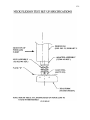

Download U.S. DEPARTMENT OF TRANSPORTATION

Transcript