Download AIRWELL -YCVFD280

Transcript

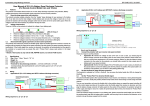

Installation Manual for Outdoor Unit AWAU-YCVFD224-H13 AWAU-YCVFD280-H13 AWAU-YCVFD335-H13 No. 0150513922 Please read this manual carefully before using Keep this operation manual for future reference User Manual CONTENT Flow Logic II series adopts "simultaneous control" type, all indoors should be heating or cooling simultaneously. Safety .......................................................... 1 Installation instruction .................................. 3 Installation procedure .................................. 6 To protect compressor, before startup, the XQLWVKRXOGEHHOHFWUL¿HGIRURYHUKRXUV If the unit is not used for a long time, please FXWRIIWKHSRZHUWRVDYHHQHUJ\RUWKHXQLW will consume the power. Electric wiring and the application ............. 21 Failure code ............................................... 25 Trial operation and the performance ......... 30 Disposal ..................................................... 32 Whole model AWAU-YCVFD224-H13 AWAU-YCVFD280-H13 AWAU-YCVFD335-H13 Brief model YCVFD224 YCVFD280 YCVFD335 For reference only For reference only 7KHEULHIPRGHOLVXVHGLQWKLVPDQXDOIRUDERYHPRGHOV Operation condition: To use the air conditioner normally, please perform as to the below conditions. Operating Range of Air Conditioner Indoor Cooling dry Outdoor Indoor Heating Outdoor Max. %#ą8#ą Min. %#ą8#ą Max. %#ą8#ą Min. %#ą Max. %#ą Min. %#ą Max. %#ą8#ą Min. %#ą Safety This manual should always be accessible and close to this air condition equipment. 7KHUHDUHWZRW\SHVRILQGLFDWLRQV WARNING" and " &$87,217KHLQGLFDWLRQSUHYHQWLQJ IURPGHDWKRUKHDY\LQMXU\LVOLVWHGDV :$51,1*(YHQWKHLQGLFDWLRQOLVWHGDV " CAUTION" may also cause serious accident. Both of them are related to safety, and should be strictly followed. $IWHULQVWDOODWLRQDQGVWDUWXSFRPPLVVLRQLQJSOHDVHKDQGRYHUWKHPDQXDOWRWKHXVHU7KH manual should be well kept in safe place and close to the unit. WARNING The installation or the maintenance should be performed by an authorized agency. The wrong RSHUDWLRQRIWKLVDLUFRQGLWLRQHTXLSPHQWPD\FDXVHZDWHUOHDNDJHHOHFWULFVKRFNRU¿UH Please install the unit on the top of a solid foundation or structure which is strong enough to support the unit. The installation of this air condition equipment should follow local construction codes. 8VHWKHULJKWFDEOHVL]HVHFXUHWKHWHUPLQDO¿UPO\RUJDQL]HWKHFDEOHVZHOODQGPDNHVXUHQR tension is added on cables. Cable insulation should not be damaged. The incorrect installation PD\OHDGWRRYHUKHDWRU¿UH :KHQLQVWDOOLQJRUPRYLQJWKHXQLWWKHUHIULJHUDQWV\VWHPVKRXOGEHYDFXXPHGDQGUHFKDUJHG with R-410A refrigerant. If any other gas enters the system, it may lead to abnormal high SUHVVXUHZKLFKPD\FDXVHGDPDJHRULQMXU\ Please use the proper manifolds or branches during the system installation. The wrong parts may cause refrigerant leakage. .HHSWKHGUDLQSLSHDZD\IURPWR[LFJDVYHQWVWRSUHYHQWSRVVLEOHSROOXWLRQRILQGRRU HQYLURQPHQW During or after the installation, please check whether there is refrigerant leakage. If any OHDNDJHSOHDVHWDNHDQ\PHDVXUHVIRUYHQWLODWLRQ7KHUHIULJHUDQWPD\EHWR[LFDWVRPH FRQFHQWUDWLRQOHYHOV 7KHXQLWLVQRWH[SORVLRQSURRI3OHDVHNHHSLWDZD\IURPÀDPPDEOHJDVHV The drain pipe should be installed per this manual to ensure proper drainage. The pipe should EHZHOOLQVXODWHGWRDYRLGFRQGHQVDWLRQ:URQJLQVWDOODWLRQPD\OHDGWRZDWHUOHDNDJH Both liquid pipe and the gas pipe should be also well insulated. Not enough insulation may lead to system performance deterioration or humidity formation. This air condition equipment is not intended to be operated by persons with lack of experience DQGWUDLQLQJXQOHVVWKH\KDYHVXSHUYLVLRQRULQVWUXFWLRQFRQFHUQLQJXVHRIWKLVDLUFRQGLWLRQ equipment. Please keep children away from this air condition equipment. 1 Safety CAUTION Grounding wire should be connected with the grounding bar. The grounding wire can not be connected to the gas pipe, water pipe, lightening rod or the telephone grounding wire. Improper grounding may cause electric shock. 8QLWVLQVWDOOHGRQURRIVKRXOGKDYHDSSURSULDWHDFFHVVDQGKDQGUDLO 8VHWKHZUHQFKWRIDVWHQWKHQXWDQGÀDUHDWSURSHUWRUTXH([FHVVLYHWRUTXHPD\FDXVH ÀDUHGVHFWLRQWREURNHOHDGLQJWRUHIULJHUDQWOHDNDJH $IWHUUHIULJHUDQWSLSHLQVWDOODWLRQSOHDVHWDNHQLWURJHQOHDNDJHWHVWWRDYRLGUHIULJHUDQW leakage. R-410A is the only permitted refrigerant. 7RDYRLGPLVFKDUJLQJZURQJUHIULJHUDQWWKHFKHFNYDOYHGLDPHWHULVFKDQJHGIRU5$7R VWUHQJWKHQWKHSLSHWKHÀDUHGSLSHGLPHQVLRQLVDOVRFKDQJHG3OHDVHXVH5$VSHFL¿HG tools as shown below. 