Download RSC-1650LS LSH Service Manual

Transcript

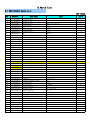

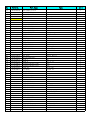

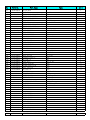

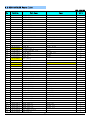

ROLL LAMINATOR Service Manual www.royalsovereign.com Table of Contents 1. Safety Precautions 2. Troubleshooting ……………………………………………………………………… …………………………………………………………………………… 2 ~ 2 3 ~ 7 2.1) Rollers Not Heating ……………………………………………………………………………… 3 ~ 4 2.2) Rollers Over Heating ………………...…………………………………………………………… 4 ~ 5 2.3) Rollers Not Running ……………….……………………………………………………………… 5 ~ 6 2.4) No Main Power ……………………..……………………………………………………………… 6 ~ 7 3. Replacing Parts ……………………………………………………………………………… 8 ~ 11 3.1) Right Cover ………………………………………………………………………………………… 8 ~ 3.2) Left Cover ………………………………………………………………………………………… 9 ~ 9 3.3) Rear Cover ………………………………………………………………………………………… 9 ~ 9 3.4) Main PCB …………………………………………………………………………………………… 9 ~ 10 3.5) Sub PCB ……………………………………………………………………………………………… 10 ~ 10 3.6) Heaters ……………………………………………………………………………………………… 10 ~ 11 3.7) Cross Cutter ………………………………………………………………………………………… 11 ~ 11 4. Adjustments …………………………………………………………………………………… 4.1) Adjusting Take-Up Shaft Speed 4.2) Adjusting Front Roller 9 12 ~ 12 ……….………………………………………………………… 12 ~ 12 …………………………………………………………………………… 12 ~ 12 5. Installation of Options ……………………………………………...…………………… 6. Parts List ………………………………………………………………………………………… 13 ~ 13 14 ~ 20 6.1) RSC-1650LS Parts List ……………………………………………………………………………… 14 ~ 16 6.2) RSC-1650LSH Parts List …………………………………………………………………………… 17 ~ 20 7. Exploded Drawings ……………………………………………………………………… 21 ~ 33 7.1) RSC-1650CF Whole Exploding Drawing and Part Exploding Drawing …………………… 22 ~ 27 7.2) RSC-1650HF Whole Exploding Drawing and Part Exploding Drawing …………………… 28 ~ 33 8. Wire Diagram ………………………………………………………………………………… 34 ~ 39 1. Safety Precautions Failure to comply any of the following safety procedures could result in serious injury. Please read the instructions carefully and keep for future reference. 1. Only a licensed electrician should install wiring and outlet for the laminator. 2. Ensure the unit is plugged into a properly grounded outlet with the correct 3 ~ 7 voltage. 3. Keep hands and clothing (ie.Neckties) away from the rollers. The rollers have pinch points that can trap body parts or clothing and cause serious injury. Safety Precaution 4. Keep flammable and wet objects away from the machine. 5. Place machine on a level surface. 6. Avoid excessive sunlight, humidity and extreme temperatures. 7. Ensure the unit is turned off, cooled, and unplugged from the outlet prior to moving and/or repairing. 9 ~ 10 8. Keep out of reach of children. 9. Only Royal Sovereign authorized maintenance and service technicians 10 should ~ 11 make repairs. 11 ~ 11 10. Do not attempt to laminate items that exceed total recommended material thickness for the unit. 12 ~ 12 11. When cleaning the machine, don't use flammable sprays or materials. 12 ~ 12 12. Do not touch the rollers when they are hot or place foreign objects inside the 12 ~ 12 machine. 13. Do not cover the surface of the machine until the machine has completely cooled. 13 ~ 13 14 ~ 21 14 ~ 17 18 ~ 21 22 ~ 36 2 2. Troubleshooting 2.1 Rollers Not Heating (RSC-1650LSH Only) CAUSES 1. Disconnected Heater Wire. 2. Defective T/Fuse. 3. Defective Bi-metal. 