Download Toaster with cover for reduced energy consumption

Transcript

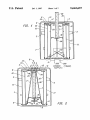

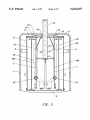

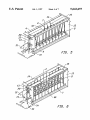

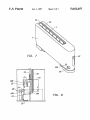

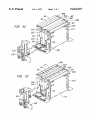

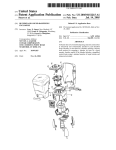

USOO564265 7A Umted States Patent [19] [11] Patent Number: 5,642,657 Yeung et al. [45] Date of Patent: Jul. 1, 1997 [54] TOASTER WITH COVER FOR REDUCED [75] FOREIGN PATENT DOCUMENTS ENERGY CONSUMPTION 3045598 7/1982 Germany’ ............................... .. 99/391 Inventors: PatH0k_Kw0ng Yeung; Miu_choy 2285389 7/1995 Umted Kingdom .......... .. A47J 37/08 Young; Eric Wah Ho, all of Hong Kong, Hong Kong Primary Examiner—Tirnothy F. Simone Attorney, Agent, or Firm—-Limbach & Limbach L.L.P. [73] Assignee: SEMK Industrial (Holding) Co. Ltd., A toaster having a mechanically actuated cover for each of one or more toasting volumes. Each cover at least partially [21] APPI' N04 527,349 [22] Filed: Se“ 12’ 1995 covers a toasting volume within the toaster during toasting, thereby reducing heat transfer (primarily due to convection) [51] Int. C16 ...... .. ................... .. A47J 37/08 away from the toaster and the object being toasted. In [52] US. Cl. ............................... .. 99/334; 99/385; 99/391; preferred embodiments, each cover is a pair of slidably 99/393 mounted plates. When a carriage (supporting an object to be [58] Field of Search ................................ .. 99/329 R, 33 1, toasted) is manually lowered by a user, a mechanical linkage 99/332, 395, 326-328, 329 P, 329 R1", 334, 335, 339, 337, 340, 335, 389.393, 399, attached to the carriage cause the plates to slide together to cover (substantially or totally) a toasting volume. When the carriage springs up (at the end of the toasting operation), the mechanical linkage slides the plates away from each other to 401, 402; 219/521, 537, 386, 413 [56] References Cited allow removal of the toasted object from the toaster. In other referred embodiments, each cover is a air of rotatabl U'S' PATENT DOCUMENTS Fnounted plates. When a carriage supportling an object 2,997,941 3,760,713 3,789,749 8/1961 Phelan et al. .. 9/1973 Sato ............ .. 2/1974 Paaskesen . 99/391 99/339 99/391 manually lowered by th9 user, a mechanical link?gc attached t0 the carriage rotates (and optionally also translates) the plates so that they cover a toasting volume. Then, when the 4,254,695 3/1931 Landry ---- ~ 99/334 carriage springs up (at the end of the toasting operation), the mechanical linkage rotates (or rotates and translates) the u 99,391 plates 1n the opposrte drrectron to uncover the toasting volume and allow removal of the toasted ObJCClZ. lwa'ldry " , , erss .................. .. 4,972,768 11/1990 Basom San Juan __ 5,181,455 1,1993 Masel et aL ________ __ 5,216,944 6/1993 Trujillo ....... .. 5,423,246 6/1995 McNair et al. - . 219/521 - - - 99/385 .. 99/334 14 Claims, 7 Drawing Sheets - U.S. Patent V /7_ Jul. 1, 1997 Sheet 2 0f 7 C / FIG. 3 5,642,657 US. Patent Sheet 3 0f 7 5,642,657 / ? ~P f 7 » / A . 7 ~ i;/ 5c/%: w Jul. 1, 1997 M: // 3\ Q\/71? FIG. 4 r / x A u m wg US. Patent Jul. 1, 1997 ‘swrli/ ii4!; Sheet 4 of 7 US. Patent Jul. 1, 1997 Sheet 5 of 7 5,642,657 US. Patent Jul. 1, 1997 Sheet 6 of 7 5,642,657 ---—115 /-20 [85 \-1 .1514 FIG. .10 FIG. 104 US. Patent Jul. 1, 1997 Sheet 7 of 7 5,642,657 1 2 TOASTER WITH COVER FOR REDUCED ENERGY CONSUMPTION also holes in the sides) of the toaster, the cool air is heated by the heating element, and the heated air then ?ows out through the slot above the food. Thus, much heat energy is wasted (by the mechanism of convective heat loss) due to FIELD OF THE INVENTION the stream of hot air which escapes from the toasting volume. The energy consumed by a toaster when toasting food is the product of the average power consumed by the toaster’s heating elements and the time of the toasting operation. It The invention relates to improved energy-saving design for a toaster. The toaster of the invention has a mechanically actuated cover which is closed during toasting to reduce heat loss (primarily heat loss due to convection) away from the object being toasted, and which is opened automatically after each toasting operation, and/or kept closed until 10 opened in response to manual actuation of a control (e.g., a would be desirable if ?'re consumed energy could be reduced without decreasing the energy transferred to the food. cancellation button) to continuously recycle residual heat The present invention achieves this objective by reducing energy within the heating compartment of the toaster after the energy wasted during a toasting operation by at least each toasting operation. 15 BACKGROUND OF THE INVENTION 20 25 The invention is a toaster having a mechanically actuated cover for each toasting volume within the toaster. Each cover at least partially (and preferably, substantially totally) covers a toasting volume during toasting, thereby reducing heat transfer away from the toaster and the object being toasted. In preferred embodiments, each cover is a pair of slidably mounted plates (which can but need not be made of bread caniage closes an electrical switch thereby connecting a power supply to heating elements within the toaster, and it also activates a solenoid (23) and a timer. When activated, the solenoid exerts a magnetic force on elements attached to elements). perature (and thus drawing less power), than would be required in a conventional toaster. SUMMARY OF THE INVENTION lowered into a lowered position (in response to manual force applied by a user). The action of manually lowering the bread carriage 15 which overcomes the biasing force of spring 29 and holds bread carriage in the lowered position (while the bread is toasted by the power-consuming heating thereby reducing the amount of heat transfer (primarily heat transfer due to convection) away from the toasting volume. This allows the inventive toaster to toast food either in less time, or with heating elements operating at a lower tem An example of a known toaster is the toaster described in British Patent Application Publication No. 2,285,3 89A, pub lished on Jul. 12, 1995, assigned to the assignee of the present invention. The disclosure of British Patent Applica tion Publication No. 2,285,389A is incorporated herein by reference. The toaster of British Application Publication No. 2,285, 389A has a bread carriage (15) which is biased by a spring (29) to be in a raised position, but which can be manually partially covering the toasting volume during toasting, 35 metal or thermally insulating material). When the food lifting carriage is manually lowered by the user, a mechani cal linkage attached to the carriage cause the plates to slide together to at least partially cover a toasting volume. Then, when the carriage