Download Operations manual - Sitek Process Solutions

Transcript

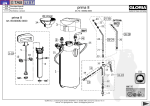

TABLE O USER MANUAL MODEL L11SS ELLIPSOMETER GAERTNER SCIENTIFIC CORPORATION 71 09-C--229S 1201 West Wrightwood Avenue, Chicago, 1L 60614 S S 1116$ ELLIPSOMETER DESCR TABLE OF CONTENTS Warranty Laser Safety 1.0 Specifications 2.0 AbbreviatIons and Symbols 3.0 Introduction 4.0 Optical System 5.0 Ellipsometer Components 5.1 Laser 5.2 Polarizer 5.3 Sample Monitor Assembly 5.4 Reference Sample . 5.5 Analyzer 5.6 Electronic Chassis 5.7 tnstrument Power Supply 5.8 Sample Stage and Table 6.0 Determination of Psi and Delta 7.0 Standard Programs . . 1-1 1-2 1-3 1-5 1-6 1-6 1-8 1-8 1-8 1-9 1-9 1-11 1-11 1-11 1-11 -12 1-13 LIST OF FIGURES 1-1 1-2 TABLE 1-1 Optical System Functional Diagram Ellipsorneter Components Identification Right-Front 1-7 1-10 Standard aid Microspot Beam Dimensions on the Sample Wafer 1-4 1109-C- 229 5 1-0 DESCRIPTION LII6S EL WARRANTY ALL OF THE OPTICAL, MECHANICAL AND ELECTRICAL COMPONENTS OF THE GA ELLIPSOMETERS, INCLUDING THE LASERS, ARE WARRANTED FOR ONE YEA THE DATE OF DELIVERY. ANY DEFECTS IN MATERIAL OR WORKMANSHIP CORRECTED BY GAERTNER AT NO COST. SHIPPING CHARGES, TRAVEL AND L COSTS INCURRED BY THE SERVICE PERSONNELARENOTCOVEREDBYTHISWAR WARRANTIES ON DEFECTS IN MATERIAL OR WORKMANSHIP FOR COMPUTER EOU SUPPLIED WITH THE Li i6S ELLIPSOMETER IS WARRANTED BY THE COMPUTE FACTURER AND THEIR STANDARD WARRANTY CONDITIONS APPLY. THE CO MANUFACTURER WILL, AT THEIR OPTION, REPAIR OR REPLACE EQUIPMEN PROVES DEFECTIVE DURING THE WARRANTY PERIOD. REPAIRS THAT ARE N TATED BY THE MISUSE OF THE EQUIPMENT, INCLUDING THE USE OF SOFTW INTERFACING NOT SUPPLIED BY GAERTNER, ARE NOT COVERED BY THIS WAR NO OTHER WARRANTY IS EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMI IMPLIED WARRANTY OF MERCHANTABILITY AND SUITABILITY FOR A PAR PURPOSE. 7109-C-229S GAERTNER SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAG 1-i L116S ELLIPSOMETER DESCR LASER SAFETY GOVERNING REGULATION The Gaertner ellipsometer utilizes a helium-neon laser light source. The accessible rad not exceed one milliwatt and, therefore, Is classified as a Class II laser product by Radiation Performance Standards 21CFR, Subchapter J Federal Register, Volume 10 #1 1975. Appropriate WARNING and Conformance labels are affixed to the ellipsometer to al nel of the presence of laser radiation during operation. WARNING Logotype APE R TLJR E Label Attached to the polarizer arm and reads: LASER RADIATION. DO NOT STARE INTO BEAM. Attached to the exit aperture o polarizer module and reads: AVOID EXPOSURE. LASER RADIA IS EMITTED FROM THIS APERTU CAUTION USER fla&ou 00 ICT STARE 1470 BEAu çAVOID EXPO$URI!IJ HELIUM-NIONItm* CLASS I LAIU PR0uCT CERTIFICATION Lthe I Not Shown CAUTI ON Attached to the left front face of the vertical plate and reads: THIS LASER COMPLIES WITH DHEW/ CDRH RADIATION PERFORMANCE STANDARDS 2ICFR SUBCHAPTER J. 71 09-C-229S Use of controls or adjustment performance of procedures other those specified herein may resu hazardous radiation exposure. 1-2 DESCRIPTION 1.0 1116S E SPECIFICATIONS Net Weight approx. Shipping Weight 30 kg 65 Ibs #3 kg 95 Ibs Dimensions approx. Height Width Depth Film Thickness Range 0 to 6 0 to 6 #5.7 cm 83.8 cm Accuracy ±3 Angs 38.0 cm Repeatability ±1 Angs Refractive Index ±0.005* Laser Light Source 632.8 nm Helium-Neon Red than 1 less mW accessible radiation Line Voltage 500 and 70° are used the Incidence Angles Detented most. Beam Diameter Standard 1 mm** 1.0 x 1.6 mm at 500 1.0 x 3.0 mm at 70° Polarizer Drum 360° graduated at 10 intervals with 10-part venier 0° to 1° Sample Size Up to 150 mm 5.9" diameter and 10 mm thick Method of Measurement Four detector-voltages are used to determine state-ofpolarization of light of reflected beam. The surface parameters Psi and Delta, and hence film thickness and index of refraction, are calculated. 7109-C-229S 115V ac boy ac ac or 2 See the next page. Standard Program See Se manual. Optional Programs See Se manual. *Over most of the mea **Sce the next page for ted angles. There is a is only for adjustments 1-3 11165 ELLIPSOMETER 1.0 DESC SPECIFICTIONS Continued This ellipsometer has the detented angles of incidence in the table below for measuremen There are also detents for 900, but this angle is only for adjustments. $ Standard Beam on Sample Microspots* Ream on Sample 300 1 mm x 1.15 mm 15 pm x 17.2 pm 450 1 mm x 1.41 mm 15 pm x 21.1 pm 50° 1 mm x 1.55 mm 15 pm x 23.2 pm 55° 1 mm x 1.74 mm 15 pm x 26.0 pm 60° 1 mm x 2.00 mm 15 pm x 30.0 pm 65° 1 mm x 2.37 mm 15 pm x 35.5 pm 70° 1 mm x 2.92 mm 15 pm x 43.8 pm 750 1 mm x 3.86 mm 15 pm x 57.9 pm 80° 1 mm x 5.76 mm 15 pm x 86.3 pm *The Microspot Optics are optional components for the polarizer and analyzer arms. See "Optional Components", section 6. Table 1-1 Standard and Microspot beam dimensions on the sample wafer. 7109-C-229S 1-4 DESCRIPTION 2.0 ABBREVIATIONS AND SYMBOLS Nf Real value of refractive index for film being measured Kf Extinction value of refractive index for film being measured L116S ADJ Adjust PD Ph AMPL Amplifier PFLG Pe AS Autoset PIG Pa A/AUTO Automatic PWR Po N Real value of refractive index for substrate cm Centimeter RECT Re K5 Extinction value of refractive index for substrate CTL Control REF Re PHI Angle of incidence DET Detector SM St `v PSI Amplitude ratio as determined by measurement M/MAN Manual SOP St mm Millimeter SPLY Su A DELTA Phase difference as determined by measurement nm Nanometer STU St PCTL Peripheral Control SW Sw W/O Wi ` AID Analog-to-digital 1109-C--229S 1-5 11165 ELLIPSOMETER DESC 3.0 INTRODUCTION This section describes the components of this ellipsometer and shows how the ellipsomet the effect of reflection on the polarization of the laser light striking the surface of such as bare substrates, to acquire measurement data identifying properties critical control. Interpretation of the data yields the optical constants of the material material surface is film-covered, the thickness and optical constants of the film. On by the user, analysis and measurement are automatic, utilizing a programmed, desktop comp faced with the ellipsometer. Parameters are entered by the user via the computer keyboar requiring operator/computer interaction and actual measurement data are displayed on t screen. Measurement data may be printed for a permanent record. Optional equipmen Optional Components section. 4.0 OPTICAL SYSTEM Reference Figure 1-1 Ellipsometric measurements involve illuminating the surface of a sample wafer with mon light of a known wavelength and polarization and then anatyzing. the polarization of th lIght. The light is projected along a fixed path or angle of incidence . This e has provisions for precise, pin-located settings of the angle of incidence at 300, 45° 600, 65°, 70°, 75°, 800 or 900. For measurement purposes, the angle of reflection is always set at the same angle as t incidence. Since the two angles are always equal, It is usual to refer to both angles a Incidence. With the angles properly set, their respective optical axes intersect t center line of the plane of incidence at the same point The spjjj*Ie Is raised or that the intersection of the incidence ai reflective optical axes occurs on the samples that tThe sample surface is normal to the vertical centerline of the plane of Incide ensures that tiw light from the polarizer aperture is reflected from the sample surfa analyzer apertui'e. 7109-C-229S 1-6 DESPCRIPTION L116S 633 nm RED LASER POLARIZER ARM ATTENUATOR C POLARIZED LIGHT ANALYZER ARM POLARIZER DRUM MANUALLY TURNED I DEPOLARI ZER POLARIZER PRISM // ANGLE OF INCIDENCE LI NEARLY POLARIZED LIGHT S ELLI PTI POLARI SAMPLE WAFER ON THE TABLE Figure 1-1 7109-C-2295 This is the Optical System Functional Diagram for a single-waveleng 1-7 DESC L116S ELLIPSOMETER 4.0 OPTICAL SYSTEM Continued A low-power Class II laser-light source is employed; a helium-neon laser having a beam of 632.8 nm. The 632.8 nm red laser is in the line of the optical axis, and the b through a polarizer prism. In passing through this prism, the beam polarization Is con circular to linear. The reflected light, with Its polarization altered by the optical properties of the samp tured by the Stokesmeter SM measurement head. The four detector-voltages of the Stok then computer-analyzed and converted into a measurement of the State-of-Polarization S of the reflected light. 