4. Defective Heater Assembly. 5. Defective Main PCB. MEASURES NOTE: Below steps require you to disassemble the Right, Left, and/or Rear Covers. (Refer to the "Replacing Parts" section) Follow the below steps in order. 1. Disconnected Heater Wire. a) Check to make sure that the heater wire is connect to the Main PCB. Figure 1 Heater Wires Figure 1 2. Defective T/Fuse. a) Use the multi-tester to check the continuity on the "Wire-T/Fuse". If it fails replace the Wire-T/Fuse. Figure 2 WIRE-T/FUSE 23 ~ 29 30 ~ 36 37 ~ 42 Figure 2 3 3. The Bi-metal is defective. a) Use the multi-tester to test the continuity on the "Bi-Metal". If it fails replace it with a new one. Figure 3 Bi-metal Figure 3 4. The heater in the roller is defective. a) Use a multi-tester to test the continuity on the "Heater Assembly". If it fails replace the Heater Assembly. Figure 4 HEATER Figure 4 5. Main PCB is defective a) Replace Main PCB. 2.2) Rollers Over Heating (RSC-1650LSH Only) CAUSES 1. The temperature sensor wire is improperly connected to the SUB-PCB. 2. Defective Heater Assembly 3. Main PCB is defective MEASURES 1. If the temperature sensor wire is improperly connected to the SUB-PCB. a) Unplug the temperature sensor wire and reconnect it properly. Figure 1 WIRE SENSOR Figure 1 4 2. Defective Heater Assembly a) Replace the broken Heater Assembly. Figure 2 Figure 2 Broken 3. Main PCB is defective a) Replace Main PCB. 2.3) Rollers Not Running CAUSES 1. Emergency Switches are Active. 2. Pressure Plate is not in Proper Position. 3. Film is Jammed on the Rollers. 4. Main Motor Wires are Disconnected. 5. Defective Main PCB. 6. Defective Main Motor. MEASURES 1. Emergency Switch is (are) Active. a) Deactivate front and rear emergency switches. 2. Pressure Plate is not in Proper Position. a) Ensure that the Pressure Plate is in the proper position and the Pressure Plate switch is active. Figure 1 Pressure Plate Switch Figure 1 3. Film is Jammed on the Rollers. a) Carefully un-jam the film from the rollers. 5 4. Main Motor Wires are Disconnected. a) Ensure that the wire is connected properly. Figure 2 Motor wire connector from the PCB Motor wire connector from the Motor Figure 2 5. Defective Main PCB. a) Replace the Main PCB. 6. Defective Main Motor. a) Replace the Main Motor. 2.4) No Main Power CAUSES 1. Main Power is Not Turned On. 2. No Power from the Outlet. 3. Defective Main Fuse. 4. Control Panel (Sub-PCB) Wire is Not Connected. 5. Disconnected Main Power Wire. 6. Defective Transformer. MEASURES 1. Main Power is Not Turned On. a) Turn on the power switch which is located on the rear left. 2. No Power from the Outlet. a) Ensure there is power on the outlet - check the circuit breaker. 3. Defective Main Fuse. a) Using Multi-Meter test the continuity of the Main Fuse. If it fails, replace it. Figure 1 Main Fuse Figure 1 6 4. Control Panel (Sub-PCB) Wire is Not Connected. a) Ensure that the control wires are connected to the Control Panel (Sub-PCB). 5. Disconnected Main Power Wire. a) Connect the Main Power wires. Figure 2 Main Power wires Figure 2 6. Defective Transformer. a) Replace the Transformer. Figure 3 Transformer Figure 3 7 3. Replacing Parts NOTE : Before replacing any parts, ensure that the machine is turned off and unplugged from the outlet. 