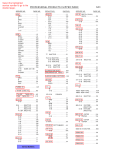

Download OPERATING INSTRUCTIONS

Transcript