5.0 ELLIPSOMETER COMPONENTS The main components of the single-wavelength LII6S ellipsometer are shown in Figure 1 5.1 Laser Assemblies A red laser, with a fixed wavelength of 632.8 nm, has an attenuator that reduces the las Class II, which is for under one milliwatt. A built-in quarter-wave depolarizer in the put produces a circular polarization of the beam. NOTE: When the beam attenuator subsection 5.2 is pulled out, the laser beam strikes wafer or table surface, both the polarizer and analyzer arms must he at the same angle o Then the ellipsometer can make measurements and will be safe to work with. 5.2 PolarIzer Reference Figures 1-1 and 1-2 Polarizer Drum and Prism. The polarizer prism, mounted in the polarizer drum, is a Gla calcite prism that converts the circularly polarized light from the laser to linear light. Any given angle of prism orientation from 0° to 3600 can be set by adjusting t drum. The angle can be set to within tenths of a degree by setting a number in wh indicated on the drum just below zero 0 on the 0-to-i vernier scale and then ali duation on the vernier scale to one on the drum scale. For automatic measurements, the fix the polarizer drum at exactly 200 by inserting the locking screw into the drum's det 7109-C-229S 1-8 DESCRIPTION 5.0 ELLI P SOMETER COMPONENTS Continued 5.2 Polarizer Reference Figures 1-1 and 1-2 L116S Beam Attenuator. The beam attenuator more correctly called a "beam blocker polarizer module output aperture, is a manually-operated slide device to either b beam or to allow passage of the beam to the sample surface. 5.3 Sample Monitor Assembly The Sample Monitor Assembly has a combination tilt monitor and 39-power, sample scope. tJsing the viewing scope function, the operator can examine the sample surfa imperfections. The light source for the surface illumination is built-in, origi sample monitor assembly enclosed in a housing above the objective end of the samp intensity of illumination is variable by the rotation of a control on the left sid Monitor Assembly. Using the tilt monitor function, the operator can detect an out-of-flatness conditi surface and compensate for this condition. The amount of out-of-flatness is determi a reflected image projected as background on 90-degree crosshairs in the eyepiece. accomplished by tilt adjustment of the sample table in X and V planes. The tilt ad are just under the table. See the Operation section. The Sample Monitor Assembly includes the following: * Emission indicator * Electrical Control Group: * Key-operated ellipsometer and laser power ON/OFF switch * Sample illumination control 5.4 Reference Sample A silicon substrate wafer reference sample with a single-layer silicon oxide fi Initially, the sample sh about 780A or 7Bnm is supplied with the ellipsometer. obtain sample measurements in the process of instrument familiarization. Periodic should be used to obtain measurement data for comparison with previous data to ellipsometer is in proper adjustment. 7109-C-229S 1-9 DESCRIP L116S ELLIPSOMETER SAMPLE MONIT A SSE MB LV EMISSION INDICATOR KEY-OPERATED AC ON/OFF SWITCH 39-POWER MICROS POLARIZER MOD POLARIZER DRUM BEAM ATTENUATOR MICROSPOT Optional A M A 150mm ROTATION VACU TRANSLATION STAGE Figure 1-2 1109-C- 229 S Front-view components of the L1I6S Ellipsometer. 1-10 DESCRIPTION 5.5 L116S E Analyzer Module StokesMeter Measurement Head. The SM is a four-detector-photopolarimeter consisti larly reflecting photodetectors which intercept the incident tight at oblique ang The electrical signals of the four detectors are computer-analyzed to determine SOP of the incident light in terms of the Stokes parameters. 5.6 Electronic Chassis This assembly is in the ellipsometer base; it consists of sample and hold circui gain circuitry, and computer interfaces. 5.7 Instrument Power Supply This assembly is in the vertical enclosure, at the rear of the support frame. The p vides the conversion of various line voltages, compensator control and laser drive 5.8 Sample Stage and Table The sample stage provides a combination rotary and linear manual positioning of t allowing measurement at any point on the sample surface. This is achieved by line the N- X direction from center and rotation from 00 to 3600. The linear scale is 1 mm increments, numbered at 10 mm intervals from 0 to 75 mm full scale. The rot duated in 10 increments, numbered at 100 intervals from 00 to 3600. See Figure 1 The table is vertically adjustable, so that the laser beam reflected from the s maximized when entering the analyzer aperture. The vertical position is adjust knurled knob on the support structure. A clockwise rotation raises the table. secures the vertical adjustment. The standard table up to one 1 degree Gaertner just before Assembly page 1-9. An attachment for the will accept samples up to 150 mm 5.9" in diameter, in both X and V planes from the predetermined level positi the shipment of the ellipsometer. See the description of th A fine-motion vertical position adjustment option may be ad vacuum pump is on the right side of the stages. See Figure Yellow plastic locator strips are supplied for use in centering a wafer sample on t For example: A plastic strip can be inserted into either the 3-inch, 100 mm, 1 diameter groove in the surface of the standard table. 7109-C-229S 1-11 L116S ELLIPSOMETER 6.0 DESCR DETERMINATION OF PSI AND DELTA The state of polarization of the beam is determined by the relative amplitude amplitude the relative phase shift phase difference between the two component plane waves resolv electric field of the beam. If the phase difference between the components is either the beam is linearly polarized. All other phase differences result in elliptical p When a monochromatic beam of polarized light strikes the surface of a sample, the refle light causes a change in the relative phases of the component plane waves and a change of their amplitudes. The angie DaTA 4 is defined as a phase difference. PSI V} Is defined as the arctan and the amplitude ratio w thus characteriz amplitude ratio. The phase difference tically polarized iit reflected from the sample surface. These parameters are used the optical constants of bare surfaces or substrates and, if film covered, the th refractive index of the film. The refractive Index Nf is used to determine the ph position of the film and in the case of transparent films, to establish the magnitude of i.e., the thickness cycle before ellipsometric readings repeat. Using measurement data obtained from the four detectors of the StokesMeter, the compute the Stokes parameters of the reflected light. This information, coupled with the kno state-of-polarization, is used to determine the surface parameters, PSI and DELTA. 7109-C-229S 1-12 DESCRIPTION 7.0 L116S E STANDARD PROGRAM DESCRIPTIONS One standard single-point program computer. Sits is supplied with each ellipsometer The Standard Single-Point Program, SiT S65+S7S+GSS+SuhS is for both L115S ometers. There are four subprograms: * G5S FILM: This subprogram determines the thickness and refractive i layer, transparent nonabsorbing film of silicon dioxide or sili silicon suhtrate. Data Output: Thickness, index, PSI f, DEL is, There is a fixed index option. * S6S SPECIFIC: This is similar to the Film subprogram. luated at an incidence angle of only 700. * S7S TWO ANGLE: This subprogram measures the thickness of silicon oxid or other nonabsorbing film on silicon substrate. Two-angle measure and 700 incidence angle. It determines the solute thickness of on the order or period from a matched measurement at each angl Matched thickness values, index and a listing for each angle. * SubS SUBSTRATE: This subprogram determines the optical constants of These constants need to be known before making thin film measuremen PSI , DEL is, real N5 and extinction K5 refractive indexes 7109-C-229S 1-13 Oxide or nitri OPE L116S ELLIPSOMETER TABLE OF CONTENTS PAGE SUBSECTION 1.0 2-1 Premeasurement Setup 1.1 Setting the Angle of Incidence 2-1 1.2 Turn on and Warmup 2-3 1.3 Sample Table Vacuum and Alignment 2-3 2.0 2.1 3.0 3.1 2-8 Measurement Procedure 2-8 Standard and Optional Programs 2-10 User Maintenance 2-10 Cleaning LIST OF FIGURES 2-2 2-1 L116S Eilipsometer Rear View 2-2 El I ipsometer Controls and indicators 2-4 2-3 150 mm Diameter Table 2-5 2-4 L116S Sample Stage and Table 2-5 TabieMax Display Screen 7109-C-229S . . . 