3.1 Right Cover 1. Using Philips Screw Driver, loosen the screw on the Pressure Lever. Figure 1 Figure 1 2. Take out the four screws as shown in Figure 2. Figure 2 3. Disconnect the temperature sensor (RSC-1650LSH only) and control wires from the Sub-PCB. Figure 3 Figure 3 8 4. Take out two Sub-PCB screws. Figure 4 Figure 4 5) Repeat the steps in reverse to assemble the Right Cover. 3.2 Left Cover 1. Take out four screws on the Left Cover. 3.3 Rear Cover 1. Disassemble the Left and Right Covers. 2. Take out the side screws - one on each side. Figure 5 3. Loosen eight Rear Cover screws. Figure 5 Figure 5 3.4 Main PCB 1. Pull out all the connectors from the main PCB. Figure 6 Figure 6 9 2. Detach the main PCB from the 4 white plastic supporters. Figure 7 Figure 7 3.5 Sub PCB 1. Follow the same steps as in the "Replacing the Right Cover" section. 3.6 Heaters (RSC-1650LSH Only) 1. Take off the Left and Right Covers. 2. Using pliers (one to hold and one to loosen the nut) as shown in Figure 8, take out the two 5/16 (8mm) nuts on each side. Figure 8 3. Take out two screws and disassemble the upper heater bracket on each side. Figure 9 Figure 9 10 4. Carefully take out the heater from the roller. Figure 10 Figure 10 * When inserting the heater into the roller, rotate the heater slightly and the heater will enter the roller smoothly. 3.7 Cross Cutter 1. Disassemble the nut from the frame-cutter. 2. Unfasten the spring from the cutter . 3. Change the cutter-knob. 11 4. Adjustments 4.1 Adjusting Take-Up Shaft Speed CAUSES: 1. Main rollers and Take-Up Shaft speed is not synchronized. MEASURES: 1. Take out the Take-Up Shaft Cover by loosing three screws. Figure 1 2. Use a 11/16" (17mm) wrench to loosen (increases speed) or tighten (reduces speed) the bolt. Figure 2 Decrease Figure 1 Increase Figure 2 4.2 Adjusting Front Roller Clockwise Pressure • Use 5/16” or 8mm Allen wrench to adjust the roller pressure: Clockwise – Increase pressure. Counter Clockwise – Decrease pressure. (Figure 3) 1. Using Push-Pull Scale , measure 5 spots as shown on Figure 4 & 5: Front roller should read between 2-3 on the gauge Counterclock i Figure 3 2. Checking for over all tension – when the machine is running, check that the top and the bottom films are fed in without any wrinkles. Figure 4 3. Laminating Test – Laminate samples with different thickness of substrates. 4. Check above steps 2 through 3 with 1.5mil & 5mil films. Figure 5 12 5. Installation of Options Note: Below options are to be installed by an authorized RS reseller. Installation of the Front Feeder Option (Includes 2 brackets, one spindle, and mounting hardware). 1. Install the Front Feeder to the inside of the front frames using four 9/16” hexagon bolts on each side (Figure 1). 3 ~ 7 Figure 1 Installing the Rear Rewinder Option (Includes motorized winder, bracket, one spindle, and mounting hardware). 1. Remove the left and right covers by using a Phillips screwdriver (four screws on each side cover) (Figures 1 & 2). 9 ~ 10 Figure 1 Figure 2 2. Remove the lever knob screw and lever (Figure 3). Figure 3 3. Remove the rear cover by removing all 10 screws (4 top, 4 bottom, and 1 on each side) (Figure 4 & 5). Figure 4 Figure 5 4. Disassemble the power switch bracket and place the left rewinder (included in the option kit). Then, reinstall the power switch bracket (Figure 6). Figure 6 5. Install the right rewinder on the outside of the frame and connect the motor wire to the rear wire (Figures 7 & 8). 