4095

A/D

S [04]

Not used

S [05]

W/H command st'bd 10

S [06]

Port wing command full scale

0-300

Degree x 10

S [07]

Port wing command port 10

0-20

A/D

S [08]

Not used

-

-

S [09]

Port wing command zero

2038 ~ 2058

A/D

S [10]

Not used

-

-

S [11]

Port wing command st'bd 10

4075 ~ 4095

A/D

S [12]

STBD wing command full scale

0-300

Degree x 10

S [13]

STBD wing command port 10

0-20

A/D

S [14]

Not used

-

-

S [15]

St'bd wing command zero

2038 - 2058

A/D

S [16]

Not used

-

-

S [17]

St'bd wing command st'bd 10

4075 - 4095

A/D

Remark

0> Remark

Have no any effect if a data was set or indicator on the above " %. " address

KTE CO., LTD.

æ

^

«

8

æ

æ

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

Addres

Function

s

S [18]

Feedback full scale

S [19] Feedback port 25

REV

PAGE : 36 OF 43

DOCU. NO :

Range

Unit

0 ~ 300

Degree x 10

0-20

A/D

S [20]

Feedback port 20

309 - 4 1 9

A/D

S [21]

Feedback port 15

809 - 829

A/D

S [22]

Feedback port 10

1218 ~ 1238

A/D

S [23]

Feedback port 5

1628 ~ 1648

A/D

S [24] Feedback zero

2038 ~ 2058

A/D

S [25] Feedback st'bd 5

2447 ~ 2467

A/D

S [26] Feedback st'bd 10

2857 ~ 2877

A/D

S [27] Feedback st'bd 15

3266 ~ 3286

A/D

S [28] Feedback st'bd 20

3676 - 3696

A/D

S [29] Feedback st'bd 25

4075 ~ 4095

A/D

S [30] Neutral zone

0 ~ 300

Degree x 10

S [31]

0 ~ 300

Degree x 10

0 or 1

0 : On

1 : Off

S [33] Change over Interlock zone

0 ~ 300

Degree x 10

S [34]

0 ~ 300

Degree x 10

S [35] St'bd max. limit

0 ~ 300

Degree x 10

S [36]

Follow up start gab

0 ~ 300

Degree x 10

S [37]

Follow up S/V on time

1 ~ 2500

SEC x 10

S [38]

Follow up S/V off time

1 ~ 2500

SEC x 10

Dead band zone

S [32] Change over Interlock On/Off

Port max. limit

KTE CO., LTD.

Remark

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

Address

Function

REV

PAGE : 37 OF 43

DOCU. NO :

Range

Unit

S [39]

Auto load control limit

0 ~ 2000

A

S [40]

Auto load control proportional gain

0 ~ 300

Degree x 10

S [41]

Auto load control integral gain

1 ~ 2500

SEC x 10

S [42]

Load value full

0 ~ 2000

A

S [43]

Maximum dimmer value

0 ~ 255

D/A

S [44]

Minimum dimmer value

0 ~ 255

D/A

S [45]

Dimmer sensitivity value

0-10

0 : Fast

1 : Slow

S [46]

Fan & hyd. pump off delay time

0-50

SEC

S [47]

Zero pitch function On/Off

0 or 1

S [48]

Portable function On/Off

0 or 1

S [49]

W/H pitch Indicator offset

0 ~ 1024

D/A

S [50]

W/H pitch indicator gain

0 ~ 1024

D/A

S [51]

W/H ampere indicator offset

0 ~ 1024

D/A

S [52]

W/H ampere indicator gain

0 ~ 1024

D/A

S [53]

Wing pitch indicator offset

0 ~ 1024

D/A

S [54]

Wing pitch indicator gain

0 ~ 1024

D/A

S [55]

Wing ampere indicator offset

0 ~ 1024

D/A

S [56]

Wing ampere indicator gain

0 ~ 1024

D/A

S [57]

Command output offset for VDR

0 ~ 1024

D/A

S [58]

Command output gain for VDR

0 ~ 1024

D/A

S [59]

Feedback output offset for VDR

0 - 1024

D/A

S [60]

Feedback output gain for VDR

0 ~ 1024

D/A

KTE CO., LTD.

0 : Off

1 : On

0 : Off

1 : On

Remark

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 38 OF 43

DOCU. NO :

2) Monitoring parameter & value

Addres

Range

Unit

M [00] W/H command A/D value

0 ~ 4095

A/D

M [01] W/H command degree

0 ~ 300

Degree x 10

M [02] port command A/D value

0 ~ 4095

A/D

M [03] port command degree

0 ~ 300

Degree x 10

M [04] St'bd command A/D Value

0 ~ 4095

A/D

M [05] St'bd command degree

0 ~ 300

Degree x 10

M [06] Feed back A/D Value

0 ~ 4095

A/D

M [07] Feed back degree

0 ~ 300

Degree x 10

M [08] Over load value

0 ~ 2000

Ampere

2048 ~ 4095

A/D

M [10] Non-follow port max. limit

0 ~ 100

V x 10

minus voltage

M [11] Non-fo!!ow st'bd max. limit

0 - 100

V x 10

plus voltage

s

Function

M [09] Over load A/D value

KTE CO., LTD.

