Download to View Val6 KBE5S, KBE5L Manual

Transcript

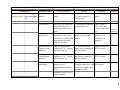

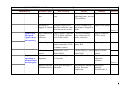

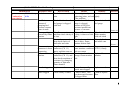

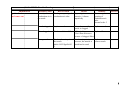

800-292-3279 916 638-0828 http://easycleansystems.com/heaters/heater-parts.html VAL6 KBE5S and KBE5L Service manual KBE5S 1 Specifications Type Heat Output Fuel Tank Capacity Fuel Consumption Power Source Power Consumption Ignition System VAL6 KBE5S 111,000BTU/h Kerosene, Diesel 9 gallons 0.85gallon/h 120V, 60Hz single phase 80W (in burning), 100W (in igniting) High Intensity Discharge EXTERNAL DIMENSION (L/W/H) 27.4/27.9/36.2(in) [695/708/918(mm)] Safety Device Photocell Flame Monitor Overload Check Device 3A Fuse Dry Weight 83.8lbs 2 Names of Components 3 Wiring Diagram of Burner Control PS : Power Source SW1 : Operating Switch TH : Thermostat (Short) FE : Flame Monitor FG : Frame Ground HT : Pre Heater FM : Fan Motor CM : (Open) IG : Igniter SP : Solenoid Pump SV : (Open) RL : Running Lamp AL : Misfire Lamp KA : Control Relay F : Line Fuse Z : Surge Absorber ES : Emergency (Short) CN6 CN3 CN7 CN12 CN1 CN2 CN4 CN5 CN11 CN10 CN9 CN13 CN8 RUN Conn ector No. CN1 Power Source CN2 CN3 Fan Motor CN4 Igniter CN5 CN6 Solenoid Pump CN7 Tran CN8 Operating Switch CN9 Thermostat (Short) CN10 CN11 Flame Monitor Runnin g Lamp, CN12 Misfire Lamp CN13 - MISFIRE Sequence Time Chart ON ignition OFF Operation Switch Fan Igniter Solenoid Pump 5 sec. within 10 sec. 10 sec. (post ignition) 180 sec. VAL6 KBE5S Troubleshooting Phenomenon 1 The heater does not start 2 The heater does not ignite 3 4 5 6 7 8 Misfire within 25 seconds after ignition Combustion stop during the operation Odor comes out Smoke comes out Combustion is not stable Fuel leaks 9 Fuse blows out page The lamp does not light on Misfire lamp is lit Fuel pump does not operate at all No fuel or a little fuel is pumped up Igniter does not spark. [Igniter does not operate] Sequence of operation is normal, but it doesn't ignite Misfire lamp is lit Misfire lamp is lit 1 3 5 6 7 8 9 When the plug is put into the socket When the switch is turned on About 5 seconds after turning on 10 VAL6 KBE5S Trouble Shooting Phenomenon Possible Cause How to check Result Remedy No power source Measure voltage of AC If circuit tester indicates Connect power 1.The heater The lamp outlet. 0V, power source is source does not start. does not light supplied disconnected on. Standard: AC120V Fuse blowout Take fuse out from fuse box, and then check each lead with circuit tester Disconnection of Take power source power cord connector (CN 1) out from burner control, and then check each lead with circuit tester If circuit tester reads ∞ Find a cause of Ω, fuse blows out blown fuse and replace with a new Picture 8 one Picture 9 If either of the lead is Make sure the broken, power cord is power cord is broken connected, or replace it Loose connection Plug in power source If it works normally, Plug in connector of power source connector (CN 1) again, power source connector (CN 1) firmly connector and then turn on fails on contact Loose connection Plug in transformer If it works normally, of transformer connector (CN 7) again, transformer connector connector and then turn on fails on contact Failure of transformer Measure voltage at output side of transformer connector (CN 7) Reference Plug in connector (CN 7) firmly If tester reads normal Replace voltage at input side, and transformer reads 0V at output side, transformer fails Standard: about AC15V (purple-purple) 1 VAL6 KBE5S Trouble Shooting Phenomenon Possible Cause How to check Result Loose connection Plug in operation switch If it works normally, of operation connector (CN 8) again, operation switch switch connector and then turn on connector fails on contact Failure of Take operation switch If it doesn't conduct operation switch connector (CN 8) out, when turned on, then check lead with operation switch fails circuit tester Standard: Conducting (0 Ω) when turned on Failure of burner Measure voltage at input If power source is control side of transformer normal and tester reads connector (CN 7) 0V at input side, burner control fails Standard: AC120V (white-red) Run lamp is Loose terminals Firmly connect terminals If it works normally, on control device for control device terminals