Download Installation Guide

Transcript

TP -20214

Revised 10 -05

MERITOR WABCO

Enhanced Easy -StopTM

Trailer ABS 2S /2M, 4S /2M and

4S/3M Premium with

Installation Guide

Hazard Alert Messages

PLC

If

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

How to Obtain Additional Maintenance

and Service Information

-

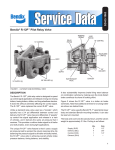

this assembly

the trailer

BU

Installation Instructions

is

mounted facing forward

-

toward the front of

the YE sensor connections go to the curbside and the

sensor connections go to the roadside.

If

this assembly

is

mounted

facing the rear, the YE sensor connections go to the roadside, and the

BU

sensor connections go to the curbside. Figure 1.

All premium systems use the same ECU /dual modulator valve

assembly.

The ECU /dual modulator assembly cannot be used as a 2S/1 M system.

Refer to Maintenance Manual MM -0180, Enhanced Easy -StopTM

Trailer ABS with PLC, and Maintenance Manual 33, Easy -StopTM

Trailer ABS. To obtain these publications, call ArvinMeritor's

ECU /DUAL MODULATOR VALVE MOUNTED WITH

SENSORS FACING FRONT OFTRAILER

Customer Service Center at 800 -535 -5560, or visit the Tech Library

CURBSIDE

on our website at meritorwabco.com.

Differences Between Easy -StopTM and

Enhanced Easy -StopTM

There are some changes to Enhanced Easy -StopTM that you need to

SUPPLY

PORT

Enhanced Easy -StopTM includes Power Line Communication

(PLC) function.

The ECU /dual modulator valve assembly must be mounted as

one unit.

ABS lamp on the trailer.

It is

ROADSIDE

SUPPLY

PORT

tat

PORTS

DELIVERY

ROADSIDE

/

sV.

Crsiek

fr

The valve portion of the ECU /dual modulator valve assembly contains

-I¡ßÿ (Th

two separate modulator valves that share common control and

DELIVERY

ROADSIDE

whether the valve is facing the front or the rear of the

EXHAUST

PORT

determines sensor hookup.

Figure

CONTROL

PORT

in

iss

exhaust ports.

trailer

UNUSED

ear]

912,

Enabling the Lift Axle Function (4S /3M Installations) in the

Each valve has three delivery ports. Therefore, the mounting

PLUG ALL

CURBSIDE

BU1

CURBSIDE

BU2

YE1

ROADSIDE

YE2

not automatically enabled. Refer to

Appendix for instructions. For 4S /2M lift axle installations, the lift

axle function is automatically enabled.

PORT

ECU /DUAL MODULATOR VALVE MOUNTED WITH

SENSORS FACING REAR OF TRAILER

must use TOOLBOXTM Software, version 4.6 or higher, to enable

--

at

CONTROL

PORT

For Enhanced Easy -StopTM 4S /3M lift axle installations, you

the lift axle function.

ROADSIDE

BU2

O

IkliSid

EXHAUST

The blink code tool LED does not operate simultaneously with the

orientation

BUI

sSC

1

DELIVERY

CURBSIDE

The LED on top of the ECU has been eliminated.

'

I

e.

be aware of before you begin the installation.

'

ROADSIDE

YE1-

CURBSIDE

YE2

PLUG ALL

UNUSED

PORTS

DELIVERY

CURBSIDE

4003566a

1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Preparation

End of line testing must be done after all installations. Meritor

WABCO recommends using TOOLBOXTM Software to perform

A WARNING

To

this testing.

If

you do not have TOOLBOXTM Software, this

bulletin also includes instructions for testing without the

prevent serious eye injury, always wear safe eye protection

software.

when you perform vehicle maintenance or service.

The Anti -lock Braking System (ABS) is an electrical system.

When you work on the ABS, take the same precautions that

you must take with any electrical system to avoid serious

personal injury. As with any electrical system, the danger of

electrical shock or sparks exists that can ignite flammable

Installation

I.

Install the ECU /dual modulator valve

assembly.

substances. You must always disconnect the battery ground

The assembly may be mounted on the air tank or on the cross

cable before working on the electrical system.

member of the vehicle.

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal injury and

damage to components can result.

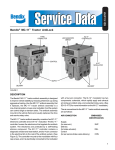

Tank -Mounted

Refer to Figure 2.

ECU /DUAL MODULATOR VALVE MOUNTED WITH

1.

SENSORS FACING FRONT OFTRAILER

(TANK- MOUNTED)

Before beginning the installation procedure, inspect the

modulator valve assembly for damage that may have

occurred during shipping or storage.

ECU /dual

CURBSIDE

Look for crushed or bent connectors.

VE2

Verify that the retainer clips have not been bent or

CURBSIDE

otherwise damaged.

YE1

Do not install a damaged ECU /dual modulator valve

assembly. Notify your supervisor, or contact Meritor WABCO

if there is any apparent damage.

2.

/

ROADSIDE

BU1

ROADSIDE

BU2

Have the following installation material available.

* ECU /dual modulator valve assembly

* ABS relay valve and relay valve extension cable with bayonet

ECU /DUAL MODULATOR VALVE MOUNTED WITH

SENSORS FACING REAR OFTRAILER

connector (3M systems)

* Power cable or power /diagnostic cable

* Sensor extension cables (two pieces for 2S systems, four

pieces for 4S systems)

CURBSIDE

BU2

* Sensors (two or four) for non -ABS prepped axles

CURBSIDE

BU1

* ABS Indicator Label (TP- 95172)

U!!

5/8 -inch O.D. nylon tubing for supply (frame mount)

Pipe plug (3/4 -inch NPTF)

Schedule 80 hex pipe nipple (3/4 -inch NPTF) for air tank

mounts or two Grade 8 bolts (3/8 -inch) and prevailing torque

PLUG UNUSED

PORT

nuts for frame mounts

SAE -standard, DOT- approved thread sealant

To

ROADSIDE

R

YE1

ROADSIDE

VE2

Exhaust port

must face DOWN.

4003548a

ensure correct lamp operation, use an incandescent -type

Figure 2

DOT- approved lamp, or an LED with integral load resistor.

* Meritor WABCO components

TP -20214

Revised 10 -05

Page 2

i

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed

in

USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

A

When mounting the ECU /dual modulator valve assembly to the

WARNING

trailer cross member, refer to SAE specification J447, Prevention of

You must use a Schedule 80 hex nipple (3/4 -inch NPTF) to

ECU /dual

mount the

modulator valve assembly securely to the

air tank to avoid possible serious personal injury and damage

to the component.

Corrosion of Motor Vehicle Body and Chassis Components. Follow

all recommendations and procedures. Your supervisor should have a

copy of this specification.

Install a 3/4 -inch NPTF fitting in the supply port. Use a 3/4 -inch

1.

1.

Use a

3/4 -inch NPTF Schedule 80 hex nipple to attach the

ECU /dual

modulator valve assembly to

a

NPTF pipe plug to plug the unused supply port (Port 1).

reinforced air tank.

Apply SAE -standard, DOT- approved Teflon tape or paste -type

Do not overtighten.

thread sealant to all pipe plugs beyond the first two threads.

Meritor WABCO does not recommend the use of

a vise

when

Pipes with pre -applied thread sealant may also be used.

installing the hex nipple. Use of a vise may cause

Locate a position for mounting the assembly to the vehicle

2.

overclamping. Overclamping may damage the internal

cross member midway between the side rails, close to the

components of the ECU /dual modulator valve assembly.

2.

Use a

brake chambers the valve serves.

3/4 -inch NPTF pipe plug to plug the unused supply port.