6. Reinstall the rear cover. 7. Reinstall the side covers. 8. Reinstall the lever knob and screw. 13 Figure 7 Figure 8 6.Parts List 6.1 RSC-1650LS Parts List RSC-1650LS No. Part No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 44-1 44-2 13500X005A 13500X006A WSB13038D2 212LR1012A BHE08015D2 212LR1011A WSB08016D2 BHE08065D2 365LR4004A 23300X008A 013LR2118A 34000S010A MBC04008D2 013LR3002Q WSB05013D2 MBC05018D2 350LR3038A 23200X001A 21000S029A 014LR1003B TFH04018D2 381LR4009A 122LR4008A 12200X043A 013LR2116D 122LR4100A 133LR2030A 120LR3035D 120LR4002B MFC04008D2 021LR3006A 140LR4037A 147LR4002A 12200X022A WPB15010D2 138LR4002A 032LR4020A SKE04010B6 SKE04015B6 12200X004A WPB05030H8 RIV05013E8 013LR2117D 380LR4001A 380CR4007A 380CR4004A Part Name Spec. CASTER-STAND1 CASTER-STAND2 WASHER-SPRING STAND-FRAME BOLT STAND-CENTER WASHER-SPRING BOLT SWITCH-FOOT ASS'Y CABLE GRAND FRAME-BASE POWER-TRANSFORMER SCREW-BH FRAME-CUTTER WASHER-SPRING SCREW-BH PCB-MAIN ASS'Y SUPPORT-BRACKET PCB MOTOR-MAIN TABLE-FRONT SCREW-FH WIRE-TAKE UP BUSH-ROLLER LAMI,LO DU-BUSH FRAME-FRONT BUSH-ROLLER,LAMI UP ROLLER-LAMI SHAFT-CAM SHAFT-TAKE UP SCREW-FH BRACKET-CLAMPER LEVER HOLDER-SHAFT,T PAD-TENSION BEARING-RADIAL WASHER-PLAIN SPRING-TENSION SHEET-PRESSURE SCREW-SET SCREW-SET DU BUSH WASHER-PLAIN BRINDER-RIVET FRAME-MIDDLE POWER-CORD EU POWER-CORD UK POWER-CORD CUL 2" 2" SWRH φ13.2*3.8T SPCC M8*15 SPCC SUS27 M8*65 SPCC AC220V-230V 50/60Hz M4*8 SUS27 AL6063 5.1*1.3T M5*18 SUS27 NYLON 36V 60W 75:1 AL6063 M4*18 S45C 40*35 SPCC S45C S45C S45C M4*8 SUS27 ABS S45C LEATHER NTB 15.5*18*1.0T Φ3.8 PC 0.3T M4*10 FZB M4*15 FZB 10*10 11.8*5*3T AL SPCC AC230 16A AC240V 13A AC125V 15A 14 Qt'y 2 2 4 2 8 1 12 7 1 2 1 1 22 1 26 2 1 4 1 1 16 1 2 4 1 2 2 1 1 8 1 1 1 4 2 2 1 1 1 1 1 1 1 1 1 1 No. Part No. 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 381LR4013B 381LR4020B 381LR4083A 381LR4008A 136LR4004D 013LR2111A 12200X032A 122LR4004A WSB04010D2 141LR2038A 141LR3041A 138LR4008A WPB06015D2 BHE06050D2 124LR4019A SKE05015B6 MPC03014D2 31300S006A 141LR4114A WSB03007D2 MBC03006D2 MBC05010D2 RC001500C8 36400X018A 021LR2001A 013LR2112A 131LR4005A 131CR4001A SKE06010B6 32500X0011 36600X001A WSB06015D2 BHE06020D2 131LR4004B RE001000C8 134LR4001A 141LR2039A 032LR3006A 021LR2003B 021LR2002B 112004001D MBC04018D2 SKE05010B6 125LR4003A 023LR4010A 350LR3039A 023LR3008A TPH03006B8 011LR2003A 23300X001A Part Name Spec. WIRE-POWER S/W,EU WIRE-FUSE,EU WIRE-EMER/MOTOR WIRE-MAIN CHAIN-ROLLER FRAME-L DU-BUSH BUSH-PLATE PRESSURE WASHER-SPRING PLATE-PRESSURE,L PLATE-PRESSURE,LAMI SPRING-PRESSURE WASHER-PLAIN BOLT ECCENTRIC-CAM SCREW-SET SCREW-PH SAFETY-SENSOR BRACKET-SENSOR WASHER-SPRING SCREW-BH SCREW-BH SNAP RING SWITCH-EMERGENCY COVER-L FRAME-R SPROCKET-ROLLER,LAMI SPROCKET,ROLLER,LEFT SCREW-SET FUSE-MAIN FUSE-BLOCK WASHER-SPRING BOLT SPROCKET-MOTOR E-RING PULLY-CHAIN PLATE-PRESSURE,R SHEET-FUNC COVER-TAKE UP,L COVER-R NUT SCREW-BH SCREW-SET LEVER-PRESSURE KNOB-LEVER PCB-SUB ASS'Y BUTTON-FUNC SCREW-TAP TITE PH COVER-REAR BUSHING-CORD,EU 64EA 35# SPCC 12*10 4.1*1.0T SPCC SPCC SWRH 6.5*15*1.5T M6*50 S45C M5*15 FZB M3*14 SECC 1.2T 3.1*0.7T M3*6 SUS27 M5*10 STW-15 WON IL ABS SPCC 4.5T S45C S45C M6*10 FZB AC250V 5A SUS27 S45C ETW-10 WON IL S45C SPCC PC 0.75T ABS ABS M6*1.25 SUS27 M4*18 SUS27 M5*10 S45C NYLON SILICON KE-9X1 M3*6 SUS27 AL6063 15 Qt'y 1 1 1 1 1 1 2 1 68 1 2 4 10 4 2 26 4 1 2 4 5 6 1 2 1 1 1 1 1 1 1 12 12 1 1 3 1 1 1 1 4 3 4 1 1 1 1 2 1 1 No. Part No. 