springs up (at the end of the toasting operation), the mechanical linkage slides the plates away After being activated at the start of a toasting operation, the timer generates a signal for deactivating the solenoid, at the end of a selected period of time (the duration of this time is determined by manual actuation of a control by a user). When the solenoid is deactivated by the signal from the from each other to allow removal of the toasted object from the toaster. Alternatively, the mechanical linkage slides the plates away from each other in response to a user’s manual actuation of a lever after a toasting operation; not automati cally in response to the carriage springing up at the end of timer, the carriage rises (in response to the biasing force the operation. exerted by spring 29) until an arm (18B) attached to the In another class of preferred embodiments, each cover is a pair of rotatably mounted plates (which can but need not be made of metal or thermally insulating material). When the food lifting carriage is manually lowered by the user, a mechanical linkage attached to the carriage rotates (and optionally also translates) the plates so that they cover a carriage is caught by a latch (24). In response to this limited movement of the carriage to an intermediate position (between the lowered and raised positions), the electrical 45 switch opens (thereby disconnecting the power supply from the heating elements). While the carriage remains'in the intermediate position (i.e., while arm 18B is latched by latch 24), the cooling of any toasted food resting on the carriage 50 is slowed, since the food remains near the heating elements which themselves cool slowly after being disconnected from the power supply. toasting volume. Then, when the carriage springs up (at the end of the toasting operation), the mechanical linkage rotates (or rotates and translates) the plates in the opposite direction to uncover the toasting volume and allow removal of the toasted object. Alternatively, the mechanical linkage moves the plates away from each other in response to a toaster, the user manually actuates another control to release 55 user’s manual actuation of a lever after a toasting operation; When a user wishes to remove the toasted food from the not automatically in response to the carriage springing up at the end of the operation. latch 24. thereby releasing arm 18B and allowing the car riage to rise (in response to biasing force exerted by spring 29) from the intermediate position to the fully raised posi The inventive cover can be made of metal or other high temperature resistant material. When closed, the cover acts as a barrier to the rising hot air within the toasting volume, causing the hot air to recirculate back to the heating elements tion. During the toasting period (when power is supplied to the heating elements), the heating elements become hot and transfer heat to the air surrounding them. The heated air ?ows past the carriage and the food on the caniage, thus toasting the food In a conventional toaster (which has an open slot above the food being toasted), a continuous stream of air ?ows through the toaster (from bottom to top) during toasting: cool air ?ows in through the bottom (and optionally and the food being toasted, and reducing the ?ow rate of incoming cool air through the bottom of the toaster, and the ?ow rate of hot air escaping out through the top of the 65 toaster. In a given time, the heating elements can raise the recirculated hot air to a higher temperature than the tem perature to which they could raise an equivalent amount of 5,642,657 3 4 cool air freshly taken in through the bottom of the toaster. Thus, when used with the inventive closed cover, the heating position in which the object is within the toasting volume (e.g., the position shown in FIG. 2), and the carriage is releasibly latched into the lowered position. As shown in FIGS. 1-4, the toaster has ‘a chassis (or “frame”) which includes vertically oriented insulation plates 11, horizontally oriented bottom plate 9 connected between plates 11, horizontally oriented top insulation member 4 connected between plates 11, end plates 13 (shown in FIGS. 5 and 6) oriented parallel to the plane of FIG. 1, and vertical coils cause the transfer of more heat to the food while drawing the same power as heating coils in a conventional toaster without a cover. Thus, food can be toasted to the same degree in less time, or in the same time but with less average power supplied to the heating elements, than in a conventional toaster. The inventive cover thus increases the energy efficiency of a toaster. 10 BRIEF DESCRIPTION OF THE DRAWINGS FIG. 1 is a cross-sectional view (in a ?rst plane) of a ?rst preferred embodiment of the inventive toaster with bread carriage 8 in a raised position. FIG. 2 is a cross-sectional view (in the ?rst plane) of the ?rst preferred embodiment of the inventive toaster, with bread carriage 8 in a lowered position. FIG. 3 is a cross-sectional view (in a second plane) of the ?rst preferred embodiment of the inventive toaster with handle assembly, and the handle assembly is slidably bread carriage 8 in the raised position. FIG. 4 is a cross-sectional view (in the second plane) of the ?rst preferred embodiment of the inventive toaster, with bread carriage 8 in the lowered position. FIG. 5 is a perspective view of the toaster of FIGS. 1-4 25 (with enclosure 1. walls 11, and handle 32 removed), with carriage 8 in the lowered position. FIG. 7 is a perspective view of a variation on the toaster of FIGS. 1 and 3, with the bread carriage (within enclosure 1) and handle 32 (rigidly connected to the bread carriage) in 35 FIG. 8 is an end view of the toaster of FIG. 7 (with enclosure 1 and handle 32 removed), with the bread carriage latched (by latch 26) in its intermediate position. FIG. 9 is a cross-sectional view (in a ?rst plane) of a second preferred embodiment of the inventive toaster with its bread carriage in a raised position. FIG. 10 is a cross-sectional View (in the ?rst plane) of the second preferred embodiment of the inventive toaster, with its bread carriage in a lowered position. FIG. 10A is an enlarged detail of a portion of the appa ratus of FIG. 10. FIG. 11 is an exploded perspective view of the toaster of FIGS. 9-10 (with enclosure 110 removed), with the bread carriage in the lowered position. FIG. 12 is an exploded perspective view of the toaster of FIGS. 9-10 (with enclosure 110 removed), with the bread carriage in the raised position. DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT described below. An opening 1A extends through the top surface of enclo sure 1, and opening 4A extends through member 4. An object to be toasted (e.g., bread slice 30 or 30') can be lowered through openings 1A and 4A until it rests on carriage 8. When carriage 8 is manually lowered into the lowered