Drill two 3/8 -inch mounting holes. The distance between

Apply SAE -standard, DOT- approved Teflon tape or paste -type

the two holes (O.D.) must be 6.06- inches (154 mm) and

thread sealant to all pipe threads beyond the first two threads.

mount directly to the cross member.

Pipes with pre -applied thread sealant may also be used.

3.

until the exhaust port faces DOWN and the connection is

Build a mounting bracket with two 3/8 -inch mounting holes

secure. Use a torque wrench or ratchet with an extension at the

spaced 6.06- inches (154 mm O.D.) apart.

3/4 -inch pipe plug installed on the front supply port.

'

OR

Rotate and tighten the ECU /dual modulator valve assembly

attach the assembly. Tighten the bolts to 18 lb -ft (24 Nm).

Mounted to Cross Member of Vehicle (Mounting

Bracket Not Supplied)

II.

Refer to Figure 3.

ECU /DUAL MODULATOR VALVE MOUNTED

TO A CROSS MEMBER OF THE VEHICLE WITH

SENSORS FACING FRONT OF TRAILER

Exhaust port

must face DOWN.

1-

PLUG ALL

UNUSED PORTS

- -

ROADSIDE

BU2

mount the

l

modulator valve assembly securely to the

to the component.

Use a

3/4 -inch NPTF Schedule 80 hex nipple to attach the

relay valve assembly to a reinforced air tank. Do not

CURBSIDE

overtighten.

VE1

Mentor WABCO does not recommend the use of

overclamping. Overclamping may damage the internal

components of the ECU /dual modulator valve assembly.

2.

PLUG ALL

UNUSED PORTS

when

a vise

installing the hex nipple. Use of a vise may cause

Exhaust port

must face DOWN.

I

ECU /dual

air tank to avoid possible serious personal injury and damage

ECU /DUAL MODULATOR VALVE MOUNTED WITH

SENSORS FACING REAR OF TRAILER

ROADSIDE

YE2

WARNING

You must use a Schedule 80 hex nipple (3/4 -inch NPTF) to

1.

YE2

Attach the ABS external relay valve

(4S /3M systems only).

A

BU1

CURBSIDE

O

Tank -Mounted

ROADSIDE

FRONT OF

TRAILER

Use two 3/8 -inch Grade 8 bolts with prevailing torque nuts to

3.

Use a

3/4 -inch NPTF pipe plug to plug the unused supply port.

Apply SAE -standard, DOT- approved Teflon tape or paste -type

thread sealant to all pipe threads beyond the first two threads.

Pipes with pre -applied thread sealant may also be used.

ROADSIDE

VE1

CURBSIDE

BU1

Figure

CURBSIDE

BU2

FRONT OF

TRAILER

4005403b

3

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Rotate and tighten the relay valve assembly until the exhaust

3.

port faces down and the connection

is

secure. Use a torque

2.

Connect the air delivery lines to the appropriate brake

chambers (3/8 -inch NPT). Figure 5 and Figure 6.

wrench or ratchet with an extension at the 3/4 -inch pipe plug

installed on the front supply port. Figure 4.

The valve portion of the ECU /dual modulator valve assembly

contains two separate valves: one dedicated to roadside

wheel ends, the other dedicated to curbside wheel ends,

Each valve has three delivery ports.

PLUG

UNUSED

The external relay valve designated RED (RD)

PORTS

axle

is an

control valve. It controls brake chambers on one or two

Exhaust

port must

face DOWN.

important that delivery lines from Port

CONTROL

axles.

PORT 4

plumbed as shown. Refer to Figure 13 through Figure 19.

It is

2 are

-

SUPPLY

PORT 1

TYPICAL 2M INSTALLATION

VALVE MOUNTED

WITH SENSORS FACING FRONT OFTRAILER

ABS EXTERNAL MODULATOR VALVE

Il

1002073d

Figure 4

.

1

1

I

1

I

Mounted to Cross Member of Vehicle (Mounting

Bracket Not Supplied)

141--r

:_

-

1

;'

I

I

.

;.

j

-.I

I

-

'

,,.,: I

'1`tI

yv'

I

A

I

When mounting the relay valve assembly to the trailer cross

member, refer to SAE specification J447, Prevention of Corrosion of

I

11

r:5°-------!

I------------

Motor Vehicle Body and Chassis Components. Follow all

recommendations and procedures. Your supervisor should have

-----------

a

copy of this specification.

1.

- - - --

Install a 3/4 -inch NPTF fitting in the supply port. Use a 3/4 -inch

NPTF pipe plug to plug the unused supply port (Port 1).

Apply SAE -standard, DOT- approved Teflon tape or

paste -type thread sealant to all pipe plugs beyond the first

I

SERVICE /CONTROL LINES

SERVICE BRAKE

SUPPLY AIR

SPRING BRAKE AIR

4003550a

Figure 5

two threads. Pipes with pre -applied thread sealant may also

-

be used.

2.

Install the valve with two locknuts and washers as required.

Tighten the hex nuts to 18 lb -ft (24 Nm).

III.

TYPICAL 2M INSTALLATION

VALVE MOUNTED

WITH SENSORS FACING REAR OFTRAILER

-----------------1

-' 'T-------c&-

O

I

Connect the air lines.

Before connecting the air lines, plumb the spring brake relay or

emergency brake relay into the system as usual.

If you are

o

I

i

I

1

1

e a.

1

mounting on a bracket, connect the air supply line from

W

..

i

e

the supply tank to the supply Port 1. Plug the unused port.

1

Use

II

1

I

supply tank.

- - - --

Connect the air delivery lines to the ECU /dual modulator valve

assembly Port 2. For 4S /3M installations, connect the air

delivery lines to Port 2 on the external relay valve (3/8 -inch

NPTF).

.., .

.I

-----------'

I-----------------r

-- -

5/8 -inch O.D. min. nylon tubing or heavy -walled Schedule

80 pipe nipple (3/4 -inch NPTF) if you are mounting directly to the

1.

i

1If

i

Figure

SERVICE /CONTROL LINES

SERVICE BRAKE

SUPPLY AIR

SPRING BRAKE AIR

4003551a

6

TP -20214

Revised 10 -05

Page 4

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

3.

4.

Connect the brake service (control) line to the ECU /dual

Do not overtighten the tie wraps on a cable. Overtightening can

modulator valve assembly Port

damage the cable. Do not tie wrap the molded sensor plug.

4

(1

/4 -inch NPTF).

The sensor extension cable must follow the brake hose to the

For 4S/3M installations, perform the following procedures.

ECU /dual

A.

Connect the brake service (control) line to the ECU /dual

modulator valve assembly Port

4

modulator valve assembly to allow for axle jounce

and rebound.

(1/4-inch NPTF) and

ABS external relay valve control Port 4 (3/8 -inch NPTF).

4.

Secure the cables every eight inches (203 mm) with tie wraps

or cable clips.

B.

Use an ABS relay valve connection cable to connect the

ECU

/dual modulator valve assembly with the ABS external

5.

assembly

relay valve.

5.

6.

Plug any unused delivery ports.

Push the sensor retainer clip on the ECU /dual modulator valve

UP.

Remove the protective caps from YE2 and YE1 sensor

connectors.

IV.

Install the sensor extension cables

(ABS- prepped axles).

7.

Plug the sensor extension cables into the ECU /dual modulator

valve assembly. To secure the connection, push the sensor

retainer clip DOWN. Retainer clips must fit in the groove of the

Instructions for installing sensors on non -ABS- prepped axles are

included

in

sensor connectors to ensure correct connection.

the Appendix.

ECU /Dual

Meritor WABCO recommends placing sensors on the axle that will

Modulator Valve Assembly Mounted with

Sensors Facing Front of Trailer

provide the most braking performance. The suspension

2S/2M

manufacturer can provide this information.