for control lit device are loose Unplug flame monitor It starts to operate Misfire lamp Flame monitor sensor connector (CN 11), and is lit. malfunctions then start operation Failure of burner control Reference Remedy Plug in connector (CN 8) firmly Replace operation switch Replace burner control Firmly connect terminals on control device Avoid direct sunlight on radiation disk Picture 6 It doesn't start to operate Replace burner control 2 VAL6 KBE5S Trouble Shooting Phenomenon Possible Cause How to check Result Loose connection Plug in fuel pump If it works normally, 2.The heater Fuel pump of fuel pump connector (CN 6) again, fuel pump connector does not ignite. does not and turn on fails in contact operate at all. connector Loose connection of joint connectors for fuel pump Failure of fuel pump No fuel or a little fuel is pumped up. Failure of burner control Fuel line is clogged Plug in joint connectors for fuel pump again, and then turn on Measure voltage at output side of fuel pump connector on burner control Standard: AC60~96V (red-blue) Disconnect each fuel line, and then clean up each of them Reference Remedy Plug in connector (CN 6) firmly If it works normally, Plug in Joint connectors on fuel pump connectors firmly fails in contact If voltage is normal, fuel Replace fuel pump pump fails If tester reads 0V, burner Replace burner control fails control If it ignites after ・Clean fuel lines cleaning, fuel flow ・Clean and rinse decreases because of the tank with clogged in fuel lines kerosene, alcohol or acetone Filter is clogged Check condition of filter If filter is dirty, amount ・Replace filter of fuel flow decreases ・Clean and rinse because of clogged filter the tank with kerosene, alcohol or acetone Nozzle is clogged Replace nozzle If it ignites, nozzle is ・Replace nozzle clogged ・Clean and rinse the tank with kerosene, alcohol or acetone 3 VAL6 KBE5S Trouble Shooting Phenomenon Possible Cause How to check Result Remedy Loose joint of fuel Check looseness of each If heater ignites by Tighten joints lines joint tightening joints, air leak is the problem Reference Fuel pump is Remove burner cover No fuel is pumped up, Replace fuel pump clogged, or failure and fuel outlet line, and fuel pump is clogged or then turn on the switch failure Picture 4 Plug in connector Igniter does Loose connection Plug in igniter connector If it works normally, of igniter (CN 4) again, and then loose connection of (CN 4) surely not spark. turn on the switch igniter connector [Igniter does connector not operate.] Failure of igniter Measure voltage at If voltage is normal, Replace igniter igniter connector (CN4) igniter fails on burner control Sequence of operation is normal, but it doesn't ignite Failure of burner control Electrode is out of alignment Standard:AC120V (black-black) Measure the alignment of electrode If tester reads 0V, burner Replace burner control fails control Refer to Picture 5 Replace electrode (adjust the position) Picture 5 Improper amount Check gate opening of of combustion air fan motor Find adequate amount of Adjust gate air flow for better opening. combustion Normal scale: 3 4 VAL6 KBE5S Trouble Shooting Phenomenon Possible Cause Misfire lamp Loose flame 3.Misfire monitor is lit. within 25 seconds after Shortage of light ignition. sensed from flame How to check Open burner cover, and check if the flame monitor is in Take flame monitor out, and check condition of its lens Remove burner, and then check clarity of draft tube and vane Check extent of combustion air inlet opening Result Remedy If flame monitor comes Put in flame off, it doesn't work monitor firmly If photorecepter is dirty, sensor becomes less sensitive. If draft tube or fan is dirty, it senses little light If opening is too wide, flame is short because combustion air is too much Loose connection Plug flame monitor If it works normally, of flame monitor connector (CN 11) flame monitor connector again, and then turn on fails on contact Failure of flame Unplug flame monitor If resistance doesn't monitor connector (CN 11), and change, flame monitor then check transition of fails resistance by changing quantity of light into flame monitor Nozzle clogged Replace nozzle If it ignited, nozzle is clogged Filter clogged Check clarity of filter If filter is dirty, fuel flow decreases because of filter