position (of FIGS. 2, 4, and 5), a conventional electrical switch (not shown) is closed, thereby connecting a power supply (e.g., power supply 200 shown in phantom view in FIG. 1) to heating elements 12. Power supply 200 can have conventional design, but can be selected to be a less expen sive (and less costly to operate) model that produces lower output power than would be required to enable a conven tional toaster (without covers 14 and 15) to toast bread to the 45 same degree in the same time as can the inventive toaster (with covers 14 and 15). The power supply causes electrical current to ?ow 50 through heating elements 12, which raises the temperature of elements 12, and thus the surrounding air in the toasting volume between elements 12, to a high temperature. The heated air toasts an object (e.g., bread slice 30 or 30‘) resting on carriage 8 in the toasting volume. Mica holding elements 6 are mounted to the toaster frame, 55 and heating elements 12 are mounted to holding elements 6 in a vertical orientation. Each heating element 12 can be a mica card having a heating ribbon on the side facing the bread (not on the other side), or an array of quartz tubes with a heating ribbon (e. g., a coiled heating wire) inside each tube and a metal plate attached to the side of the tube array facing the bread. One heating element 12 is mounted between wire assembly 2 and a ?rst one of insulation plates 11, and the other heating element 12 is mounted between wire assembly A toaster designed in accord with a preferred embodiment of the invention will be described with reference to FIGS. 1-6. This embodiment has a cover consisting of slidably mounted metal plates 14 and 15. When bread carriage 8 is manually lowered by a user (into the position shown in FIG. 2), a mechanical linkage attached to carriage 8 causes plates 14 and 15 to slide together to cover (at least partially) a toasting volume within the toaster. To toast an object (e.g., slice of bread 30 of FIGS. 1, 3, and 4, or slightly larger slice of bread 30' of FIG. 2) in the toasting volume, the object is placed on carriage 8, the carriage is lowered into a lowered mounted to rod 33 of the frame. The handle assembly comprises handle member 31 (rigidly connected to carriage 8) and a handle attached to an end portion of member 31 (a handle such as handle 32 shown in FIG. 7). In response to force exerted on handle 32 (typically by the hand of a human user), carriage 8 is lowered relative to the frame from the raised position shown in FIG. 1 (and FIG. 3) to the lowered position shown in FIG. 2 (and FIG. 4). Carriage 8 is biased by extension spring 29 (shown in FIGS. 5 and 6) so that it is normally in the raised position. The action of manually lowering carriage 8 to the lowered position thus overcomes the biasing force exerted by spring 29. The mechanism for releasibly locking carriage 8 in the lowered position will be FIG. 6 is a perspective view of the toaster of FIGS. 1-4 (with enclosure 1, walls 11, and handle 32 removed), with carriage 8 in the raised position. their fully raised position. rod 33 (shown in FIGS. 5 and 6) attached to one of end members 13. The frame is mounted within enclosure (or “housing”) 1, and spacer members 3 are mounted between enclosure 1 and each plate 11 to stabilize the frame with respect to enclosure 1. Carriage 8 within the frame is rigidly connected to a 7 and a second one of insulation plates 11. 65 When carriage 8 is manually lowered into the lowered position (of FIGS. 2, 4, and 5), an electromagnetic solenoid (not shown) and a solid state timer (timer 202 shown in 5,642,657 5 6 phantom view in FIG. 1) are activated. The solenoid (and also the timer, the above-mentioned power supply and electrical switch, and the below-described mechanical latch) a unit with lever 49) from the position shown in FIGS. 1 and 3 to the position shown in FIG. 2 or 4. As a result of such rotation of assemblies 2 and 7, bread slice 30 (or 30‘) on can be identical to that described in above-referenced British carriage 8 is ?rmly gripped between (or its motion is Patent Application Publication No. 2,285,389A. When activated, the solenoid exerts a magnetic force on handle member 31 which overcomes the biasing force of spring 29 and holds caniage 8 in the lowered position (while an object of assembly 2 (which upper end is rotatably attached to slidably mounted plate 14 by hinge 2A) pulls plate 14 to the constrained by) assemblies 2 and 7, the upper end of a rod variations on the embodiment of FIGS. 1-6, the activated right (from the position shown in FIG. 3 to that shown in FIG. 2 or 4), and the upper end of a rod of assembly 7 (which upper end is rotatably attached to slidably mounted plate 15 is toasted by power-consuming heating elements 12). In solenoid exerts a magnetic force on an element (other than by hinge 7A) pulls plate 15 to the left (from the position handle member 31) ?xedly attached to carriage 8 which overcomes the biasing force of spring 29 and holds carriage 8 in the lowered position. shown in FIG. 3 to that shown in FIG. 2 or 4). With a su?iciently thin slice of bread on carriage 8 (e.g., slice 30 shown in FIG. 4), the bread slice does not prevent Each of cover plates 14 and 15 rests on a pair of horizontal assemblies 2 and 7 from pulling plates 14 and 15 together until they meet (as shown in FIG. 4). In their position shown in FIG. 4, plates 14 and 15 completely (or substantially completely) cover the toasting volume, and heated air within the toasting volume recirculates dining toasting in the direc edges of plates 13 of the toaster frame (each plate rests on two parallel, horizontal edges, each edge on a di?erent one of plates 13), so that each plate has freedom to slide horizontally on the edges. The mechanism for sliding plates 14 and 15 between their “opened” and “closed” positions includes wire rack assem blies 2 and 7. spring elements 73 and 74 (shown in FIGS. 1 and 2), levers 48 and 49 and hinges 50 and 51 (shown in FIGS. 3 and 4). and spring wire 44 (shown in FIGS. 3 and 4). Arm 48A of lever 48 is rigidly attached to wire assembly 2, and arm 49A of lever 49 is rigidly attached to wire assembly 7. Spring element 73 has one end ?xedly attached 20 slice 30' of FIG. 2, which is thicker than slice 30 of FIG. 4), the bread slice will engage and stop assemblies 2 and 7 (as 25 to wire assembly 2, and spring element 74 has one end ?xedly attached to wire assembly 7. Each of spring elements the toaster frame, and that is positioned to be engaged by central ridge portion 8A of carriage 8. Ann 4813 of lever 48 and arm 49B of lever 49 are also positioned to be engaged 35 While carriage 8 is manually lowered into the lowered position shown in FIG. 2 (and FIG. 4) in response to 45 engages arm 48B of lever 48 and arm 49B of lever 49, 50 clockwise (away from the positions shown in FIGS. 1 and 3) assembly 7). When