1.

Visually inspect the tooth wheel and sensor to ensure no

damage occurred during shipping. Perform any necessary

repairs.

-

Connect curbside sensor at YE1.

Connect roadside sensor at BU1.

4S /2M*

2.

Connect the sensors and cables on the prepped axles to the

sensor extension cables. Figure 7.

Ensure that each connection is secure.

Connect curbside front sensor at YE1.

Connect curbside rear sensor at YE2.

Connect roadside front sensor at BU1.

Connect roadside rear sensor at BU2.

4S /3M*

SENSOR

EXTENSION

CABLE

-

Sensor locations vary by type of installation.

Refer to the diagrams on the following pages for specific

sensor locations.

For Enhanced Easy- StopTM 4S /3M lift axle

installations, you must use TOOLBOXTM Software,

SENSOR

AND CABLE

version 4.6 or higher, to enable the lift axle function.

It is not

automatically enabled. Refer to Enabling the Lift

Axle Function (4S/3M Installations) in the Appendix for

instructions.

4003567b

Figure

'

3.

7

Route the sensor cable along the back side of the trailer axle to

the ECU /dual modulator valve assembly. Route the cable with

the brake hose.

-

Connect curbside sensor at YE1.

Connect curbside sensor at YE2.

Connect roadside sensor at BU1.

Connect roadside sensor at BU2.

* If the lift axle is sensed in 4S /2M and 4S /3M installations:

Sensors YE2 and BU2 must always be used on the lift axle to

avoid an unwanted ABS indicator lamp illumination.

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

3.

4.

Connect the brake service (control) line to the ECU /dual

Do not overtighten the tie wraps on a cable. Overtightening can

modulator valve assembly Port 4 (1/4 -inch NPTF).

damage the cable. Do not tie wrap the molded sensor plug.

The sensor extension cable must follow the brake hose to the

For 4S /3M installations, perform the following procedures.

ECU /dual

A.

Connect the brake service (control) line to the ECU /dual

modulator valve assembly Port

4

modulator valve assembly to allow for axle jounce

and rebound.

(1/4-inch NPTF) and

ABS external relay valve control Port 4 (3/8 -inch NPTF).

4.

Secure the cables every eight inches (203 mm) with tie wraps

or cable clips.

B.

Use an ABS relay valve connection cable to connect the

ECU /dual

modulator valve assembly with the ABS external

5.

assembly

relay valve.

5.

6.

Plug any unused delivery ports.

Push the sensor retainer clip on the ECU /dual modulator valve

UP.

Remove the protective caps from YE2 and YE1 sensor

connectors.

IV.

Install the sensor extension cables

(ABS- prepped axles).

7.

Plug the sensor extension cables into the ECU /dual modulator

valve assembly. To secure the connection, push the sensor

retainer clip DOWN. Retainer clips must fit

Instructions for installing sensors on non -ABS- prepped axles are

included in the Appendix.

Meritor WABCO recommends placing sensors on the axle that will

provide the most braking performance. The suspension

the groove of the

ECU /Dual

Modulator Valve Assembly Mounted with

Sensors Facing Front of Trailer

2S /2M

manufacturer can provide this information.

1.

in

sensor connectors to ensure correct connection.

Visually inspect the tooth wheel and sensor to ensure no

damage occurred during shipping. Perform any necessary

repairs.

-

Connect curbside sensor at YE1.

Connect roadside sensor at BU1.

4S /2M*

2.

Connect the sensors and cables on the prepped axles to the

sensor extension cables. Figure 7.

Ensure that each connection is secure.

Connect curbside front sensor at YE1.

Connect curbside rear sensor at YE2.

Connect roadside front sensor at BU1.

Connect roadside rear sensor at BU2,

4S/3M*

-

Sensor locations vary by type of installation.

Refer to the diagrams on the following pages for specific

sensor locations.

For Enhanced Easy- StopTM 4S /3M

lift axle

installations, you must use TOOLBOXTM Software,

version 4.6 or higher, to enable the lift axle function.

It is

not automatically enabled. Refer to Enabling the Lift

Axle Function (4S /3M Installations) in the Appendix for

instructions.

Figure

3.

7

Route the sensor cable along the back side of the trailer axle to

the ECU /dual modulator valve assembly. Route the cable with

the brake hose.

-

Connect curbside sensor at YE1.

Connect curbside sensor at YE2.

Connect roadside sensor at BU1.

Connect roadside sensor at BU2.

* If the lift axle is sensed in 4S /2M and 4S /3M installations:

Sensors YE2 and BU2 must always be used on the lift axle to

avoid an unwanted ABS indicator lamp illumination.

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

ECU /Dual

Modulator Valve Assembly Mounted with

9.

Bundle any excess cable in a loop (bow tie). Figure 9.

Sensors Facing Rear of Trailer

2S /2M

-

Connect curbside sensor at BU1.

Connect roadside sensor at YE1.

4S /2M*

Connect curbside front sensor at BU1.

Connect curbside rear sensor at BU2.

Connect roadside front sensor at YE1.

Connect roadside rear sensor at YE2.

4S/3M*

-

Figure 9

Sensor locations vary by type of installation.

Refer to the diagrams for specific sensor locations.

10. Secure excess cable

For Enhanced Easy- StopTM 4S /3M lift axle

in

the sub -frame of the vehicle or along

the air hoses as appropriate. Excess cable should not exceed

installations, you must use TOOLBOXTM Software,

two feet (0.61 meter).

version 4.6 or higher, to enable the lift axle function.

It is

Various cable lengths are available.

not automatically enabled. Refer to Enabling the Lift

Axle Function (4S/3M Installations) in the Appendix for

V.

instructions.

-

Connect curbside sensor at BU1.

1.

Connect curbside sensor at BU2.

Install the power and lamp or power and

lamp /diagnostic cable.

Identify the type of cable to be installed. Figure 10.

Connect roadside sensor at YE1.

ABS trailer industry- standard pigtail connector power cable

Connect roadside sensor at YE2.

Blunt -cut power cable (not shown)

* If the lift axle is sensed in 4S /2M and 4S /3M installations:

Sensors YE2 and BU2 must always be used on the lift axle to

avoid an unwanted ABS indicator lamp illumination.

8.

Create a strain relief to protect the sensor extension connector

terminals. Without this strain relief, normal trailer jounce and

vibration will cause the terminals to spread and loosen. Use a

tie wrap or clip to secure the cable to the brake air delivery

hose as close to the fitting as possible. Figure 8.

Figure 10

2.

For industry- standard pigtail connector power cables, route the

cable from the harness connector to the ECU /dual modulator

valve assembly and secure it to prevent damage.

Attach individual sensor

cables to corresponding

brake air delivery hoses.

For blunt -cut power cables, route the cable from the ECU /dual

modulator valve assembly to

a

junction box which interfaces

with the seven -way connector at the front of the trailer.

4005457b

Leave enough slack in the cable to compensate for flexing of

Figure

8

the trailer and sub -frame.

TP -20214

Revised 10 -05

Page 6

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

3.

Bundle any excess cable in a loop (bow tie) and secure it in the

8.

sub -frame of the trailer body to prevent cable damage.

4.

If

you are installing the power /diagnostic "Y" cable:

Install the diagnostic cable bracket so that the diagnostic

A.

Push the hinged power /diagnostic connector retainer clip UP

plug is accessible. The normal location is on the right

and remove the protective cap from the ECU /dual modulator

front corner of the sub -frame, but will vary depending on

valve assembly. Figure 11.

the type of trailer.

Route the diagnostic cable from the ECU /dual modulator

B.

valve assembly to the diagnostic cable bracket.

-4- -

l'

CAP

Correctly secure the cable in the sub -frame to prevent

C.

cable damage.