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 36400X002B MBC04025D2 141LR4069A 021LR3008A 013LR3022A 147CR4003A MBC05030D2 141LR4070A 021LR3009A 013LR3023A 141LR4050A 051LR4007A 145LR3001A 023LR4002A 111LR4006A 141LR4113A 141LR4115A 140CR4001B 130CR4001B 122LR4006B RC000800C8 136LR4001H 032LR4008A 130CR4002A 147LR4009A 141LR4006A 125LR4001A 140LR4036A 120LR3004B 015LR3008B 12200X009A 143LR3001A WPB08016D2 147LR4019A 112004001C 141LR4009A 147LR4002A MBC04006D2 381LR4005A 138LR4012A 12200X003A 013LR3002B 140LR3003A 138LR4001A 213LR4001A MPC03006D2 023LR3003A NHB03024D2 SKE06006B6 381LR4032A Part Name Spec. SWITCH-MAIN SCREW-BH 2"FILM CORE SUPPORT PLATE 2"FILM CORE COVER 2"FILM CORE HOUSING SILICON RUBBER SCREW-BH 3'FILM CORE SUPPORT PLATE 3"FILM CORE COVER 3"FILM CORER HOUSING PLATE-BEARING LABEL-EMER2 GUIDE-DOCUMENT KNOB-BOLT GUIDE BOLT-GUIDE BRACKET-BASE PLATE-SENSOR HOLDER-TAKE UP 2 GEAR-MIDDLE BUSH-PULLY SNAP RING CHAIN SHEET-CUTTER SPROCKET-TAKE UP PAD-TAKE UP PLATE-SLIP HANDLE-TENSION HOLDER-SHAFT,FILM SHAFT FILM,LO BAR-IDLE,UP DU-BUSH SUPPORT-SHAFT,LO WASHER-PLAIN RUBBER-SPONGE NUT BRACKET-REAR COVER PAD-TENSION SCREW-BH WIRE-MOTOR SPRING-TENSION BEARING FRAME-CUTTER HOLDER-CUTTER,C SPRING-CROSS CUTTER-CROSS SCREW-PH KNOB-CUTTER,C NUT SCREW-SET WIRE-REMOTE(CUL) M4*25 SPCC ABS AL6063 SILICON M5*30 SUS27 SPCC ABS AL6063 SECC 2T ZWP5 ABS PHENOL BLK S45C EGI S45C Cu+Ni+Cr S45C S45C STW-8 WON IL #25 156E PC 0.18T S45C NBR SPCC 2.0T S45C S45C S45C S45C FLANGE 15*20 S45C 8.5*25*1.6T 36*36*2T M10*1.25 SEC 2.0T LEATHER 1.5T M4*6 SUS27 M3*6 SUS27 M6*6 Qt'y 1 36 12 12 6 12 36 12 12 6 2 2 2 2 2 2 2 1 1 3 1 1 1 1 1 1 2 2 2 2 2 2 1 1 1 4 2 8 1 1 2 1 1 1 1 1 1 1 1 1 16 145 025LR4001A CASE-REMOCON ASS'Y(CUL) 1 No. Part No. 146 350CR4001A Part Name Spec. PCB-REMOCON(CUL) Qt'y 1 17 6.2 RSC-1650LSH Parts List RSC-1650LSH No. Part No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 44-1 44-2 45 46 13500X005A 13500X006A WSB13038D2 212LR1012A BHE08015D2 212LR1011A WSB08016D2 BHE08065D2 365LR4004A 23300X008A 013LR2118A 34000S010A MBC04008D2 013LR3002Q WSB05013D2 MBC05018D2 350LR3038B 23200X001A 21000S029A 014LR1003B TFH04018D2 381LR4009A 122LR4008A 12200X043A 013LR2116D 122LR4100A 133LR2030A 120LR3035D 120LR4002B MFC04008D2 021LR3006A 140LR4037A 147LR4002A 12200X022A WPB15010D2 138LR4002A 032LR4020A SKE04010B6 SKE04015B6 12200X004A WPB05030H8 RIV05013E8 013LR2117D 380LR4001A 380CR4007A 380CR4004A 381LR4013B 381LR4020B Part Name Spec. CASTER-STAND1 CASTER-STAND2 WASHER-SPRING STAND-FRAME BOLT STAND-CENTER WASHER-SPRING BOLT SWITCH-FOOT ASS'Y CABLE GRAND FRAME-BASE POWER-TRANSFORMER SCREW-BH FRAME-CUTTER WASHER-SPRING SCREW-BH PCB-MAIN ASS'Y SUPPORT-BRACKET PCB MOTOR-MAIN TABLE-FRONT SCREW-FH WIRE-TAKEUP BUSH-ROLLER LAMI,LO DU-BUSH FRAME-FRONT BUSH-ROLLER,LAMI UP ROLLER-LAMI SHAFT-CAM SHAFT-TAKE UP SCREW-FH BRACKET-CLAMPER LEVER HOLDER-SHAFT,T PAD-TENSION BEARING-RADIAL WASHER-PLAIN SPRING-TENSION