2-7 . 2-9 2-0 OPERATION 1.0 L1165 ELL PREMEASIJREMENT SETUP The premeasurement setup includes setting the polarizer aid analyzer angles of incide on and the warmup of the ellipsometer, and initial alignment of the sample stage. 1.1 Setting the Angle of Incidence See Figure 2-i, next page CAUTiON Do not grasp the 632.8 nm red laser when setting the polarizer arm. That may easily cause laser misalignment. a. Grasp the polarizer arm but never by the laser; aid at the rear of the arm, lo screw Figure 2-i about one turn. b. Pull outward on spring-loaded locator pin next to the clamp screw, and move the angle of incidence. c. Release the locator pin, aid move the arm slowly up or down until the pin seats in the vertical plate. Tighten the clamp screw. This accurately sets the angle of d. Repeat steps a through c to set the analyzer arm angle of incidence, but do not a to the SM StokesMeter measurement head. NOTE: Follow steps a to d also when setting the angle of incidence at any other de The detented angles are 3Q° and 45° to 80° in 50 steps. There is also 90°, whic adjustments. See Table i-i in subsection 1.0 and Table 1-I of the Description sect detented angles. e. Set the polarizer drum to 200, and secure it by inserting the locking screw Figu hole on the side of the drum. *See the Caution note at the top of Figure 2-i about the arms with the optional Mi Note the statement with the asterisk just abov at the 90° angle of incidence. about the fact that with microspots the arms cannot be set at 90° with the larger 7109-C-229S 2-i OPE hiSS ELLIPSOMETER CAUTION For 90° AngIe of lncidence* if the 11165 has Microspot Optics, rotate the 150 mm table so that its lifting slot is under the analyzer Microspot. Move the taWe to the left and down so that neither Microspot Optic will contact the table when both of the arms are at 90°. SAMPLE ILLUMINATOR CONTROL SAMPLE MONITOR, ASSEMBLY POLARIZER DRUM DRUM L STOKESMETER 632. RE ANALYZER ARM ELLI P SOME TER TIME LAG FUSES .80A 115 or 230V P GPIO SOCKET, F CABLE TO THE C *The optional 200 mm diameter table cannot be moved out of the way of the optional Micros Therefore the arms cannot be set at 90° with both of these options. Figure 2-1 7109-C- 229 S Rear and left view of the L116S Ellipsometer with the standard table. 2-2 OPERATION 1.2 LII6S EL Turn-on and Warmup a. Connect the etlipsonieter and the computer according to the Installation Section. b. To turn on the ellipsometer and the 632.8 nm red laser, turn the key-operated po the Sample Monitor Assembly fully clockwise, ON Figure 2-2, next page. The Emis tamp should illuminate. Power is applied to the laser, which should be on. A 1 mum warmup of the 632.8 nm laser Is recommended before performing ellipsometric c. Pull to open the beam attenuator Figure 1-2 in the Description section, and pr following subsection. 1.3 Sample Table Vacuum and Alignment Vacuum In the rear part of the table are small #O-80x1/8" round head, stainles that can be removed when a vacuum pump is connected to the ellipsometer. Remove only will be under the wafer, but not the plug under the edge of the wafer see Figure 2 Alignment Follow this procedure, beginning with step a. a. With tweezers, air wand, etc., put a reference sample or wafer with a single-layer, film of a known thickness on the table via the insertion slot. Turn on the vacuu connected to the table vacuum hose. b. Loosen the sample table clamp screw. c. Look into the Sample Monitor Assembly eyepiece, turn the sample illumination c desired illumination, and then adjust the eyepiece by slightly pushing it in o for the sharpest focus of the 90° crosshairs. d. Rotate either one of the Sample Monitor Control knobs in Figure 2-2 so th reflected image of the two diagonal lines into view if not already in view, as the eyepiece. section 1.3 continued on page 2-6 7109-C-2295 2-3 L116S ELLIPSOMETER OP EYEPIECE EMISSION INDICATOR ON/OFF KEY SAMPLE ILLUMI NATI ON CONTROL 39-POWER MICROS MONITOR CONTROL FIgure 2-2 7109-C -229 S Ellipsometer controls and indicators on the Sample Monitor Assembly. 2-4 OPERATI ON L116S EL INN ER GROOVE 150mm GRO 12 1 CENTRAL HOLE 3 INCH Figure 2-3 Top view of the 150 mm approximately 6 inches diameter sample table. in the Optional Components Section for the top view of the optional 200 mm 7109-C-229S 2-S 11165 ELLIPSOMETER OPE 1.3 Sample Table Vacuum and Alignment continued e. Observe the intersection of the two wide diagonal lines and the intersection of t crosshairs. Slowly rotate as needed the X- and Y-p?ane tilt adjustment controls Fi to center the diagonals precisely on the crosshairs intersection. This makes corre the sample surface out-of-flatness condition. NOTE The the may the width/height of the intersection of diagonals is four arc minutes. This be used as a reference in determining approximate tilt adjustment needed. f. Using the adjustment wheel under the rear of the table and the TMAX option of th SIPS Section 3, Standard Programs, raise or lower the table for the maximu Figure 2-5. A clockwise rotation of the wheel raises the table. g. If the reading the "s" key on for a maximum for a maximum h. Repeat steps e through g as often as necessary to fine tune the sample table adjustm I. Tighten the sample table clamp screw. j. See the standard single-point program instructions such as 511Th in the Standard Section for the loading instructions, and use the Film program or subprogram. Proce a measurement. k. Compare the thickness data measurement with previously acquired sample thickness data. pared data should be within ±3 A ±0.3 nm. 7109-C-2295 from the previous step overshoots the graph upper limit, or is too the computer keyboard to change sensitivity. Then readjust the tab reading. Repeat the adjustment of the drum and the table vertically, reading. 2-6 L1165 ELL OPERATI ON VERTICAL POSITION ADJUST TILT ADJ tx-PLAN VERTICAL ADJUSTMENT CLAM P TILT A V-PLA ROTATI ON CONTROL X-TRANSLATION CLAMP STAGE Figure 2-4 7109-C--229S i- X TRANSLATION CONTROL L11GC Sample Stage and TnIe. 2-7 OPE L116S ELLIPSOMETER 2.0 MEASUREMENT PROCEDURE Place the sample wafer on the sample table, load the program software into the computer tiate the measurements. Once the measurements are started, press the keys as the instructions request, then measurements are automatic. Some measurements can be made after a 15-minute ellipsorneter warmup, the stability of improves after a few hours, which is better for important measurements. If the ellipso use several times a day, the laser should operate continuously. WARNING To avoid the hazard of laser beam disper sion, the beam attenuator must be closed while you adjust the polarizer or ana lyzer arm, or when the two arms are not at the same angle of incidence. 2. 1 Standard and Optional Programs Valid measurements are dependent upon the selection of a program applicable to the sa measured, and correct Interaction by the user with the computer. The standard program with the ellipsometer are in the Standard Programs section. The optional programs availa cial order are identified in the Optional Programs section, first page. 7109-C-229S 2-8 OPERATION L116S ELL TABLE ADJUSTMENT 1. 2. ic 6- Adjust tilt of table Adjust table height for maximum gain The line marker on the right indicat the maximum gain. For new sample, press exit and reenter TMAX. 1 Press s to change sensitivity. Use only near point of maximum gain 3-.-. Press eto exit and autorange. 21- 0- FIgure 2-5 7109-C-229S Computer screen displaying the photodetector output vertically. 2-9 L116S ELLIPSOMETER 3.0 OPER USER MAINTENANCE These maintenance instructions are operator-level procedures for routine servicing. See t Section regarding trouble analysis, adjustment, and replacement qualified service perso of defective components. Instructions are not included for the replacement of any laser izer/analyzer optical or precision electro-mechanical components. Contact Gaertner Corporation for the repair or replacement of these items. 