carriage 8 is lowered, wire assembly 2 rotates clockwise and pushes member 46 toward member 47 and wire assembly 7 rotates counter-clockwise and pushes member 47 toward member 46 (e.g., from the position shown in FIG. 3 to that shown in FIG. 4), thus causing spring wire 44 to bend (as shown in FIG. 4). Then (after a toasting operation) when carriage 8 rises to its fully raised position (shown in FIG. 3), wire 44 relaxes back to its normal, unbent position (shown in FIG. 3), thereby separating members 46 and 47 (and thus returning wire assemblies 2 and 7 and 55 described solenoid. As lever 48 and element 73 rotate clockwise (away from the positions shown in FIGS. 1 and 3) they exert a clockwise torque on wire assembly 2 and thus assembly 2 rotates clockwise (together as a unit with lever 48) from the position shown in FIGS. 1 and 3 to the position shown in FIG. 2 or 4. Similarly, as lever 49 and element 74 rotate counter they exert a counter-clockwise torque on wire assembly 7 and thus assembly 7 rotates counter-clockwise (together as with covers 14 and 15 omitted). 47 (which is in turn ?xedly attached to a rod of wire user-exerted force on the handle assembly comprising mem forcing lever 48 to rotate clockwise about hinge 50 (from the position shown in FIG. 3 to that shown in FIG. 4), and forcing lever 49 to rotate counter-clockwise about hinge 51 (from the position shown in FIG. 3 to that shown in FIG. 4). When carriage 8 has been manually lowered into the low ered position (of FIGS. 2 and 4), it is held in the lowered position by the downward force exerted by the above 15 (as shown by arrows B in FIG. 2), but much of the air heated by heating elements 12 recirculates within the toast ing volume substantially as shown by arrows A of FIG. 4 (and thus energy e?iciency of the toaster is improved relative to the e?iciency that the FIG. 2 toaster would have Wire spring 44 is provided for separating wire assemblies 2 and 7 (and thus cover plates 14 and 15) when carriage 8 returns to its fully raised position (shown in FIG. 3). The left end of spring 44 is attached to member 46 (which is in turn ?xedly attached to a rod of wire assembly 2), the central portion of member 46 is ?xedly attached to the toaster frame. and the right end of spring 44 is attached to member rotatably attached to an end plate 13 of the toaster frame. Lever 49 is rigidly attached to hinge 51, and hinge 51 is rotatably attached to the same end plate 13 of the toaster frame. ber 31 and handle 32, portion 8A of carriage 8 engages spring elements 73 and 74, forcing elements 73 and 74 to rotate (and slightly bend) into the position shown in FIG. 2. Also while carriage 8 is manually lowered into the lowered position, handle member 31 (rigidly connected to carriage 8) shown in FIG. 2) before assemblies 2 and 7 have pulled cover plates 14 and 15 completely together. In their position shown in FIG. 2, plates 14 and 15 partially cover the toasting volume. With plates 14 and 15 partially covering the toasting volume during toasting, some heated air in the toasting volume escapes out from the toaster between plates 14 and 73 and 74 also has a free end that is free to move relative to by a member (e.g., handle member 31) rigidly connected to carriage 8. Lever 48 is rigidly attached to hinge 50, and hinge 50 is tions of arrows A of FIG. 4. With a su?iciently thick slice of bread on carriage 8 (e.g., 65 levers 48 and 49 to their vertical orientation as shown in FIG. 3). The toaster frame (elements 4, 9, 11, and 13) and cover plates 14 and 15 are preferably made of plated steel. Enclosure 1 is preferably made of plated or painted steel, or (to make the toaster cool to the touch during operation) high temperature thermal plastic such as polypropylene or poly carbonate. In variations on the described toaster, spring elements 73 and 74 are omitted (or levers 48 and 49 and optionally also spring wire 44 are omitted). In other variations on the described toaster, the solenoid is omitted, and instead a mechanical latch means holds an 5,642,657 7 8 element rigidly attached to carriage 8 (such as member 31) to keep carriage 8 in the fully lowered position during a toasting period determined by the timer. At the end of the toasting period, the timer sends a control signal to electrical circuitry within the toaster to disconnect the power supply 18 is caught by latch 24. Latch 24 thus holds arm 18B (and the entire carriage assembly) in the intermediate position shown in FIG. 8. One end of pin 26 is attached to the upper end of latch 24, and button 26A (shown in FIG. 7) is attached to the other end of pin 26. When a user presses button 26A, latch 24 pivots from heating elements 12. Then, when the user desires to remove the toasted food, the user manually actuates a away from arm 18B, thereby releasing the carriage assembly so that spring 29 pulls the entire carriage assembly up to its control to release the mechanical latch. thus allowing spring 29 to pull up carriage 8 to the fully raised position (the upward movement of the carriage opens the cover over the toasting volume in the manner described above). In some embodiments of the inventive toaster, the bread fully raised position. 10 In the embodiment of FIGS. 7 and 8, the carriage assem bly (including carriage 8) moves only a small distance from the fully lowered position to the intermediate position, and the cover (comprising plates 14 and 15) over the toasting carriage is pulled up (by a spring such as spring 29) from its fully lowered position all the way to its fully raised position automatically in response to deactivation or release of the means (e.g., the above-discussed solenoid or mechanical volume remains closed even when the carriage has moved to the intermediate position. This is also true in other embodi ments of the invention. For example, in an implementation latch) which had held it in the lowered position during a of the FIG. 4 embodiment which includes means for relea toasting operation. In other embodiments, the toaster includes means for latching the bread carriage in an intermediate position (between the lowered and raised positions) in response to deactivation (or release) of the means which had held it in the lowered position during a toasting operation. An example of such an embodiment is that shown in FIGS. 7 and 8. This embodiment is almost identical to that of FIGS. 1-6 (and the elements of the embodiment of FIGS. 7 and 8 that correspond to those of the embodiment of FIGS. 1-6 are 20 sibly latching carriage 8 in an intermediate position, carriage 8 will typically be the position of carriage 8' (shown in phantom view in FIG. 4), which is only a short distance above the fully lowered position of carriage 8. When the latch (not shown in FIG. 4) retains carriage 8 in the intermediate position, member 31 engages arms 48B and 25 49B and retains them in substantially the position