SHEET-PRESSURE SCREW-SET SCREW-SET DU BUSH WASHER-PLAIN BRINDER-RIVET FRAME-MIDDLE POWER-CORD EU POWER-CORD UK POWER-CORD CUL WIRE-POWER S/W,EU WIRE-FUSE,EU 2" 2" SWRH φ13.2*3.8T SPCC M8*15 SPCC SUS27 M8*65 SPCC AC220V-230V 50/60Hz M4*8 SUS27 AL6063 5.1*1.3T M5*18 SUS27 NYLON 36V 60W 75:1 AL6063 M4*18 S45C 40*35 SPCC S45C S45C S45C M4*8 SUS27 ABS S45C LEATHER NTB 15.5*18*1.0T Φ3.8 PC 0.3T M4*10 FZB M4*15 FZB 10*10 11.8*5*3T AL SPCC AC230 16A AC240V 13A AC125V 15A 17 Qt'y 2 2 4 2 8 1 12 7 1 2 1 1 22 1 26 2 1 4 1 1 16 1 2 4 1 2 1 1 1 8 1 1 1 4 2 2 1 1 1 1 1 1 1 1 1 1 1 1 No. Part No. 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 381LR4083A 381LR4008A 136LR4004D 013LR2111A 12200X032A 122LR4004A WSB04010D2 141LR2038A 141LR3041A 138LR4008A WPB06015D2 BHE06050D2 124LR4019A SKE05015B6 MPC03014D2 31300S006A 141LR4114A WSB03007D2 MBC03006D2 MBC05010D2 RC001500C8 36400X018A 021LR2001A 013LR2112A 131LR4005A 131CR4001A SKE06010B6 32500X0007 36600X001A WSB06015D2 BHE06020D2 131LR4004B RE001000C8 134LR4001A 141LR2039A 032LR3006A 021LR2003B 021LR2022A 112004001D MBC04018D2 SKE05010B6 125LR4003A 023LR4010A 350LR3044A 023LR3008A TPH03006B8 011LR2003A 23300X001A 36400X002B MBC04025D2 Part Name Spec. WIRE-EMER/MOTOR WIRE-MAIN CHAIN-ROLLER FRAME-L DU-BUSH BUSH-PLATE PRESSURE WASHER-SPRING PLATE-PRESSURE,L PLATE-PRESSURE,LAMI SPRING-PRESSURE WASHER-PLAIN BOLT ECCENTRIC-CAM SCREW-SET SCREW-PH SAFETY-SENSOR BRACKET-SENSOR WASHER-SPRING SCREW-BH SCREW-BH SNAP RING SWITCH-EMERGENCY COVER-L FRAME-R SPROCKET-ROLLER,LAMI SPROCKET,ROLLER,LEFT SCREW-SET FUSE-MAIN FUSE-BLOCK WASHER-SPRING BOLT SPROCKET-MOTOR E-RING PULLY-CHAIN PLATE-PRESSURE,R SHEET-FUNC COVER-TAKE UP,L COVER-R NUT SCREW-BH SCREW-SET LEVER-PRESSURE KNOB-LEVER PCB-SUB ASS'Y BUTTON-FUNC SCREW-TAP TITE PH COVER-REAR BUSHING-CORD,EU SWITCH-MAIN SCREW-BH 64EA 35# SPCC 12*10 4.1*1.0T SPCC SPCC SWRH 6.5*15*1.5T M6*50 S45C M5*15 FZB M3*14 SECC 1.2T 3.1*0.7T M3*6 SUS27 M5*10 STW-15 WON IL ABS SPCC 4.5T S45C S45C M6*10 FZB AC250V 15A SUS27 S45C ETW-10 WON IL S45C SPCC PC 0.75T ABS ABS M6*1.25 SUS27 M4*18 SUS27 M5*10 S45C NYLON SILICON KE-9X1 M3*6 SUS27 AL6063 M4*25 18 Qt'y 1 1 1 1 2 1 68 1 2 4 10 4 2 26 4 1 2 6 7 6 1 2 1 1 1 1 1 1 1 12 12 1 1 3 1 1 1 1 16 3 4 1 1 1 1 2 1 1 1 36 No. Part No. 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 141LR4069A 021LR3008A 013LR3022A 147CR4003A MBC05030D2 141LR4070A 021LR3009A 013LR3023A 141LR4050A 051LR4007A 145LR3001A 023LR4002A 111LR4006A 141LR4113A 141LR4115A 140CR4001B 130CR4001B 122LR4006B RC000800C8 136LR4001H 032LR4008A 130CR4002A 147LR4009A 141LR4006A 125LR4001A 140LR4036A 120LR3004B 015LR3008B 12200X009A 143LR3001A WPB08016D2 147LR4019A 112004001C 141LR4009A 147LR4002A MBC04006D2 381LR4005B 138LR4012A 12200X003A 013LR2012B 381LR4027B 021LR3003A 021LR3004A 223LR2003A 133LR2045A 142LR4001A WPB04008D2 138LR4014A WPB05008F8 141LR4011A Part Name Spec. 2"FILM CORE SUPPORT PLATE 2"FILM CORE COVER 2"FILM CORE HOUSING SILICON RUBBER SCREW-BH 3'FILM CORE SUPPORT PLATE 3"FILM CORE COVER 3"FILM CORER HOUSING PLATE-BEARING LABEL-EMER2 GUIDE-DOCUMENT KNOB-BOLT GUIDE BOLT-GUIDE BRACKET-BASE PLATE-SENSOR HOLDER-TAKE UP 2 GEAR-MIDDLE BUSH-PULLY SNAP RING CHAIN SHEET-CUTTER SPROCKET-TAKE UP PAD-TAKE UP PLATE-SLIP HANDLE-TENSION HOLDER-SHAFT,FILM SHAFT FILM,LO BAR-IDLE,UP DU-BUSH