3.1 CleanIng Interior cleaning of the ellipsometer i.e., the four detector measurement head, monito and instrument power supply should not be needed. These units are designed to keep for out. When not being used, the ellipsometer should be enclosed by the dust cover suppli instrument. Exposed optical surfaces may be cleaned with a camel-hair brush or compressed air not to exceed 5 PSI. All other external surfaces may be wiped clean us lint-free cloth, If a solvent is needed, a cloth dampened with wood or isopropyl alcohol mended. 7109-C--2295 2-10 L116S E OPERATION NOTES: 7109-C-229S 2-11 sm s LI16S ELLIPSOMETER STANDAR TABLE OF CONTENTS PAGE SIJBSECTI ON 1.0 Introduction and set up 1.1 Software Installation and loading 1.2 2.0 3-1 . . 3-1 Sample stage or table alignment Standard program S6S + S7S + G5S 3-i + SubS 3-2 3-3 2.1 S6S 2.2 Subssubstrate 3-7 2.3 S7S Two Angle 3-8 + GSS Film subprogram LIST OF FIGURES 3-1 Program menu of standard film subprogram 3-6 CHARTS 3-1 Standard program flow chart 7109-C-229S 3-10 3-0 S S S STANDARD PROGRAM SUDS L116S ELLIPS . 1.0 INTRODLJCT}ON AND SET tiP Gaertner Ellipsometer program software is supplied on two types of discs for use on the IR PS Series Computers. The prograni software for the IBM computers are as foflows: * IBM PC and IBM PC XI Computers are supplied on discs compatible with a 360k-byte, S-i/ * The IBM PSI1 Computer is supplied on discs compatable with a 1.,4M-byte, 3_If?" driv * The IBM PC At Computer Is supplied on discs compatible with a 1.2M-byte, 5-1/4" dri This system is set up according to Section 5, %nstaflation. 1.1 Software Installation and Loading See "Software Installation and Loading" in the Installation Section 5 of this manual. 1.2 The Sample Stage or Table Alignment See "Sample Table Vacuum and Alignment" in the Operation Section 2 of this manual. 7109-C-229S 3- LI16S ELLIPSOMETER 2.0 STANDARD PROGRAM S6S STDS + S75 + G5S + STAND SubS STDS This is a single-layer, nonabsorhing transparent film program with three subp following line will be displayed in the lower left corner of the screen: "SELECT KEY FROM BELOW AS DESIRED 1PRINT 2DISP" Press Fl If the printer is connected and on and is to be used. either Fl PRINT or F2 DISP will produce the main menu: Otherwise, press "SELECT KEY FROM BELOW AS DESIRED IFILM 2SUBSTR 3TWOANG `lEND" Press Fl FILM to select subprogram S6S See Figure 3-1. + G5S, in which oxide or nitride films Press F2 SUBSTR to select subprogram SubS, which evaluates bare substrates lik Press F3 TWOANG to select subprogram 575, which takes measurements at both determines the proper film thickness order. 5 Press F4 END to exit a program so that any other program on the disc or on anot entered. Re sure to turn off the computer to change discs. Observe the display; and press function key El, F2 or F3 corresponding to the desir i.e., film S6S + G5S, substrate Subs, or two angle S7S. This is the main working with one of the three subprograms, to return the main menu to the screen, key FlO. 7109-C-229S 3-2 STANDARD PROGRAM 2.1 565 + 11165 STD S E C5S Film Subprogram When the Film subprogram is selected, page 3-6; * * * * * * these are the "Default Values" left side o Silicon substrate: N5=3.85; K5=-.02 Wavelength 6328A 632.8 nm Si02 oxide film: Estimated index, N=1.46* Mode of measurement: Measure N aid thickness Angle of incidence: PHI7O° Polarizer drum aigle: POL=20° *For the silicon nitride films, the estimated index is N=2.OO. NOTE: To change aiy parameter below, press SETUP F3 Any one of the following can be selected by using the corresponding key in the Film bottom of Figure 3-1: Key Fl F2 F3 F4 F5 F6 Fl F8 F9 Function PRINT/DISP TMAX SETUP SAMPLE OXIDE NITRIDE N MEAS N FXD LIST FlO MENU 71 09-C-229S This allows the choice of printed or dis This activates the TahieMax subprogram S This allows the setup of the input parame The user enters identifying numbers aid/ This automatically fixes or measures inde This is the same as the thove except for This calculates index N aid thickness. This fixes index N and calculates only th This gives a listing of all of the possib periodic multiples. This returns the main menu to the screen substrate or two-angle subprogram can 3-3 LI16S ELLIPSOMETER 2.1 S6S + STAND STDS G5S Film Subprogram continued As seen on these pages, it is very often important to know the periods of the oxide films when making measurements. The table below gives the periods for oxide and 500 and 70° with the red laser at 6328 A. FILM Nf 50° 70° OXIDE 1.46 2545 2832 NITRIDE 2.00 1713 1792 For very thin films or films close to a periodic multiple, the sensitivity of the ind is very poor; therefore, accurate thickness measurements can be obtained only by fix the index N and then calculating the thickness. The two-angle subprogram S7S fi thickness of thick films, based on the order or period from matched measurements The SETUP key F3 allows entry of substrate values, fixing or measuring of index value of index N, angle of incidence PHI, and expected film thickness. Default above parameters will be displayed. Pressing Enter with no entry produces defaults Otherwise, other desired values parameters may be entered. Press Enter after The SAMPLE key F4 allows the user to assign identification letters and/or number If the OXIDE key FS is selected for oxide films, the program automatically dete the index N should be fixed or measured. The same is true for nitride films if t F6 is selected. Hence, for either oxide or nitride film on a silicon substrate incidence, the above keys are recommended. 7109-C-229S 3-4 STANDARD PROGRAM 2.1 S6S + L116S STDS E G5S Film Subprogram continued NMEAS F7 and NFXD F8: The automatic fixing or measuring of the index N can using function keys Nfxd and N Meas. These keys fix the index N and measure respectively, regardless of sensitivity considerations, although sometimes answers ma puted. For example: if attempting to measure the index N of very thin films un stroms or 10 nm it may not be possible to compute an answer. Rut, if the index N thickness will be computed. One oxide film example is this appears in the center while "Select optional from below" disappears: SAMPLE :xxx THICK: 1051 Nf 1.464 PSI: p44.48 DEL: 79.33 The LIST key F9 gives the thickness and the eight smallest possible thicknesses period. One example is this appears in the lower-right of Figure 3-1: LISTING: 1051 3870 6689 PERIOD 281gM 9508 17965 12327 20784 15146 23603 One nitride film example of a display is this center of Figure 3-1: SAMPLE :nnn THICK: 2614 PSI: 15.81 Nf 1.986 DEL: 106.07 The LIST key F9 gives lower right of the screen the thickness and the eight sma thicknesses with a given period. One example is this: LISTING: 264 2073 3882 7109-C-229S PERIOD 2819fl 5691 11118 7500 12927 9309 14736 3-5 L116S ELLIPSOMETER GAERTNER G5S N5 K5 WL N PHI POL = = = = = = STDS + SubS + S6S + STAND S7S AUTOMATIC ELLIPSOMETRY PROGRA FOR IBM PC 3.850 -0.020 6328 1.460 70.00 115.00 Select Option From Below: IPRINT 2TMAX 3SETUP 4SAMPLE 5OXIDE 6NITRIDE 7WMEAS 8NFXI 9LIST IO Figure 3-1 7109-C-229S Screen display with the Standard Film subprogram Program Menu at the 3-6 STANDARD PROGRAM 2.2 L1165 EL SitS SubS Substrate Press F2 SUBSTR when the main menu is displayed see subsection 2.0, "Standard Prog program SubS is selected so that the optical constants PSI, DEL, real N and extin bare substrate can be evaluated. These constants are needed before making any film m Pressing MENU F5 enters the main menu. The angle of incidence * * 700 is selected automatically. Verify that the polarizer dru Angle of incidence: PU170° Polarizer drum angle: POL=20° Any one of the following can be selected by using the corresponding key: Key At $ = FunctIon Fl F2 F3 F4 PRINT/DISP TMAX PHI MEAS F5 MENU F6 F7 SAMPLE POLRZR 700, Allows the choice of printed or displayed Activates the TableMax subprogram. Allows change of angle of incidence to ot Instructs the ellipsometer and computer to urement with the given input parameter Terminates the Substrate subprogram an program to the main menu. Allows identifying numbers