shown in FIG. 4, and thus spring 44 remains bent (substantially as shown in FIG. 4) when carriage 8 is in the intermediate position. Due to its bent con?guration, spring 44 exerts a numbered identically in FIGS. 1-8). Only those elements of force on cover plates 14 and 15 which retains cover plates FIGS. 7 and 8 that have not been described above with reference to FIGS. 1-6 will be described below. With reference to FIGS. 7 and 8, carriage 8 within the 14 and 15 in their closed position (shown in FIG. 4) when carriage 8 is in the intermediate position. Thus, the invention frame (not shown in FIGS. 7 and 8) is rigidly connected to a handle assembly slidably mounted to rod 33 of the frame. The handle assembly comprises member 18 (rigidly con nected to carriage 8), bracket 19 rigidly attached to member 18), and handle 32 (shown in FIG. 7) which is attached to protruding arm portion 19B of bracket 19. Extension spring 29 is mounted with its upper end attached to the toaster frame and its lower end attached to arm 18A of member 18 (so that spring 29 biases member 18 and the bread carriage attached thereto in their fully raised position). Latch 24 is hingedly attached to the toaster frame by elbow spring 25. 35 40 ready to remove it from the toaster. When the user wishes to remove the toasted item from a toaster whose carriage is in the intermediate position, he or she manually actuates a release control (e.g., presses a control such as button 26A on the outside of the toaster), to release the latch which holds carriage 8 in the intermediate position, thus triggering the following actions: release of 50 selected time period by manipulating knob 28. Solenoid 23 is mounted to the toaster frame, and soft iron plate 22 is mounted to arm portion 19B of bracket 19. When a user manually lowers handle 32 (and bracket 19, plate 22, 55 carriage in the fully lowered position) and a manually actuatable release control for releasing the mechanical latch thereby allowing a spring to pull up the carriage to its fully raised position, are described in above-referenced British activates solenoid 23, to cause solenoid 23 to exert a caniage assembly (carriage 8, handle 32, bracket 19, plate 22, and member 18) in the fully lowered position. Patent Application Publication No. 2,285 ,389A. At the end of a toasting operation, a timer (described 29 to pull up the carriage assembly until arm 18B of member 49B in a position keeping the inventive cover closed, making spring 44 free to relax and thereby open the inven tive cover (i.e., separate assembly 2 from assembly 7 and cover plate 14 from cover plate 15). A suitable mechanical latch for latching the bread carriage position (after deactivation of a solenoid which had held the magnetic force on plate 22 thereby holding the entire heating elements from their power supply, allowing spring carriage 8 so that it is free to be pulled up by spring 29 to its fully raised position; and release of the carriage assembly component (e.g., member 31) which had held arms 48B and of other embodiments of the invention in an intermediate member 18, and carriage 8 rigidly attached to handle 32) into the fully lowered position, a switch (described above) above) deactivates solenoid 23 and decouples the toaster’s is in the intermediate position. This has ‘ the bene?t of keeping the toasted item warm and crisp until the user is Conventional circuitry, including a power supply (for heating elements 12), a solenoid, and a timer, is housed in enclosure 1 in both the embodiments of FIGS. 1-6 and FIGS. 7-8. At the end of a selected period of time after the timer is activated (in response to closure of a switch by movement of the can‘iage assembly to its lowered position), the timer generates a signal which deactivates the solenoid (thus allowing the carriage to rise su?iciently far to open the switch, which in turn disconnects the power supply from the heating elements). The user selects the duration of the slows the cooling of a toasted item on carriage 8 (after toasting), retaining the crispiness of the toasted item for a longer time, since the entire toasted item remains near heating elements 12 when the carriage is in the intermediate position (elements 12 will themselves cool slowly, after they have been disconnected from the power supply before carriage 8 enters the intermediate position) and since cover plates 14 and 15 remain closed thereby causing hot air to recirculate within the toasting volume even when carriage 8 65 In all variations of the embodiments of FIGS. 1-6 and 7-8, the electric power supplied to the toaster’s heating elements (e.g., heating elements 12) should be limited so 5,642,657 9 10 that the temperature within each toasting volume, and the temperature at the toaster components surrounding the toast ing volume (e.g., at closed plates 14 and 15), during a freedom to move between a raised position shown in FIG. 9 toasting operation does not increase to a level that would cause the object being toasted or components of the toaster (e.g., the closed cover plates) to burn or melt. The material FIG. 10 (in which the upper ends of slots 115A are stopped comprising the inventive toaster cover (e.g., the material comprising slidable plates 14-15, or rotatable plates 80-83 protruding ?om plate 112, with freedom to pivot with to be described below) should be chosen to retain a desired amount of heat within the toasting volume. The toaster cover is made of metal in preferred embodiments, but it can be (in which the lower ends of slots 115A through plate 115 are stopped by rivets 114) and the lowered position shown in by rivets 114). Each of levers 101 and 102 is mounted to a rivet 99 10 made of non-metallic, thermally insulating material in other embodiments. The material comprising the inventive toaster cover should be chosen so that it does not melt or burn during toasting. We next describe another embodiment of the inventive 15 toaster with reference to FIGS. 9-12. In this embodiment, the toaster has two slots (toasting volumes). A cover designed in accordance with the invention is provided to cover each slot. Each cover comprises a pair of rotatably mounted plates (pair of plates 80 and 81 or pair of plates 82 and 83). Each plate is preferably made of metal. The toaster frame includes vertical side plates 111, end 20 plate 115, with lever 101 ?ee to pivot relative to portion 115B when plate 115 slides relative to plate 112. Pin 102A protruding ?om lever 102 is attached to bottom right portion 115C of plate 115, with lever 102 ?ee to pivot relative to portion 115C when plate 115 slides relative to plate 112. When carriage 108 is manually lowered ?om the FIG. 9 position to the FIG. 10 position, carriage 108 engages levers 101 and 102 and rotates levers 101 and 102 (about rivets 99) from their positions shown in FIG. 9 to their positions shown in FIG. 10. Rotating levers 