KEYED CABLE

Leave enough slack in the cable to compensate for flexing

CONNECTOR

of the trailer and sub -frame.

Bundle excess cable in a loop (bow tie) and secure the

D.

cable

9.

in

the sub -frame. Figure 9.

Install the ABS indicator lamp on the trailer. Refer to the vehicle

specification sheet for the exact location of the indicator lamp.

MATING

TRAILER

HARNESS

CONNECTOR

Use a DOT- approved lamp with ABS etched on the lens

(available from major trailer parts suppliers).

To

4003569a

Figure

ensure correct lamp operation, use an incandescent -type

DOT- approved lamp or an LED with integral load resistor.

If

11

you are using the industry- standard connector cable and do

not have access to the mating trailer harness, mask the open

5.

connector to protect it from paint or grease.

Plug the power 8 -pin connector on the power or power/

diagnostic cable into the ECU /dual modulator valve assembly.

6.

10.

Pull the hinged power/diagnostic connector retainer clip on the

ECU /dual

For industry- standard connector cables: Attach the power

modulator valve assembly DOWN to secure the

connection.

7.

Connect the power. Use the industry- standard connector cable

or a blunt -cut power cable.

If you

cable to the harness on the trailer.

are installing the power cable only, go to Step 9.

For an optional blunt -cut power cable: Wire the cable and

ABS indicator lamp to the seven -way connector on the trailer

according to the following diagram. Figure 12.

GENERIC INPUT /OUTPUT (EXPANDED CAPABILITY)

WHITE AND YELLOW

WHITE

WHT

4 OR 5 WIRE

BLK

SCHEMATIC

7

WAY

o

BLU

o

BRN

o

GRN

L

RO

(GROUND)

o'

1

BLUE

(CONSTANT POWER)

:#1

RED

(STOP LAMP)

GREEN AND WHITE

(

1

r77

GROUND

C

TRAILER ABS

INDICATOR LAMP

ECU POWER CONNECTOR

Junction box not shown.

4003570a

Figure 12

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Typical Easy- StopTM Trailer ABS Installations

Refer to Figure 13 through Figure 19 for typical Easy- StopTM trailer ABS installations.

Mentor WABCO recommends placing sensors on the axle that will provide the most braking performance. The suspension manufacturer can

provide this information.

== ==j

YE

2S /2M VALVE MOUNTED WITH SENSORS

FACING FRONT OFTRAILER

SIDE -TO -SIDE CONTROL

-

I

4. TRAILER

FRONT OF

W

- -,

!Ì

YE

o

.

BU1

NOTE: Spring brake

lines not shown.

rTh

fTk-

1

------

I

I

,

==

¡_ ==

=_=

==

BU7

-----J

M. WO

l

2S /2M VALVE MOUNTED WITH SENSORS

FACING REAR OFTRAILER

SIDE -TO -SIDE CONTROL

-

aut

411.

FRONT OF

TRAILER

114--

- - - - -__

-__-_-_-_-_-_-_-_--_-_-_-_-_

_____________ -I

I:6I

-d

W

I

1

I

I

II

euB

o

ri' iir

BU1

o

IÌ

ii

YE1

II

YE2

I

----------------------------------I

1

131

===

C-=

r--- _`

__-

NOTE: Spring brake

1

lines not shown.

YE1

SERVICE /CONTROL LINES

-- - - -

SENSOR CABLES

SERVICE BRAKE

SUPPLY AIR

40035543

Figure 13

TP

-20214

Revised 10

Page 8

-05

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Meritor WABCO recommends placing sensors on the axle that will provide the most braking performance. The suspension manufacturer can

provide this information.

4S /2M VALVE MOUNTED WITH SENSORS FACING FRONT OFTRAILER

I___

YE1

I

y

- SIDE -TO -SIDE CONTROL

lllllllllll

/11111/11

YE2

..

f

FRONT OF

TRAILER

Ii'r

Typical Tandem Axle Trailer

o

rlñ

¡-

---------- -----

1

=.=

=7_3 ==

BU1

;

NOTE: Spring brake

BU2

'

lines not shown.

1

4S /2M VALVE MOUNTED WITH SENSORS FACING REAR OFTRAILER

- SIDE -TO-SIDE CONTROL

7- = =

r---

_-

BU1

I]

BU2

4

t

C

Typical Tandem Axle Trailer

4.

FRONT OF

TRAILER

BU2

Ij

BU1

O

YE1

NOTE: Spring brake

S'itirOr

700-

lines not shown.

YE2

fTP-

l--

SERVICE /CONTROL LINES

-----

SENSOR CABLES

YE1

SERVICE BRAKE

SUPPLY AIR

L__

==

__=_

YE2 ÍJ.LI.L1.Ll.0

4003555a

Figure 14

TP

(16579/22882)

Printed in USA

-20214

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Mentor WABCO recommends placing sensors on the axle that will provide the most braking performance. The suspension manufacturer can

provide this information.

-

4S /2MTYPICALTRI -AXLE

VALVE MOUNTED WITH SENSORS

FACING FRONT OFTRAILER

SIDE -TO -SIDE CONTROL

=:_=

=-=

-

=__=

L_

-=

L_

YE2

YE1

FRONT OF

TRAILER

r

------r

I

I

)

-..

--ri

O

9F.

4411.

--

__

nnnu

C

I

II

YE2

..

NOTE: Spring brake

YE1

lines not shown.

o

But

;71}

BU2

'

II

1-,

DIY

BU1

---------------

J4

D:W

C1=03

)

===

L

Anta

'

_C

L _J

_

-

4S /2MTYPICALTRI -AXLE

VALVE MOUNTED WITH SENSORS

FACING REAR OFTRAILER

SIDE -TO -SIDE CONTROL

-=

C==J

L_ -

=0;0

77=

C===

C

C;=)

BU2

BU1

D:W

tI

I.

I

+.....

Dt

I-

FRONT OF

TRAILER

)

J, r---

r

--------I

III

NOTE: Spring brake

lines not shown.

BU2

o

BU7

'«I[

SERVICE /CONTROL LINES

YE1

YE2

-- ---

SENSOR CABLES

SERVICE BRAKE

SUPPLY AIR

JJL----1

I

CCFYE1

__

L__J

J

C=á-=

L_

E6-

L _J

4003556a

Figure 15

TP -20214

(16579/22882)

Revised 10 -05

Page 10

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Meritor WABCO recommends placing sensors on the axle that will provide the most braking performance. The suspension manufacturer can

provide this information.

-

4S /2M TYPICAL AXLE CONTROL INSTALLATION

VALVE MOUNTED

WITH SENSORS FACING FRONT OFTRAILER

--

L

L_.____J

=1;13

BU1

111/

L_

IIIIIIIII

.._

VE7

FRONT

YE2

o

o

NOTE: Spring brake

lines not shown.

1=6-

TIPYE2

MUMS

®82 I

C

=_ _

)

-

4S /2M TYPICAL AXLE CONTROL INSTALLATION

VALVE MOUNTED

WITH SENSORS FACING REAR OFTRAILER

CT=

)

IIUIIIII

BU1

YE1

Q.

s

'

LJ.I

BU2

ION

FRONT

.i'nr

o

o

NOTE: Spring brake

lines not shown.

YE2

1--

i

SERVICE /CONTROL LINES

SENSOR CABLES

BU2

SERVICE BRAKE

YE2

Iluunl

SUPPLY AIR

L____J

4002773a

Figure 16

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

NOTE: For Enhanced Easy- StopTM 4S /3M

lift axle installations,

you must use TOOLBOXTM Software, version 4.6 or higher, to enable the

lift axle function. It is not automatically enabled. Refer to Enabling the Lift Axle Function (4S /3M Installations) in the Appendix for instructions.