SUPPORT-SHAFT,LO WASHER-PLAIN RUBBER-SPONGE NUT BRACKET-REAR COVER PAD-TENSION SCREW-BH WIRE-MOTOR SPRING-TENSION BEARING FRAME-SENSOR SENSOR-ASS'Y CASE-SENSOR,UP CASE-SENSOR,LO HEATER-ASS'Y ROLLER-LAMI SPACE-HEATER,BKT WASHER-PLAIN SPRING-HEATER WASHER-PLAIN BRACKET-HEATER,STOPPER SPCC ABS AL6063 SILICON M5*30 SUS27 SPCC ABS AL6063 SECC 2T ZWP5 ABS PHENOL BLK S45C EGI S45C Cu+Ni+Cr S45C S45C STW-8 WON IL #25 156E PC 0.18T S45C NBR SPCC 2.0T S45C S45C S45C S45C FLANGE 15*20 S45C 8.5*25*1.6T 36*36*2T M10*1.25 SEC 2.0T LEATHER 1.5T M4*6 SUS27 19 Qt'y 12 12 6 12 36 12 12 6 2 2 2 2 2 2 2 1 1 3 1 1 1 1 1 1 2 2 2 2 2 2 1 1 1 4 2 8 1 1 2 1 1 1 1 1 1 4 4 4 8 2 No. Part No. 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 NHB05038F8 MBC04045D2 NHB05038D2 MFC04018D2 381LR4030A 381LR4036C 381LR4055A 013LR3002B 140LR3003A 138LR4001A 213LR4001A MPC03006D2 023LR3003A NHB03024D2 363LR4002A 141LR4056A SKE06006B6 381LR4032A 025LR4001A 350CR4001A Part Name Spec. NUT SCREW-BH NUT SCREW-FH WIRE-UP HEATER,EU WIRE--T FUSE UP WIRE-UP HEATER2,EU FRAME-CUTTER HOLDER-CUTTER,C SPRING-CROSS CUTTER-CROSS SCREW-PH KNOB-CUTTER,C NUT BI-METAL BRACKET-T/FUSE SCREW-SET WIRE-REMOTE(CUL) CASE-REMOCON ASS'Y(CUL) PCB-REMOCON(CUL) M4*45 M4*18 M3*6 SUS27 M6*6 20 Qt'y 2 4 2 4 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 6. Exploded View 6.1 RSC-1650LS Explored View Frame L Frame R Stand Part, Frame-Base Frame, Roller, Shaft,Front Table Wire and Film Shafts 6.2 RSC-1650LSH Explored View Frame L Frame R Stand Part, Frame-Base Frame, Roller, Shaft,Front Table Wire and Film Shafts 21 7.1 RSC-1650LS Explode View 22 Frame - L 23 Frame - R 24 Stand Part, Frame-Base 25 Frame, Roller, Shaft,Front Table 26 Wire and Film Shafts 27 7.2. RSC-1650LSH Exploded View 28 Frame - L 29 Frame - R 30 Stand Part, Frame-Base 31 Frame, Roller, Shaft,Front Table 32 Wire and Film Shafts 33 8. RSC-1650LS / LSH Wire Diagram RSC-1650LS Wire Diagram VCC_5V VCC_5V VCC_5V CARBON S/W SPEED_UP SW R104 10K RA101 10K x 10 SW2 U101 PIC16C72 MCLR/Vpp 1 TEMP_UP SW C106 3.3/50V SW4 HEATER PWM OUT TAK_UP RELAY REV RELAY TEMP_DOWN SW SW5 SW6 SW7 12 13 11 28 REV_SW 15 16 17 18 3 5 14 4 6 SPEED_UP SW SPEED_DOWN SW TEMP_UP SW TEMP_DOWN SW REV SW STOP SW RUN SW FOOT SW EM SW STOP_SW RUN_SW TEMP SENSOR 12v 2 RC1/T1OSI RC2/CCP1 RC0/T1OSO/T1CKI RB0/INT RB7 RB1 RB2 RB3 RB4 RB5 RC4/SDI/SDA RB6 RC5/SDO RA5/AN4/SS RC6 RC7 RA1/AN1 OSC1/CLKIN RA3/AN3/VREF RC3/SCK/SCLOSC2/CLKOUT RA2/AN2 RA4/TOCKI 21 22 23 24 25 26 27 7 SRCLK1 RCLK1 SER1 SRCLK2 RCLK2 SER2 BUZZER H/Display Com 9 R102 1M 3 6 5 QF1 8 7 10 9 QD1 12 11 QC1 14 13 QB1 16 15 QA1 18 17 20 19 XTAL101 8Mhz RA102 330R 10P 1 4 QE1 QG1 10 RA0/AN0 LA101 LDQ-N51G 2 QH1 VCC_5V VCC_5V SW6 SW7 REV SW 7 6 5 4 3 2 1 15 REV-RELAY T UP-RELAY PWM-OUT FOOT HEATER E/M QH SRCLR QH QG QF QE QD QC QB QA SER SRCLK RCLK 10 SER1 SRCLK1 RCLK1 14 11 12 G 13 REV 1 2 1N4007 Q2 C102M 1 Q3 C102M TAK_UP 1 VCC_5V CNN10 SMH025-05 STOP_SW CN10 SMW025-05 5 4 3 2 1 RUN_SW 5 4 3 2 1 REV STOP RUN B+_24V C7 104 FOOT_SW C10 104 C9 104 1K sensor _power VCC_5V R5 FOOT HS? HS-501 D4 FR105 + CN7 YW396-03V 1 2 3 EM BD2 DB105G - + VI B+_13V CN8 YW025-03 C12 104 1 2 3 1 VO 2 HS? HS-529 4 1N4148 3 R9 FUSE1 T 6.3AL 250V C4 1000/25V C5 470/16V C6 104 C101 104 C102 104 C103 104 330 3 R8 R10 680 4.7K CNN7 YH396-03V DC 1 2 3 