and/or letters Allows the input of the polarizer drum mally 20° for the best overall sen setting the polarizer drum close to PSI, sensitivity and stability can he i one substrate produced these measurements middle of the screen: SAMPLE :Sss Ns: Ks: 3.791 7109-C-229S -0.153 PSI: 9.99 3-7 DEL 173.21 LI16S ELLIPSOMETER 2.3 STNAD STDS S7S Two Angle The ellipsometric thickness measurement of transparent films is a periodic functio only one angle of incidence, the expected thickness of the film has to be known w For 5102, a period Is 2832A 283.2 nm at a 70° angle of incidence. If the thickness this accuracy, then measurements at two angles of incidence are needed to find thickness. Press F3 TWOANG in the main menu to select subprogram S7S, which takes measurem and 70° for the most accurate film thickness measurements. A sample serial number can be typed in and press Enter. Then sele Just press Enter for no number. Nitride F2, or Nf F3. The Two Angle program requires the cooperation of the user in changing the angle o taking measurements at 700 and 50° angles of incidence on Oxide or Nitride films strates, a-id determines the actual thickness of films. The thickness does not ha within a period; however, minimum and maximum possible thicknesses, such as 0 and 3 entered. Following is an example of a nitride film display, as it appears in the screen: SAMPLE :nnn PHI=70 Nf FXD: 2.000 MATCHED THlCKNESS 265 1PRINT 2TMAX 7109-C--229S 3OXIDE 4NITRIDE PHI=50 Nf FXD: 2.000 268 5Nf? 6SAMPLE 3-8 7LIST 8PSIDEL 9MENU STANDARD PROGRAM 2.3 L1165 EL STDS 575 Two Angie continued The LISTING key F7 gives all of the possible thicknesses [within the minimum 0 20000 enteredj for 700 and 500 from which the actual thickness is matched. Piffe values can be selected; a listing will appear on the right side of the screen. F listing obtained using the above minimum and maximum: THICKNESS LISTING: P1-11=70 265 2057 38149 5641 7433 9225 11017 12809 114601 16393 18185 19977 P1-11=50 268 1981 3694 5407 7120 8833 10546 12259 13972 15685 17398 19111 For films, of thicknesses less than 400A or within 400A of a periodic multiple, be fixed at 1.46 for oxides and 2.00 for nitrides. Any other default index may prompted. 7109-C-229S 1-9 ____ ____ L116S ELLIPSOMETER STAN STD S I Fl Print P3 Displsy I I I I I I F, F I I HI I I I I a ogit. L5515 jJFs JJ F21kS"I slUr, I TUs. Chart 3-1 I I Fill I Nuirld.jJ NUns Full j[_NIFxd Standard Program Flow Chart 7109-C-229S I I H 3-10 Jj List I lipi. I Menu STANDARD PROGRAM sits NOTES: 7109-C-229S 3-11 L1165 S S S OPTIONAL 1116$ ELLIPSOMETER SINGLE-POINT MEASUREMENTS TABLE OF CONTENTS SECTI ONS G C4 S Single-layer nonabsorbing with Time Option GC6S Single-layer absorbing GCOS Two-layer nonabsorbing GC8S4 Four-layer nonabsorbing GC9S Two-layer absorbing GC9S3 Three-layer absorbing GC1OS Two-angle, two-layer absorbing SC 115 Polysilicon on Oxide/Nitride on Silicon SC12S Oxide on Polysilicon on Oxide/Nitride on Silicon PDS Psi and delta only S TD S # R5-232 STDS# and Optional Programs . INFORMATION ON THE ABOVE OPTIONAL PROGRAMS IS AVAILABLE THROUGH GAERTNER SCIENTIFIC CORPORATION 71 09-C-229S 4-0 S . . L11SC/D WAFERSKAN ELLIPSOMETER OPTIONAL PROGRA TABLE OF CONTENTS SECTION 1.0 Introduction 2.0 Set Up 3.0 Starting the Program 14.0 5.0 Working in the Engineering Mode 4.1 Setting Parameters 4.1.1 Film Parameters 4.2 Setup Files Working in the Production Mode LIST OF FIGURES Figure Figure Figure Figure Figure Figure Figure Figure Figure 4-6.1 4-6.2 4-6.3 4-6.4 4-6.5 4-6.6 4-6.7 4-6.8 4-6.9 Option Portion of the WS11A Main Menu Screen Typical Parameter Box Section of Engineering Mode Screen Typical Engineering Mode Screen of WSI1A Program Example of Parameters Option Screen Example of Film Parameters Option Screen Example of Film Parameters Option Screen Example of Engineering Mode SETUP Files List Screen Example of SETUP Files List in Production Mode . Example of Attempt to Retrieve Out-of-Mode File . . LIST OF CHARTS Chart 14-6.1 7 109-C-230F-Rev WS11A Modification of WS Flow Chart 4-6.0 . . OPTIONAL PROGRAMS 1.0 - L1ISC/D WAFERSKAN E WS1IA INTRODUCTION The WS1IA Optional Program is a specific two-layer, waferskan measurement, absorbi for use with the Gaertner L115C/D Waferskan Ellipsometer and an IBM PC/PS Computer calculates thickness and absorption of a polysilicon film on a layer of oxide or silicon substrate. It is a modified version of the WS Standard Waferskan Program. This instruction describes the unique features and functions of the WS1IA Optional work effectively in the program a thorough familiarity with the WS Standard Wafers recommended. While the WS11A optional instruction may describe, in some cases, a p the two operations are similar, in some other instances, where the two programs ar reference is made because the point has been discussed in detail in the standard waf instruction. 2.0 SET UP Refer to the INSTALLATION Section and the "Program Software" Instructions #710 STANDARD PROGRAMS Section for information regarding setup, software installati and table vacuum and alignment. 3.0 STARTING THE PROGRAM Several seconds after the WS11A program is selected from the waferskan system Figure 4-6.1, the Main Menu appears. Select Option: 1: Production Figure 4-6.1 2: Engineering 1O:ENI Option portion of the WS11A Main Menu screen. 7109-C-230F-Rev. 4-6.1 L1TSC/D WAFERSKAN ELLIPSOMETER 4.0 OPTIONAL PROGR WORKING IN THE ENGINEERING MODE To start the Engineering Mode press the F2:Engineering key in the Main Menu. Figure 14-6.2 pears. WSI1A: SETUP file: Default Solve: Kf index Film parameters for the Polysilicon on Oxide or Nitride: Poly -Thick exp: ? Nf fxd: 4.060 Kf exp: Oxide -Thick2fxd: 0 Nf2fxd: 1.460 Kf2fxd: Substrate -Ns: 3.850 Ks: -0.020 INSTRUMENT PARAMETERS Wavelength A Phi Ambient Polarizer Angle : 6328 : 70.00 : 1.000 : 45.00 A scre -0.049 -0.000 5-Point WAFERSKAN PARAMETERS Plot: Thickness Wafer diameter-mm: 150.00 Outer meas dia-mm: 132.00 Measure center point: Yes STATUS Figure 4-6.2 Typical parameter box section of the Engineering Mode screen. Enter these parameter values in the following order: 1. 2. 3. 4. Poly thickness Poly Nffxd Poly Kfexp Oxide: Thick2fxd 7 109-C-230F-Rev expected thickness entry is required in the initi default value=4.060 at 6328A. default value=-0.049 at 6328A. entry is required in the initial film setup. 4-6.2 OPTIONAL PROGRAMS 4.0 - WS11A L11SC/D WAFERSKAN E WORKING IN THE ENGINEERING MODE continued When all the parameter values are entered, the screen display is similar to Figure WS11A: SETUP file: Default Solve: Kf index Film parameters for the Polysilicon on Oxide or Nitride: Poly -Thick exp: 500 Nf fxd: 4.060 Kf exp: Oxide -Thick2fxd: 100 Nf2fxd: 1.460 Kf2fxd: Substrate -Ns: 3.850 Ks: -0.020 INSTRUMENT PARAMETERS Wavelength A Phi Ambient Polarizer Angle : 6328 : 70.00 : 1.000 : 45.00 -0.049 -0.000 5-Point WAFERSKAN PARAMETERS Plot: Thickness Wafer diameter-mm: 150.00 Outer meas dia-mm: 132.00 Measure center point: Yes STATUS Select Option: 1:Pmtrs 2;Exe 3:SetupFiles 4:Sample 5:PrtON 8 Figure 4-6.3 Typical Engineering Mode screen of the WS11A program. Oxide layer have been entered. 