Meritor WABCO recommends placing sensors on the axle that will provide the most braking performance. The suspension manufacturer can

provide this information.

4S

==

L__=J

I

I'

Q

1

)

Q

I----

I

.

I

y

===

YE1

YEI

FRONT OF

TRAILER

-

-AXLE WITH FRONT LIFT

VALVE MOUNTED

WITH SENSORS FACING FRONT OFTRAILER

I

YE2

YE1

o

'r""

o

',c1,f:

BU1

Ll

BU2

ee

--------------

I

BU2

-

NOTE: Spring brake

BUi

Le__J

1--,

lines not shown

77_

C==C

J

-

4S /3MTYPICALTRI -AXLE WITH FRONT LIFT

VALVE MOUNTED

WITH SENSORS FACING REAR OFTRAILER

==

=PPP=

=L.=

:=

C

__

=

BU2

BU1

4

sr

4.

- -I

FRONT OF

TRAILER

==-7

-

r

+....

1--------s--------7 i

I

L

1

W

SERVICE /CONTROL LINES

I

o

- 1711

I

t,,i

- - - --

SENSOR CABLES

I

l

,_,

BU2

BU1

SERVICE BRAKE

SUPPLY AIR

rl

YE1

I

Á1

YE2

NOTE: Spring brake

l

lines not shown.

1

_J

r- 1g

YEI

1

=

===

LLF

YEl

lllll 1111

C=_

r

C--=

4003557a

Figure 17

TP -20214

Revised 10 -05

Page 12

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Meritor WABCO recommends placing sensors on the axle that will provide the most braking performance. The suspension manufacturer can

provide this information.

4S /3MTYPICALTRI -AXLE

==

-- -

- VALVE MOUNTED WITH SENSORS FACING FRONT OFTRAILER

---

L---

L,--_

0=0:1

YE1 .....

YE2

V.4

S

FRONT OF

TRAILER

I

I

_

o

o

.

I

o

±

1=r1

4

-------- ¡- ------- I

1

NOTE: Spring brake

o

o

E2

o

YE1

SERVICE /CONTROL LINES

Typical Tandem

Axle Trailer

I

I

lines not shown.

.

---- -

But

BU2

SENSOR CABLES

SERVICE BRAKE

SUPPLY AIR

1

1

-1-----------------L

I10-

==

==

BU2

4S /3MTYPICALTRI -AXLE

Buz

-d-

S

40.

FRONT OF

TRAILER

I

BU1

.J

I

- VALVE MOUNTED WITH SENSORS FACING REAR OFTRAILER

==

7-7

r-

L____a._J

C®R=

G®

®

==

==

==

11111111111

¢Q

BUt

D?I

I

II

O

13

1

BU2

I

1,

o

r2

Typical Tandem

Axle Trailer

!IA

I IIII4J

I

o

nI

Il

YE1

LIT

Sf

.EI

L

YE2

Imo,

I

=rJ¡

.,1'

YJ

L_l.-

_

NOTE: Spring brake

lines not shown.

-

BU1

i

Em-

=:=

==

YE1

___J

4003558a

Figure 18

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Meritor WABCO recommends placing sensors on the axle that will provide the most braking performance. The suspension manufacturer can

provide this information.

-

4S /3M TYPICAL FOUR AXLE PULLTRAILER

VALVE MOUNTED

WITH SENSORS FACING FRONT OFTRAILER

=1C

=C

CIC C==C

C__C C=_C

111111111

YE2

--I

¢

S

114.

FRONT OF

TRAILER

T

i

1rI

1

1

I

NOTE: Spring brake

lines not shown.

la.

i

-

YE2

It

I

1

I

o

4

___

I

SERVICE /CONTROL LINES

- - - --

SENSOR CABLES

SERVICE BRAKE

SUPPLY AIR

81.12

II

I_ J

I

i1

.

Le __A__

E6Bata,

B US

=

T___D

IN. NO

L______)

-

4S /3M TYPICAL FOUR AXLE PULLTRAILER

VALVE MOUNTED

WITH SENSORS FACING REAR OF TRAILER

=_=

COI=

=== L.:7r=

=

C__

FRONT OF

TRAILER

BU7

¢

+

0,*

S?

11

la

o

`

I1>U$ID

BU2

II-I

ÌI

I

4

a

I

W

11

n

BUS

r

g

NOTE: Spring brake

lines not shown.

C

...

A1

BU7-

I.

Á

o

YrS

r

-- -I

l.F

I

1:3!

==

=C ==e7

YE2

YE1

C==C C==C

C==C C==C

¡¡

11

L__

4003559a

Figure 19

TP

-20214

Revised 10 -05

Page 14

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

End of Line Testing

I(

It Mentor WADCO

rr

installations. To run these tests, Meritor WABCO recommends you

use TOOLBOXTM Software.

ECU

own

Tresin ADS Dnaannstscs

gads, ÇanponereTesh NOON deb

Teak. ECU

End of line testing is required on all Enhanced Easy- StopTM

"i, ritSq A0I

tnte, euon

ro#.lrs

Marwiactue Date

TOOLBOXTM Software and general test procedures are included in

ECU Type

this bulletin.

Cabala,

45/111

Sed Mambo

Pact Wade.

446ICECCO1

Scene* Review.

If

you are using a Pro -Link, refer to the operating

manual for test instructions.

I

-

bream

Ecy

I

Voted

hS

),;r.,

B::.r

Voltages

'

AMITYY

you are testing an installation that has a power only cable,

temporarily install

a

t

YE2

(.

SWUM

Ivan

BONI

=^aÌ

-

FT-

EU1

7

I

1

r7"--

eU2

Saurian InfaacMìron

.

.1

¡1;,

]

109+2000

I

Curer* Mint

lci

Sera We:

p

Revs/Mb

495

I

World

13 G6i

rJ

I1

Meritor WABCO combination power /diagnostics

Menage Center'

"Y" style cable.

1.

,

II

YE1

13 G6;

Secondary

If

-

r

i

Wheel Sena

Kr

Fault.

Enhanced Easy- StopTM 2S /2M, 4S /2M and

4S /3M Premium Installation

End of Line

Testing Procedure with TOOLBOXTM

Software

i

Connect the diagnostic connector on the cable to the PC serial

port/SAE diagnostic interface (J1587/J1708 to RS232

interface).

-

'

.

4003560a

Figure 20

Refer to the Software Owner's Manual, TP- 99102, for

instructions for running TOOLBOXTM Software.

2.

Display the Trailer ABS Main Screen.

3.

Verify the power supply.

Check the Faults field on the Main Screen,

4.

NONE = No faults present, proceed with end of line test.

YES = Faults present, double -click on "YES" to bring up the

Apply 12 volts DC to the blue wire (constant). Check the

fault information screen.

screen for the correct voltage (9.5 to 14 volts). Constant

power voltage

is

Use the information in the

displayed in the PRIMARY field. Figure 20.

Repair Instructions field

to perform

the necessary repairs. Figure 21.

Apply 12 volts DC to the red wire (stoplight power). Check

the screen for the correct voltage (9.5 to 14 volts). Stoplight

power voltage

is

displayed

in the SECONDARY

field.

c

Figure 20.

The internal field is not applicable to this test.

t AAA

rda,...d,n

la]

lases

r

UI

trau:

IaillEMEINIEMIMH'KA1110

mII

11® ..,.... ......,o...

Rawl

J

j

twMro411oaY

llY..p.-'.V

rear awes C.i.': s.,+-:u..vr.y+t:,eUav *Weep d'.,a

Pula ea.a.ea.x.e

*NO to

^.lFJc.V..l.',(:

1

çlaors

I(

_f

Qw resh

1

+

Dirt

(

S.,.

