Download I 1 - Artisan Technology Group

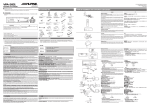

Transcript