clogged Reference Clean the sensor with soft cloth Clean draft tube and whirl vane Picture 8 Decrease opening to reduce combustion air. Normal scale: 3 Plug connector (CN 11) firmly Replace flame monitor Replace nozzle Replace filter 5 VAL6 KBE5S Trouble Shooting Phenomenon Possible Cause 4. Misfire lamp Air leak Combustion is lit. stops during Insufficient amount of pumping fuel because vacuum forms in tank Shortage of light detected by flame monitor Reference How to check Result Remedy Check looseness of each If heater ignites by Fasten joints more joint tightening joints, air leak tightly is the problem Check if air intake of If air intake of fuel Clean air intake of fuel gauge is clogged gauge is clogged, fuel gauge with dust amount of fuel flow becomes insufficient because of vacuum Picture 10 Take flame monitor out, If lens of flame monitor Wipe lens of and then check clarity of is dirty, it detects a little flame monitor its lens light with soft cloth Remove burner, and If draft tube or whirl Clean draft tube then check clarity of vane is dirty, flame and whirl vane draft tube and vane monitor detects little Picture 7 Flame monitor Plug flame monitor If it works normally, Plug connector connector is loose connector (CN 11) flame monitor connector (CN 11) firmly connection again, and then turn on fails on contact Failure of flame Unplug flame monitor If resistance doesn't Replace flame monitor connector (CN 11), and change, flame monitor monitor then check transition of fails resistance by changing quantity of light into flame monitor Nozzle clogged Replace nozzle If it works normally, Replace nozzle nozzle was clogged Filter clogged Check clarity of filter If filter is dirty, fuel Clean or replace flow decreases because filter of clogged filter 6 VAL6 KBE5S Trouble Shooting Phenomenon 5.Smell of fuel comes out. Possible Cause How to check Quantity of Check gate opening of combustion air is combustion air inlet too much Nozzle clogged Filter clogged Wrong nozzle Result If opening is too extensive, it burns imperfectly Remedy Decrease gate opening of combustion air inlet. Normal scale: 3 Reference Replace nozzle If it works normally, Replace nozzle nozzle is clogged Check condition of filter If filter is dirty, amount Replace filter of fuel flow decreases because of clogged filter Check makers imprint of If makers imprint is the nozzle incorrect, the nozzle is Mark: 0.85USgal/h 60° should not be used H Replace to a correct nozzle 7 VAL6 KBE5S Trouble Shooting Phenomenon 6.Smoke comes out. Possible Cause How to check Shortage of Check extent of combustion air combustion air inlet opening Decrease of air brought from fan Check if fan is dusty Result Remedy If combustion air inlet is Extend too small, it burns in combustion air short of oxygen inlet opening. Normal scale: 3 If fan is dusty, it is short Clean fan of air Reference Decrease Measure voltage at If voltage at power Check voltage revolutions of the power source connector source is lower than fan standard, combustion air is decreased because of low voltage (Power source voltage is insufficient) Standard: AC120V Nozzle clogged Replace nozzle If it works normally, nozzle was clogged Using at high Know the altitude If using at higher than altitude area (Low the altitude of 3300ft, oxygen heater burns imperfectly concentration) because of lack of oxygen Wrong nozzle Check makers imprint of If makers imprint is the nozzle incorrect, the nozzle is Mark: 0.85USgal/h 60° should not be used H Replace nozzle Extend combustion air inlet opening. Normal scale: 3 Replace to a correct nozzle 8 VAL6 KBE5S Trouble Shooting Phenomenon 7. Combustion is not stable. 8.Fuel leaks. Possible Cause How to check Result Remedy Loose joints in Check looseness of each If any joints are loose, Tighten joints fuel line joint air is absorbed into fuel lines from loose joint Loose joints in fuel line Check looseness of each If any joint is loose, fuel Tighten joints joint is leaking Failure of drain gasket Remove drain bolt after Fuel leaks because of removing fuel from broken gasket tank, and then check that gasket isn't broken Amount of fuel in Check the fuel level the tank is too much Reference Replace drain gasket Fuel overflows because Drain excess fuel quantity of fuel in the tank is too much 9 VAL6 KBE5S Trouble Shooting