101 and 102 overcome the biasing force exerted thereon by spring 100, thus displacing plates 112 and 112' (each ?xedly attached to end plates 111), horizontal top insulation member 113 connected between plates 111, and end member 130 ?xedly attached to end plate 112. Two rivets 114 protrude ?om plate 112, and two identical rivets 114 protrude ?om plate 112'. Two slots 20, respect to the rivet 99. Spring 100 is attached between levers 101 and 102. Spring 100 exerts a biasing force on levers 101 and 102 tending to separate the levers and thus to maintain the levers in the FIG. 9 orientation. Pin 101A protruding from lever 101 is attached to bottom left portion 115B of 25 which de?ne tracks along which bread carriage 108 moves, extend through each of plates 112 and 112'. Two rivets 99 spring 100 into the position shown in FIG. 10. Also when levers 101 and 102 rotate into their FIG. 10 position, pins 101A and 102A pull plate 115 down to its lowered position shown in FIG. 10 (until rivets 114 stop further downward motion of plate 115 relative to plate 112). This downward motion of plate 115 causes cover plates 80, 81, 82, and 83 to rotate into their closed positions (shown in FIGS. 10 and 11) in which plates 80 and 81 cover the toasting volume on the toaster’s left side and plates 82 and 83 cover the toasting volume on the toaster’s right side. The manner in which this is accomplished will be described with protrude ?om plate 112, a lever 101 is mounted to one of rivets 99, and a lever 102 is mounted to the other of rivets 99. Similarly, two rivets 99 (not shown) protrude ?om plate 112', a lever 101 (not shown) is mounted to one of these rivets 99, and a lever 102 (not shown) is mounted to the other of rivets 99. 35 reference to FIG. 10A, which is an enlarged view of a Enclosure 110 (not shown in FIGS. 11 and 12) sm'rounds the frame. The ?ame and cover plates 80, 81, 82, and 83 are portion of the FIG. 10 apparatus. preferably made of plated steel. Enclosure 110 is preferably portion 80A protruding ?om each end of the central portion. Plate 80 consists of a ?at central plate portion, and ?at rod made of plated or painted steel, or (to make the toaster cool to the touch dining operation) high temperature thermal The ?at surface of each rod portion 80A is oriented at an 40 plastic such as polypropylene or polycarbonate. Carriage 108 (shown in phantom view in FIGS. 9 and 10) is sized and shaped to support two slices of bread (one in each toasting volume), and is mounted within the frame with ?eedom to move relative to the frame along slots 20. One end of carriage 108 (the end that rides in slots 20 in plate 45 are ?ee to rotate but not translate relative to the toaster mounted to end member 130. In response to force exerted on 50 Each plate 115 has four curved slots (85, 86, 87, and 88) extending therethrough. As best shown in FIG. 10A, slot 85 provides a track along which rod portion 80A of cover plate 80 “rides” (slot 87, identical to slot 85, provides a track along which rod portion 82A of plate 82 rides) when plate 115 translates up or down relative to the toaster frame, and 55 slot 86 provides a track along which rod portion 81A of cover plate 81 rides (slot 88, identical to slot 86, provides a track along which rod portion 83A of plate 83 rides) when plate 115 translates up or down relative to the toaster ?ame. When levers 101 and 102 pull down plates 115 into the position shown in FIG. 10 (and FIG. 10A), the downward moving plates 115 rotate cover plates 80, 81, 82, and 83 until the cover plates reach their closed positions shown in FIG. 10 and FIG. 10A (by the action of slots 85, 86, 87, and 88, on rod portions 80A, 81A, 82A, and 83A, respectively, as This means is preferably identical to the means (described above with reference to FIGS. 1-6 or FIGS. 7-8) for performing the corresponding functions in the embodiment of FIGS. 1-6 or FIGS. 7-8, and the description thereof will not be repeated with reference to FIGS. 9-12. The toaster of FIGS. 9-12 also includes two plates 115, each slidably mounted to one of end plates 112 and 112' with ?at central plate portion with a ?at rod portion (81A, 82A, and 83A, respectively) protruding ?om each end of the central portion. End portions 80A, 81A, 82A, and 83A are rotatably mounted to the toaster frame (so that plates 80-83 frame). 112) is rigidly connected to a handle assembly (which includes member 131), and the handle assembly is slidably the handle assembly (typically by the hand of a human user), carriage 108 is lowered relative to the frame ?om the raised position shown in FIG. 9 to the lowered position shown in FIG. 10. Carriage 108 is biased by an extension spring (not shown. but which is preferably identical to spring 29 of the embodiment of FIGS. 5 and 6) to be normally in the raised position. The action of manually lowering carriage 108 to the lowered position thus overcomes the biasing force exerted by the spring. A means for releasibly locking car riage 108 in the lowered position (and/or in an intennediate position after release ?om the lowered position) is provided. acute angle relative to the central portion (as best shown in FIG. 10A). Each of plates 81, 82, and 83 also consists of a the rod portions ride along the slots to the outer ends of the 65 slots). When carriage 108 is released (so that its bias spring pulls it up to the FIG. 9 position, spring 100 relaxes to its FIG. 9 5,642,657 12 11 period after entry of the mechanical link assembly into the ?rst con?guration, wherein the carriage assembly position, thereby returning levers 101 and 102 to their FIG. 9 position. As levers 101 and 102 return to their FIG. 9 enters the raised position automatically thereby causing position, pins 101A and 102A push plates 115 up to their raised position. The upward-moving plates 115 rotate cover plates 80, 81, 82, and 83 until the cover plates reach their opened positions shown in FIG. 9 (by the action of slots 85, 86, 87, and 88. on rod portions 80A, 81A, 82A, and 83A, the mechanical link assembly to enter the second con?guration in response to assertion of the timer signal. 