Remark

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

3) W/H Control panel Internal arrangement

KTE CO., LTD.

REV

PAGE : 39 OF 43

DOCU. NO :

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

KTE

REV

PAGE : 40 OF 43

DOCU. NO :

4) Method of changing a data by keyboard

1. Procedure of keyboard operation

Push

F1

Select an equivalent parameter

Change to setting mode

Push

Push

or

by cursor (

>=>

Input new data

Finish of adjustment

Change to monitoring mode

2. Appearance of keyboard

—t

B

Monitoring mode

> M[00]

M[01]

M[02]

NO :

>M[00] : 00000

M[01] : 00000

M[02] : 00000

NO :

DATA :

: 0000

: 0000

: 0000

DATA :

I Push ' F1 "

•i

J

S[37] : 0000

S[38] : 0000

>S[39] : 0000

NO : DATA :0129

| Push "Enf

V-

N

^ 1

2

3

4

5

6

7

8

9

Set

0

Ent

> S [00] : 0000

S [01] : 0000

S [02] : 0000

NO :_ DATA :

S[37] : 0000

S[38] : 0000

>S[39] : 0129

NO :_ DATA :

| Push " F2 '

Push "J." or'f

Monitoring mode

S[37]

S[38]

>S[39]

NO :_

[T

F2

V

Setting mode

*

: 0000

: 0000

: 0000

DATA :

Push " Set

)

_^

S[37]

S[38]

>S[39]

NO :

: 0000

: 0000

: 0000

DATA :_

| Push " new dato *J

KTE CO., LTD.

>M[00]

M [01]

M [02]

NO :

: 0000

: 0000

: 0000

DATA :

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 41 OF 43

DOCU. NO :

5) Trouble shooting

Trouble

A. AC source fail.

B. DC source fail.

C. W/H dial is not

effective

D. Port wing dial

is not effective

E. St'bd wing dial

is not effective

Check point

Place

Check AC source input

Terminal

board A

U, V

Check DC source input

Measure voltage of

potentiometer in W/H dial.

(Port 10 : -10 VDC

St'bd 10 : + 10 VDC)

Measure voltage of

potentiometer in port wing

dial.

(Port 10 : -10 VDC

St'bd 10 : + 10 VDC)

Measure voltage of

potentiometer in st'bd

wing dial.

(Port 10 : -10 VDC

St'bd 10 : + 10 VDC)

Measure voltage of

potentiometer in feedback

F. Feedback is not

box.

effective

(Port 10 : -10 VDC

St'bd 10 : + 10 VDC)

G. Change over is

not available

Check that control dial

position agrees with the

actual blade angle. (In the

case there is an interlock

for the agreement)

Terminal

board A

P, N

Result

0 VAC

220 VAC

0 VDC

Cause/Remedy

Check wire for source

Consult with maker

Check wire for source

24 VDC

Consult with maker

Analog

board

GND, TP1

Abnormal

Check potentiometer and

cable connection

Analog

board

GND, TP3

Abnormal

Analog

board

GND, TP2

Abnormal

Analog

board

GND, TP4

Para.

M [01]

M [03]

M [05]

M [07]

KTE CO., LTD.

Normal

Normal

Normal

Abnormal

Consult with maker

Check potentiometer and

cable connection

Consult with maker

Check potentiometer and

cable connection

Consult with maker

Check potentiometer and

cable connection

(feedback box)

Normal

Consult with maker

Agree

Consult with maker

Disagree

Check interlock

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

Trouble

H. Follow up

control is not

available.

Check Point (CP)

Place

1. When port button is

pressed, measure contact of

relay for port solenoid

TB2

1. Non-follow up

control is not

available.

2. When st'bd button is

PAGE : 42 OF 43

DOCU. NO :

Cause / Remedy

Close

Consult with maker

Open

Check wiring between TB2

BSP.BSC and solenoid valve

Close

Consult with maker

Open

Check wiring between TB2

BSS.BSC and solenoid valve

Available

Consult with maker

TB2

BSS.BSC

TB2

BSP.BSC

Is follow up control

available?

TB2

BSS.BSC

1) Connect an am-meter

between TB4 18A.18B

with thruster stopped, and

J. ALC does not

function.