7109-C-230F-Rev. 4-6.3 10:Exit Arbitrary L115C/D WAFERSKAN ELLIPSOMETER 4.0 OPTIONAL PROGR WORKING IN THE ENGINEERING MODE continued Choose any option of the Engineering Mode in any order as needed: Key Function Fl:Pmtrs Set or change the values of the parameters section 11.1. F2:Exe Execute a measurement with the current status of the parameters be "active set of parameters". A menu choice is available between and wafer scan measurement section 1.2 of the WS instructions F3:SetupFiles Save an active set of parameters or delete an existing set secti F4:Sample Assign a sample ID to a graphic screen. F5:PrtON/OFF This is a toggle function. Press: Menu Display: F1O:Exit 4.1 F5:PrtON F5:PrtOFF F5:PrtOFF F5:PrtON Printer Response: a. Automatically print the measure each measurement during the Execu b. When the current parameters a press F5:PrtON, choose the correspo from the F1:Pmtrs menu and press print the parameters. The printer is deactivated. Terminate the Engineering Mode and return the WS11A Main Menu t Setting Parameters Use the F1:Pmtrs key to review and settchange the sample parameter values. The Eng menu is replaced by the Parameters menu when the Fl:Pmtrs key is pressed Figure 7109-C-230F-Rev. 4-6.4 OPTIONAL PROGRAMS 4.1 - WS11A L11SC/D WAFERSKAN E SettIng Parameters continued WS11A: *SETUP file; TEST3 Solve: Kf index Film parameters for the Polysilicon on Oxide or Nitride: Poly -Thick exp: 500 Nf fxd: 4.060 Kf exp: Oxide -Thick2fxd: 100 Nf2fxd: 1.460 Kf2fxd: Substrate -Ns: 3.850 Ks: -0.020 INSTRUMENT PARAMETERS 6328 Wavelength A Phi : 70.00 Ambient : 1.000 Polarizer Angle : 45.00 -0.049 -0.000 S-Point WAFERSKAN PARAMETERS Plot: Thickness Wafer diameter-mm: 150.00 Outer meas dia-mm: 132.00 Measure center point: Yes STATUS Select Parameter Option: 1:Film Figure 4-6.4 4:Waferskan 10:Exit Example of the Parameters option screen. Function See section 4.1.1. F1:Film Set the Film parameters. F4:Waferskan Set the parameters for a 5-Point, 9-Point, X-V GRID, USER-Mo Waferskan. See section 1.1.3 of the WS instructions. F10:Exit Terminate the Parameters option and return the Engineering men 7109-C-230F-Rev. 4-6.5 LIISCID WAFERSKAN ELLIPSOMETER 4.1.1 OPTIONAL PROGR Film Parameters Choose the F1:Fiim option from the Parameters Menu Figure 4-6.14 and the Film Para appears at the bottom of the screen. Reference Figures 4-6.5 and 4-6.6. *SETtJP file: TEST3 WSI1A: Solve: Kf index Film parameters for the Polysilicon on Oxide or Nitride: Poly -Thick exp: 500 Nf fxd: 4.060 Kf exp: Oxide -Thicklfxd: 100 Kf2fxd: Nf2fxd: 1.1460 Substrate -Ns: 3.850 Ks: -0.020 INSTRUMENT PARAMETERS Wavelength A Phi Ambient Polarizer Angle : 6328 : 70.00 : 1.000 : 45.00 -0.049 -0.000 5-Point WAFERSKAN PARAMETERS Plot: Thickness Wafer diameter-mm: 150.00 Outer meas dia-mm: 132.00 Measure center point: Yes STATLJ S Select film parameters: 2:Poly Layer FIgure 4-6.5 3:Oxide Thk 4: +Nitride Example of the Film Parameters option screen. 10:Fxit The second layer is an Function F2:Poly Layer F 3: OxideThk / Nitride Thk F't: -*Nitride/-,Oxide F 10: Exit 7109-C-230F-Rev Enter new values for thickness. refractive index and/o of the Poly Layer Top Layer. Enter new thickness for the second layer. The F3 key lab automatically when the FIt key is toggled. Toggle function: Change the second layer from Oxide to N -*Nitride or from Nitride to Oxide press ÷Oxide. Terminate the Film Parameters option and return the Par to the screen. 4-6.6 OPTIONAL PROGRAMS 4.1.1 - WS11A LI15C/D WAFERSKAN E FIlm Parameters continued *SETUP file: TEST3 WS1IA: Solve: Kf index Film parameters for the Polysilicon on Oxide or Nitride: Poly -Thick exp: 500 NI fxd: 4.060 Kf exp: Nitride Kf2fxd: -Thick2fxd: 100 Nf2fxd: 2.000 Substrate --Ns: 3.850 Ks: -0.020 INSTRUMENT PARAMETERS Wavelength A Phi Ambient Polarizer Angle : 6328 : 70.00 : 1.000 : 45.00 -0.0149 -0.000 5-Point WAFERSKAN PARAMETERS Plot: Thickness Wafer diameter-mm: 150.00 Outer meas dia-mm: 132.00 Measure center point: Yes STATUS Select film parameters: 2:Poly Layer Figure 4-6.6 3:Nitride Thk 4: -`Oxide Example of the Film Parameters option screen. 7109-C-230F-Rev. 4-6.7 10:Exit The second layer is a L1I5C/D WAFERSKAN ELLIPSOMETER 4.2 OPTIONAL PROGR Setup Flies The active set of parameters can be stored into a SETUP File and used later in th Mode. Press the F3:SetupFiles key in the Engineering Menu Figure 4-6.3 to displa files list. Disc Drive C:OOTTT Files currently on disc File name Date Store Option REDI 05-22-1995 SETUP DATA : RED2 05-22-1995 SETUP DATA : TEST1 12-06-1995 SETUP DATA : TEST2 12-06-1995 SETUP DATA TFST3 12-06-1995 SETUP DATA : <<cc >>>> End of File List 5 files Film Mode WS WS WS1IA WS1IA WSIIA Select option: 1:Store FIgure 4-6.7 3:Delete 7:Up 8:Down 1O:Exit Example of an Engineering Mode SETUP files list screen DIRECTRY.OO Key Function F1:Store Store the active set of parameters to an external SETUP file Only W511A film mode flies can be created and then used in t Mode with this WSI1A optional program. Delete y existing SETUP file in the list WS, WSI1A optional program film mode, i.e., WS6A, WS8A, etc.. Roll the screen up. The number of files in the list appears Screen capacity is 14 files, If more files right corner. the legend "" * more * **" appears at bottom of the page. Roll the screen down. Terminate the SETUP Files program and return the Engineeri to the screen. F3:Delete F7:Up F8:Down F10:Exit 7109-C-230F-Rev. 4-6.8 OPTIONAL PROGRAMS 5.0 - WS11A L11SC/D WAFERSKAN E WORKING IN THE PRODUCTION MODE Press the F1:Production key in the WS11A Main Menu Figure `t-6.1 to begin Production Mode. The Production Mode pathway is the same as the WS Standard Wafe pathway. Disc Drive C:OOTTT Files currently on disc File name RED1 : RED2 : TEST1 TEST2 : TEST3 5 files Date Store Option 05-22-1995 SETUP DATA 05-22-1995 SETUP DATA SETUP DATA 12-06-1995 12-06-1995 SETUP DATA 12-06-1995 SETUP DATA <<<< >>>> End of File List Film Mode wS wS WS11A WS11A WS11A Select one option: 1:Retrieve file 7:Up 8:Down 10:Exit Figure 4-6.8 Example of a SETUP file list in the Production Mode. WS11A Production Mode It is the firs Key Function F1:Retrieve file Retrieve a WS11A SETUP file for execution of a measur file created in this WS11A optional program can be retrie Roll the screen up. Screen capacity is 14 files. The files in the list is shown in the upper right corner. Roll the screen down. Terminate the Production Mode and return the WSIIA Ma screen. F7:Up F8:Down FlO: Exit 7109-C-230F-Rev 4-6.9 LJTSC/D WAFERSKAN ELLIPSOMETER 5.0 OPTIONAL PROGR WORKING IN THE PRODUCTION MODE continued Disc Drive C:'i.,OOTTT Files currently on disc File name RED1 RED2 TEST1 TEST2 TEST3 S files Date Store Option 05-22-1995 SETUP DATA 05-22-1995 SETUP DATA 12-06-1995 SETUP DATA 12-06-1995 SETUP DATA 12-06-1995 SETUP DATA <<<< >>>> End of File List Film Mode WS WS WS11A WS1JA WS11A Filename to retrieve for a WS11A only? RED1 Not a WS1IA file ! <ENTER> key & retry. To Exit, press just <ENTER> key. RED1 is a FIgure 4-6.9 Example of an attempt to retrieve an out-of-mode file. Only file and cannot be retrieved while working in the WS11A optional program. TEST2 and TEST3 can be retrieved at this time. 7109-C-230F-Rev. 4-6.10 OPTIONAL PROGRAMS - L115C/D WAFERSKAN ELL WS11A Parameters Menu Continued From Chart 3-1.1 I I I I Continue F2 Poly Layer F3 Oxidemk/ NitrideThk Fit .Nitride/ `Oxide rio Exit Chart 3-1.2 Chart 4-6.1 WS11A modification of 7109-C-230F-Rev. the WS flow chart. With L1I6S ELLIPSOMETER INSTALLATION/IBM CO TABLE OF CONTENTS Unpacking 5-1 Inspection 5-2 Location Considerations 5-2 Interconnections Ellipsometer and Computer Computer & Printer 5-2 5-2 5-4 Software Installation and Loading 5-4 Computer Circuit Board Installation 5-8 LIST OF FIGURES 5-1 5-2 5-3 5-4 5-5 5-6 AC Power Plugs L1I6S System Interconnection Diagram Ellipsometer Left and Rear View IBM PS/i Computer and Connections AID Interface Card A/D Interface with Cable Adapter removed 7 i09-C-229S 5-0 5-3 5-5 5-6 5-7 5-8 5-9 INSTALLATION Li 16 The Gaertner ellipsometer is shipped fully assembled, along with needed items, in crate. The applicable items are as follows: * * . * * * Ellipsometer User's Manual Ellipsometer/Computer Interface Cable Analog to Digital Converter Card Software Programs Silicon Wafer Reference Sample Dust Cover *This component is supplied to customers with their own computers. But c shipped with the ellipsometer will have the AID card already installed. UNPACK I NC Remove the protective wrapping from the ellipsometer. Remove the lag bolts that down clamps to base of the ellipsometer. Remove the hold-down clamps. This allo the ellipsometer from the shipping crate base platform. DO NOT apply any pressu NOTE Store the shipping platform, shipping crate parts and protecttive wrapping in case of a reshipment to Gaertner for repair. WHEN PACKING THE ELLIPSOMETER FOR RESHIPMENT TO GAERTNER FOR REPAI SOFTWARE PROGRAMS AND INTERFACE CABLES WITH AID INTERFACE CARD, CONTACT GAERTNER FIRST. CAUTION In event of reshipment, care must be taken to ensure that 1 the polarizer arm is set and clamped at 500 angIe of inci dence and 2 the analyzer arm is set and clamped at 500 angle of incidence before packing. This will prevent damage to the helium-neon red laser assembly and analyzer module. 