3. The toaster of claim 1, also including: respectively, as the rod portions ride along the slots to the inner ends of the slots). With the covers opened, toasted bread can be removed from the bread carriage. In variations on the embodiment of FIGS. 9-12, when the heating elements; bread carriage is manually lowered by the user, other power supply means for supplying power to the heating elements in response to entry of the mechanical link assembly into the ?rst con?guration, and for decou pling the power from the heating elements in response mechanical linkages attached to the carriage rotate a pair of to a timer signal generated upon termination of a cover plates so that they cover a toasting volume. Then, toasting period- after entry of the mechanical link assembly into the ?rst con?guration; carriage biasing means for urging the carriage assembly to the raised position; latch means for releasibly holding the carriage assembly in the lowered position in response to the carriage assembly moving to said lowered position; when the carriage springs up (after a toasting operation), the mechanical linkages rotate the plates in the opposite direc tions to uncover the toasting volume and allow removal of the toasted object. Various other modi?cations and alterations in the appa ratus of the invention will be apparent to those skilled in the art. Although the invention has been described in connection with speci?c preferred embodiments, it should be under latch release means for releasing said latch means in response to an external force applied after assertion of stood that the invention as claimed should not be unduly the timer signal, thereby allowing the carriage biasing limited to such speci?c embodiments. What is claimed is: 1. A toaster, including: a frame enclosing a toasting volume, wherein the frame de?nes an opening for admitting an object into the 25 4. The toaster of claim 1, wherein the cover substantially totally covers the opening when the mechanical link assem bly is in the ?rst con?guration. toasting volume; 5. The toaster of claim 1, wherein the frame also encloses a second toasting volume and the frame also de?nes a a carriage assembly; a member rigidly attached to the carriage assembly, wherein the member is translatably engaged with the frame so that the carriage assembly is movable relative to the frame between a raised position and a lowered position in the toasting volume in response to transla tion of the member relative to the frame; a mechanical link assembly having a ?rst con?guration and a second con?guration, wherein the mechanical link assembly enters the ?rst con?guration in response to the carriage assembly moving to the lowered posi tion and engaging a portion of said mechanical link assembly, and wherein the mechanical link assembly 40 second opening for admitting a second object into the second toasting volume, and wherein the toaster also includes: a second mechanical link assembly having a ?rst member attached to the carriage assembly, wherein the second mechanical link assembly enters a ?rst con?guration in response to the carriage assembly moving to the low ered position, and wherein the second mechanical link assembly enters a second con?guration in response to the carriage assembly moving to the raised position; and a second cover attached to the second mechanical link enters the second con?guration in response to the carriage assembly moving to the raised position; and means to move the carriage assembly to the raised position. 45 assembly, wherein the second mechanical link assem bly holds the second cover in a ?rst position at least a cover attached to the mechanical link assembly, wherein the mechanical link assembly holds the cover in a ?rst partially covering the second opening when the mechanical link assembly is in the ?rst con?guration, position at least partially covering the opening when and wherein the second mechanical link assembly holds the second cover in a second position uncovering the mechanical link assembly is in the ?rst con?guration, and wherein the mechanical link assem bly holds the cover in a second position uncovering the opening when the mechanical link assembly is in the second con?guration, wherein the cover includes a ?rst plate slidably mounted to the frame and a second plate slidably mounted to the frame, and wherein the mechanical link assembly includes: means for sliding the ?rst plate and the second plate 55 bottom end positioned for engagement by the carriage assembly when said carriage assembly moves into the into positions at least partially covering the opening lowered position, wherein the ?rst subassembly moves the ?rst plate into a position at least partially covering the opening in response to the carriage assembly engag ing the bottom end of the ?rst subassembly when said carriage assembly moves into the lowered position; and a second subassembly movably mounted to the frame and having a top end connected to the second plate and a in response to movement of the carriage assembly into the lowered position. 2. The toaster of claim 1, also including: heating elements; and power supply means for supplying power to the heating elements in response to entry of the mechanical link assembly into the ?rst con?guration. and for decou pling the power from the heating elements in response to a timer signal generated on termination of a toasting the second opening when the second mechanical link assembly is in the second con?guration. 6. The toaster of claim 1, wherein the means for sliding the ?rst plate and the second plate includes: a ?rst subassembly movably mounted to the frame, and having a top end connected to the ?rst plate and a 65 bottom end positioned for engagement by the carriage assembly when said carriage assembly moves into the lowered position, wherein the second subassembly 5,642,657 14 13 rotatably mounted to the frame, and wherein the moves the second plate into a position at least partially covering the opening in response to the carriage assem bly engaging the bottom end of the second subassembly when said carriage assembly moves into the lowered position. 5 7. The toaster of claim 6, wherein the ?rst subassembly includes: a hinge means rotatably mounted to the frame; a ?rst lever arm having one end attached to the hinge mechanical link assembly includes: means for rotating the ?rst plate and the second plate into positions at least partially covering the opening in response to movement of the carriage assembly into the lowered position, wherein the means for rotating the ?rst plate and the second plate includes: a sliding plate slidably mounted to the frame, wherein there is a ?rst slot and a second slot in said sliding plate, the ?rst plate has an end portion which extends through the ?rst slot, and the sec a second lever arm having one end attached to the hinge ond plate has an end portion which extends means and whose opposite end is said bottom end of the through in the second slot. ?rst subassembly; and 10. The toaster of claim 9, wherein the end portion of the a wire assembly rigidly attached to the ?rst lever arm and 15 ?rst plate is rotatably mounted to the frame, the end portion having an upper portion which is said top end of the of the second plate is rotatably mounted to the frame, ?rst subassembly. wherein the sliding plate translates in response to movement 8. The toaster of claim 7, wherein the second subassembly of the carriage assembly into the lowered position thereby includes: causing the ?rst slot to rotate the end portion of the ?rst plate a second hinge means rotatably mounted to the frame; 20 in a ?rst rotational direction as said end portion of the ?rst means; 10 plate rides in the ?rst slot during said translation, and a third lever arm having one end attached to the hinge causing the second slot to rotate the end portion of the second plate in a second rotational direction as said end means a fourth lever arm having one end attached to the second portion of the second plate rides in the second slot during hinge means and whose opposite end is said bottom end of the second subassembly; and 25 said translation. 