Result

BSP.BSC

during non-follow up control

pressed, measure contact of

relay for st'bd solenoid

during non-follow up control

REV

then check that the current

value is the same as

the design value after

starting thruster.

(Before removing the

am-meter, stop thruster)

TB3

BA1,

Not

available

Check 'H' of list

Same as

designed

value.

Consult with maker

There is a

difference.

Check CT.

BA2

0 A.

Check wiring between TB3

BA1 ,BA2 and CT for

looseness.

Check CT.

K. W/H dimmer

is not

available.

Para.

Available

Is setting date of parameter

M [43]

right ?

M [44]

Not

M [45]

available

KTE CO., LTD.

Consult with maker

Adjust parameter

KTE

USER'S MANUAL OF

Thruster Control System ( KT - TCS )

REV

PAGE : 43 OF 43

DOCU. NO :

6) Analog board comp.

TP1

a

WGAIN

< CONTROL DIAL SETTING >

TP1.GDN : Measurement of setting value(-10V~+10V)

at W/H

SettingtZERO.WGAIN : Setting(-10V~+10V)

of control dial

at W/H

TP3

D

PZERO

PGAIN

TP2.GDN : Measurement of setting value(-10V~+10V)

at P/W

PZERO.PGAIN : Settinq(-10V~+10V) of control dial

at P/W

TP2

D

SZERO

SGAIN

TP3.GDN : Measurement of setting value(-10V~+10V)

at S/W

SZERO.SGAIN : Setting(-10V~+10V) of control dial

at S/W

TP4

VR4VR5

TP4.GDN : Measurement of setting value(-10V~+10V)

at feedback box

VR4.VR5 : Setting(-10V~+10V) of potentiometer

at feedback box

< STBD AND PORT MAXIMUM UMT SETTING(NON-FOLLW) >

VR1

VR2

VR1 : Setting of port maximum limt value(0~100%)

at non— follow

VR2 : Setting of starboard maximum limt value(0~100%)

at non-follow

< AMPERE METER SETTING >

VR8

^"

Maker Charge

GND

n

* NOTE : The 0V should be set in advance by mens of

measuring SIG terminal and GND terminal of

potentiometer(W/H. P/W. S/W. F/B)

KTE CO., LTD.

DAEWOO SHIPBUILDING &

MARINE ENGINEERING CO., LTD.

MESSRS :

HNo. 4437/4438/4441

BOW & STERN THRUSTER REMOTE CONTROL SYSTEM

DRAWING No.

DATE

210x297(mm)

APPROVED

KTM-0037

JULY

1.

2004

FILE NAME:

D4437

CHECKED BY

KTECo.,Ltd.

CHECKED BY

1487-1, SongJcong-Dong, OangMO-Ou,

Busan 618-Z70, Koraa

T«l i +82-51-285-0255 Fax:+82-51-285-O25O

DESIGNED BY

S. H. OH (9L&3.)

DD-25

PLAN HISTORY

REV.

A

DATE

D E S C R I T I O N

2004. 07. 01

SUBMITTED TO SHIPYARD & CLASS

2004. 12. 15

REVISED BY SHIPYARD

COMMENTS

SHEET No.

CONFIRMED BY

2,3,4,5,6,7,8,13,14.15,16

17,18,19,20,21,22,23,26

#£&

^

(

«>-

4>

HISTORY

BOW & STERN THRUSTER REMOTE CONTROL SYSTEM

INSTRUCTION MANUAL

- Micro Computer Type 1. Outline of system

This system is so designed that bow thruster (Controllable Pitch Propeller type)

is controlled by means of follow-up control by the maneuvering dial which is

located on W/H control panel and the both wing control panels.

2. Electric source

AC 220V 60Hz 01

DC 24V battery power supply (for back up alarm system)

3. Constitution of the control system

1) Wheel house control panel :

2 ( Bow, Stern )

( with power supply )

2) Both wing control panel :

2 ( Bow & Stern )

3) Terminal board :

2 sets ( Bow, Stern )

4) Follow up transmitter :

2 ( Bow, Stern )

4. General description of the system

1) Change-over control position

Change-over can be carried out within matching zone between the existing

position and the position to be changed by pushing change-over switch on W/H

control panel and both wing control box. the switch lamp will be flickering

with alarm sounding when the position was out of range.

2) Pitch control

When operating the maneuvering dial, the difference of position between the

potentiometer incorporated in the maneuvering dial and that attached to

feedback box transmitter results.

The voltage resulted from the difference of position is amplified and excites

the solenoid valve in the hydraulic unit.

Therefore, the blade of CPP begins shifting in the direction ordered by the

maneuvering dial.

At the same time, the potentiometer connected to the blade by means of link and

chain begins turning too and when its position corresponds to the position of