7109-C-229S 5-i 1116S ELLIPSOMETER INST INSPECTION Thoroughly inspect the ellipsometer for shipping damage. the carrier. If there is damage from tra A key should be installed in the keylock switch located on the right side of the Sam Assembly above the sample table; it should be off. Check that good a fuse is in the el Verify that all applicable items have been included in the shipment. LOCATION CONSIDERATIONS The Gaertner ellipsometer is designed for use in either a production or laboratory fa relatively constant room temperature and a relatively dry, dust-free atmosphere. The requires a clean, level solid work surface sufficient to also accommodate the interface The input ac line voltage must be free of large transients having harmonics in the range frequencies to several megahertz. Do not obstruct the ventilation holes on any of the INTERCONNECTIONS DO NOT plug or unplug any component into or from ac power or make connections to othe with its power ON/OFF switch ON! The ac line cable for the ellipsometer is on the left side, near the rear of the instr supply and is labeled INPUT POWER. The ac line cable for the helium-cadmium laser at the rear of the laser power supply. CAUTION Verify that the power switches on all of the components are OFF before connecting or disconnecting the interface cabling. An interconnection diagram for the ellipsometer is shown in Figure 5-2. Ellipsometer and Computer See Figure 5-3 ellipsometer rear view, and Figure 5-4 computer. See Figure 5-5 A/D interface card, &id Figure 5-6 A/D interface card adapter removed. 7i09-C-229S 5-2 INSTALLATION 11165 AC POWER PLUGS The Gaertner ellipsometer is supplied with a U.S. plug NEMA 5-15P. the plug, the following guidelines apply: If it is nec NEWt liP It nfl'. Great Britain, Cyprus, Nigeria, Rhodesia and Singapore 8 Underwriter's Lab for the United Stat Japan, Mexico, Phi Ti awan 110* SiR Australia and New Zealand UL approved for th stv liii tEE lull Eastern and Western Europe, Saudi Arabia, and United Arab Republic Switzerland Figure 5-1 NOTE: All plugs are for single-phase power and are viewed above from the co prongs are: * L = * N = Neutral or identified conductor. * E = Earth or safety ground. 7109-C- 2 29 S Line or active conductor, also called "live" or "hot". The insula The insulation is white The insulation is green. 5-3 INST L1I6S ELLIPSOMETER Computer aid Printer Connect the Centronics Interface Cable 7108-E-239t to the parallel receptable on the computer and at the connector on the printer. See Figure 5-3 ellipsometer rear Figure 5-4 IBM PS/I computer. Hand tighten the connector thumb screws. SOFTWARE INSTALLATION AND LOADING NOTE: Wherever in this instruction the prompt is to type in some specific characters, ters are in boldface and just after "type". Type in the characters, and press Enter. Software installation on the Customer-Suppl led Computer: The computer will ioad DOS from the hard disc which must have at least three megaby space, drive C. a. * Turn on the computer, aliow it to "boot-up", and insert the program disk into driv * The screen should show that drive C is the default by displaying, for example, th "C:>". Type a: and press Enter to make A the default, i.e., "A:V". * Type install aid press Enter. disc C. * Remove the program disc. b. All of the files on the program disk will then be Go to step c. for installing any optional programs. NOTE: The following occur during the software installation: 1 A directory is created: c:'.gsc. 2 All of the driver and executable files are copied in that directory. 3 Autoexec.bat and config.sys files on c: root directory are created. If the and config.sys files already exist on c: drive, it copies them to autoe config.bak before installing new ones. c. OPTIONAL PROGRAM INSTALLATION: If one or more optional programs has been ord each optional program disc into drive A. The default drive should be A. If it is not, press Enter so that A is the default. Type Install aid press Enter. Remove the prog 7109-C-229S 5-4 ______ ____________________ ______________ INSTALLATION Li 16S IBM DISPLAY UNIT GPIO COMPUTER INTERF CABLE C-10161-'ISDh IBM PS/i CbMPUTERCOILED ELLIPSOMETER LE KEYBOARD L116S F I NEC P6200 PR? NT ER PARALLEL CENTRONICS INTERFACE CABLE 7 108-F-239t Figure 5-2 L116S Ellipsometer Interconnection Diagram. with the L116S is the IBM PS/i. 7109-C-229S s-s The computer that Gaer L116S ELLIPSOMETER INSTA RED 632.8 MICRO ELLIPSOMETER SLOW-BLOW FUSE, .75A 115 or 230V GPIO SOCKET, CABLE TO THE TO AN AC OUTLET Figure 5-3 Rear and left view of the L116S Ellipsometer with the 6-inch diameter tab 632.8 nm helium-neon laser. 7 109-C-2295 5-6 L116S INSTALLATION LOWER SOCKET FO TO THE E TO AC POWE PARALLEL SOCKET FOR THE CENTRON1CS INTERFACE CABLE TO THE PRINTER Figure 5-k 7109-C-229S IBM PS/i computer and its connections. 5-7 . `1 C V ;o.-i > cD; CD a *1 tZ -*i W° kC ,a CD r" 5* 0 0' 0 °fl > fl `1 m' C, >, r 0 t0 cow ` . C 0 -I to CD z - C ... - n o Z 00 `° rn 3 -w CD, n, s 1CD a' 50. `r tO rn r r . c -u r -ti ° u, If' CM V r - -`- m -.cI IA u, > E q a CD'.° - - -w 03C 0 - m -t D. a_. 5D ?a CD CD -ti 0, C CD 0 Dr r - C, 0, I -1 -4 > t-. cui 0 *0 z a -I a. °*`a -s hiiiiIliuoivmoIw1ivflu! -, IMCD ` Vc 11 ttlD 0-o - m Ig*5 - D `<C m C m a V " z to X `S'? - > 0 - m 5 - CD U' tmu, `r r< , ; C, tD Oi <U, -n r or - to aV r? V r Vu, .c 3 -tic a. fl V C c -tim -0 m a *t o,W ? 0 V 0 3 w . . r r In > - - CD 0 V 0. 5'_ ____ _____ !` I* INSTALLATION 1116S EL AID INTERFACE CARD Continued Now carefully remove the cable adapter as shown in Figure 5-6. The A/F card may no seated into a computer expansion slot. Once the A/fl card is properly installed, rep adapter and stand-offs; then firmly tighten. * r-?,.i u.e *-T rv'v" `i -s_- Li I I - . C-.,-. F * - - - p____,_..__** - J - - C" CIT 111:1 H -. - -- -. I:,.. -4%' -S - S 4 - FIgure 5-6 7109-C-229S Photograph of the AID Interface Card with the Cable Adapter removed. 5-9 L116S ELLIPSOMETER OPTIONAL CO TABLE OF CONTENTS Page Hand Positioning stages, L116HXY6 and L116HXY5 6-1. Micrometer Positioning Stages, L116MXY6 and L116MXYS 6-1. Fine Motion Height Adjustment L117FM 6-1. Microspot Optics, L116MS 6-1. Interface LR5232 6-1. Video Monitor L115VM 6-1. Wafer Handler L1I6WH 6-1. 200 mm Sample Table 6-1. FIGURE 6-1.1 7109-C-229S 200 mm Sample Table Top View 6-1. 6-0 . . . L116S ELLI OPTIONAL COMPONENTS HAND POSITIONING STAGES LI16HXY6 This stage accepts 6-inch samples and enables the sample table to he move in X,Y and 0 directions to facilitate measurement at any desired point on the sample surfac and Y coordinates translation facilitates measurement on a rectangular or grid pattern; z 2 inch left-to-right translation X direction, 1 inch in the -Y direction from center, and - in the +Y direction. If the whi Total rotational travel 9 direction is 00 to 3600. retainers are removed from the table, translation in the +Y direction is increased to 1 i L116HXY5 This stage is identical to the L116HXY6 stage except that this table will allow ments on samples 5 inches in diameter or less. The front-to-back translation Y direc inch from the center. - MICROMETER POSITIONING STAGES L116MXY6 This stage is identical to the L116HXY6 stage except micrometer thimbles are allow fine motion translation in the X and Y directions to facilitate positioning within r scribe lines. One division on the thimble equals 0.001 inch. This stage Is especially u the Microspot Optics L116MS accessory. - L116MXYS This stage is identical to the L116MXY6 stage except that this will allow measur sample wafers no greater than 5 inches in diameter. - EINE MOTION HEIGHT ADJUSTMENT LI17FM This feature may be added to &iy type of sample stage and consists of a rotatable incl acting through a transfer plate and the standard height vertical position adjustment t lower the table 0.010 inch maximum from the mid-position reference after setting the vertical position. One half turn of the knob moves the table 0.010 inch. The knob is a position when the center line of the reference hole on the knob is at the centerline of clamp screw. A clockwise rotation of the knob raises the table CC.W lowers the ta pages 6-2.1 and 6-2.2 for detailed information. 