I

eel

I

4003561a

Figure 21

TP

(16579/22882)

Printed in USA

-20214

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

End of Line Test with TOOLBOXTM Software

7.

Verify Correct Valve and Lamp Installation

To

verify valve and lamp installations with TOOLBOXTM Software:

1.

Apply 12 volts DC to the ABS.

2.

Apply air to the emergency line to fill the air tanks and release

Repeat this test for the Blue valve.

A.

Repeat Steps

B.

Select the Blue valve from the valve activation screen.

C.

Click on the Activate button to verify correct valve

1

-3.

installation (Blue).

D.

the spring brakes.

Check for correct air line installation. To accomplish this,

observe the slack adjusters.

3.

Apply air to the control line.

4.

At the Trailer Main Screen, click on Component Test, then

adjusters will move in and out as the ROADSIDE

select Valves/Lamp to display the Valve Activation Screen.

portion of the dual modulator valve cycles. If this does

The Yellow valve indicator will be highlighted. Figure 22.

not happen, the air lines are not correctly connected.

If

the ECU faces the FRONT of the trailer, the slack

Perform the necessary repairs.

: Valve Activation

the ECU faces the REAR of the trailer, the slack

Select Valve to Activate

adjusters will move

r.

portion of the dual modulator valve cycles.

r

r

r

Yellow

in

and out as the CURBSIDE

If

this does

not happen, the air lines are not correctly connected.

Skie

Actnate

Perform the necessary repairs.

(

Red

8.

AI Wives

r

Test Warning Lamp

,

If

111

--

For 4S /3M installations: Repeat this test for the red valve.

Red: The external relay valve designated RED (RD) is an axle

-

control valve.

Warning Lamp

lest

II

It is

It

controls brake chambers on one or two axles.

important that delivery lines from Port

2 are

plumbed as

shown on the installation drawings. The 4S/3M system is

Test Status

designed to be used with a variety of trailer configurations. Call

ArvinMeritor's Customer Service Center at 800 -535 -5560 for

additional information.

9.

40035620

Click on the Test button to activate the ABS indicator lamp

this

Figure 22

is

-

the lamp that is mounted on the side of the trailer. The

lamp will flash eight times, indicating lamp installation

is OK.

The Test Status box at the bottom of the menu will display the

5.

Click on the Activate button.

6.

Check for correct air line installation. To accomplish this,

status of this test. Figure 22.

10.

Click on Close to exit.

observe the slack adjusters.

Sensor Orientation Test

If

the ECU faces the FRONT of the trailer, the slack adjusters

will move in and out as the CURBSIDE portion of the dual

modulator valve cycles.

If

this does not happen, the air lines

are not correctly connected. Perform the necessary repairs.

If

the ECU faces the REAR of the trailer, the slack adjusters

This test is not for use on 4S/3M installations.

For 4S /3M

installations, use the standard Sensor Test.

To run the

standard test, select Sensor Test from the Components Test

Menu.

will move in and out as the ROADSIDE portion of the dual

The sensor orientation test must be performed as part of the end of

modulator valve cycles.

line testing procedure.

If

this does not happen, the air lines

are not correctly connected. Perform the necessary repairs.

The Test Status box at the bottom of the menu will display the

status of this test.

TP -20214

Revised 10 -05

Page 16

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Sensor Orientation Test Screen

01 ICS I1 Sensor

Before beginning this test, look at the ECU to see if the sensors face

Orientation Test

the front or rear of the trailer. TOOLBOXTM will ask for this

information to start the test (Step 5). To perform the sensor

orientation test:

Mlle 400

1.

Raise the sensed wheel ends off the ground.

2.

Apply air to the emergency line to fill the air tanks and release

X

...

Warning Message: This test demands that the wheels be spun in a

predetermined order and that the ECU mounting orientation is

entered by the operator. It is applicable to the following TCS2

configurations only:

2S/1M

25/2M

2S/2M

46/2M

500 101

500 104

500 102

500 103

400

400

400

400

Ut

0

0

0

500 103 0

1

the spring brakes so that the wheels can be rotated.

t

0

Sensors Facing

2

r

r Peer

Front

Sensors

3.

Apply 12 volts DC to the ABS.

4.

At the Trailer Main Menu, click on Component Test, then

Max RPM

But

B a

A wo

Bue

select Sensor Orientation Test to display the Sensor

YE1

Orientation Test screen. Figure 23.

-

OMB

When the Sensor Orientation Test screen first appears, the

Sensors Facing field will display the default

YE2

Front. This

4

will occur regardless of the actual sensor orientation of the

installation being tested.

S

!3

YE1

<7

YE2

<7

But

<7

BU2

E

J

E

E

E

<7

sign

Order

J

Close

4005514a

SP

Figure 24

J

sein outstation ism

Warning Message: This test demands that the wheels be spun in a

predetermined order and that the ECU mounting orientation is

entered by the operator. It is applicable to the following TCS2

configurations only

ICs 11

2S/1 M 400

2S/1M 400

2S/2M 400

2S/2M 400

4812M 400

1

500

500

500

500

500

NOTE: 2S/2M installations use YE1 and BU1 locations.

Sensors Facing

front

Rear

2

Vas_

Click on

6.

101 0

104 0

102 0

103 0

103 0

r

r

-

ml

¡YEi

BU1

_

frE2

YeI

Ye]

BU2

A

B

S

YE1

<7

BUt

F-7

BU2

t7

r

Front

(

rgp

'

3

NMI NIB

YE1

Bu1

Max RPM

YE1

BU2

A

B

S

YE2

BU1

Front or Rear in

the Sensors Facing field to select

411111113

assembly. Figure 24.

Order

p- E

r

rrr- pr

_ ÿ

E2

C Rear

Sensors

But

the mounting orientation of the ECU /dual modulator valve

.

I

WWI

__

4005459a

Refer to Figure 23 and Figure 24 for illustrations of the

ECU

Sensors Facing

2

Figure 23

I

as shown on the diagram...

1

4005458a

Click on

1

Order

......_oore

5.

x

r

YE2

sign

Intl Sensor orientation Test

Spin tire number

Max RPM

<7

begin the test. Figure 25.

-Sensor Orientation Test-

- Sensors

1

Start to

Figure 25

mounted with sensors facing forward and rear. The

correct mounting orientation must be selected prior to starting

the test (Step 5).

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 17

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

7.

4S /3M*

sensed wheel end at a rate of 1/2 revolution per second. This

Refer to the diagrams for specific sensor locations.

rate equals a wheel speed of approximately 4 mph (7 kph).

lift axle

installations, you must use TOOLBOXTM Software,

identification block on the screen for results. Sensor

version 4.6 or higher, to enable the lift axle function.

identification boxes are located in the bottom left portion of the

Axle Function (4S /3M Installations) in the Appendix for

Green background: Correct sensor location. Spin the next

instructions.

-

sensed wheel as indicated by the screen prompt.

If

you get a red

background, you must stop the test (click on stop), make the

necessary corrections and repeat Steps 3 through 6.

finish the Sensor Orientation Test, click on Stop, then on

To

Close.

9.

a

Connect curbside sensor at YE2.

Connect roadside sensor at BU1.

Connect roadside sensor at BU2.

tone ring has been installed and that the sensor is

necessary repairs and repeat the test.

If

2S/2M

-

the problem persists,

contact Meritor WABCO (800- 535 -5560). Sensor output

appears in the Sensors field located

in

Modulator Valve Assembly Mounted with

Sensors Facing Rear of Trailer

pushed all the way in against the tone ring. Perform the

the bottom right portion

Connect curbside sensor at BU1.

Connect roadside sensor at YE1.