5$VSHFL¿HGWRROV Remarks 1 Gauge manifold Range:HP Ḱ 4.5MPa,LP Ḱ 2MPa 2 Charge hose Pressure:HP:5.3MPa,LP:3.5MPa 3 Electronic weight for charging R410A No other means permitted 4 Torque wrench 5 Flare tool 6 &RSSHUSLSHJDXJHIRUDGMXVWLQJSURMHFWLQJPDUJLQ 7 9DFXXPSXPS¿WWLQJ Vacuum pump must be equipped with FKHFNYDOYH 8 Leakage detector Only Helium detector permitted When charging refrigerant, the refrigerant must be in liquid state from the tank. 7RSUHYHQW(0&LQWHUIHUHQFHRQRWKHUDSSOLDQFHVSOHDVHNHHSLQGRRUXQLWRXWGRRUXQLWSRZHU cable and connecting wire at least 1m away from those appliances . )OXRUHVFHQWODPSUHYHUVHSKDVHRUUDSLGVWDUWW\SHPD\LQWHUIHUHWKHUHPRWHFRQWUROOHU V VLJQDO3OHDVHLQVWDOOLQGRRUXQLWDZD\IURPÀXRUHVFHQWODPS7KHIDUWKHUWKHEHWWHU 2 Installation instruction )RULQVWDOODWLRQSOHDVHUHYLHZWKHLWHPVEHORZ Is the connected units quantity and the total capacity in the allowable range? Is the refrigerant pipe length in the limited range? Is the pipe size proper? And if the pipe installed horizontally? ,VWKHEUDQFKSLSHLQVWDOOHGKRUL]RQWDOO\RUYHUWLFDOO\" Is the additional refrigerant counted correctly and weighed by the standard balance? Is there refrigerant leakage? Is all the indoor power supplies can be on/off simultaneously? ,VWKHSRZHUYROWDJHLQFRPSOLDQFHZLWKWKHGDWDPDUNHGRQWKHUDWLQJODEHO" Is the address of indoors has been set? (1) Before installation %HIRUHLQVWDOODWLRQFKHFNLIWKHPRGHOSRZHUVXSSO\SLSHZLUHVDQGSDUWVSXUFKDVHG UHVSHFWLYHO\DUHFRUUHFW &KHFNLIWKHLQGRRUVDQGRXWGRRUVFDQEHFRPELQHGDVWKHIROORZLQJ Outdoor &DSDFLW\;: YCVFD224 YCVFD280 YCVFD335 Indoor Qty 13 16 19 Indoor 7RWDOLQGRRUFDSDFLW\;: 113~293 140~364 167~436 3 Installation instruction (2) Installation place selection $LUFRQGLWLRQHUFDQ WEH installed in the place with LQÀDPPDEOHJDV2ULWZLOO FDXVH¿UHKD]DUG The unit should be installed at the place with good YHQWLODWLRQ1RREVWDFOHDW the air inlet/outlet. And no strong wind blows the unit. The installation space refers to the latter info. The unit should be installed at the place where the cold/hot air or noise will not interfere the neighbours. The place where the water FDQÀRZÀXHQWO\ The place where no other heat source will affect the unit. Pay attention to the snow against clogging the outdoor. In installation, install WKHDQWLYLEUDWLRQUXEEHU between the unit and the bracket. 4 The unit should be installed at the strong enough place. Or it will FDXVHYLEUDWLRQDQGQRLVH The unit is better not be installed at the below places, or it will cause damage. The place where there is FRUURVLYHJDVVSDDUHDHWF The place blowing salty air VHDVLGHHWF Exsits the strong coal smoke. The place with high humidity. 7KHSODFHZKHUHWKHUHLVGHYLFH HPLWWLQJ+HUW]LDQZDYHV 7KHSODFHZKHUHYROWDJH changes greatly. Installation instruction (3) Transportation and hoisting Hoisting 3OHDVHUHPRYHWKHRXWGRRUXQLWWRWKHLQVWDOODWLRQORFDWLRQDVIDUDVSRVVLEOHQHDUSODFHEHIRU open the packaging. Forbid on the equipments to place anything, need to use 2 ropes while promoting outdoor. Please according to following way hoisting outdoor: (QVXUHWKDWWKHRXWGRRUXQLWZKHQKRVWLQJWKHOHYHOWRULVHVORZO\ 'RQRWUHPRYHWKHSDFNDJLQJ :KHQ KRLVWLQJ GR QRW KDYH WR WLH XS WKH HOHYDWRU WR WKH XQLW KLWV RQ WKH SDFNDJLQJ DQG WKH outside wrapping. When hoisting exterior must use the suitable protection. Handling %HIRUHWKHLQVWDOODWLRQRXWGRRUGRQRWGHSRVLWDQ\PDWHULDORWKHUZLVHOLNHO\KDVWKH¿UHRUWKH accident. :KHQKDQGOLQJXQLWSOHDVHRSHUDWHDVVKRZQLQWKHIROORZLQJ¿JXUHDQGQRWHWKHIROORZLQJSRLQWV 1.Forbids to demolish the wooden foundation. 3UHYHQWWKHRXWGRRUWRLQFOLQH 3.Should be handling more than two. handle 3 handle 2 handle 1 5 handle 4 Installation procedure Outdoor Installation Installation location 2XWGRRUXQLWVKRXOGEHSODFHGLQZHOOYHQWLODWHGDQGGU\SODFH 2XWGRRUQRLVHDQGH[KDXVWVKRXOGQRWDIIHFWQHLJKERUVDQGDURXQGWKHYHQWLODWLRQ Ensure the ground steadily reliable. Do not install the outdoor unit on high oil,salt spray or harmful gases. 'RQ WEHLQJLQVWDOOHGWRHOHFWURPDJQHWLFZDYHFDQGLUHFWO\UDGLDWHDQHOHFWULFLW\ER[DQGNHHS RIIHOHFWURPDJQHWLFZDYHUDGLDWLRQSRVVLEO\DWOHDVWPRUHWKDQPHWHUV :KHQLFHVQRZRYHUOD\DUHDLQVWDOOVRXWGRRUXQLWSOHDVHDGGWRGHIHQGVQRZFRYHU 2XWGRRUXQLWLQVWDOOHGLQWKHVKDGHDYRLGLQJGLUHFWVXQOLJKWRUKLJKWHPSHUDWXUHKHDWVRXUFHV of radiation. 'RQRWLQVWDOOLQGXVW\RUSROOXWHGSODFHWRSUHYHQWRXWGRRUXQLWKHDWH[FKDQJHUMDP The outdoor unit should install in the public unapproachable place. Installation and maintenance space $VVKRZQEHORZLQVWDOOWKHRXWGRRUXQLWVKRXOGDOORZVXI¿FLHQWVSDFHIRUKDQGLQJDQG maintenance. Case 1: stumbling block on the inlet ,also upside opens. Single installation around the opening Inlet Min200mm A Outlet Single installation around the closed h H Min300mm Inlet Min150mm Outlet Min300mm Min360mm 6 Installation procedure Multi Outdoor Inlet Min300mm Outlet Min300mm h Min3 00m m mm Min360 A 7 Installation procedure Case 2: stumbling block on the inlet and top side Single Outdoor Max300mm Min 500 mm Min 500 mm Max300mm L H H A Min360mm Min360mm Multi Outdoor H Min3 00m m Min500mm m 00m Max3 mm Min360 8 Installation procedure Min500mm m Max300m L H Min3 00m m mm Min360 A Case 3:stumbling block on the outlet, both right and left side Single Outdoor h H Min1000mm Min360mm Min300mm Min1000mm Min150mm 9 Installation procedure Multi Outdoor Min 300 mm m 000m 1 n i M h H Min 300 mm m Min360m mm Min1000 ,IK!+SOHDVHVHWWKHRXWGRRURQWKHIRXQGDWLRQWRPDNHVXUH+K H=The height of outdoor and foundation h K+ +K+ A 2YHU 2YHU 1RWH$YRLGPDNLQJDLUVKRUWF\FOHLQDQ\FDVH 10 Installation procedure h Multi Row Outdoor n Mi m 0m 36 mm 00 0 n3 Mi m 0m 0 in6 h M A Note: Make sure the distance at least 300mm between two neighbor units and no stumbling block. h K+ +K+ A 2YHU 2YHU 11 Installation procedure A. Refrigerant pipe connection Pipe connection method: 7RHQVXUHWKHHI¿FLHQF\WKHSLSHVKRXOGEHDVVKRUWDV possible. 