7109-C-229S 6-1.1 L116S ELLIPSOMETER OPTt MICROSPOT OPTICS L116CMS Gaertner Installed This option has a projector optic that reduces the normal 1 mm diameter beam at t down to 0.015 mm to measure very small areas and a receiver optic for added the table in subsection 1.0 Specifications in the "Description" Section of this u NOTE: The table in subsection 1.0 Specifications shows the dimensions of the sample with and without the Microspot Optics at different angles of incidence, j. INTERFACE LRS232 This option enables the user to send or receive serial data via an interface with R equipment such as a large-scale host computer, data terminal and modems. I cable, modified software and program User Instructions. Contact Gaertner for d data communication specifications. VIDEO MONITOR L115VM This option allows the ease of monitoring a wafer pattern display on a CRT screen standard viewing microscope. An MIT switch is usually mounted on the front of t Assembly when a video monitor is included with an ellipsometer. WAFER HANDLER L1I6WH Model L116WH Wafer Handler permits unattended automatic measurement of up to cassette. The randon-access indexer on the Wafer Handler is ultra clean with th contained within the housing so that there are no moving parts near the wafer. Th of motion of the arm is simple, clean and gentle. 200 mm 7.9 inches diameter SAMPLE TABLE This larger table is for 3" 76 mm. 100 mm, 125 mm, 150 mm and 200 mm wafers for fi See Figure 6-1.1 for a top view of this table. NOTE: If an ellipsometer has a 200 mm diameter table and the Microspot Optics, to move this table out of the two arms so that they can be set at a 900 incidence a any instructions that call for setting the arms at 90°. 7109-C-2295 6-1.2 OPTIONAL COMPONENTS L116S ELLI OUTER GROOVE IUNER GROOVE 126 M FIgure 6-1.1 7 109-C-229S ThIs Is a top view of the 200 mm 1.9 inches diameter sample table. 6-1.3 S S S LII6S ELLIPSOMETER PAGE TABLE OF CONTENTS 1.0 TroubleAnalysis . 1.1 Measurement system 1.2 Troubleshooting 7-1 7-1 7-1 2.0 DiagnostIcs 2.1 Photodetector Zero Offset Adlustment 2.2 Automatic Amplifier Gain Check 2.3 Optical Alignment Check 7-7 7-7 7-7 7-7 LIST OF FIGURES 7-1 7-2 7-3 7-4 7-S Measurement System Functional Diagram L1J6S Left and Rear View Diagnostic Program DIAG Main Menu Test/Display A-B Board Outputs DIAG Alignment Display D1AG H 7-2 7-6 7-8 7-9 7-10 LIST OF TABLES 7-1 7-3 Troubleshooting Guide 7109-C-229S 7-0 SERVICE 1.0 L116S TROUBLE ANALYSIS Caertner ellipsometers should have long-life, trouble-free operation. In the eve tion, symptoms are readily traceable by the use of diagnostic software and i points. Fault isolation This should be done by qualified service personnel. shooting to isolate the cause of failure only to a component or assembly readi further fault isolation and repair or replacement. During automatic operation, usually shown by no measurement data, inconsistent measurements, or even operato 1.1 Measurement System During automatic operation, the four-detector-voltages of the StokesMeter are amp to the circuitry of the Sample and Hold Board. See Figure 7-1. Digital control p with timing circuitry to provide a trigger for the Sample and Hold system. Thi voltages to be sampled simultaneously. The sampled voltage levels are adjus Finally, the a controlled auto-gain circuitry to fall within a lv 9V range. converted to digital signals and are read by the AID Computer Interface Card. - Computer analysis of the measured data yields the desired ellipsometric measureme 1.2 Troubleshooting Table 7-1, starting on page 7-3, lists the symptoms of malfunction, possible cause a actions relative to fault isolation. The symptoms are listed in a sequence genera operating procedure, i.e., premeasurement setup and measurement procedure. As guide, the listing assumes all dc power supplies are operative and no discontinuit NOTE The AID Circuit Board must be initialized by the batch file INIT.BAT. ll'4lT should he the last entry in the AUTOEXEC.BAT file on the program disc. 7109-C-2295 7-1 L116S ELLIPSOMETER r SM MODULE 1 AID COMPUT INTERFACE C SAMPLE AND HOLD BOARD CO PO CO PO CO PO CO PO C P ZERO OFFSET ADJUST L Figure 7-1 7109-C-229S L -j Measurement System Functional Diagram. 7-2 L116 SERVICE TABLE 7-1. SYMPTOM No power to the ellipsometer Key switch at ON TROUBLESHOOTING GUIDE POSSIBLE CAUSE No line voltage FAULT ISOLAT Verify that the el cord is seated in an Check the fuses; rep They are .75A, slow Emission indicator does not illuminate at power turn-on Lamp burned out Replace the lamp. still present, the supply transformer bly transformer may No light is emitted from the polarizer aperture The Ream attenuator is closed Check the position o if it is closed, PULL Defective laser or laser power supply Needs the replaceme laser or removal of supply for repair co 7109-C-229S 7-3 LII6S ELLIPSOMETER TABLE 7-1. SYMPTOM Inconsistent or inaccurate measurenients TROUBLESHOOTING GUIDE continued POSSIBLE CAUSE FAULT ISOLATION Failure to use TableMax program prior to measurement See Section 3 Upon exiting the TMax progr the autoranging-gain cir activated. Hence, TMax m whenever P, P1-U, or the changed. Inaccurate Polarizer Azimuth p Observe the Polarizer dr Ensure that it matches tha displayed by the computer Inaccurate incidence angle PHI Ensure that the angle of match that which is displa computer program. Check the knobs. Sample table misalignment 7109-C-229S 7-4 Check the TMAX. detents tilt and and t tab SERVICE L116 TABLE 7-1 * SYMPTOM Inconsistent or inaccurate measurements continued 7109-C-229S TROUBLESHOOTI NC GUIDE Continued POSSIBLE CAUSE FAULT ISOLAT Photdetector darkcurrent dc offset has changed Dark-current may b the diagnostic prog section 2. Photodiode or circuit failure This may he verif the measured detect the program DIAG. This problem should SERVICE PERSONNE Optical Misalignment Alignment may he ve of the program DIAG DO NOT ATTEMPT INSTRUMENT. This addressed by SERV ONLY! 7-5 SE 11165 ELLIPSOMETER CAUTION For 90° AngIe of incidence' If the ellipsometer has Microspot Optics, turn the table so that its notch lifting slot is under the analyzer arm. Move the table to the left and down so that neither Microspot Optic will touch the table when the arms are at 990* 632.8 nmj L ELLIPSOMETER TIME LAG FUSES 115 or 230V1 MICROSPOT OPTIONA CABLE `The optional 200 mm dia. tahle cannot be moved out of the way of the optional Microspo Thus, the arms cannot be set at 90° with both options. Figure 7-6 7109-C-229S Rear and left view of the L1165 Elllpsometer. 7-6 SERVICE 2.0 L116S DIAGNOSTICS A diagnostic program named DIAG.EXE has been supplied with this unit. This pro troubleshooting aid. Upon running [NAG, the menu illustrated by Figure 7-3 will 2.1 Photodetector Zero Offset Adjustment Selection F2 of the Main Menu yields the display illustrated by Figure 7-4. Ph Offset may be checked by simply closing the laser shutter. All voltages should th any voltage is non-zero, press the Fl key followed by ENTER to measure the dar information is stored in a file named DARI<CUR.DAT. 2.2 Automatic AmplifIer Gain Check The proper operation of the autoranging-gain circuitry can be verified by usin option shown in Figure 7-4. Note that the laser shutter should be open, and th occur if the four-detector-voltage average is within the IV 9V range. - 2.3 Optical Alignment Check Selection of Fl of the Main Menu yields the display illustrated by Figure 7-5. cated by the centering of the crosshairs + within the target area. NOTE The dark-current should be measured subsection 2.2 prior to the use of this option. CAUTION DO NOT ATTEMPT TO ADJUST THE ALIGNMENT OF THIS INSTRUMENT. THIS WILL CAUSE A CALIBRATION FAIL URE. CONSULT GAERTNER ABOUT ALIGNMENT PROBLEMS. 7109-C-229S 7-7 A L116S ELLIPSOMETER THE STOKESMETER ***** MAIN MENU Fl - ALIGNMENT DISPLAY F2 - TEST AND DISPLAY A-D BOARD OUTPUTS F3 - EXIT THIS PROGRAM Gaertner Scientific Corporation Figure 7-3 7109-C-229S Diagnostic Program Main Menu. 7-8 - ©1992 Ver. 1.0 SERVICE L116 0.946 1.080 0.728 0.716 A-D BOARD VOLTAGE DISPLAY - RANGE = 0.025 1X 0.026 - 0.0214 0.025 Fl: Measure Dark Current Figure 7-4 7109-C-229S F2: Range Other Key: Oult Test and Display A-D Board Outputs DIAG. 7-9 LI16S ELLIPSOMETER Figure 7-5 7109-C- 22 9 S Alignment Display DIAG 7-10 S S S