4S/2M*

of the Sensor Orientation Test screen. Figure 24.

End of Line Testing without TOOLBOXTM

Software

Sensor Installation

1.

Connect curbside sensor at YE1.

ECU /Dual

Verify there is sensor output. If there is no sensor output, verify

that

not automatically enabled. Refer to Enabling the Lift

It is

Sensor Orientation Test screen. Figure 24.

Red background: Incorrect sensor location.

Sensor locations vary by type of installation.

For Enhanced Easy- StopTM 4S /3M

As each sensed wheel is rotated, check the color of the sensor

8.

-

Follow the screen prompts, starting with 1, to rotate each

Look at the sensor connectors on the ECU /dual modulator valve

Connect curbside front sensor at BU1.

Connect curbside rear sensor at BU2.

Connect roadside front sensor at YE1.

Connect roadside rear sensor at YE2.

-

assembly. Ensure that the connectors are routed to the correct

4S /3M*

wheel-end location, as follows:

Refer to the diagrams for specific sensor locations.

ECU /Dual

For Enhanced Easy- StopTM 4S /3M lift axle

Modulator Valve Assembly Mounted with

Sensors Facing Front of Trailer

Sensor locations vary by type of installation.

installations, you must use TOOLBOXTM Software,

version 4.6 or higher, to enable the lift axle function.

2S /2M

I

-

not automatically enabled. Refer to Enabling the Lift

It is

Axle Function (4S/3M Installations) in the Appendix for

Connect curbside sensor at YE1.

instructions.

-

Connect roadside sensor at BU1.

4S /2M*

Connect curbside front sensor at YE1.

Connect curbside rear sensor at YE2.

Connect roadside front sensor at BU1.

Connect roadside rear sensor at BU2.

Connect curbside sensor at BU1.

Connect curbside sensor at BU2.

Connect roadside sensor at YE1.

Connect roadside sensor at YE2.

* If the lift axle is sensed in 4S /2M and 4S /3M installations:

Sensors YE2 and BU2 must always be used on the lift axle to

avoid an unwanted ABS indicator lamp illumination.

2.

If

sensors are not correctly installed, perform the necessary

repairs.

TP -20214

Revised 10 -05

Page 18

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Air Line Installation

'

'

1.

2.

3.

For 4S /3M installations: Repeat this test for the red valve.

Ensure that all unused air ports are plugged and that the

Red: The external relay valve designated RED (RD) is an axle

exhaust port

control valve.

is

facing DOWN.

axles. It is

Look at the air line installation to verify that all air lines are

It

controls the brake chambers on one or two

important that delivery lines from Port

plumbed

2 are

as shown in Figure 17, Figure 18 and Figure 19. The

correctly installed.

4S/3M

system is designed to be used with a variety of trailer

If

the ECU /dual modulator valve assembly is mounted with

configurations. Call ArvinMeritor's Customer Service Center at

the sensors facing the FRONT of the trailer, the air lines for

800 -535 -5560 for additional information.

the three delivery ports located under the YE sensor

connectors must be routed to CURBSIDE; the air lines for

4.

If

the air lines are not correctly routed, perform the necessary

repairs.

the three delivery ports on the opposite side of the valve

must be routed to roadside. Figure 26.

If

the ECU /dual modulator valve assembly

is

mounted with

the sensors facing the REAR of the trailer, the air lines for

the three delivery ports located under the YE sensor

connectors must be routed to ROADSIDE; the air lines for

the three delivery ports on the opposite side of the valve

must be routed to curbside. Figure 27.

Perform End of Line Test

1.

Apply 12 volts DC power to the ABS.

2.

Listen for the ECU /dual modulator valve assembly to click four

times (six times for

3.

If the

indicator lamp comes on for three seconds then goes

out, this indicates

` ']

I[ó

l!

SENSORS FACING FRONT OFTRAILER

YE1

If

/i=I

L

O-O

CURBSIDE

the ABS indicator lamp comes on and stays on, check the

BU1

- ROADSIDE

BU2

`r/r

,1`=i'9''.,y_u

Il

YE

DELIVERY

correct installation. The end of line test is

sensor installation.

CURBSIDE ROADSIDE

YE2

a

complete.

ECU /DUAL MODULATOR VALVE MOUNTED WITH

CURBSIDE

a 4S/3M).

A.

Remove the power from the ABS and raise the sensed

wheels so they may be rotated.

B.

Apply emergency air to fill the air tanks and release the

spring brakes so that the wheels may be rotated.

PLUG ALL

UNUSED

PORTS

C.

Repeat Steps

D.

Rotate each sensed wheel

1

and 2.

-

one at a time

-

at a rate

of 1/2 revolution per second. This rate equals a wheel

BU

DELIVERY

ROADSIDE

speed of approximately 4 mph (7 kph).

4003564a

The ABS indicator lamp should now go out and stay out

Figure 26

indicating a correct installation. The end of line test is

complete.

I^

ECU /DUAL MODULATOR VALVE MOUTED WITH

SENSORS FACING REAR OFTRAILER

ROADSIDE

YE2

Cs

YE

DELIVERY

ROADSIDE

VA.

i

BU1

CURBSIDE

BU2

.419

iV

O

GLlt,-

L7

If

the ABS lamp does not go out, there is a sensor gap problem

or hardware fault. Adjust the sensor and, if necessary, perform

a

ROADSIDE CURBSIDE

YE1

4.

fault code check.

Sensor Gap Adjustment

Push the sensor into its holder until it contacts the tooth wheel.

At installation, there must be no gap between the sensor and the

tooth wheel.

PLUG ALL

UNUSED

PORTS

BU

DELIVERY

CURBSIDE

4003565a

Measure the AC voltage output. The value should be 0.2 volt AC

when the wheel

is

rotated at a rate of 1/2 revolution per second.

Perform any necessary repairs.

Repeat the end of line test. If the trailer lamp still does not go out, a

system fault exists. Perform a fault code check.

Figure 27

TP -20214

(16579/22882)

Printed in USA

Revised 10 -05

Copyright ArvinMeritor, Inc., 2005

Page 19

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Fault Code Check

Blink Code Chart

Use constant power activation to perform the following fault

Blink Code Problem Area

Action

14

Verify correct electrical

code check.

1.

Power Supply

Apply constant power to the ECU /dual modulator valve

installation.

assembly for more than one, but less than five seconds.

Check power supply.

2.

Remove the power.

3.

Reapply the power.

4,

Check the trailer ABS indicator lamp on the side of the trailer.

Perform necessary repairs.

15

ECU Failure

If code

16

Find the fault on the chart and perform the necessary repairs.

6.

After performing the necessary repairs, repeat the end of

continues, contact

Meritor WABCO for assistance.

The fault code will be displayed three times.

5.

Verify correct installation.

SAE

J1708 Failure

Internal failure, contact Meritor

WABCO.

17

SAE

J2497 Failure

line test.

Internal failure, contact Meritor

WABCO.

18

Generic I/O Failure

Blink Code Chart

Verify correct electrical

installation.

Blink Code

Problem Area

Action

3

Sensor BU1

Determine sensor location.

Check power supply.

Perform necessary repairs.

Check sensor installation.

4

Sensor YE1

Perform necessary repairs.

Trailer Identification

Determine sensor location.

After ensuring the Enhanced Easy- StopTM trailer ABS has been

Check sensor installation.

correctly installed, attach the ABS indicator label included with the

ECU

Perform necessary repairs.

5

Sensor BU2

/single modulator valve assembly to the trailer. Generally, this

will be applied near the ABS trailer indicator lamp. Figure 28. Refer

Determine sensor location.

to the vehicle specification sheet for the correct location.

Check sensor installation.

Perform necessary repairs.