DC? MOTOR DC - RY1A CH2-MD12F Q1 IRFP450A 220 PC817 R4 C11 104 D3 470 U3 U1 KA7805/1A 2 4 3 2 1 F&EM SW 100 PWM CN11 SMW025-04 4 3 2 1 B+_24V R7 Q4 A1271 G VO G E/M_SW R6 U4 KA7812/1A C8 104 VI CNN11 SMH025-04 B+_24V 12v B+_13V VCC_5V SW7 D2 1 2 sensor _power REMO-CON SW7 D1 1N4007 Q101 C102M BUZZER 1 2 REV STOP RUN 3 12 11 10 9 8 7 6 5 4 3 2 1 FF/REV Motor D5 1 SW5 MAIN-SUB F 2 1 D M 1 H C _ 2 Y R SENSOR 12 11 10 9 8 7 6 5 4 3 2 1 B+_13V F 2 1 D M 2 H C 1 Y R REV STOP RUN REV-RELAY T UP-RELAY PWM-OUT FOOT HEATER E/M C104 104 9 CN9 SMW250-12 CN101 SMAW250-12 R103 10K 2 VCC_5V 1 2 3 4 5 B+_13V U102 74LS595 3 CN102 SMW025-05 BZ1 BUZZER R101 330 C105 104 2 SPEED_DOWN SW SW3 3 SW1 FR105 ZD1 1W 15V CoolingFan AC 13 V AC 24 V POWER TRANSFORMER 1 2 3 4 5 6 1 2 3 1 2 3 CNN3 YH396-03 CN3 YW396-03AV CNN2 YH396-03 CN2 YW396-03AV 1 2 3 1 2 3 P/T INPUT SK1 104 120з B+_24V BD1 BR-106 - CN6 YW396-03V 傈盔钎扁 + 3 P/T OUTPUT VCC_5V B+_13V T-up Motor B+_24V 5 4 1 2 3 1 CN4 YW396-06 1 2 3 4 5 6 MOTOR AC CNN6 YH396-03V AC 1 2 3 2 CNN4 YH396-06 RY2A CH1-MD12F P/T OUTPUT C2 4700/50V C3 104 C1 100nF/275V MKP AC POWER S/W AC_in FUSE1 T 15A 250V CN1 BR-1103C02P 1 2 AC INPUT Title RSC-1650C schematic Size A2 Date: 34 Document Number <Doc> Tuesday, Apr il 26, 2005 Rev Sheet 1 of 1 V1.2 RSC-1650LSH Wire Diagram REV.-DATE REV.-DATE REV.-DATE REV.-DATE PART-NO PART-NO PART-NO DESCRIPTION DESCRIPTION DESCRIPTION DRA.BY DRA.BY DRA.BY DRA.BY MATERIAL MATERIAL MATERIAL 0 3rd GRADE MEDIUM DEFECT 2nd GRADE FATAL DEFECT 0 4th GRADE SLIGHTLY DEFECT IMPORTANCE OF QUALITY TOTAL 1st GRADE FATAL DEFECT ~ 6 7 ~ 30 31 ~ 120 121 ~ 300 35 DESCRIPTION-OF-REVISION DESCRIPTION-OF-REVISION DESCRIPTION-OF-REVISION DESCRIPTION-OF-REVISION 0.08 0.1 0.2 301 ~ 600 0.4 0.6 601 ~ 1200 0.8 IMPORTANCE OF QUALITY SCALE DRA-BY CH-BY APP-BY DRA-DATE CH-DATE APP-DATE Q'TYCOLOR/FINISH Q'TYCOLOR/FINISH Q'TYCOLOR/FINISH 6 CH.BY CH.BY CH.BY CH.BY APP.BY APP.BY APP.BY APP.BY REMARK REMARK REMARK T.I.Q 0 TOTAL RSC-1650H < RSC-1650LS MAIN PCB Layout > 1 2 3 4 6 5 7 8 <connect part> 1.WIRE MAIN :above photo① →connect SUB PCB①. 5.WIRE MOTOR : above photo5 →connect DC MOTOR. 2.WIRE REMOCON:above photo2 →connect REMOCON S/W. 6.above photo's 6/7/8 wire in POWER TRANSFORMER 3.WIRE EMER:above photo3 →connect FOOT&EMER S/W. 4.WIRE POWER : above photo4 →connect FRAME-L S/W MAIN 36 < RSC-1650LSH MAIN PCB Layout > 2 1 3 10 4 8 5 6 7 9 <connect part> 1.WIRE MAIN :above photo① →connect SUB PCB①. 5.WIRE POWER : above photo6 →connect FRAME-L S/W MAIN 2.WIRE REMOCON:above photo2 →connect REMOCON S/W. 6.WIRE TAKE UP : above photo6 →connect AC MOTOR. 3.WIRE EMER:above photo3 →connect FOOT&EMER S/W. 7.above photo's 7/8/9 wire in POWER TRANSFORMER 4.WIRE UP HEATER :above photo4 →connect with 10.WIRE MOTOR : above photo10 →connect DC MOTOR. FRAME-R HEATER UP BIMETAL, 37 <FRAME-R HEATER Layout> <SUB PCB> BIMETAL (100℃) A B 1 2 <connect part>( only RSC-1650LSH) <connect part> 1.WIRE-UP HEATER 2 : connect above photo"B" BIMETAL and HEATER. A. WIRE-SENSOR : connect temperature sensor 2.WIRE-LOW HEATER 2 : connect above photo" A" BIMETAL and HEATER. B.WIRE-MAIN : connect the main pcb 38 < FRAME-L HEATER Layout> T-FUSE A A <connect part> <connect part> A. WIRE T/FUSE, UP : connect with above photo A WIRE UP HEATER,Eu and HEATER.(only RSC-1650LSH) 39