'DXEWKHUHIULJHUDQWRLORQWKHFRQQHFWRUDQGWKHÀDUH nut. When bending the pipe, the bending semi-diameter should be as large as possible against the pipe being broken or bent. When connecting the pipe, aim at the center to thread the nut by hand and tighten it with the double spanners. Fastening torque please refers to "pipe specs and fastening torque" on page 15. 'RQ WOHWWKHLPSXULW\VXFKDVVDQGZDWHUHWFLQWRWKH pipe. Antifouling measures refer to page 13. Cautions in piping installation: When fastening and loosing the nut, operate with double spanners, because only one spanner cannot H[HFXWH¿UPO\ spanner connector nut spanner If threading the nut as not aiming at the center, the screw thread will be damaged, further it will cause leakage. 1. When welding the pipe with hard solder, charge nitrogen into the pipe against oxidation. The pressure gauge should be set at 0.02MPa.Perform the procedure with nitrogen circulation. 2WKHUZLVHWKHR[LGH¿OPLQWKHSLSHPD\FORJWKHFDSLOODU\DQGH[SDQVLRQYDOYHUHVXOWLQJLQ accident. 2. The refrigerant pipe should be clean. If the water and the other impurity enter the pipe, charge WKHQLWURJHQWRFOHDQWKHSLSH7KHQLWURJHQVKRXOGÀRZXQGHUWKHSUHVVXUHRIDERXW0SD and when charging the nitrogen, stop up the end of the pipe by hand to enhance the pressure LQWKHSLSHWKHQORRVHWKHKDQGPHDQZKLOHVWRSXSWKHRWKHUHQG 7KHSLSLQJLQVWDOODWLRQVKRXOGEHH[HFXWHGDIWHUWKHVWRSYDOYHVDUHFORVHG :KHQZHOGLQJWKHYDOYHDQGWKHSLSHFRROGRZQWKHYDOYHZLWKZHWWRZHO 5. When the connection pipe and the branch pipe need to be cut down, please use the special shears and cannot use the saw. :KHQZHOGLQJFRSSHUSLSHXVHWKHSKRVSKRUFRSSHUZHOGLQJURGZLWKRXWDQ\ZHOGLQJÀX[ ZHOGLQJÀX[ZLOOGDPDJHWKHSLSLQJV\VWHP7KHZHOGLQJÀX[FRQWDLQLQJFKORULQHZLOOFRUURGH SLSHHVSHFLDOO\WKHZHOGLQJÀX[ZLWKÀXRULQZLOOGDPDJHUHIULJHUDWLRQRLO Pipe material and specs selection 1. Please select the refrigerant pipe of the below material. Material: the phosphoric oxidize seamless copper pipe, model: C1220T-1/2H (diameter is RYHU&7GLDPHWHULVEHORZ 2. Thickness and specs: &RQ¿UPWKHSLSHWKLFNQHVVDQGVSHFVDFFRUGLQJWRWKHSLSHVHOHFWLRQPHWKRGWKHXQLWLVZLWK 5$LIWKHSLSHRYHULVW\SHWKHSUHVVXUHSUHVHUYDWLRQZLOOEHEDGWKXVLWPXVWEH +W\SHDQGRYHUWKHPLQWKLFNQHVV 3. The branch pipe and the gather pipe must be from Airwell. :KHQLQVWDOOLQJWKHVWRSYDOYHUHIHUWRWKHUHODWLYHRSHUDWLRQLQVWUXFWLRQ 5. The pipe installation should be in the allowable range. 7KHLQVWDOODWLRQRIEUDQFKSLSHDQGJDWKHUSLSHVKRXOGEHSHUIRUPHGDFFRUGLQJWRWKHUHODWLYH manual. 12 Installation procedure Anti-fouling measures First, clean the pipe. Position Outdoor Indoor Installation period More than 1 month Less than 1 month Nothing to do with period Measures Flat the pipe end )ODWWKHSLSHHQGRUVHDOZLWKDGKHVLYHWDSH 3LSHVSHFL¿FDWLRQ c a 7KH¿UVWEUDQFKSLSH a b a a 3LSHDGLDPHWHUEHWZHHQLQGRRUDQGEUDQFKSLSHGHSHQGVRQLQGRRUSLSH Indoor [: *DVSLSHPP /LTXLGSLSHPP 22~28 Ø9.52 Ø6.35 36~56 Ø12.7 Ø6.35 71~140 Ø15.88 Ø9.52 226~280 Ø25.4 Ø9.52 Note: AS072 AS092 gas pipe: Ø12.7mm AS182 gas pipe/ liquid pipe: Ø15.88mm/9.52mm 3LSHEGLDPHWHUEHWZHHQEUDQFKSLSHV 7RWDOLQGRRUFDSDFLW\DIWHUWKHEUDQFKSLSHN: <16.8KW .:;.: .:;.: .:;.: *DVSLSHPP Ø15.88 Ø19.05 Ø22.22 Ø28.58 /LTXLGSLSHPP Ø9.52 Ø9.52 Ø9.52 Ø12.7 Note: $GMXVWWKHGLDPHWHURQ¿HOGFKDQJLQJSLSHLVQHHGHG When the latter indoor total capacity is less than 14.0kw, pipe b will use the specs as the pipe a. 13 Installation procedure 3LSHFGLDPHWHUPDLQSLSHEHWZHHQRXWGRRUJDWKHUSLSHDQGWKH¿UVWEUDQFKSLSH Outdoor capacity N: 22.4 28.0 33.5 Main pipe *DVSLSHPP /LTXLGSLSHPP Ø22.22 Ø9.52 Ø22.22 Ø9.52 Ø25.4 Ø12.7 Enlarged main pipe *DVSLSHPP /LTXLGSLSHPP Ø22.22 Ø12.7 Ø25.4 Ø12.7 Ø28.58 Ø12.7 Note: :KHQWKHGLVWDQFHIURPRXWGRRUWRWKHORQJHVWLQGRRULVRYHUPWKHPDLQSLSHVKRXOGEH enlarged diameter. Copper pipe selection: Material 3LSHGLDPHWHUPP 7KLFNQHVVPP Ø6.35 0.8 O type pipe: Soft pipe Ø9.52 Ø12.7 Ø15.88 0.8 1.0 1.0 Material 3LSHGLDPHWHUPP 7KLFNQHVVPP Hard pipe Ø19.05 Ø22.22 Ø25.4 Ø28.58 1.0 1.0 1.0 1.0 Ø31.8 1.1 Long pipe and high drop 1. Applicable range Model Item Single way total pipe length Single way pipe length Main pipe beween outdoor to 1st branch Pipe length between outdoors Outdoor is upper Height difference between indoor and outdoor Outdoor is lower Height difference between outdoors LQWKHVDPHV\VWHP Height difference between indoors Outdoor 300m 0D[P(TXDO/HQJWKP 0D[P(TXDO/HQJWKP Less than 10m to 1st branch pipe Max. 50m Max. 40m :LWKLQPEHWWHUEHKRUL]RQWDO Max. 15m Unit pipe spec and connection method (unit: mm) A. Outdoor unit Gas pipe side Mobel YCVFD224 YCVFD280 YCVFD335 Diameter PP Ø19.05 Ø22.22 Ø25.4 Liquid pipe side Connecting method )ODUHGMRLQW )ODUHGMRLQWDQG%UD]LQJ 14 Diameter PP Ø9.52 Ø12.7 Ø12.7 Connecting method )ODUHGMRLQWDQG%UD]LQJ )ODUHGMRLQW Installation procedure B. Indoor unit Model Capacity 07 09 12 16 18 24 28 30 38 48 72 96 Gas pipe side Connecting 'LDPHWHUPP method Ø9.52 Ø9.52 Ø12.7 Ø12.7 Ø12.7 Ø15.88 Braze Ø15.88 Ø15.88 Ø15.88 Ø15.88 Ø25.4 Ø25.4 Liquid pipe side Connecting 'LDPHWHUPP method Ø6.35 Ø6.35 Ø6.35 Ø6.35 Ø6.35 Ø9.52 Flared Ø9.52 Ø9.52 Ø9.52 Ø9.52 Ø9.52 Ø9.52 Note: AS072, AS092 gas pipe: ØPP$6JDVSLSHOLTXLGSLSHØ15.88/9.52mm C. Pipe spec and the torque 'LDPHWHUPP Ø6.35 Ø9.52 Ø12.7 Ø15.88 Ø19.05 Torque(N.P 14~18 34~42 49~61 68~82 84~98 Branch pipe Branch pipe selection: 7RWDOLQGRRUFDSDFLW\: Less than 335 More than 335, less than 506 PRGHORSWLRQDO FQG-B335A