11. A toaster, including: a second wire assembly rigidly attached to the third lever a frame enclosing a toasting volume, wherein the frame arm and having an upper portion which is said top end de?nes an opening for admitting an object into the of the ?rst subassembly, and wherein the means for toasting volume; sliding the ?rst plate and the second plate also includes: spring means attached between the wire assembly and 30 ‘ the second wire assembly, for exerting a biasing force urging said wire assembly away from said second wire assembly and thus the ?rst plate away from the second plate, wherein said wire assembly to the frame between a raised position and a lowered and said second wire assembly overcome said bias- 35 ing force and move together in response to move ment of the carriage assembly into the lowered position. 9. A toaster, including: a ?ame enclosing a toasting volume, wherein the frame de?nes an opening for admitting an object into the tion of the member relative to the frame; a pair of cover plates movably mounted to the frame; and means for moving the cover plates into a ?rst con?gura con?guration uncovering the opening in response to a carriage assembly; 45 movement of the carriage assembly into the raised position, wherein the cover plates are slidably mounted to the frame, and wherein the means for moving the cover plates is a mechanical link assembly including: means for sliding the cover plates into the ?rst con to the frame between a raised position and a lowered position in the toasting volume in response to transla tion of the member relative to the frame; a mechanical link assembly having a ?rst con?guration and a second con?guration, wherein the mechanical position in the toasting volume in response to transla tion at least partially covering the opening in response to movement of the carriage assembly into the lowered position, and for moving the cover plates into a second toasting volume; a member rigidly attached to the carriage assembly, wherein the member is translatably engaged with the frame so that the carriage assembly is movable relative a carriage assembly; a member rigidly attached to the carriage assembly, wherein the member is translatably engaged with the frame so that the carriage assembly is movable relative ?guration in response to movement of the carriage 50 assembly into the lowered position. 12. The toaster of claim 11, wherein the cover plates substantially totally cover the opening when in said ?rst con?guration. link assembly enters the ?rst con?guration in response to the can‘iage assembly moving to the lowered posi 13. The toaster of claim 11, wherein the cover plates tion and engaging a portion of said mechanical link 55 include a ?rst plate and a second plate, and wherein the assembly, and wherein the mechanical link assembly \ means for sliding the cover plates includes: enters the second con?guration in response to the a ?rst subassembly movably mounted to the frame, and carriage assembly moving to the raised position; and having a top end connected to the ?rst plate and a bottom end positioned for engagement by the carriage a cover attached to the mechanical link assembly, wherein assembly when said carriage assembly moves into the the mechanical link assembly holds the cover in a ?rst lowered position, wherein the ?rst subas sembly moves position at least partially covering the opening when the ?rst plate into a position at least partially covering the mechanical link assembly is in the ?rst the opening in response to the carriage assembly engag con?guration, and wherein the mechanical link assem ing the bottom end of the ?rst subassembly when said bly holds the cover in a second position uncovering the opening when the mechanical link assembly is in the second con?guration, wherein the cover includes a ?rst plate rotatably mounted to the frame and a second plate 65 carriage assembly moves into the lowered position; and a second subassembly movably mounted to the frame and having a top end connected to the second plate and a 5,642,657 15 16 bottom end positioned for engagement by the carriage assembly when said carriage assembly moves into the lowered position, wherein the second subassembly moves the second plate into a position at least partially covering the opening in response to the carriage assem bly engaging the bottom end of the second subassembly when said carriage assembly moves into the lowered position. wherein the ?rst subassembly includes: a hinge means rotatably mounted to the frame; a ?rst lever arm having one end attached to the hinge 10 mounted to the frame, and wherein the means for means; moving the cover plates is a mechanical link assembly a second lever arm having one end attached to the hinge means and whose opposite end is said bottom end of including: means for rotating the cover plates into the ?rst con the ?rst subassembly; and a wire assembly rigidly attached to the ?rst lever arm 15 and having an upper portion which is said top end of the ?rst subassembly. 14. A toaster, including: assembly into the lowered position, wherein the a sliding plate slidably mounted to the frame, wherein there is a ?rst slot and a second slot in toasting volume; to the frame between a raised position and a lowered ?guration in response to movement of the carriage cover plates include a ?rst plate and a second plate, and wherein the means for rotating the cover plates includes: a frame enclosing a toasting volume, wherein the frame de?nes an opening for admitting an object into the a carriage assembly; a member rigidly attached to the carriage assembly, wherein the member is translatably engaged with the frame so that the carriage assembly is movable relative position in the toasting volume in response to transla tion of the member relative to the frame; a pair of cover plates movably mounted to the frame; and means for moving the cover plates into a ?rst con?gura tion at least partially covering the opening in response to movement of the carriage assembly into the lowered position, and for moving the cover plates into a second con?guration uncovering the opening in response to movement of the carriage assembly into the raised position, wherein the cover plates are rotatably said sliding plate, the ?rst plate has an end portion which extends through the ?rst slot, and the sec ond plate has an end portion which extends 25 through in the second slot.