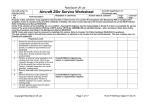

Download RSUK0043 issue 6 MTOsport Pilots Handbook

Transcript