Download DRYPIX 7000 SERVICE MANUAL REMOVAL AND ADJUSTMENT (MC)

Transcript

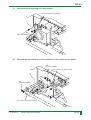

DRYPIX 7000 SERVICE MANUAL REMOVAL AND ADJUSTMENT (MC) MC-1 CONTROL SHEET Issue Date Revision Number Reason 10/15/2002 11/10/2002 00 01 New release (FM3343) Revised (FM3601) 04/01/2003 02 Revised (FM3978) 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual Pages Affected All pages 1, 3-11, 13-17, 20, 22, 23, 26, 27, 33-39, 44, 46-149 1, 10, 11, 15, 16, 22, 23, 28, 31, 35, 37, 44, 54-57, 60, 75-77, 90-94, 107-109, 118, 120, 135, 141-149 MC-1 MC-2 PRECAUTIONS ON INSPECTIONS, REPLACEMENTS, AND ADJUSTMENTS This chapter does not describe parts which require no special note or adjustments in removal and installation. For details on the removal of these parts, refer to the Parts List. Also follow the precautions below when performing inspections, replacements, and adjustments of parts. WARNING To prevent electrical shocks, be sure to turn OFF the power of this equipment before starting work. WARNING/CAUTION Observe the warnings and cautions described in “SAFETY PRECAUTION”. CAUTION Be sure to wear a wristband for grounding when performing maintenance of boards and optical units. Otherwise static electricity in the body may cause damage to electronic parts on the boards and optical units. CAUTION Never remove the screws painted in red. <INSTRUCTIONS> The screws painted in yellow must be adjusted after the installation of parts. When installing parts, follow the check/adjustment procedure provided. <NOTE> When removing the covers, insert shutter into the film tray to prevent exposure of film to light. 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-2 MC-3 The diagrams in this manual displays the CHECK and FIT ON icons where necessary. When removing/reinstalling, following these icons. • CHECK icon: CHECK • FIT ON icon: 006-259-01 11.10.2002 FM3601 When reinstalling removed parts, this is indicated if reinstalling positions must be checked or adjusted. This symbol is shown inside illustrations of parts removal procedures. Whenever this is shown, be sure to refer to "■ CHECK/ Adjusting procedure". When installing parts, this is indicated if alignment to the boss is required. DRYPIX 7000 Service Manual MC-3 MC-4 HOW TO READ REMOVAL AND ADJUSTMENT VOLUME The REMOVAL AND ADJUSTMENT (MC) Volume is constructed in such a way that it can be referred together with the SERVICE PARTS LIST (SP) Volume. The following describes how to refer to this REMOVAL AND ADJUSTMENT (MC) Volume. ■ Example (REMOVAL AND ADJUSTMENT Volume) Chapter No. 5 3 (1) Upper Conveyor Unit Exit Motor (MD2) Section. No. (2) FP7C0523.EPS ■ Removing Procedure (1) • (2) (3) Remove the following cover. Rear cover Remove the conveyor unit exit clutch (CLD1) Remove the exit conveyance motor (MD2). (3) #3 [Disconnect] Connector MD2 (3) #3 [Disconnect] Connector CLD1 (3) #3 [Release] Clamp (3) #4 [Disconnect] Clutch connector (3) #1 [Remove] 2-DT3x6 (3) #2 [Remove] Upper conveyor unit exit motor (MD2) (2) #1 [Remove] E5 (2) #2 [Pull out] Upper conveyor unit exit clutch (CLD1) FP7C0504.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 MC-58 FP7C0005.EPS (1) Chapter No. .. The Chapter No. in the REMOVAL AND ADJUSTMENT Volume is related to the INDEX No. of the SERVICE PARTS LIST Volume. (2) Section No. ... The Section No. in the REMOVAL AND ADJUSTMENT Volume indicates enclosed REF. No. (example 3 ) in the SERVICE PARTS LIST Volume (exploded view). For the above example, the item to be referred for “MC Conveyor Unit Exit Motor (MD2)” is “SP 05C 3 ”. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual 5 3 Upper MC-4 MC-5 ■ Example (SERVICE PARTS LIST Volume) (1) INDEX No. 05C E6 FP7Z0513.EPS 15 (2) REF. No. 3 2 16 2-BR3X8 1 4 E6 6 E4 E3 DT3X6 14 5 E6 8 6 13 10 E6 6 7 17 6 E6 9 DT3X6 10 3-BR3X10 11 18 12 FP7Z0503.EPS 006-259-01 11.10.2002 FM3600 SP-30 FP7C0006.EPS To refer to the service parts information on “MC (MD2)”, refer to “SP 05C 3 ”. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual 5 3 Upper Conveyor Unit Exit Motor MC-5 MC-6 CONTENTS 1. COVERS 1.1 Covers MC-10 2. FRAME 2.1 BCR Assembly MC-12 3. TRAY LOADING UNIT 3.1 Tray Loading Unit 3.2 Tray 3.3 Film Pack/Shutter Detection Sensor (SA11, SA21, SA31) 3.4 Tray Detection Switch (SA12, SA22, SA32) 3.5 Tray Lock Assembly 3.6 Tray Loading Unit Rail 3.7 Tray Rail 3.8 Squeezing Roller 3.9 Special Screw MC-14 MC-18 MC-22 MC-24 MC-25 MC-26 MC-30 MC-32 MC-34 FP7C0001.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-6 MC-7 4. REMOVAL UNIT 4.1 4.2 4.3 4.4 4.5 Removal Unit Removal Drive Cam Suction Cup Arm Suction Cup Bellows MC-36 MC-40 MC-44 MC-48 MC-50 5. CONVEYOR UNIT 5.1 5.2 5.3 5.4 Upper Conveyor Unit Film Positioning Motor (Lower) (MD6) Upper Conveyor Unit Exit Motor (MD2) Cleaning Roller Grip Release Motor (MD4) Film Positioning Assembly (Lower) Film Positioning Motor (Upper) (MD5) Film Positioning Assembly (Upper) Conveyor Unit Exit Guide Conveyance Driving Roller (Upper) Conveyance Driving Roller (Lower) Conveyor Unit Guide Grip Idle Gear Lower Conveyor Unit MC-52 MC-58 MC-60 Sub-Scanning Unit Sub-Scanning Motor (ME1) Sub-Scanning Roller Film Leading Edge Detection Sensor (SE1) MC-82 MC-92 MC-94 MC-98 5.5 5.6 5.7 5.8 5.9 5.10 5.11 5.12 5.13 6. SUB-SCANNING UNIT 6.1 6.2 6.3 6.4 MC-62 MC-64 MC-66 MC-68 MC-72 MC-74 MC-76 MC-78 MC-79 MC-80 FP7C0002.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-7 MC-8 7. SCANNING OPTICS UNIT 7.1 Scanner Unit MC-104 8. HEAT DEVELOPMENT UNIT 8.1 8.2 8.3 8.4 8.5 8.6 MC-110 MC-112 MC-114 MC-116 MC-118 MC-122 9. FILM RELEASE UNIT 9.1 Film Release Unit 9.2 Density Measurement Light-Emitting Board (LED15A) MC-124 MC-126 10. CONTROLLER 10.1 10.2 10.3 10.4 10.5 MC-128 MC-130 MC-132 MC-134 MC-135 Cooling Fan Assembly Filter Section Cooling Fan Film Cooling Section Heat Development Unit Heat Development Rack Assembly Heat Development Roller Operation Panel Controller Assembly HDD PC Board MCT Board FP7C0003.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-8 MC-9 11. SORTER 11.1 Film Conveyance Timing Belt 11.2 Jam Removing Guide Plate Magnet MC-136 MC-139 12. VERSION UPGRADE AND FULL INSTALLATION OF MAIN UNIT SOFTWARE 12.1 Preparations (Same for Version Upgrades and Full Installation) 12.2 Version Upgrade 12.3 Full Installation MC-140 13. BOARD SETTING AND LED LIGHTNG INFORMATION MC-141 MC-144 MC- FP7C0004.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-9 1 COVERS FP7Z0111.EPS 1 - 1 Covers FP7C0105.EPS ■ Removing Procedure (1) • • • • Remove the following covers. Jam clear cover Upper left side cover Upper right side cover Side ejection cover Upper left side cover 2-T4x12 Jam clear cover Operation panel fixing screw 2-T4x12 Upper right side cover Side ejection cover 2-T4x8 3-BR3x8 BR3x12 FP7C0100.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-10 MC-11 (2) • • • • • Remove the following covers. Film release unit cover Right side cover Left side cover Rear cover Lower front cover 8-T4x25 Film release unit cover Left side cover BR3x8 Rear cover 8-T4x16 Front cover 8-T4x16 8-BR3x8 Lower front cover Right side cover FP7C0101.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-11 2 FRAME FP7Z0211.EPS 2 - 1 BCR Assembly FP7C0201.EPS ■ Removing Procedure (1) (2) Remove the following cover. • Rear cover Remove the trays “3.2 Tray” 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-12 MC-13 (3) Remove the BCR assembly. BCR assembly #3 [Remove] 2-TP3x8 #2 [Release] Clamp #1 [Disconnect] Connector FP7B0541.EPS <REMARKS> Attaching position of the BCR 35 x 43 cm size BCR 26 x 36/20 x 25 cm size Shield plate Shield plate BCR FP7B0542.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-13 3 TRAY LOADING UNIT FP7Z0311.EPS 3 - 1 Tray Loading Unit FP7C0322.EPS <NOTE> The following describes the procedure for the upper tray loading unit. Perform the same procedure for the middle and lower tray loading units. Steps that differ between the three units are indicated separately. ■ Removing Procedure (1) (2) Remove the following covers. • Rear cover Remove the trays. “3.2 Tray” 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-14 MC-15 (3) Remove the tray inside cover. Tray inside cover [Remove] 4-TP4x8 FP7C0301.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-15 MC-16 (4) Remove the bracket. (5) Remove the tray loading unit. (5) #2 (5) #2 [Disconnect] Connector (5) #2 [Disconnect] SA12-COM Connector SA12-NC [Disconnect] Connector SOLA11 (5) #1 (5) #2 [Release] Clamp x 5 [Disconnect] Connector SA13 (4) #2 [Release] Clamp Bracket (4) #1 [Remove] 2-BR4x8 FP7C0302.EPS (5) #4 [Disconnect] Connector SA11 (5) #3 [Release] Clamp x 2 (5) #5 [Remove] 3-BR4x8 Tray loading unit Film pack/shutter detection sensor FP7C0303.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-16 MC-17 ■ Reinstalling Procedure Reinstall in the reverse order of removal. <INSTRUCTIONS> Bind the extra length of the cable so that it does not come out of the tray insertion portion. Clamp #1 [Bind] Cable FP7B0552.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-17 3 - 2 Tray FP7C0323.EPS ■ Removing Procedure (1) Remove the following cover. • Rear cover <NOTE> When pulling out the tray from the equipment, insert shutter in the tray to prevent exposure of film to light. 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-18 MC-19 (2) Remove the tray. #2 [Push slightly] Tray #1 [Release manually] Tray lock FP7B0506.EPS #3 [Push] Stopper #4 [Pull out] Tray #3 Tray [Push] Stopper FP7C0304.EPS 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-19 MC-20 CAUTION After removing the tray, return the rail back into the equipment as it will come in the way of the job and is also dangerous. #2 L R [Push] Rail (Left) #1 #3 #4 [Release] Latch [Release] Latch [Push] Rail (Right) FP7C0305.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. However, there is no need to pull out the rail pushed into the equipment. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-20 MC-21 BLANK PAGE 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-21 3 - 3 Film Pack/Shutter Detection Sensor (SA11, SA21, SA31) FP7C0324.EPS ■ Removing Procedure (1) Remove the tray. “3.2 Tray” (2) Remove the tray inside cover. Tray inside cover [Remove] 4-TP4x8 FP7C0301.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-22 MC-23 (3) Remove the film pack/shutter detection sensor (SA11, SA21, SA31). #2 [Disconnect] Connector SA11 #1 [Release] Clamp x 2 #3 [Remove] BR4x8 Film pack/shutter detection sensor FP7C0306.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. <INSTRUCTIONS> Bind the extra length of the cable so that it does not come out of the tray insertion portion. Clamp #1 [Bind] Cable FP7B0552.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-23 3.4 3 - 4 Tray Detection Switch (SA12, SA22, SA32) FP7C0325.EPS ■ Reinstalling Procedure <INSTRUCTIONS> Check that the connectors are connected at the correct positions. Tray lock switch SA12-NC SA12-COM FP7C0307.EPS Reinstall in the reverse order of removal. 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-24 3 - 5 Tray Lock Assembly FP7C0326.EPS ■ Removing Procedure (1) Remove the following cover. • Rear cover (2) Pull out the tray. (3) Remove the tray lock assembly. #3 #2 [Disconnect] Connector SOLA11 #2 [Remove] 2-BR4x8 [Disconnect] Connector SA13 #2 [Disconnect] Connector SA12-COM #1 [Release] Clamp #2 [Disconnect] Connector SA12-NC Tray lock assembly FP7C0308.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. Tray lock assembly Back side FP7C0309.EPS 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-25 3 - 6 Tray Loading Unit Rail FP7C0327.EPS ■ Removing Procedure (1) Remove the tray loading unit. (2) Remove the tray lock assembly. “3.5 Tray Lock Assembly” <NOTE> When removing the tray loading unit rail, while sliding the inner rail and inner slide rail, remove the screws. Outer rail Inner slide rail Inner rail Inner slide rail FP7C0320.EPS (3) Remove the tray loading unit rail. #1 #2 [Push to rear] Inner slide rail [Remove] 4-T4x4 #3 [Remove] 4-T4x4 Tray loading unit rail Auxiliary plate Tray loading unit rail #4 [Remove] 2-T4x4 FP7C0310.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-26 MC-27 ■ Reinstalling Procedure (1) While pressing the tip in front and behind the left rail of the tray loading unit against the aperture of the tray loading unit, secure the rail with the screws. #2 [Press] Rail Tray loading unit rail #4 #1 [Press] Rail [Temporarily tighten] 2-T4x4 #3 [Tighten] 2-T4x4 #1 [Temporarily tighten] 2-T4x4 aperture #5 [Tighten] 2-T4x4 aperture FP7C0311.EPS (2) Secure the auxiliary plate to the tray loading unit right rail using the screws. (3) Place the tip in front and behind the right rail of the tray loading unit on the aperture of the tray loading unit, tighten the rail temporarily with the screws. Auxiliary plate (3) [Temporarily tighten] 2-T4x4 Tray loading unit rail (right) (2) [Tighten] 2-T4x4 Aperture (3) [Temporarily tighten] 2-T4x4 Aperture FP7C0312.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-27 MC-28 (4) Push the protrusion in front and behind the auxiliary plate secured to the tray loading unit right rail against the part for attaching on the tray loading unit, and while pressing the rail against the aperture, tighten the temporarily tightened screws firmly. (4) #2 (4) #1 [Press] Rail [Push] Rail (4) #4 (4) #5 [Press] Rail [Push] Rail Auxiliary plate (4)#3 [Tighten] 2-T4x4 Tray loading unit rail (right) (4)#6 [Tighten] 2-T4x4 FP7C0334.EPS ■ CHECK/Adjusting Procedure • After reinstalling the tray loading unit rail, insert the tray into the tray loading unit, and check that it moves smoothly. • Apply bonding to the ten screws securing the tray loading unit rail. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-28 MC-29 BLANK PAGE 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-29 3 - 7 Tray Rail FP7C0328.EPS ■ Removing Procedure (1) Remove the tray. “3.2 Tray” (2) Remove the tray rail. #1 [Remove] 5-T4x4 Tray rail Tray rail CHECK #2 CHECK [Remove] 5-T4x4 FP7C0313.EPS 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-30 MC-31 ■ Reinstalling Procedure (1) Temporarily secure the tray rail to the tray. (2) While pressing the tray rail downwards, tighten the screws. (1) [Temporarily tighten] 5-T4x4 (2) #2 (2) #3 [Push against] Tray rail [Tighten] 5-T4x4 Tray rail (2) #1 [Press downwards] Tray rail FP7C0314.EPS ■ CHECK/Adjusting Procedure • After reinstalling the tray rail, insert the tray into the tray loading unit, and check that it moves smoothly. • Apply bonding to the ten screws securing the tray rail. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-31 3 - 8 Squeezing Roller FP7C0329.EPS ■ Removing Procedure (1) Remove the tray. “3.2 Tray” <NOTE> When removing the squeezing roller, be careful not to damage the bearing of the tray, (2) Remove the squeezing roller. #2 [Remove] Squeezing roller #1 [Pull] Bearing FP7C0315.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-32 MC-33 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-33 3 - 9 Special Screw FP7C0333.EPS ■ Removing Procedure (1) Remove the tray. “3.2 Tray” (2) Remove the upper rear cover of the tray. (3) Remove the special screws. Upper rear cover (3) [Remove] Special Screw (2) #1 [Remove] 3-Q4x6 FP7C0318.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-34 MC-35 ■ Reinstalling Procedure <INSTRUCTIONS> Attach the special screws so that only the ball bearing at the tip of the special screw protrudes from the tray surface. REMARKS> These special screws are producing the click sound when inserting shutters. Shutter Ball bearing Tray surface Special screw FP7C0319.EPS Reinstall in the reverse order of removal. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-35 4 REMOVAL UNIT FP7Z0411.EPS 4 - 1 Removal Unit FP7C0412.EPS ■ Removing Procedure (1) Remove the tray loading unit. “3.1 Tray Loading Unit” 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-36 MC-37 (2) Remove the shield cover. (3) Remove the removal unit. <NOTE> • Remove the screws (4-BR4x8) securing the removal unit while supporting the removal unit with the hand. • To remove the removal unit, slide it to the left until the pins dislocate from the frame, then tilt the removal unit to remove. Make sure that the removal unit does not touch the BCR assembly at this time. (3) #1 [Disconnect] Connecter CNB1 (3) #2 (3) #1 [Remove] 4-BR4x8 [Disconnect] Connecter MB11 (2) #2 [Remove] Shield cover Removal unit CHECK (2) #1 Pin Shield cover [Remove] BR3x8 FP7C0401.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-37 MC-38 ■ Reinstalling Procedure Reinstall in the reverse order of removal. ■ CHECK/Adjusting Procedure • When reinstalling the removal unit, insert the pins on the removal unit into the holes on the equipment. • Perform the following adjustment if the idle gear of the removal unit has been removed or if the idle gear has been loosened. (1) Secure the gear while pressing the flange of the idle gear against the gears in the arrow direction shown below. Upper removal unit Idle gear Upper conveyor unit Middle removal unit Middle conveyor unit Idle gear Lower removal unit Lower conveyor unit Idle gear FP7C0402.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-38 MC-39 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-39 4 - 2 Removal Drive Cam FP7C0413.EPS ■ Removing Procedure (1) Remove the removal unit. “4.1 Removal Unit” <NOTE> When performing the following procedure, move the suction cup arm assembly to the home position first. (2) Remove the gear fixing cover. (3) Remove the gear 1 and gear 2. (3) [Remove] Gear 1 Gear fixing cover (2) #1 [Release] Clamp (3) [Remove] Gear 2 Bearing (2) #1 [Release] Clamp (2) #3 [Remove] 4-DT3x6 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual (2) #2 [Remove] E6 FP7C0403.EPS MC-40 MC-41 (4) Remove the removal drive cam together with the crank. Crank Crank #1 [Remove] E3 #1 [Remove] E3 Removal drive cam Removal drive cam FP7C0404.EPS ■ Reinstalling Procedure <NOTE> When performing the following procedure, move the suction cup arm assembly to the home position first. (1) Reinstall the removal drive cam to the removal unit together with the crank. (2) Insert pins such as hexagonal wrench into the two holes on gear 1, and adjust the phase of the removal drive cam. (3) Reinstall gear 2. Gear 1 (3) [Reinstall] Gear 2 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual (2) #1 [Insert] Pin FP7C0405.EPS MC-41 MC-42 (4) Align the gear fixing cover to the attaching position, and pull out the pin. (5) Align the rib positions of gears 1 and 2. (5) #1 [Align] Rib Gear 2 Gear 1 Gear 1 Gear 2 (4) [Pull out] Pin Gear fixing cover (5) #2 [Reinstall] Bearing FP7C0406.EPS (6) Secure the gear fixing cover with the screws. (7) Secure the cable with the clamp. ■ CHECK/Adjusting Procedure After reinstalling the removal drive cam, check that the suction cup arm assembly moves smoothly. 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-42 MC-43 BLANK PAGE 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-43 4 - 3 Suction Cup Arm FP7C0414.EPS 4.3.1 Removal/Reinstallation ■ Removing Procedure (1) Remove the tray. “3.2 tray” (2) Remove the tray inside cover. Tray inside cover [Remove] 4-TP4x8 FP7C0301.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-44 MC-45 (3) Remove the suction cup arm. (3) #2 [Disconnect] Connector SB2 Suction cup arm (3) #1 [Release] Clamp (3) #3 [Remove] 4-BR3x8 FP7C0407.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-00 10.15.2002 FM3343 DRYPIX 7000 Service Manual MC-45 MC-46 4.3.2 Changing Film Size to 20 x 25 cm Perform the following procedure to change the film size of the current film tray (35 x 43 cm, 26 x 36 cm) to 20 x 25 cm size. (1) Remove the removal unit. “4.1 Removal Unit” (2) Remove the suction cup arm, and replace with the 20 x 25 cm size suction cup arm. #3 [Remove] suction cup arm #4 [Replace] 20 x 25 cm size suction cup arm #2 [Remove] 4-BR3x8 #5 [Secure] 4-BR3x8 Removal unit #1 [Disconnect] Connector #6 [Connect] Connector (3) FP7C0542.EPS Change the attaching position of the film release plate. #1 [Remove] 4-DT3x6 #3 [Secure] 4-DT3x6 For 20 x 25 cm size Mark #2 [Move] Film release plate x 2 FP7C0543.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-46 MC-47 (4) To change the film size from 35 x 43 cm to 20 x 25 cm, change the attaching position of the barcode reader. “2.1 BCR Assembly” 35 x 43 cm size BCR 26 x 36/20 x 25 cm size Shield plate Shield plate BCR FP7B0542.EPS (5) Reinstall the removed parts in the reversed order of the removing procedure. <REMARKS> The attaching position of the film release plate of the removal unit is marked with the respective film sizes. To return the film size from 20 x 25 cm to other sizes, refer to the following figure and change the attaching position of the film release plate. Not used For 20x25 cm size For 35x43, 26x36 cm sizes FP7C0544.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-47 4 - 4 Suction Cup FP7C0415.EPS ■ Removing Procedure (1) Remove the suction cup arm. “4.3 Suction Cup Arm” (2) Remove the suction cup. #2 [Remove] Suction cup #1 [Remove] Nozzle FP7C0408.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-48 MC-49 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-49 4 - 5 Bellows FP7C0416.EPS ■ Removing Procedure (1) Remove the suction cup arm. “4.3 Suction Cup Arm” <INSTRUCTIONS> Rotate the bellows in the tightened state to remove. (2) Remove the bellows. CHECK #3 #2 [Remove] Bellows [Pull out] Bellows #1 [Lower] Plate O ring Stopper FP7C0409.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-50 MC-51 ■ Reinstalling Procedure <INSTRUCTIONS> • If the bellows has been removed, be sure to replace the O ring. • To reinstall, insert the second groove on the top of the bellows into the plate. • To reinstall, leave a space of 1 mm between the bellows and stopper. 2nd groove Bellows Space of approx. 1 mm Stopper FP7C0410.EPS Reinstall in the reverse order of removal. ■ CHECK/Adjusting Procedure Check for air leakage as follows. (1) Push down the plate, and with an approximately 50 mm space between the plate and stopper, push the suction cup against the film. (2) Two minutes later, check that the space is still 50 mm. [Push down] Plate 50mm Stopper Film FP7C0411.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-51 5 CONVEYOR UNIT FP7Z0511.EPS 5 - 1 Upper Conveyor Unit FP7C0521.EPS ■ Removing Procedure (1) Insert the shutter into the film tray. (2) Remove the following covers. • Upper right side cover • Rear cover (3) Remove the cleaning roller. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-52 MC-53 (4) If the equipment mounts film tray 2, loosen the screws securing the idle gear of the middle conveyor unit. Upper removal unit Upper conveyor unit Middle removal unit #1 [Loosen] 2-BR3x6 Middle conveyor unit Lower removal unit Lower conveyor unit FP7C0540.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-53 MC-54 (5) Remove the sub-scanning unit fixing bracket. Sub-scanning unit fixing bracket [Remove] 4-BR4x8 FP7C0613.EPS (6) Reinstall the sub-scanning unit fixing bracket at the position shown below. [Tighten] 2-BR4x8 Sub-scanning unit fixing bracket FP7C0546.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-54 MC-55 (7) Remove the screws securing the sub-scanning unit. #1 [Remove] 2-BR4x8 Sub-scanning unit FP7C0535.EPS (8) Remove the upper conveyor unit removing jig. [Remove] BR4x8 Upper conveyor unit removing jig FP7C0533.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-55 MC-56 (9) Insert the upper conveyor unit removing jig below the sub-scanning unit. Turn the upper conveyor unit removing jig clockwise direction to lift the subscanning unit. Sub-scanning unit #2 [Lift] Sub-scanning unit #1 [Turn] Upper conveyor unit removing jig #3 [Insert] Pin FP7C0534.EPS (10) Remove the upper conveyor unit. #1 [Disconnect] Connector CND2 #1 [Disconnect] Connector CND1 #1 [Disconnect] Connector CND3 #1 [Disconnect] Connector CND4 #1 [Disconnect] Connector CND4 #1 [Disconnect] Connector MD4 #1 [Disconnect] Connector MD2 #1 [Disconnect] Connector CLD1 #3 [Remove] BR3x8 Upper conveyor unit #4 #2 #1 [Disconnect] [Release] Clamp Connector CND6 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual Shield cover #3 [Remove] BR3x8 [Remove] 5-BR4x8 FP7C0501.EPS MC-56 MC-57 ■ Reinstalling Procedure <INSTRUCTIONS> When reinstalling the upper conveyor unit, check that the pin on the upper conveyor unit is inserted into the groove of the sub-scanning unit rail. Sub-scanning unit rail Upper conveyor unit Pin FP7C0545.EPS Reinstall in the reverse order of removal. ■ CHECK/Adjusting Procedure Perform the following adjustment if the idle gear of the middle conveyor unit has been removed or if the idle gear has been loosened. (1) Secure the gear while pressing the flange of the idle gear against the gears in the arrow direction shown below. Upper removal unit Upper conveyor unit Middle removal unit Idle gear Middle conveyor unit FP7C0541.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-57 5 - 2 Film Positioning Motor (Lower) (MD6) FP7C0522.EPS ■ Removing Procedure (1) (2) Remove the following cover. • Right side cover Remove the film positioning motor (lower) (MD6). #2 [Disconnect] Connector MD6 #1 [Release] Clamp #3 [Remove] 2-DT3x6 Film positioning motor (lower) MD6 FP7C0502.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-58 MC-59 ■ Reinstalling Procedure <INSTRUCTIONS> Open the left and right positioning guides of the positioning guide assembly until they touch the sides when installing the film positioning motor (MD6). [Push] Positioning guide Positioning guide assembly Positioning guide [Push] Positioning guide FP7C0503.EPS Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-59 5 - 3 Upper Conveyor Unit Exit Motor (MD2) FP7C0523.EPS ■ Removing Procedure (1) Remove the following cover. • Rear cover (2) Remove the conveyor unit exit clutch (CLD1) (3) Remove the exit conveyance motor (MD2). (3) #3 [Disconnect] Connector MD2 (2) #3 [Disconnect] Connector CLD1 (3) #3 [Release] Clamp (3) #4 [Remove] Clutch connector (3) #1 [Remove] 2-DT3x6 (3) #2 [Remove] Upper conveyor unit exit motor (MD2) (2) #1 [Remove] E5 (2) #2 [Pull out] Upper conveyor unit exit clutch (CLD1) FP7C0504.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-60 MC-61 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-61 5 - Cleaning Roller Grip Release Motor (MD4) 4 FP7C0524.EPS ■ Removing Procedure (1) (2) Remove the following cover. • Rear cover Rotate the worm gear of the cleaning roller grip release motor (MD4) in the arrow direction shown in the figure with the hand so that it grips the cleaning roller. #1 [Rotate] Worm gear FP7C0539.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-62 MC-63 (3) Remove the cleaning roller grip release motor (MD4). <NOTE> Remove the one-way gear assembly making sure not to drop the bearing. Bearing One-way gear assembly Bearing CHECK #1 [Disconnect] Connector MD4 #2 [Remove] 2-DT3x6 Cleaning roller grip release motor (MD4) FP7C0505.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. ■ CHECK/Adjusting Procedure Reinstall the motor with the D cut side of the one-way gear assembly shaft facing up. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-63 5 - 5 Film Positioning Assembly (Lower) FP7C0525.EPS ■ Removing Procedure (1) Remove the upper conveyor unit. “5.1 Upper Conveyor Unit” (2) Remove the grip position detection sensor bracket. (3) Remove the connector bracket. (2) #2 [Disconnect] Connector SD3 (2) #1 [Remove] DT3x6 (2) #2 Grip position detection sensor bracket [Disconnect] Connector SD4 (3) #1 Connector bracket [Remove] BR3x8 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual FP7C0506.EPS MC-64 MC-65 (4) Remove the film positioning assembly (lower). Flange gear #1 [Remove] E6 #2 [Release] Clamp #3 [Disconnect] Connector MD6 Film positioning assembly (lower) #4 #3 [Remove] 3-DT3x6 [Disconnect] Connector SD7 FP7C0507.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-65 5 - 6 Film Positioning Motor (Upper) (MD5) FP7C0526.EPS ■ Removing Procedure (1) Remove the upper conveyor unit. “5.1 Upper Conveyor Unit” (2) Remove the film positioning motor (upper) (MD5). #2 [Disconnect] Connector MD5 #1 [Release] Clamp Film positioning assembly (upper) #3 [Remove] 2-DT3x6 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual Film positioning motor (upper) (MD5) FP7C0508.EPS MC-66 MC-67 ■ Reinstalling Procedure <INSTRUCTIONS> Open the left and right positioning guides of the positioning guide assembly until they touch the sides when installing the film positioning motor (MD5). [Push] Positioning guide Positioning guide assembly Positioning guide [Push] Positioning guide FP7C0503.EPS Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-67 5 - 7 Film Positioning Assembly (Upper) FP7C0527.EPS (1) Remove the upper conveyor unit. “5.1 Upper Conveyor Unit” (2) Remove the film positioning motor (upper) (MD5). “5.6 Film Positioning Motor (Upper) (MD5)” (3) Remove the conveyance guide. #1 [Remove] Guide Conveyor guide #3 [Remove] 2-DT3x6 #4 [Release] Clamp #2 [Disconnect] Connector SD1 FP7C0509.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-68 MC-69 (4) Remove the turn guide. (5) Remove the connector bracket. (4) #2 [Remove] Bearing Turn guide (4) #1 [Remove] E4 (5) #1 [Remove] DT3x6 Connector bracket (4) #2 [Remove] Bearing (4) #1 (5) #1 [Remove] E4 [Remove] DT3x6 Connector bracket FP7C0510.EPS (6) Remove the stay. (7) Remove the screws of the conveyor unit exit guide. (8) Remove the film positioning assembly (upper). (6) #1 [Remove] 4-DT3x6 Stay Conveyor unit exit guide (7) #1 [Remove] 2-DT3x6 (8) #1 [Release] Clampx6 (7) #2 [Remove] 2-BR3x8 (8) #3 [Remove] 3-DT3x6 (8) #2 Film positioning assembly (upper) [Disconnect] Connector FP7C0511.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-69 MC-70 ■ Reinstalling Procedure <INSTRUCTIONS> Open the left and right positioning guides until they touch the sides when installing the film positioning motor (MD5). [Push] Positioning guide Positioning guide assembly Positioning guide [Push] Positioning guide FP7C0503.EPS Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-70 MC-71 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-71 5 - 8 Conveyor Unit Exit Guide FP7C0528.EPS ■ Removing Procedure (1) Remove the upper conveyor unit. “5.1 Upper Conveyor Unit” (2) Remove the sensor bracket. (3) Remove the stay. (4) Remove the conveyor unit exit guide. #1 [Release] Clamp Sensor bracket #4 #2 [Loosen] [Remove] DT3x6 Stay #5 [Remove] 2-DT3x6 #7 [Release] Conveyor unit exit guide #3 [Remove] 4-DT3x6 #6 [Remove] 2-BR3x8 Conveyor unit exit guide FP7C0512.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-72 MC-73 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-73 5 - 9 Conveyance Driving Roller (Upper) FP7C0529.EPS (1) Remove the upper conveyor unit. “5.1 Upper Conveyor Unit” (2) Remove the knob. (3) Remove the handle. Knob (3) #1 [Remove] BR3x10 (2) #1 [Remove] BR3x8 Handle FP7C0513.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-74 MC-75 (4) Remove the grip idler gear. (5) Remove the grip arm. (6) Remove the spring. (6) [Remove] Spring Grip arm (6) [Remove] Spring (5) #3 [Remove] E6 (5) #1 [Remove] Conveyor drive gear (5) #3 [Remove] E4 Grip arm (4) #1 (5) #2 (5) #2 [Remove] E6 [Remove] E6 Grip idler gear [Remove] E4 FP7C0514.EPS (7) Remove the conveyance grip roller (upper). (8) Remove the conveyance driving roller (upper). Conveyance grip roller (upper) (8) #2 [Remove] Bearing (8) #1 [Remove] E6 (7) #1 [Remove] Bearing (8) #2 [Remove] Bearing (8) #1 [Remove] E6 (7) #1 [Remove] Bearing Conveyance driving roller (upper) FP7C0515.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-75 5 - 10 Conveyance Driving Roller (Lower) FP7C0530.EPS ■ Removing Procedure (1) Remove the upper conveyor unit. “5.1 Upper Conveyor Unit” (2) Remove the upper conveyor unit lower bracket. (3) Remove the drive transmission gear. (3) #2 [Remove] E6 Bearing (2) #3 (3) #1 [Remove] 4-DT3x6 [Remove] E6 Upper conveyor unit lower bracket (2) #1 [Disconnect] Connector (2) #2 [Release] Clamp Shield cover Drive transmission gear FP7C0517.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-76 MC-77 (4) Remove the grip idler gear. (5) Remove the grip arm. (6) Remove the spring. Grip idler gear (4) #1 [Remove] E6 (6) [Remove] Spring Grip arm (6) [Remove] Spring (5) #3 [Remove] Conveyor drive gear (5) #5 [Remove] E6 (5) #4 (5) #5 [Remove] E6 [Remove] E4 (5) #2 Grip arm [Remove] Idler gear (5) #1 (5) #4 [Remove] E6 [Remove] E4 FP7C0518.EPS (7) Remove the conveyance grip roller (lower). (8) Remove the conveyance driving roller (lower). (8) #2 [Remove] Bearing (8) #1 [Remove] E6 (7) #1 [Remove] Bearing Conveyance driving roller (lower) (8) #2 [Remove] Bearing (8) #1 Conveyance grip roller (lower) (7) #1 [Remove] E6 [Remove] Bearing FP7C0519.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-77 5 - 11 Conveyor Unit Guide FP7C0531.EPS ■ Removing Procedure (1) Remove the upper conveyor unit. “5.1 Upper Conveyor Unit” (2) Remove the film positioning assembly (lower). “5.5 Film Positioning Assembly (Lower)” (3) Remove the conveyance driving roller (upper). “5.9 Conveyance Driving Roller (Upper)” (4) Remove the conveyance driving roller (lower). “5.10 Conveyance Driving Roller (Lower)” (5) Remove the conveyor unit guide. Boss Conveyor unit guide Boss #1 [Release] Conveyor unit guide #2 [Remove] 2-BR3x8 FP7C0520.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-78 5 - 12 Grip Idle Gear If the grip idle gear of the upper conveyor unit has been removed, reinstall the gear as following. ■ Adjusting Procedure (1) Align the holes on the upper and lower grip release gears with the holes on the side frame, insert the pins of a hexagonal wrench into the holes to adjust the upper and lower arm phases, and then reintall the grip idle gear. Pin #1 [Reinstall] Grip idle gear Grip release gear #2 [Attach] E6 Pin 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual FP7C0516.EPS MC-79 5 - 13 Lower Conveyor Unit FP7C0536.EPS ■ Removing Procedure (1) (2) Remove the following covers. • Right side cover • Rear cover Remove the lower conveyor unit. Idle gear Middle conveyor unit #1 [Loosen] 2-BR3x6 #4 [Remove] Lower conveyor unit #3 [Remove] 4-BR4x8 #2 Shield cover [Remove] 2-BR3x8 FP7C0537.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-80 MC-81 ■ CHECK/Adjusting Procedure Perform the following adjustment if the idle gear of the middle conveyor unit has been removed or if the idle gear has been loosened. (1) Secure the gear while pressing the flange of the idle gear against the gears in the arrow direction shown below. Upper removal unit Upper conveyor unit Middle removal unit Middle conveyor unit Idle gear Lower removal unit Lower conveyor unit FP7C0538.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-81 6 SUB-SCANNING UNIT FP7Z0611.EPS 6 - 1 Sub-Scanning Unit FP7C0609.EPS 6.1.1 Removal/Reinstallation ■ Removing Procedure (1) (2) Insert the shutter into the film tray. Remove the following covers. • Right side cover • Rear cover 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-82 MC-83 (3) Remove the sub-scanning unit fixing bracket. Sub-scanning unit fixing bracket [Remove] 4-BR4x8 FP7C0613.EPS (4) Reinstall the sub-scanning unit fixing bracket at the position shown below. #2 [Tighten] 2-BR4x8 Sub-scanning unit fixing bracket #1 [Tighten] 2-BR4x8 Sub-scanning unit fixing bracket FP7C0614.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-83 MC-84 (5) Remove the shield plate. (6) Remove the connector cover. (7) Remove the sub-scanning unit. (7) #1 [Disconnect] Connector LDD16A-CN1 (7) #1 [Disconnect] Connector LDD16A-CN3 (7) #1 [Disconnect] Connector LDD16A-CN7 Shield plate (5) #1 [Remove] 2-BR3x8 (7) #1 [Disconnect] Connector LDD16A-CN9 (6) #1 [Loosen] 2-BR4x12 Connector cover FP7C0601.EPS (7) #2 [Disconnect] Connector ME1 (7) #2 [Disconnect] Connector CNS2 (7) #3 [Remove] BR4x12 (7) #3 [Remove] 2-BR4x8 Sub-scanning unit FP7C0602.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-84 MC-85 ■ Reinstalling Procedure (1) Insert the sub-scanning unit into the equipment, and temporarily secure with the screws. #1 #1 [Temporarily tighten] 2-BR4x8 [Temporarily tighten] BR4x12 #1 [Temporarily tighten] 2-BR4x8 FP7C0616.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-85 MC-86 (2) Press the positioning screw against the rail, and secure the sub-scanning unit. #2 #2 [Tighten] 2-BR4x8 [Tighten] BR4x12 #2 [Tighten] 2-BR4x8 #1 [Press against] Positioning screw Positioning screw Rail of equipment FP7C0603.EPS (3) Remove the sub-scanning unit fixing bracket, and reinstall it to its original position. CAUTION When removing the sub-scanning unit fixing bracket, be careful never remove the screws painted in red. ■ CHECK/Adjusting Procedure Check that connectors are connected properly. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-86 MC-87 6.1.2 Adjusting the Sub-Scanning Unit Positioning Screw When adjusting the sub-scanning unit positioning screw, or if the positioning screws has been turned accidentally, perform the following procedure. ■ Adjusting Procedure (1) Print the grid pattern. “Service Mode, [2-5] Grid”. (2) Measure the “D” and “E” on the printed film and check that they meet the specified values. For 35 x 43 cm size 20 20 D E Film conveyance direction (Unit: mm) Position 35 x 43cm size 26 x 36 cm size 20 x 25 cm size D, E 14.5 ±1.0 27.5 ±1.0 26.0 ±1.0 ≤ 1.2 ≤ 1.2 ≤ 1.2 |D-E| 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual FP7C0622.EPS MC-87 MC-88 (3) If the measured values are not the specified values, loosen the screws securing the sub-scanning unit. #1 [Loosen] 2-BR4x8 #1 [Loosen] 2-BR4x8 FP7C0617.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-88 MC-89 (4) Remove the sub-scanning unit fixing bracket. Sub-scanning unit fixing bracket [Remove] 4-BR4x8 FP7C0613.EPS (5) Reinstall the sub-scanning unit fixing bracket at the position shown below. #2 [Tighten] 2-BR4x8 Sub-scanning unit fixing bracket #1 [Tighten] 2-BR4x8 Sub-scanning unit fixing bracket FP7C0614.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-89 MC-90 (6) Rotate the positioning screw in the clockwise or counterclockwise direction and adjust. <NOTE> Rotating once in the clockwise or counterclockwise direction changes the “D” and “E” on the printed film by about 0.5 mm. [Rotate] Positioning screw FP7C0615.EPS Film conveyance direction A 006-259-02 04.01.2003 FM3978 B DRYPIX 7000 Service Manual FP7C0624.EPS MC-90 MC-91 (7) Press the positioning screw against the rail, and secure the sub-scanning unit. #2 [Tighten] 2-BR4x8 #2 [Tighten] 2-BR4x8 #1 [Press against] Positioning screw Positioning screw Rail of equipment FP7C0618.EPS (8) Print the grid pattern. “Service Mode, [2-5] Grid”. (9) Measure the “D” and “E” on the printed film and check that they meet the specified values. (10) If the measured values are not the specified values, repeat steps (3) to (9). 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-91 6 - 2 Sub-Scanning Motor (ME1) FP7C0610.EPS 6.2.1 Removal/Reinstallation ■ Removing Procedure (1) Remove the sub-scanning unit. “6.1 Sub-Scanning Unit” (2) Remove the sub-scanning motor (ME1). #1 [Remove] Q4x14 Sub-scanning motor (ME1) #2 [Remove] 4-TP4x8 FP7C0604.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-92 MC-93 6.2.2 Adjustment When Replacing Sub-scanning Motor If the sub-scanning motor (ME1) has been replaced, check/adjust the film conveyance amount as follows. (1) Print the grid pattern. “Service Mode, [2-5] Grid”. (2) Measure “F” on the printed film and check that it meets the specified value. For 35 x 43 cm size 20 Film conveyance direction F (Unit: mm) Position F (3) 35 x 43 cm size 413.0 ±1.2 26 x 36 cm size 20 x 25 cm size 226.5 ±1.0 225.0 ±1.0 FP7C0623.EPS If the measured values are not the specified values, adjust the film conveyance amount. “Service Mode, [5-2-3] Adjusting subscanner”. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-93 6 - 3 Sub-Scanning Roller FP7C0611.EPS ■ Removing Procedure (1) Remove the sub-scanning unit. “6.1 Sub-Scanning Unit” (2) Remove the scanner unit. “7.1 Scanner Unit” (3) Remove the sub-scanning motor (ME1). “6.2 Sub-Scanning Motor (ME1)” (4) Remove the handle. (5) Remove the belt cover. (6) Remove the SUS belt. (6) #1 [Remove] Spring (5) #1 [Remove] BR4x8 Belt cover (4) #1 [Remove] BR3x10 SUS belt (6) #2 [Lower] SUS belt tensioner Handle FP7C0605.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-94 MC-95 (7) Remove the sub-scanning roller (left). #2 [Pull out] Sub-scanning roller (Left) Waveform washer #1 [Remove] BR4x8 Sub-scanning roller (left) W5 FP7C0606.EPS (8) Remove the sub-scanning unit entrance guide. (9) Remove the sub-scanning roller (right). Sub-scanning unit entrance guide (9) #3 [Pull out] Sub-scanning unit roller (Right) (8) #1 Waveform washer [Remove] BR4x8 W5 Sub-scanning roller (right) (9) #1 [Remove] BR4x8 (9) #2 [Lower] SUS belt tensioner FP7C0607.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-95 MC-96 ■ Reinstalling Procedure <NOTE> • When installing the sub-scanning roller, be sure to reinstall the waveform washer. • After reinstalling the sub-scanning roller, rotate the roller four or five times with the hand, and check that it turns smoothly. Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-96 MC-97 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-97 6 - 4 Film Leading Edge Detection Sensor (SE1) FP7C0612.EPS ■ Removing Procedure (1) (2) (3) Insert the shutter into the film tray. Remove the following covers. • Right side cover • Rear cover Remove the sub-scanning unit fixing bracket. Sub-scanning unit fixing bracket [Remove] 4-BR4x8 FP7C0613.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-98 MC-99 (4) Reinstall the sub-scanning unit fixing bracket at the position shown below. #2 [Tighten] 2-BR4x8 Sub-scanning unit fixing bracket #1 [Tighten] 2-BR4x8 Sub-scanning unit fixing bracket FP7C0614.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-99 MC-100 (5) Remove the shield plate. (6) Remove the connector cover. (7) Draw the sub-scanning unit. (7) #1 [Disconnect] Connector LDD16A-CN1 (7) #1 [Disconnect] Connector LDD16A-CN3 (7) #1 [Disconnect] Connector LDD16A-CN7 Shield plate (5) #1 [Remove] 2-BR3x8 (7) #1 (6) #1 [Disconnect] Connector LDD16A-CN9 [Loosen] 2-BR4x12 Connector cover FP7C0601.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-100 MC-101 (7)#2 [Disconnect] Connector ME1 (7)#2 [Disconnect] Connector CNS2 (7)#3 [Remove] 2-BR4x8 Sub-scanning unit FP7C0619.EPS (8) Remove the film leading edge detection sensor (SE1). #1 [Disconnect] Connector SED Film leading edge detection sensor (SE1) #2 [Remove] 2-BR3x8 FP7C0608.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-101 MC-102 ■ Reinstalling Procedure Reinstall in the reverse order of removal. However, perform the following when securing the sub-scanning unit into the equipment. (1) Insert the sub-scanning unit into the equipment, and temporarily secure with the screws. #1 [Temporarily tighten] 2-BR4x8 #1 [Temporarily tighten] 2-BR4x8 FP7C0620.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-102 MC-103 (2) Press the positioning screw against the rail, and secure the sub-scanning unit. #2 [Tighten] 2-BR4x8 #2 [Tighten] 2-BR4x8 #1 [Press against] Positioning screw Positioning screw Rail of equipment FP7C0621.EPS (3) Remove the sub-scanning unit fixing bracket, and reinstall it to its original position. CAUTION When removing the sub-scanning unit fixing bracket, be careful never remove the screws painted in red. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-103 7 SCANNING OPTICS UNIT FP7Z0711.EPS 7 - 1 Scanner Unit FP7C0703.EPS CAUTION • The LD/IC may damage due to static electricity. When removing/reinstalling it, take anti-static measures by wearing a wrist band, etc. • Do not remove the upper cover of the scanner unit. • Do not place your finger inside the laser beam window (at the bottom of the scanner unit). • Handle the optical unit gently, making sure not to subject it to shock. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-104 MC-105 7.1.1 Removal/Reinstallation ■ Removing Procedure (1) Remove the sub-scanning unit. “6.1 Sub-scanning Unit” (2) Remove the scanner unit. #1 [Remove] 4-BR4x12 Scanner unit CHECK CHECK CHECK FP7C0701.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-105 MC-106 ■ Reinstalling Procedure Reinstall in the reverse order of the removing procedure. However perform the following when installing the scanner unit to the sub-scanning unit. <INSTRUCTIONS> When pushing the scanner unit against the positioning plate, push gently without subjecting it to shock. (1) Align the scanner unit to the reinstalling position of the sub-scanning unit, and secure temporarily with the screws. (2) Push the two positioning brackets and protruded part on the scanner unit against the sub-scanning unit at the positions shown in the following figure. (3) Secure the scanner unit with the screws. Scanner unit (2) (1) [Secure temporarily] 4-BR4x12 [Push] Scanner unit (3) [Tighten] 4-BR4x12 (1) [Secure temporarily] 4-BR4x12 (3) [Tighten] 4-BR4x12 (2) [Push] Scanner unit FP7C0702.EPS ■ CHECK/Adjusting Procedure • Make sure that there is no gap between the sub-scanning unit positioning plate and scanner unit positioning parts. • Make sure that the connectors are connected properly. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-106 MC-107 7.1.2 Adjustments in Replacement of Scanner Unit If the scanner unit has been replaced, the data in the scanner unit data FD provided with the scanner unit needs to be sent to the equipment. (1) Turn ON the power of the equipment. (2) Prepare the PC for servicing. “INSTALLATION, 10.1 Connecting the PC for Servicing to the Network” “INSTALLATION, 10.2 Starting the DPX7 PC Tool/Connecting DPX7 PC Tool to the Equipment” (3) Import the individual data. “Printer name importing data” → [Control] → [File Save/Load] → [Save from the printer] → [Execute] #1 #3 #4 #2 #5 FP7C0F09.EPS → The individual data is sent to the PC for servicing. When the data transfer is completed, the [File transfer is completed.] screen appears. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-107 MC-108 (4) Insert the scanner unit data FD provided with the scanner unit into the FDD of the PC for servicing. (5) Copy scanner unit data to the PC for sevicing. “Printer name” → [Data Transfer] → [FROM FD] → Scanner unit data is copied to the PC for servicing. #1 #2 #3 FP7C0F11.EPS → When completed, the [FD File transfer is completed.] screen appears. (6) Send the individual data containing the scanner unit data copied to the equipment. “Printer name” → [Control] → [File Save/Load] → [Load to the printer] → [Execute] → The individual data is sent to the equipment, and only the scanner unit data is updated. When the data transfer is completed, the [File transfer is completed.] screen appears. (7) End the DPX7 PC Tool. (8) Reboot the equipment, and start the M-Utility. (9) Output the grid pattern using the M-Utility. “SERVICE MODE, [2-5] Grid” 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-108 MC-109 (10) Measure “C” of the film output, and check that the values satisfy the specification. For 35 x 43 cm size C B A Film conveyance direction (Unit: mm) Position 35 x 43 cm size |A-B| C 26 x 36 cm size 20 x 25 cm size ≤ 1.2 ≤ 1.2 ≤ 2.0 300 ±1.2 300 ±1.2 200 ±1.2 FP7C0705.EPS (11) If they do not, change the value of “[4-3-1] Scanning Width” of the M-Utility. “SERVICE MODE, [4-3-1] Scanning Width” (12) Measure “A” and “B” of the film output, and check that the values satisfy the specification. (13) If they do not, change the value of “[4-3-2] Scanning Position” of the M-Utility. “SERVICE MODE, [4-3-2] Scanning Position” (14) Perform automatic density correction. “SERVICE MODE, [3-1] AUTO F.D.C.” (15) Check the film density. “SERVICE MODE, [3-2] Check Density” 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-109 8 HEAT DEVELOPMENT UNIT FP7Z0811.EPS 8 - 1 Cooling Fan Assembly FP7C0814.EPS ■ Removing Procedure (1) (2) Remove the following covers. • Jam clear cover • Upper left cover Remove the fan fixing bracket. Cooling fan assembly #1 [Remove] 4-BR3x8 Fan fixing bracket FP7C0801.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-110 MC-111 (3) Remove the cooling fan assembly. #2 [Remove] 4-BR4x8 Cooling fan assembly #1 [Disconnect] Connector CNG3 FP7C0802.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-111 8 - 2 Filter Section Cooling Fan FP7C0815.EPS ■ Removing Procedure (1) Remove the cooling fan assembly. “8.1 Cooling Fan Assembly” (2) Remove the fan duct. (3) Remove the filter section cooling fan. Fan duct #1 [Remove] 4-BR3x8 Auxilary plate #2 [Remove] 2-BR4x40 Filter section cooling fan FP7C0803.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-112 MC-113 ■ Reinstalling Procedure <INSTRUCTIONS> Reinstall the filter section cooling fan as shown in the figure. Filter section cooling fan Label Cable Cooling fan assembly FP7C0804.EPS Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-113 8 - 3 Film Cooling Section FP7C0816.EPS ■ Removing Procedure (1) Remove the following covers. • Jam clear cover • Upper left cover • Upper right cover (2) Remove the operation panel. “10.1 Operation Panel” (3) Remove the film release unit. “9.1 Film Release Unit” (4) Remove the film cooling section. Round hole #1 [Release] Clamp #2 CHECK [Disconnect] Connector THG10 Film cooling section CHECK #3 #4 [Loosen] 2-BR4x8 [Remove] 5-BR4x8 FP7C0805.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-114 MC-115 ■ Reinstalling Procedure <INSTRUCTIONS> When reinstalling the film cooling section, press the shaft against the bracket as shown in the figure, and secure with the screws. [Press] Film cooling section shaft FP7C0806.EPS Reinstall in the reverse order of removal. ■ CHECK/Adjusting Procedure • After reinstalling the film cooling section, check from the round hole on the back of the film cooling section that the gears of the film cooling section and heat development unit are engaged. • After reinstalling the film cooling section, rotate the jam handle, and check that it moves smoothly. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-115 8 - 4 Heat Development Unit FP7C0817.EPS ■ Removing Procedure (1) • • • • • • (2) Remove the following covers. Jam clear cover Upper left side cover Upper right side cover Rear cover Right side cover Left side cover Remove the sub-scanning unit. “6.1 Sub-Scanning Unit” (3) Remove the film release unit. “9.1 Film Release Unit” (4) Remove the cooling fan assembly. “8.1 Cooling Fan Assembly” (5) Remove the operation panel. “10.1 Operation Panel” (6) Remove the film cooling section. “8.3 Film Cooling Section” 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-116 MC-117 (7) Remove the left inside cover. (8) Remove the top panel. Left inside cover (7) #1 Top panel [Remove] 2-BR3x8 (8) #1 [Remove] 4-BR4x8 (8) #2 [Release] Clamp FP7C0807.EPS (9) Remove the heat development unit. #1 [Disconnect] Connector CNG2 Heat development unit #1 [Disconnect] Connector CNG4 #3 [Remove] 3-BR4x8 #1 [Disconnect] Connector CNG1 #1 [Disconnect] Connector MG1 #2 [Release] Clamp FP7C0808.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-117 8 - 5 Heat Development Rack Assembly FP7C0818.EPS ■ Removing Procedure (1) Insert the shutter into the film tray. (2) Remove the following covers. Jam clear cover Upper left side cover Rear cover Left side cover • • • • (3) Remove the film release unit. “9.1 Film Release Unit” (4) Remove the film cooling section. “8.3 Film Cooling Section” (5) Remove the cooling fan assembly together with the bracket. Cooling fan assembly #2 [Remove] 2-BR3x8 Bracket Bracket #3 [Remove] 4-BR4x8 #1 [Disconnect] Connector CNG3 FP7C0823.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-118 MC-119 (6) Remove the left inside cover. Left inside cover [Remove] 2-BR3x8 FP7M0320.EPS (7) Disconnect the connectors and earth cables. (8) Remove the rack fixing brackets (small). (9) Remove the rack fixing bracket (large). <NOTE> Do not remove the left and right fixing pins on the heat development rack assembly. (10) Remove the heat development rack assembly. (7) #2 [Disconnect] Connector THG7-9 (8) #2 (7) #2 [Remove] BR4x8 [Disconnect] Connector HEAT3 CHECK Rack fixing bracket (small) (8) #1 CHECK [Remove] BR4x8 Rack fixing bracket (small) (10) (7) #1 [Remove] TP4x8 [Remove] Heat development rack assembly (9) [Remove] 2-BR4x8 Rack fixing bracket (large) FP7C0809.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-119 MC-120 ■ Reinstalling Procedure <NOTE> When reinstalling the adiabatic cover, do not sandwich the thermistor cable. Reinstall in the reverse order of removal. ■ CHECK/Adjustment Procedure Check that connectors are connected properly. Third rack assembly THG7-9 HEAT3 Second rack assembly THG4-6 HEAT2 THG1-3 HEAT1 First rack assembly FP7C0810.EPS 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-120 MC-121 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-121 8 - 6 Heat Development Roller FP7C0819.EPS ■ Removing Procedure (1) Remove the heat development rack assembly, and remove adiabatic cover. “8.5 Heat Development Rack Assembly” (2) Remove the fixing pins. (3) Remove the heater assembly. (4) Remove the heat development roller. (3) [Remove] Heater assembly (2) #1 [Remove] Fixing pin (long) (4) #1 [Remove] WP3x10 Bearing (2) #2 [Remove] Fixing pin (short) Bearing Heat development roller FP7C0811.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-122 MC-123 BLANK PAGE 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-123 9 FILM RELEASE UNIT FP7Z0911.EPS 9 - 1 Film Release Unit FP7C0904.EPS ■ Removing Procedure (1) • • • • Remove the following covers. Jam clear cover Upper left side cover Upper right side cover Side ejection cover 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-124 MC-125 (2) Remove the film release unit. #1 [Release] Clamp #2 [Disconnect] Connector CNJ2 #2 [Disconnect] Connector CNJ1 #3 [Remove] 4-BR4x8 Film release unit FP7C0901.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-125 9 - 2 Density Measurement Light-Emitting Board (LED15A) FP7C0905.EPS ■ Removing Procedure (1) • • • • Remove the following covers. Jam clear cover Upper left side cover Upper right side cover Film release unit cover (2) Remove the LED15A installing bracket. (3) Remove the density measurement light-emitting board. (2) #3 [Disconnect] Connector LED-CN85 (2) #1 [Remove] 2-BR3x8 (3) #1 [Remove] BR3x12 Shield plate (3) #1 [Remove] BR3x8 Spacer (2) #2 [Remove] Clamp Density measurement light-emitting board (LED15A) (2) #3 [Disconnect] Connector SJ1 FP7C0902.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-126 MC-127 ■ Reinstalling Procedure <INSTRUCTIONS> Press the LED cover of the density measurement light-emitting board against the position shown in the figure below, and secure. [Press] Density measurement light-emitting board (LED15A) FP7C0903.EPS Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-127 10 CONTROLLER FP7Z0A11.EPS 10 - 1 Operation Panel FP7C0106.EPS ■ Removing Procedure (1) Remove the following covers. • Jam clear cover • Upper left side cover (2) Remove the operation panel. #2 #2 [Disconnect] Connector PANEL-CN2 [Disconnect] Connector PANEL-CN1 #4 [Disconnect] Connector PANEL-CN5 #4 [Disconnect] Connector PANEL-CN7 #4 Operation panel [Disconnect] Connector PANEL-CN8 #4 [Disconnect] Connector PANEL-CN6 #4 #3 [Disconnect] Connector PANEL-CN4 [Remove] BR3x8 #1 [Remove] 2-BR3x8 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual FP7C0104.EPS MC-128 MC-129 ■ Reinstalling Procedure <NOTE> When reinstalling the upper left side cover, make sure that it does not interfere with the operation panel. Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-129 10 - 2 Controller Assembly FP7C0A04.EPS ■ Removing Procedure (1) (2) Remove the following covers. • Left side cover • Rear cover • Lower front cover Remove the controller assembly. #2 [Disconnect] Shaded connector #2 [Disconnect] Connector PC-CN4 #2 [Disconnect] Connector PRINT16A-CN2 #2 [Disconnect] Connector [Disconnect] Connector PRINT16A-CN4 #1 [Release] Clamp #4 [Remove] 3-BR3x8 #2 Controller assembly #2 [Disconnect] Connector PC-CN26 #2 [Disconnect] Connector CNK1 #1 [Release] Clamp 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual #2 [Disconnect] Connector PRINT16A-CN16 FP7C0A01.EPS MC-130 MC-131 #5 [Pull out] Controller assembly FP7C0A02.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-131 10 - 10.2 3 HDD FP7C0A05.EPS ■ Removing Procedure (1) Remove the controller assembly. “10.2 Controller Assembly” (2) Remove the HDD. #2 [Remove] 4-BR3x12 HDD #1 [Disconnect] Connector HDD #1 [Disconnect] Connector HDD FP7C0A03.EPS ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-132 MC-133 ■ Replacing Procedure The service parts HDD is installed with the OS and main unit software. However, because the main unit software may not be of the latest version, if the HDD has been replaced, perform full installation of the main unit software and re-installation of individual data. Prepare the latest main unit software CD-R when replacing the HDD. (1) Turn OFF the power of the equipment. (2) Replace the HDD. “■ Removing Procedure/■ Reinstalling Procedure” (3) Turn ON the power of the equipment, and check the version of the main unit software displayed at startup. (4) Start the M-Utility, and set the network. “INSTALLATION, 7.2.2 System Management/Set Network” (5) End the M-Utility, and turn OFF and then ON the power of the equipment. (6) Prepare the PC for servicing. “INSTALLATION, 10.1 Connecting the PC for Servicing to the Network” “INSTALLATION, 10.2 Starting the DPX7 PC Tool/Connecting DPX7 PC Tool to the Equipment” <INSTRUCTIONS> If the version of the main unit software in the HDD is old: Perform steps (7) and onwards. If the version of the main unit software in the HDD is latest: Perform steps (8) and onwards. (7) Perform full installation of the latest main unit software and installation of the application program of the printer in the MCT board. “12.3 Full Installation Steps (1) to (3)” (8) Re-install the individual data. “12.3 Full Installation Step (4)” (9) Set the system date, film counter, and remaining number of films. “12.3 Full Installation Steps (5) to (7)” (10) Reboot the equipment. “12.3 Full Installation Step (8)” (11) Click [Exit] and shutdown the DPX7 PC Tool. (12) Remove the CD-R from the PC for servicing. (13) Shutdown the PC for servicing. (14) Disconnect the network cable of the PC for servicing from the network to which the equipment is connected. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-133 10 - 4 PC Board FP7C0A06.EPS CAUTION • Replace the PC board if the lithium battery has worn out. • Return the old PC board to the Parts Center (factory). • Improper replacement of the battery may result in explosion. When replacing the lithium battery, use the battery designated by Fuji Photo Film Co., Ltd. or use an equivalent battery. Dispose the old battery as specified by Fuji Photo Film Co., Ltd. ■ Removing Procedure (1) Remove the controller assembly. “10.2 Controller Assembly” (2) Remove the PRN board, MCT board, and image memory board. “SERVICE PARTS LIST, 10. Controller” (3) Disconnect all connectors on the PC board. (4) Remove the PC board. ■ Reinstalling Procedure Reinstall in the reverse order of removal. 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-134 10 - 5 MCT Board FP7C0A07.EPS ■ Removing Procedure (1) Remove the controller assembly. “10.2 Controller Assembly” (2) Remove the MCT board. “SERVICE PARTS LIST 10. Controller” ■ Reinstalling Procedure Reinstall in the reverse order of removal. ■ Replacing Procedure If the MCT board has been replaced, the software on the HD (printer installer, printer OS, printer application) needs to be installed with a new MCT board. (1) Turn OFF the power of the equipment. (2) Replace the MCT board. “■ Removing Procedure/■ Reinstalling Procedure” (3) Turn ON the power of the equipment, and start the M-Utility. (4) Install the software on the HD in the MCT board in the following order; “PRT INST” → “PRT OS” → “PRT APL”. “SERVICE MODE, [1-1-9] Reload Software” (5) Reboot the equipment. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-135 11 SORTER FP7C0B02.EPS 11 - 1 Film Conveyance Timing Belt FP7C0B03.EPS ■ Belt Structure Top belt Inside belt Bottom belt FP3F0S43.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-136 MC-137 ■ Reinstalling Procedure (1) There are three timing belts. Install the inside belt first and then the top and bottom belts. Top belt Top belt Bottom belt Inside belt Bottom belt Inside belt FP3F0S42.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-137 MC-138 ■ Adjusting Procedure (1) With the fixing screws of the tension pulleys loosened, secure the tension pulleys at the position where they are in balance by the force of the springs. Tension spring Top belt Fixing screw Bottom belt Fixing screw Inside belt Fixing screw Tension spring Tension spring FP3F0S40.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-138 11 - 2 Jam Removing Guide Plate Magnet FP7C0B04EPS (1) Loosen the fixing screws of the magnet. (2) Close the jam removing guide plate, and tighten magnet fixing screws where it touches the stopper. Stopper #2 [Push] Guide plate #1 [Loosen] Two screws #3 [Tighten] Two screws Magnet FP3F0S41.EPS 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-139 MC-140 12. VERSION UPGRADE AND FULL INSTALLATION OF MAIN UNIT SOFTWARE The main unit software is supplied on CD-R. The DRX7 PC Tool is required for version upgrading and full installation of the main unit software. Version upgrade: The concerned files excluding individual data of the currently installed software are overwritten. Full installation: The concerned files including individual data of the currently installed software are overwritten. <NOTE> • As performing full installation will clear the individual data in the HD, the individual data needs to be installed after completing full installation. Use the latest individual data for installation. • In version upgrades, individual data will be preserved. <REMARKS> The following shows the times required for software installation. Take note that these times differ according to the performance and network environment of the PC for servicing used. • Version upgrade (PC for servicing → Equipment): Approx. 2 minutes • Full installation (PC for servicing → Equipment): Approx. 3 minutes • PRT APL installation (HDD → MCT board): Approx. 1 minute 12.1 Preparations (Same for Version Upgrades and Full Installation) (1) Turn ON the power of the equipment. (2) Prepare the PC for servicing. “INSTALLATION, 10.1 Connecting the PC for Servicing to the Network” “INSTALLATION, 10.2 Starting the DPX7 PC Tool/Connecting to DPX7 PC Tool the Equipment” 006-259-01 11.10.2002 FM3601 DRYPIX 7000 Service Manual MC-140 MC-141 12.2 Version Upgrade ■ Flow of Data When Version Upgrading DRYPIX 7000 PC for servicing (DPX7 PC Tool) HDD (1) (2) Formatter program FTP folder CD-R (Main unit software) Printer program (3) MCT board Memory FP7C0F08.EPS ■ Version Upgrading Procedure (1) Insert the latest main unit software CD-R in the CD-ROM drive of the PC for servicing, and copy the main unit software to the FTP folder of the PC for servicing. “Printer name” → [Soft Ver.UP] → “CD-ROM drive” → [Copy] #1 #2 #3 #4 FP7C0F01.EPS → The main unit software is copied to the FTP folder of the PC for servicing. When completed, [File Copy Finish!!] screen appears. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-141 MC-142 (2) Write the main unit software in the HD of the equipment from the PC for servicing (FTP folder). [Verup] → [Execute] #1 #2 FP7C0F02.EPS → The main unit software is installed (version upgraded) in the equipment. When installation completed, the [System File Load Finish!!] screen appears. (3) Of the software written in the HD of the equipment, write the printer application program in the MCT board. [PRT APL] → [Install] #1 #2 FP7C0F03.EPS → The printer application program in the HD is installed in the MCT bard. When installation completed, the [Software Install Finish!!] screen appears. <REMARKS> The version of the main unit software is upgraded after the equipment is rebooted. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-142 MC-143 (4) Reboot the equipment from the PC for servicing to upgraded the software. “Printer name” → [Control] → [System Config] → [Reboot] → [Reboot All] → [Reset] #1 #4 #3 #2 #6 #5 FP7C0F04.EPS → The equipment is rebooted. (5) Click [Exit] to end DPX7 PC Tool. (6) Remove the CD-R from the PC for servicing. (7) Shutdown the PC for servicing. (8) Disconnect the network cable of the PC for servicing from the network to which the equipment is connected. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-143 MC-144 12.3 Full Installation ■ Flow of Data When Performing Full Installation PC for servicing (DPX7 PC Tool) DRYPIX 7000 HDD (1) (2) Formatter program FTP folder CD-R (Main unit software) Printer program (4) Indv Folder (3) MCT board Memory FP7C0F07.EPS ■ Full Installation Procedure (1) Insert the latest main unit software CD-R in the CD-ROM drive of the PC for servicing, and copy the main unit software to the FTP folder of the PC for servicing. “Printer name” → [Soft Ver.UP] → “CD-ROM drive” → [Copy] #1 #2 #3 #4 FP7C0F01.EPS → The main unit software is copied to the FTP folder of the PC for servicing. When completed, [File Copy Finish!!] screen appears. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-144 MC-145 (2) Write the main unit software in the HD of the equipment from the PC for servicing (FTP folder). [Full] → [Execute] #1 #2 FP7C0F05.EPS → The main unit software is installed in the equipment. When installation completed, the [System File Load Finish!!] screen appears. (3) Of the software written in the HD of the equipment, write the printer application program in the MCT board. [PRT APL] → [Install] #1 #2 FP7C0F03.EPS → The printer application program in the HD is installed in the MCT board. When installation completed, the [Software Install Finish!!] screen appears. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-145 MC-146 (4) Install the individual data. <INSTRUCTIONS> The individual data needs to be installed if full installation has been performed. To install, use the latest individual data of the corresponding printer saved in the PC for servicing. ● Installing the Individual Data in the PC for Servicing (i) “Printer name” → [Control] → [File Save/Load] → [Load to the printer] → [Execute] #1 #3 #4 #2 #5 FP7C0F06.EPS → The individual data in the PC for servicing is sent to the equipment. When the data transfer is completed, the [File transfer is completed.] screen appears. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-146 MC-147 ● When Installing the Individual Data Saved on FD (i) Insert the FD with the latest individual data in the FDD of the PC for servicing. (ii) Copy the individual data saved on FD to the PC for servicing. “Printer name” → [Data Transfer] → [FROM FD] #1 #2 #3 FP7C0F11.EPS → The individual data is copied to the PC for servicing. When the data copy is completed, the [FD File transfer is completed.] screen appears. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-147 MC-148 (iii) Install the individual data in the equipment. “Printer name” → [Control] → [File Save/Load] → [Load to the printer] → [Execute] #1 #3 #2 #4 #5 FP7C0F06.EPS → The copied individual data in the PC for servicing is sent to the equipment. When the data transfer is completed, [File transfer is completed.] screen appears (5) Set the system date and time. “Printer name” → [Control] → [System Config] → [Set Date/Time] “SERVICE MODE, [PC9-2-1] System Config” (6) Set the film counter. “Printer name” → [Control] → [System Config] → [Set Counters] “SERVICE MODE, [PC9-2-5] Set Counters” (7) Set the number of remaining films. “Printer name” → [Control] → [System Config] → [Set Remain. Films] “SERVICE MODE, [PC9-2-6] Set Remain. Films” 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-148 MC-149 (8) Reboot the equipment from the PC for servicing so that the changes made in the main unit software becomes effective. “Printer name” → [Control] → [System Config] → [Reboot] → [Reboot All] → [Reset] #1 #4 #3 #2 #6 #5 FP7C0F04.EPS → The equipment reboots. <REMARKS> The main unit software is replaced with that fully installed after the equipment is rebooted. (9) Click [Exit] and shutdown the DPX7 PC Tool. (10) Remove the CD-R and FD from the PC for servicing. (11) Shutdown the PC for servicing. (12) Disconnect the network cable of the PC for servicing from the network to which the equipment is connected. 006-259-02 04.01.2003 FM3978 DRYPIX 7000 Service Manual MC-149