FQG-B506A Outdoor unit type The master unit will choose the closest one to the 1st branch pipe. Note: 1. When connecting the outdoor branch pipe and the outdoor, please pay attention to the outdoor pipe dimension. :KHQDGMXVWLQJWKHGLDPHWHUDPRQJRXWGRRUEUDQFKSLSHDQGDPRQJWKHXQLWVSOHDVHPXVW execute at the branch pipe side. 3OHDVHLQVWDOOWKHRXWGRRUEUDQFKSLSHJDVOLTXLGVLGHLQKRUL]RQWDORUYHUWLFDOGLUHFWLRQ 4. When welding with hard solder, please must blow nitrogen. If not, a number of oxide will be SURGXFHG DQG FDXVH KHDY\ GDPDJH%HVLGHVWR SUHYHQW ZDWHU DQG GXVW LQWR WKH SLSH SOHDVH make the brim as outer roll. 15 Installation procedure $GKHVLYHVLGH Seal the connection and wrap the KHDWLQVXODWRUZLWKDGKHVLYHWDSH 3UHSDUHRQ¿HOG Cut off pipe with the cutter Horizontal Floor Cut off at the middle Right Wrong Floor Pipe installation When doing the piping connection, please do the following: 3OHDVHGRQ WOHWWKHSLSHDQGWKHSDUWVLQWKHXQLWFROOLGHHDFKRWKHU :KHQFRQQHFWLQJWKHSLSHVFORVHWKHYDOYHVIXOO\ 3URWHFWWKHSLSHHQGDJDLQVWWKHZDWHULPSXULW\LQWRWKHSLSHVZHOGLQJDIWHUEHLQJÀDWRU EHLQJVHDOHGZLWKDGKHVLYHWDSH %HQGWKHSLSHDVODUJHVHPLGLDPHWHUDVSRVVLEOHRYHUWLPHVRIWKHSLSHGLDPHWHU 7KHFRQQHFWLRQEHWZHHQRXWGRRUOLTXLGSLSHDQGWKHGLVWULEXWLQJSLSHLVÀDUHGW\SH3OHDVH expand the pipe with the special tool for R410A after installing the expanding nut. But if the SURMHFWLQJSLSHOHQJWKKDVEHHQDGMXVWHGZLWKWKHFRSSHUSLSHJDXJH\RXFDQXVHWKHRULJLQDO tool to expand the pipe. Since the unit is with R410A, the expanding oil is ester oil, not the mineral oil. :KHQGRLQJWKHÀDUHFRQQHFWLRQSOHDVHGRWKHIROORZLQJ:KHQFRQQHFWLQJWKHH[SDQGLQJ pipe, fasten the pipes with double-spanner. The torque refers to the former info. 3URMHFWLQJOHQJWKRISLSHWREHH[SDQGHG%PP ([SDQGLQJSLSH$PP Pipe outer diameter A PP Ø6.35 9.1 Pipe outer When it is hard pipe diameter Special tool The former PP for R410A tool Ø6.35 Ø9.52 13.2 Ø9.52 Ø12.7 16.6 Ø12.7 Ø15.88 19.7 Ø15.88 0-0.5 1.0-1.5 The outdoor gas pipe and the refrigerant distributing pipe, as well the refrigerant distributing pipe and the branch pipe should be welded with hard solder. When doing the braze connection, please do the following: Brazing the pipe at the same WLPHFKDUJHWKHQLWURJHQ2ULWZLOOFDXVHDQXPEHURILPSXULW\D¿OPRIR[LGDWLRQWRFORJWKH FDSLOODU\DQGWKHH[SDQVLRQYDOYHIXUWKHUFDXVHWKHGHDGO\IDLOXUH 16 Installation procedure Operation procedure Brazing the pipe at the same time charge the nitrogen. Or it will cause a number of impurity (a ¿OPRIR[LGDWLRQWRFORJWKHFDSLOODU\DQGWKHH[SDQVLRQYDOYHIXUWKHUFDXVHWKHGHDGO\IDLOXUH 6HDOWKHSLSHHQGZLWKDGKHVLYHWDSHRUWKHVWRSSHUWR LQFUHDVHWKHUHVLVWDQFH¿OOXSWKHSLSHZLWKQLWURJHQ taping <N2> Only nitrogen gas brazing can be used 3URWHFWWKHSLSHHQGDJDLQVWWKHZDWHULPSXULW\LQWRWKHSLSHVZHOGLQJDIWHUEHLQJÀDWRU EHLQJVHDOHGZLWKDGKHVLYHWDSH ÀDW DGKHVLYHWDSH brazing 7KHUHIULJHUDQWSLSHVKRXOGEHFOHDQ7KHQLWURJHQVKRXOGÀRZXQGHUWKHSUHVVXUHRIDERXW 0.5Mpa and when charging the nitrogen, stop up the end of the pipe by hand to enhance the SUHVVXUHLQWKHSLSHWKHQORRVHWKHKDQGPHDQZKLOHVWRSXSWKHRWKHUHQG 1st side 2nd side VRXUFHYDOYH 0.2MPa hand :KHQFRQQHFWLQJWKHSLSHVFORVHWKHYDOYHVIXOO\ :KHQZHOGLQJWKHYDOYHDQGWKHSLSHVXVHWKHZHWFORWKWRFRROGRZQWKHYDOYHDQGWKH pipes. 17 Installation procedure B. Leakage test 1. The outdoor unit has been executed the leakage test in the factory. The pipe should be H[HFXWHGOHDNDJHWHVWLQGLYLGXDOO\DQGIRUELGGHQWRWHVWDIWHUFRQQHFWLQJZLWKVWRSYDOYH 5HIHUWRWKHEHORZ¿JXUHWRFKDUJHWKHQLWURJHQLQWRWKHXQLWWRWDNHDWHVW1HYHUXVHWKH FKORULQR[\JHQÀDPPDEOHJDVLQWKHOHDNDJHWHVW$SSO\SUHVVXUHERWKRQWKHJDVSLSHDQG the liquid pipe. 3. Apply the pressure step by step to the target pressure. D$SSO\WKHSUHVVXUHWR03DIRUPRUHWKDQPLQXWHVFRQ¿UPLISUHVVXUHJRHVGRZQ E$SSO\WKHSUHVVXUHWR03DIRUPRUHWKDQPLQXWHVFRQ¿UPLISUHVVXUHJRHVGRZQ F$SSO\WKHSUHVVXUHWRWKHWDUJHWSUHVVXUH03DUHFRUGWKHWHPSDQGWKHSUHVVXUH G /HDYH LW DW 03D IRU RYHU GD\ LI SUHVVXUH GRHV QRW JR GRZQ WKH WHVW LV SDVVHG Meanwhile, when the temp. changes for 1degree, pressure will change 0.01MPa as well. Correct the pressure. e. After confirmation of a~d, if pressure goes down, there is leakage. Check the brazing position, flared position by laying on the soap. modify the leakage point and take another leakage test. $IWHUOHDNDJHWHVWPXVWH[HFXWHWKHHYDFXDWLRQ to indoor gauge manifold Lo nitrogen Lo handle Hi Hi handle C. Evacuation (YDFXWHDWWKHFKHFNYDOYHRIOLTXLGVWRSYDOYHDQGERWKVLGHVRIWKHJDVVWRSYDOYH7KHRLO HTXDOL]DWLRQSLSHDOVRPXVWEHYDFXXPH[HFXWHGDWWKHRLOHTXDOL]DWLRQSLSHFKHFNYDOYH UHVSHFWLYHO\ ,IYDFXXPSRLQWHUDULVHVLWVKRZVWKHUHLVZDWHURUOHDNDJHLQWKH V\VWHPSOHDVHFKHFNDQGPRGLI\LWDQGWKHQHYDFXDWHDJDLQ 18 Charge refrigerant /HDYHLWIRURYHU KRXUYDFXXPSRLQWHU does not arise. &KHFNYDFXXP After reaching -100.7KPa or OHVVEHORZPP+JOHW WKHYDFXXPSXPSUXQQLQJ FRQWLQXRXVO\IRURYHUKRXU (YDFXDWLRQHQGV (YDFXDWLRQEHJLQV Leakage test passed Operation procedure: Installation procedure Because the unit is with refrigerant R410A, the below issues should be paid attention: 7RSUHYHQWWKHGLIIHUHQWRLOLQWRWKHSLSHSOHDVHXVHWKHVSHFLDOWRROIRU5$HVSHFLDOO\IRU gauge manifold and charging hose. 7RSUHYHQWWKHFRPSUHVVRURLOLQWRWKHUHIULJHUDQWF\FOHSOHDVHXVHWKHDQWLFRXQWHUÀRZ adapter. D. Check valve operation Open Open/close method: 7DNHGRZQWKHYDOYHFDSJDVSLSHWXUQVWR RSHQVWDWHDVULJKW¿JXUH Turn the liquid pipe with hexangular spanner XQWLOLWVWRSV,IRSHQLQJWKHYDOYHVWURQJO\WKH YDOYHZLOOEHGDPDJHG 7LJKWHQWKHYDOYHFDS Close Tighten torque as the table below: For gas pipe For liquid pipe Tighten torque N·m 6KDIWYDOYHERG\ &DSFRYHU 8~9 22~27 5~6 13~16 7VKDSHQXWFKHFNMRLQW 8~10 8~10 E. Additional refrigerant charging Charge the additional refrigerant as liquid state with the gauge. If the additional refrigerant can not be charged totally when the outdoor stops, charge it at the trial mode. If the unit runs for a long period in the state of lack of refrigerant, compressor will occur failure. WKHFKDUJLQJPXVWEH¿QLVKHGZLWKLQPLQXWHVHVSHFLDOO\ZKHQWKHXQLWLVUXQQLQJPHDQZKLOH FKDUJLQJWKHUHIULJHUDQW The unit is charged only part of the refrigerant at the factory, also need additional refrigerant at the installation site. :5HIULJHUDQWFKDUJLQJYROXPHWRRXWGRRUXQLWDWIDFWRU\ :5HIULJHUDQWFKDUJLQJYROXPHWRRXWGRRUXQLWRQVLWH :5HIULJHUDQWFKDUJLQJYROXPHWROLTXLGSLSHEDVHRQGLIIHUHQWSLSLQJOHQJWKFDOFXODWLRQ W3=actual length of liquid pipe×additional amount per meter liquid pipe= L1×0.35+L2×0.25+L3×0.17+L4×0.11+L5×0.054+L6×0.022 19 Installation procedure /7RWDOOHQJWKRIOLTXLGSLSH /7RWDOOHQJWKRIOLTXLGSLSH /7RWDOOHQJWKRIOLTXLGSLSH /7RWDOOHQJWKRIOLTXLGSLSH /7RWDOOHQJWKRIOLTXLGSLSH /7RWDOOHQJWKRIOLTXLGSLSH 7RWDOUHIULJHUDQWYROXPHFKDUJLQJRQVLWHGXULQJLQVWDOODWLRQ :: :7RWDOUHIULJHUDQWYROXPHFKDUJLQJRQVLWHIRUPDLQWHQDQFH Model YCVFD224 YCVFD280 YCVFD335 Refrigerant record form :5HIULJHUDQWFKDUJLQJYROXPHWR W1: W2: Total W: Total Refrigerant Refrigerant liquid pipe base on different piping refrigerant refrigerant length calculation YROXPH YROXPH charging charging YROXPHWR YROXPHWR Liquid pipe Additional refrigerant charging on charging outdoor unit outdoor unit diameter site during on site for amount installation maintenance at factory on site PP NJ Ø6.35 0.022kg/m×__m=__kg 0kg Refer to 0kg Ø9.52 0.054kg/m×__m=__kg label 0kg Ø12.7 0.11kg/m×__m=__kg W2+W3= W1+W2+ Ø15.88 0.17kg/m×__m=__kg ___kg W3=___kg Ø19.05 0.25kg/m×__m=__kg Ø22.22 0.35kg/m×__m=__kg W3=___kg Note: 7RSUHYHQWWKHGLIIHUHQWRLOLQWRWKHSLSHSOHDVHXVHWKHVSHFLDOWRROIRU5$HVSHFLDOO\IRU gauge manifold and charging hose. Mark the refrigerant type in different colour on the tank. R410A is pink. Must not use the charging cylinder, because the R410A will change when transferring to the cylinder. When charging refrigerant, the refrigerant should be taken out from the tank as liquid state. 0DUNWKHFRXQWHGUHIULJHUDQWYROXPHGXHWRWKHGLVWULEXWLQJSLSHOHQJWKRQWKHODEHO Heat insulation Gas pipe and liquid pipe should be heat insulated separately. 7KHPDWHULDOIRUJDVSLSHVKRXOGHQGXUHWKHKLJKWHPSHUDWXUHRYHU . 7KDWIRUOLTXLGSLSHVKRXOGEHRYHU . Connection wire 7KHPDWHULDOWKLFNQHVVVKRXOGEHRYHUPPZKHQDPELHQWWHPS is 30 DQGWKHUHODWLYHKXPLGLW\LVRYHUWKHPDWHULDOWKLFNQHVV VKRXOGEHRYHUPP RYHUFP 7KHPDWHULDOVKRXOGFOLQJWKHSLSHFORVHO\ZLWKRXWJDSWKHQ $GKHVLYHWDSH EHZUDSSHGZLWKDGKHVLYHWDSH7KHFRQQHFWLRQZLUHFDQQRW be put together with the heat insulation material and should be far at least 20cm. Gas pipe Liquid pipe Fix the refrigerant pipe Heat insulator ,QRSHUDWLRQWKHSLSHZLOOYLEUDWHDQGH[SDQGRUVKULQN ,IQRWEHLQJ¿[HGWKHUHIULJHUDQWZLOOIRFXVRQRQHSDUWWRFDXVHWKHEURNHQSLSH 7RSUHYHQWWKHFHQWUDOVWUHVV¿[WKHSLSHIRUHYHU\P 20 Electric wiring and the application &RPPXQLFDWLRQZLULQJ¿JXUH Outdoor 1 Control wire for wired controller with polarity Indoor 1 Indoor 2 Indoor 3 Indoor 4 Indoor 5 Wired controller Indoor 6 Indoor 7 Wired controller Indoor 11 Indoor 12 Wired controller Indoor 16 Indoor 8 Indoor 9 Wired controller Wired controller Indoor 13 Indoor 14 Wired controller Wired controller Indoor 17 Indoor 18 Wired controller Wired controller Indoor 10 Wired controller Wired controller Indoor 15 Wired controller Wired controller Indoor 19 Wired controller Wired controller Wired controller The outdoor and all indoor units are in parallel through 2 non-polar wires. Three wiring methods between wired controller and indoor unit: $ WR PXOWL JURXS FRQWURO RQH ZLUHG FRQWUROOHU FRQWUROV a LQGRRUV DV VKRZQ LQ DERYH figure, indoor 1~indoor 5: indoor 5 is wired control master unit, the others are wired control VODYH XQLWV :LUHG FRQWUROOHU DQG WKH PDVWHU LQGRRU GLUHFWO\ FRQQHFWHG WR ZLUHG FRQWUROOHU LV FRQQHFWHGE\SRODUZLUHVWKHRWKHULQGRRUVDQGWKHPDVWHULQGRRUVDUHFRQQHFWHGE\SRODU wires. %WRRQHZLUHGFRQWUROOHUFRQWUROVRQHLQGRRUDVVKRZQLQDERYH¿JXUHLQGRRUaLQGRRU 18, indoor and wired controller are connected by 3 polar wires. &WRWZRZLUHGFRQWUROOHUFRQWUROVRQHLQGRRUDVVKRZQLQDERYH¿JXUHLQGRRU(LWKHU RIZLUHGFRQWUROOHUVFDQEHVHWDVPDVWHUZLUHGFRQWUROOHUDQGWKHRWKHULVVODYHZLUHGFRQWUROOHU 0DVWHUVODYHZLUHGFRQWUROOHUDQGPDVWHULQGRRUDUHFRQQHFWHGE\SRODUZLUHV When indoor is controlled by remote controller, refer to the "wired control master unit/wired FRQWUROVODYHXQLWUHPRWHFRQWUROXQLWWDEOH$%&RQVLJQDOWHUPLQDOEORFNQHHGQRWZLUHVDQG not connect the wired controller. 21 Electric wiring and the application 3RZHUZLULQJ¿JXUH 3OHDVHPDNHVXUHWKDWZKHQWKHXQLWLVUXQQLQJWKHLQSXWYROWDJHLVQROHVVWKDQ9 if it is lower than 380V,the unit may run abnormal. power source: 3N~, 380-400V, 50/60Hz power source: 3N~, 380-400V, 50/60Hz power source: 3N~, 380-400V, 50/60Hz power source: 3N~, 380-400V, 50/60Hz power source: 3N~, 380-400V, 50/60Hz power source: 3N~, 380-400V, 50/60Hz ,QGRRUDQGRXWGRRUXVHWKHLULQGLYLGXDOSRZHUVRXUFH All indoors use one power source. 0XVWLQVWDOOWKHOHDNDJHEUHDNHUDQGWKHRYHUFXUUHQWEUHDNHURUHOHFWULFVKRFNZLOORFFXU Outdoor power source and power cable Item ,QGLYLGXDOSRZHU Model YCVFD224 YCVFD280 YCVFD335 Power Wire Circuit Power cable length breaker source section P $ (mm2 3N~, 380400V, 50/60 Hz Rated current of residual Ground wire FLUFXLWEUHDNHU$ Ground fault Section Screw LQWHUUXSWRUP$ (mm2 UHVSRQVHWLPH6 6 60 40 40A 30mA below 0.1S 3.5 M5 10 60 40 40A 30mA below 0.1S 3.5 M5 10 60 40 40A 30mA below 0.1S 3.5 M5 3RZHUFDEOHPXVWEH¿[HG¿UPO\ Each outdoor must be earthed well. When power cable exceeds the range, thicken it appropriately. 22 Electric wiring and the application Indoor power source and communication wiring Item Indoor total FXUUHQW$ <10 DQG DQG DQG Rated current of residual Communication wire Rated Power section FLUFXLWEUHDNHU$ Wire current of cable Ground fault length RYHUFXUUHQW Outdoor/ Indoor/ section LQWHUUXSWRUP$ P breaker indoor indoor (mm2 UHVSRQVHWLPH6 $ (mm2 (mm2 2 20 20 20A, 30mA, below 0.1s 3.5 25 30 30A, 30mA, below 0.1s 2-core × (0.75-2.0mm2 shielded wire 5.5 30 40 40A, 30mA, below 0.1s 10 40 50 50A, 30mA, below 0.1s 3RZHUFDEOHDQGFRPPXQLFDWLRQZLUHPXVWEH¿[HG¿UPO\ Each indoor must be grounded well. When power cable exceeds the range, increase the gauge appropriately. Shielded layer of communication wires must be connected together and be earthed at single point. Communication wire total length cannot exceed 1000m. Communication wire for wired controller :LUHOHQJWKP :LUHOHQJWKP Wire spec Wire spec 1.25mm îFRUHVKLHOGHG <100 0.3mm2îFRUHVKLHOGHGZLUH DQG wire 2 2mm îFRUHVKLHOGHG DQG 0.5mm2îFRUHVKLHOGHGZLUH DQG wire 2 0.75mm îFRUHVKLHOGHG DQG wire 2 Shielded layer of communication wire must be grounded at one end. The total length cannot exceed 600m. 23 Electric wiring and the application Selection switch and the display In the following table, 1 is ON, 0 is OFF. 'LSVZLWFKGH¿QLWLRQ %0LVXVXDOO\VHWE\WKHSHUVRQQHORQVLWH%0LVXVXDOO\XVHGLQWKHIDFWRU\ BM1 introduction 0 1 0 1 [4] 0 BM1_4 0 Piping length selection BM1_5 1 1 [6] 0 BM1_6 'HIURVWLQJFRQGLWLRQĮVHOHFWLRQ 0 BM1_7 1 1 [8] BM1_8 Silent operation selection 0 1 Indoor searching after startup Start up after pre-heating for 2 BM1_2 hour BM1_1 Begin to search indoor Stop searching indoor and lock the quantity Allow Forbidden [5] Selection item 0 0HGLXPSLSLQJOHQJWKP/P 1 Long piping length: L > 200m 0 6KRUWSLSLQJOHQJWK/P 1 0HGLXPSLSLQJOHQJWKP/P [7] Selection item 0 8 1 10 0 6 1 8 Silent mode )RUELGGHQZLWKRXWVLOHQWRSHUDWLRQ $OORZZLWKVLOHQWRSHUDWLRQ Note: 7KHQXPEHURILQGRRUXQLWVPXVWEHORFNHGE\WKH%0B2))WR21EHIRUHUXQQLQJWKH outdoor. BM2 introduction BM2_2 Outdoor horse power selection BM2_3 [2] 0 1 1 [3] 0 0 1 24 Outdoor horse power AV08 AV10 AV12 Failure code Failure code Inverter outdoor unit failure code Digital tube Indication indication on wired on master controller KH[ unit Failure code GH¿QLWLRQ Defrosting temp.sensor TE1 failure Defrosting temp.sensor TE2 failure 20 20-0 20 20-1 21 21 Ambient temp. sensor Ta failure 22 Suction temp. sensor Ts failure 23 23 Discharging temp.sensor Td failure 24 24 Oil temp.sensor Toil failure 26 26-0 26-1 26-1 26-2 26-2 27 27 Oil temp. too high SURWHFWLRQ7RLO 28 High pressure sensor Pd failure 22 28 Indoor communication failure Failure description Remarks $'YDOXHLVEHORZRSHQFLUFXLWRU RYHUVKRUWFLUFXLWIRUVHFRQGVLQ cooling mode, if the sensor is abnormal, Resumable the unit does not deal with it, besides, in defrosting and within 3 minutes after defrosting, no alarm $'YDOXHLVEHORZRSHQFLUFXLWRU RYHUVKRUWFLUFXLWIRUVHFRQGV Resumable in defrosting and within 3 minutes after defrosting, no alarm $'YDOXHLVEHORZRSHQFLUFXLWRU RYHUVKRUWFLUFXLWIRUVHFRQGV Resumable in defrosting and within 3 minutes after defrosting, no alarm After compressor is running for 5 minutes, $'YDOXHLVEHORZRSHQFLUFXLWRU RYHUVKRUWFLUFXLWIRUVHFRQGVLQ Resumable course of startup, defrosting and within 3 minutes after defrosting, no alarm $'YDOXHLVEHORZRSHQFLUFXLWRURYHU VKRUWFLUFXLWIRUVHFRQGVLI7D Resumable 10degree or ET<=-10degree, within 5 minutes, no alarm )RUFRQWLQXRXVF\FOHVFDQQRW¿QG connected indoors For continuous 300seconds, the searched indoor quantity is less than the set quantity. Resumable For continuous 300seconds, the searched indoor quantity is more than the set quantity. 7RLOGHJUHHDWLQWHUYDORIPVHFIRU Once WZLFHFRQWLQXRXVO\DQGRYHUWKHVHWYDOXH FRQ¿UPDWLRQ WKHQVWRSDQGDODUPPLQXWHVODWHU unresume automatically. If it occurs 3 times resumable LQDQKRXUFRQ¿UPWKHIDLOXUH $'YDOXHLVEHORZRSHQFLUFXLWRU RYHUVKRUWFLUFXLWIRUVHFRQGV Resumable in defrosting and within 3 minutes after defrosting, no alarm 25 Failure code LD Indication indication on wired on master controller unit KH[ 29 1D 30 30 33 33 34 34 35 35 36 36 39-0 39-0 39-1 39-1 Failure code GH¿QLWLRQ Failure description Remarks $'YDOXHLVEHORZRSHQFLUFXLWRU RYHUVKRUWFLUFXLWIRUVHFRQGV Resumable in defrosting and within 3 minutes after defrosting, no alarm High pressure If disconnect for 50ms continuously, Once switch HPSi DODUP,IDODUPWLPHVLQDQKRXUFRQ¿UP FRQ¿UPDWLRQ failure the failure un-resumable Once EEPROM EEPROM failure FRQ¿UPDWLRQ failure un-resumable 7GGHJUHHDWLQWHUYDORIPVHF IRUWZLFHFRQWLQXRXVO\DQGRYHUWKHVHW Once Discharging FRQ¿UPDWLRQ temp.too high YDOXHWKHQVWRSDQGDODUPPLQXWHV SURWHFWLRQ7G later, resume automatically. If it occurs 3 un-resumable WLPHVLQDQKRXUFRQ¿UPWKHIDLOXUH $IWHUZD\YDOYHLVHOHFWUL¿HGIRU minutes, if the below conditions can be met for continous 10 seconds, that is Once ZD\YDOYH FRQYHUVLQJVXFFHVVIXOO\ FRQ¿UPDWLRQ UHYHUVLQJ 1. this outdoor compressor is running un-resumable failure normally 3G3V03D2WKHUZLVHWKHV\VWHP DODUPVUHYHUVLQJIDLOXUH In normal operation, if Td<CT+6 for Oil temp. too continuous 5 minutes, the unit stops and Once low protection alarms.2 minutes and 50 seconds later, FRQ¿UPDWLRQ 7RLO resume automatically. If it occurs 3 times un-resumable LQDQKRXUFRQ¿UPWKHIDLOXUH After compressor is running (except IRUUHVLGXDORSHUDWLRQLILQFRROLQJ 3V0SDLQKHDWLQJ3V0SDLQ Low pressure Once oil return, Ps<0.03Mpa for continuous 5 sensor Ps too FRQ¿UPDWLRQ minutes, alarm and stop. 2 minutes and low protection un-resumable 50 seconds later, resume automatically, LILWRFFXUVWLPHVLQDQKRXUFRQ¿UPWKH failure. After compressor is running, compression Compression ratio 8. for continuous 5 minutes stop Once ratio too high and alarm.2 minutes and 50 seconds FRQ¿UPDWLRQ protection later, resume automatically, if it occurs 3 un-resumable WLPHVLQDQKRXUFRQ¿UPWKHIDLOXUH Low pressure sensor Ps failure 26 Failure code LD Indication indication on wired on master controller unit KH[ Failure code GH¿QLWLRQ Compression ratio too low protection 39-2 39-2 40 40 High pressure sensor Pd too high protection 43 43 Discharging temp. sensor Td too low protection 46 46 71 71 75 75 78 78 Failure description In normal operation, compression ratio <1.8 for continuous 5 minutes stop and alarm.2 minutes and 1 seconds later, resume automatically, if it occurs 3 times LQDQKRXUFRQ¿UPWKHIDLOXUH In normal operation, Pd>=4.15Mpa for continuous 50ms, alarm and stop. 2 minutes and 50 seconds later, resume automatically, if it occurs 3 times in an KRXUFRQ¿UPWKHIDLOXUH In normal operation, if Td<CT+10 for continuous 5 minutes, the unit stops and alarms.2 minutes and 50 seconds later, resume automatically. If it occurs 3 times LQDQKRXUFRQ¿UPWKHIDLOXUH$IWHU¿[HG IUHTXHQF\FRPSUHVVRUDODUPVLQYHUWHU FRPSUHVVRUZLOOFRQWLQXHWRUXQ,I¿[HG frequency compressor has been locked for 3 times, the unit will stop and alarm. Communication No communication within 30 seconds ZLWKLQYHUWHU continuously board failure Running at speed below 20rpm for 30s, RUDWVSHHGRIORZHUWKDQWKHWDUJHW for 2 minutes, 2 minutes and 50 seconds DC motor later after stop, resume automatically. It blocked RFFXUVWLPHVLQDQKRXUFRQ¿UPWKH failure. ,QPLQXWHVDIWHULQYHUWHUFRPSUHVVRU No pressure starts up, Pd-Ps<=0.2MPa. 2 minutes drop between and 50 seconds later after unit stops, high pressure resume automatically, if it occurs twice and low one FRQWLQXRXVO\FRQ¿UPWKHIDLOXUH Compressor running in cooling mode, 3V03DIRUPLQXWHVFRPSUHVVRU UXQQLQJLQKHDWLQJPRGH7VL(7! Lack of LEV will fully open for 60 minutes, the refrigerant unit will output lack of refrigerant alarm, unit will not stop. 27 Remarks Once FRQ¿UPDWLRQ un-resumable Once FRQ¿UPDWLRQ un-resumable Once FRQ¿UPDWLRQ un-resumable Resumable Once FRQ¿UPDWLRQ un-resumable Once FRQ¿UPDWLRQ un-resumable -- Failure code LD Indication indication on wired on master controller unit KH[ 110 110 111 111 112 112 113 113 114 114 115 115 116 116 117 117 118 118 120 120 121 121 122 122 Failure code GH¿QLWLRQ Failure description Remarks ,30PRGXODURYHUFXUUHQWLQVKRUWFLUFXLW RYHUKHDWYROWDJHWRRORZRIFRQWURO circuit. In the course of compressor startup or Compressor out running, the unit can not detect the rotor of control position, or not connecting compressor. Radiator of 3 times in an transducer Radiator temp. too high KRXUFRQ¿UP temp.too high IDLOXUHRQFH FRQ¿UPDWLRQ Transducer Output current of transducer is too high un-resumable RYHUORDG Voltage too low of DC bus line Voltage of power source is too low of transducer Voltage too high of DC bus line Voltage of power source is too high of transducer Communication abnormal between Communication is disconnected Resumable transducer and control PCB Compressor startup fails for 5 times Transducer continuously, or compressor is running RYHUFXUUHQW GRZQWLOOVWRSVFDXVHGE\RYHUFXUUHQWRU VRIWZDUH 3 times in an RYHUKHDW KRXUFRQ¿UP The sensor used for current detecting of IDLOXUHRQFH Compressor transducer is abnormal, disconnected or FRQ¿UPDWLRQ startup failure incorrectly connection un-resumable Power supply Power supply of transducer is broken of transducer down instantly abnormal Power supply of 3RZHUVXSSO\RILQYHUWHUERDUGLVEURNHQ LQYHUWHUERDUG 3 times in an down instantly is abnormal KRXUFRQ¿UP IDLOXUHRQFH Radiator temp. FRQ¿UPDWLRQ Resistor of temp.sensor abnormal or sensor of un-resumable temp.sensor disconnected transducer abnormal IPM modular SURWHFWLRQ) 28 Failure code When there is no failure, if the starting condition can not be met, digital tube on master unit will display stand-by code: 555 555.1 555.3 555.4 6WDQGE\VWDWHRIFDSDFLW\RYHUmatch Outdoor ambient