6

Sensor YE2

NOTICE:

Determine sensor location.

If the ABS indicator lamp

comes on and stays on when you

apply the brakes to a moving vehicle,

the trailer ABS is not working properly.

The ABS must be serviced as soon as

possible upon completion of your trip to

ensure full anti -lock braking capability.

Check sensor installation.

Perform necessary repairs.

7

External ABS

Verify correct electrical

modulator valve

installation.

Check power supply.

7'P -95172

Perform necessary repairs.

9

10

11

Rev. 4/98

4005501a

Internal modulator

Verify correct installation.

failure, inlet

If

valve #2

Meritor WABCO for assistance.

NOTE:

Internal modulator

Verify correct installation.

supervisor know. Labels are available from Meritor WABCO. Ask for

failure, inlet

If

valve #1

Meritor WABCO for assistance.

Internal modulator

Verify correct installation.

failure, outlet

If code

valve

Meritor WABCO for assistance.

Figure 28

code continues, contact

If

this label is not included with the assembly, let your

part number TP- 95172.

code continues, contact

For additional assistance, contact Meritor WABCO at

800 -535 -5560.

continues, contact

TP -20214

Revised 10 -05

Page 20

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Appendix

Enabling the Lift Axle Function (4S /3M

Installations)

To

InJnECU BeYV Comma Tests

MaMy

1_4(iN IA

I1yric.l 41

`

ECU Information

enable the lift axle function, you will need a PC with TOOLBOXTM

Software, version 4.6 or higher, installed. Refer to the TOOLBOXTM

User's manual for complete operating instructions. This manual

l

4U Type

IT aller TCS II

Configuration

14S

Part Nimber

(4465001030

/3M

04

Hai,

23/2D41

Serial Number

110027453

Software Revision

ledcb

I

jtl

Faaa- -0,MRAA'

{

--

Manulacture Date

is

posted on our website at meritorwabco.com.

1.

_sow

lat1eMbwurn rime. MSDleQ,elta

mrv

Display the Trailer ABS Main Screen. Click on Modify to

SIOrM

UI Sole Stalin

Not

Baia

'

display the pull down menu. Figure A -1.

I

2.

Lift Axle,

Click on

1

ÍIIIII

I

INemel

default status and activate the lift axle function,

To change the

Cbcf9,

s«ea

I

display the default lift axle status Not Active. Figure A -2.

3.

q

PVm

The default lift axle screen will appear and

Message Center:

click on Change. The Litt Axle Status will change to Active.

Figure A -3.

...

4.

Click on Close to close the screen. Exit TOOLBOXTM.

5.

Remove power from the vehicle; then reapply power.

6.

Follow Steps 2 and

3

4005428a

Figure

Matt., wean inSet MS O.aqtwtin

Data CuaarreelTeRS tally ,W

1,

the lift axle function does not indicate active status, verify

to receive a not active status message, contact the

:I iala1 fi)411 Ì`'13,`'

+

ECU

TOOLBOXTM version 4.6 or higher is installed. If you continue

Morse/Ion

ECU Type

I

Trailer TCS

¡

Disconnect TOOLBOXTM from the vehicle and proceed with

Part Nu

()i Lift Axle

Faults

end of line testing as described in this bulletin.

Lift Axle Status

i_

Component Tests , Mealy

'OBI

p¡~I

(1#i

.V44

Part

Nurier

Feuke

Existing

Stored

TediMatio°n

r

t'r'

II

I

Software Revision

Voltages

-

Il

lAclive

I'y'rl

J

owe

Secondary

loll

Service Miles

io

Internal

113.5

Revs/Mile

1502.0

L.,r

.

Message Center.

R 2001

r

4465001030

Yes

"'"

War>tLOCatbn/OEM

4013M

23/2001

san.ae_

Primary

q

Notebook

'Trailer TCS

Configuation

Voltage

Help

Reconfigure

ECU Information

ECU Type

.mJ0J

Trailer ADS Diagnostics

Cagey

Manufactue Date

Edstiig

Stored

Tracer ECU

II

Confgu..

for assistance.

entreat WADLO

al215-1I

pboasECU

active, as illustrated in Figure A -3.

7.

A -2

to display the Lift Axle Status screen.

Verify the lift axle status display indicates the lift axle function is

If

.--

7453

ledcb

Wheel Sensor Speed (RPM

-

YEt

<7

BU1

<7

YE2

<7

BU2

<7

I

I{

_____40054293

Figure A -3

Service Information

Ilia

Primary

113.5

Current

Secondary

10.0

Service Mies

Internal

113.5

Revs/Mie

0.0

10

502.0

Message Center:

L

r

.

4005427a

Figure A -1

TP -20214

(16579/22882)

Printed in USA

Copyright ArvinMeritor, Inc., 2005

Revised 10-05

Page 21

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Installing Sensors on Non -ABS- Prepped

Axles

Sensor locations vary due to suspension type. Mentor WABCO

recommends placing the sensor on the axle that will provide the

most braking performance. Contact your suspension manufacturer

for further information.

1.

Apply a mineral oil -based grease that contains molydisulfide to

the sensor spring clip, the body of the sensor and the bore of

the sensor block. The grease must be anti -corrosive and

contain adhesive properties that will continuously endure

temperatures from

2.

-40° to 300 °F ( -40°

to 150 °C).

Figure

side, until the spring clip tabs are against the sensor holder.

5.

Push the sensor into the spring clip as far as possible.

Install the wheel hub carefully so that the tooth wheel pushes

against the sensor as the wheel bearings are adjusted. There

should be no gap between the sensor and the tooth wheel.

Use Mentor WABCO spring clips to ensure a correct fit.

3.

A -5

Push the spring clip into the sensor holder from the inboard

Push the spring clip into the sensor holder from the inboard

side until the spring clip tabs are against the sensor holder.

6.

Test the sensor output voltage. Use a volt/ohm meter to check

the output voltage of the sensors while rotating the wheel at

approximately 1/2 revolution per second. Minimum output

Push the sensor into the spring clip as far as possible.

must be 0.2 volt AC.

Figure A -4.

If

minimum output is less than 0.2 volt

AC, push the sensor toward the tooth wheel. Recheck the

sensor output.

Figure

4.

A

-4

Route the sensor cable toward the brake chamber, over the

brake spider or through the pre- stamped hole dedicated for

ABS sensors. Route to the back side of the axle. Secure the

cable to the axle between the brake spider and the suspension

brackets. Continue to route the sensor cable behind the spring

seats. Secure the cable to the axle one inch from the molded

sensor plug. Figure A -5.

Do not overtighten tie wraps on a cable. Overtightening can

damage the cable. Do not tie wrap the molded sensor plug.

The sensor extension cable must follow the brake hose to the

ECU /valve

assembly to allow for axle jounce and rebound.

Brake hose clips with a provision for the sensor extension cable

are recommended as opposed to tie wraps. Mentor WABCO

does not supply this part.

TP

-20214

Revised 10 -05

Page 22

(16579/22882)

Copyright ArvinMeritor, Inc., 2005

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

-

1~

1

DR!VETRAIN PLUS"

¢,THE

COMPLETE SYSTEM

ArvinMeritor,.

o

MERITOR WABCO

Mentor WABCO Vehicle Control Systems

2135 West Maple Road

Troy, MI 48084 -7121 USA

800-535-5560

meritorwabco.com

Information contained in this publication was in effect at the time the publication was approved for printing and is subject to

change without notice or liability. Mentor WABCO reserves the right to revise the information presented or to discontinue the

production of parts described at any time.

Copyright 2005

ArvinMeritor, Inc.

All Rights Reserved

TP -20214

Revised 10 -05

Printed in USA

(16579/22882)

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor