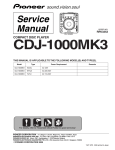

Download 1 - Madman Production

Transcript