temperature too KLJKKHDWLQJ Outdoor ambient temperature too KLJKRUWRRORZFRROLQJ Crankcase heater working :KHQFDSDFLW\LVRYHURUORZHUWKDQWKHV\VWHPLVVWDQGE\ Ta>27ć , Standby Resumable Ta>54ć or Ta<-10ć , Standby Oil temperature is too low Indoor failure code list Indication on master unit Indication on wired controller 01 02 03 04 05 01 02 03 04 05 Flash times of LED5 on indoor PCB/timer LED on UHPRWHUHFHLYHU 1 2 3 4 5 06 06 6 07 07 7 08 09 0A Outdoor failure code 08 09 0A Outdoor failure code 8 9 10 Indoor ambient temp. sensor Ta failure Indoor coil temp. sensor Tc1 failure Indoor coil temp. sensor Tc2 failure Indoor TW sensor failure Indoor EEPROM failure Communication between indoor and outdoor failure Communication between indoor and wired controller failure Indoor drainage failure Indoor repeated address Indoor repeated central control address 20 Outdoor corresponding failure )DLOXUHFRGHGH¿QLWLRQ 29 Trial operation and the performance 5-minute delay function If starting up the unit after being powered off, the compressor will run about 5 minutes later against being damaged. Cooling/heating operation ,QGRRUXQLWVFDQEHFRQWUROOHGLQGLYLGXDOO\EXWFDQQRWUXQLQFRRODQGKHDWPRGHDWWKHVDPH time. If the cool mode and the heat mode are existing simultaneously, the unit set latter will be standby, and the unit set earlier will run normally. ,IWKH$&PDQDJHUVHWVWKHXQLWDWFRROLQJRUKHDWLQJPRGH¿[HGO\WKHXQLWFDQQRWUXQDWWKH other modes. Heating mode characteristic In operation if outdoor temp. arises, indoor fan motor will turn to low speed or stop. Defrosting in heating mode ,QKHDWLQJPRGHRXWGRRUGHIURVWLQJZLOODIIHFWWKHKHDWLQJHI¿FLHQF\7KHXQLWZLOOGHIURVWIRU DERXWaPLQXWHVDXWRPDWLFDOO\DWWKLVWLPHWKHFRQGHQVDWHZLOOÀRZIURPRXWGRRUDOVR LQGHIURVWLQJWKHYDSRXUZLOODSSHDUDWRXWGRRUZKLFKLVQRUPDO,QGRRUPRWRUZLOOUXQDWORZ speed or stop, and outdoor motor will stop. The unit operation condition To use the unit properly, please operate the unit under the allowed condition range. ,IRSHUDWLQJEH\RQGWKHUDQJHWKHSURWHFWLRQGHYLFHZLOODFW 7KHUHODWLYHKXPLGLW\VKRXOGEHORZHUWKDQ,IWKHXQLWUXQVDWWKHKXPLGLW\RYHUIRUD ORQJSHULRGWKHGHZRQWKHXQLWZLOOGURSGRZQDQGWKHYDSRXUZLOOEHEORZHGIURPDLURXWOHW Protection device (such as high pressure switch) +LJKSUHVVXUHVZLWFKLVWKHGHYLFHZKLFKFDQVWRSWKHXQLWDXWRPDWLFDOO\ZKHQWKHXQLWUXQV abnormally. When the high pressure switch acts, the cooling/heating mode will stop but the running LED on wired controller will be light still. The wired controller will display failure code. :KHQWKHIROORZLQJFDVHVRFFXUWKHSURWHFWLRQGHYLFHZLOODFW In cooling mode, air outlet and air inlet of outdoor are clogged. ,QKHDWLQJPRGHLQGRRU¿OWHULVVWLFNHGZLWKGXFWLQGRRUDLURXWOHWLVFORJJHG :KHQSURWHFWLRQGHYLFHDFWVSOHDVHFXWRIIWKHSRZHUVRXUFHDQGUHVWDUWXSDIWHUHOLPLQDWLQJ the trouble. When power failure When power is failure in running, all the operations will stop. $IWHUEHLQJHOHFWUL¿HGDJDLQLIZLWKUHVDWUWXSIXQFWLRQWKHXQLWFDQUHVXPHWRWKHVWDWHEHIRUH SRZHURIIDXWRPDWLFDOO\LIZLWKRXWUHVDWUWXSIXQFWLRQWKHXQLWQHHGVWREHVZLWFKHGRQDJDLQ When abnormal occurs in running because of the thunder, the lightning, the interference of car or radio, etc, please cut off the power source, after eliminating the failure, press "ON/OFF" button to start up the unit. 30 Trial operation and the performance Heating capacity The heating mode adopts the heat pump type that absorbs outdoor heat energy and releases into indoor. So if outdoor temperature goes down, the heating capacity will decrease. Trial operation %HIRUHWULDORSHUDWLRQ %HIRUHEHLQJHQHUJL]HGPHDVXUHWKHUHVLVWRUEHWZHHQSRZHUWHUPLQDOEORFNOLYHZLUHDQG QHXWUDOZLUHDQGWKHJURXQGHGSRLQWZLWKDPXOWLPHWHUDQGFKHFNLILWLVRYHU0,IQRWWKH unit can not operate. To protect compressor, energize the outdoor unit for at least 12 hours before the unit runs.If the crankcase heater is not energized for 6 hours, the compressor will not work. &RQ¿UPWKHFRPSUHVVRUERWWRPJHWWLQJKRW ([FHSWIRUWKHFRQGLWLRQWKDWWKHUHLVRQO\RQHPDVWHUXQLWFRQQHFWHGQRVODYHXQLWXQGHUWKH RWKHUFRQGLWLRQVRSHQIXOO\WKHRXWGRRURSHUDWLQJYDOYHVJDVVLGHOLTXLGVLGHRLOHTXDOL]DWLRQ SLSH,IRSHUDWLQJWKHXQLWZLWKRXWRSHQLQJWKHYDOYHVFRPSUHVVRUIDLOXUHZLOORFFXU &RQ¿UPDOOLQGRRUXQLWVEHLQJHOHFWUL¿HG,IQRWZDWHUOHDNDJHZLOORFFXU Measure the system pressure with pressure gauge, at the same time, operate the unit. 7ULDORSHUDWLRQ In trial operation, refer to the information of performance section. When the unit can not start up at the room temperature, make trial operation for outdoor. 31 Disposal DISPOSAL: Do not dispose this product as unsorted municipal waste. Collection of such waste separately for special treatment is necessary. It is prohibited to dispose of this appliance in domestic household waste. )RUGLVSRVDOWKHUHDUHVHYHUDOSRVVLELOLWLHV D7KHPXQLFLSDOLW\KDVHVWDEOLVKHGFROOHFWLRQV\VWHPVZKHUHHOHFWURQLFZDVWHFDQEHGLVSRVHG of ate least free of charge to the user. E:KHQEX\LQJDQHZSURGXFWWKHUHWDLOHUZLOOWDNHEDFNWKHROGSURGXFWDWOHDVWIUHHRIFKDUJH F7KHPDQXIDFWXUHUZLOOWDNHEDFNWKHROGDSSOLDQFHIRUGLVSRVDODWOHDVWIUHHRIFKDUJHWRXVHU G$VROGSURGXFWVFRQWDLQYDOXDEOHUHVRXUFHVWKH\FDQEHVROGWRVFUDSPHWDOGHDOHUV Wild disposal of waste in forests and landscapes endangers your health when hazardous VXEVWDQFHVOHDNLQWRWKHJURXQGZDWHUDQG¿QGWKHLUZD\LQWRWKHIRRGFKDLQ 32