Phenomenon 9.Fuse blows When the out plug is put into the outlet. Possible Cause How to check Result Remedy Short circuit of Unplug transformer If either of the values is Replace a transformer coil connector (CN 7) from 0Ω, transformer is short- transformer burner controller, then circuited measure coil resistance values of two leads Reference Standard: about 350Ω (white-red) Standard: about 9Ω (purple-purple) When the switch is turned on. ・Without tester Unplug transformer If fuse doesn't blow out, Replace connector (CN 7) from transformer is shorttransformer burner controller, then circuited put plug into AC outlet Short circuit of fan Unplug fan connector coil (CN 3) from burner controller, then measure resistance between terminals ・Without tester Unplug fan connector (CN 3), and then start operation If resistance value is 0Ω, Replace fan fan coil is short-circuited If fuse doesn't blow out, Replace fan fan coil is short-circuited 10 VAL6 KBE5S Trouble Shooting Phenomenon Possible Cause How to check Short circuit of Unplug igniter igniter connector(CN 4) from burner controller, then measure resistance between terminals Short circuit of About 5 seconds after pump coil turning on Result Remedy If resistance value is 0Ω, Replace igniter primary side of igniter is short-circuited Reference ・Without tester Unplug connector (CN If fuse doesn't blow out, Replace igniter 4) from igniter, and then igniter is short-circuited start operation Unplug fuel pump connector (CN 6) from burner controller, then measure resistance between terminals ・Without tester Unplug fuel pump connector (CN 6), then turn on If resistance value is 0Ω, Replace fuel pump pump coil is shortcircuited If fuse doesn't blow out, Replace fuel pump pump coil is shortcircuited 11 Chart1 Standard resistance of functional parts Parts Connector No Lead Condition on off dark light input output input output Resistance 0Ω ∞Ω over 2MΩ under 10KΩ about 350Ω about 9Ω about 4.5KΩ Operation Switch CN8 Yellow-Yellow Photo Cell CN11 Black-Black Transformer CN7 Red-White Purple-Purple Igniter CN4 Black-Black Solenoid Pump CN6 Red-Blue - about 130Ω Fan motor CN3 Gray-Gray - about 10Ω Remarks gate:Normal scale 3 (60Hz)* When heater is used above 3,000ft sea level, adjust air inlet on fan motor for better combustion Chart2 Parts Input & Output of Burner Control Connector No Lead Condition Voltage Power code CN1 Transformer CN7 Igniter CN4 Black-White Red-White Purple-Purple Black-Black - input output input AC 120V (±10%) AC 120V (±10%) about AC 15V AC 120V (±10%) Solenoid Pump CN6 Red-Blue - AC 60~96V Fan motor CN3 Gray-Gray 60Hz 50Hz AC 120V (±10%) - Picture 1 How to measure resistance ① Pull out a connector which you will measure from burner ② Turn on the resistor and set resistor range ③ Insert the lead head of resistor to connector [lead wire side] and measure resistance Picture 2 How to measure voltage ① Operate the heater ② Turn on the resistor and set AC voltage range ③ Insert the lead head of resistor to connector and measure resistance Picture 3 Removing a burner screw Unscrew two screws and take a burner cover off Nut Unscrew three nuts and take a burner off Unscrew two silver nuts with holding gold nuts and remove two fuel hoses Picture 4 Inspection fuel pump Remove a pipe and check whether fuel comes out Standard pressure 99 psi (±4) Picture 5 Standard position of electrode Electrode Manufacturer does not recommend to fix electrode as they are very sensitive to position. Nozzle 4±0.5mm 8±0.5mm Electrode 10±0.5mm Picture 6 Inspection terminals for control device Check whether the terminals for control device are coupled firmly Picture 7 Inspection draft tube and fan Picture 8 Inspection fuse① Object Serial Number : 01S, 01R, 01Q-030000 whirl draft b In case of draft tube and fan are dusty, please clean them up Open the fuse box and check whether the fuse blows out Picture 9 Inspection fuse② Picture 10 Clean up fuel gauge Object Serial Number :01Q-040000, 01P, 01N Open a screw cap and take out a fuse Check whether fuse is blown out If air intake of fuel gauge is clogged, clean it up air i k Daily Maintenance Inspection of the tank inlet filter 1 Remove the fuel cap and and check inlet filter is clean 2 If the inlet filter is dirty, clean it with fuel 3 Place the inlet filter back and tighten the fuel cap firmly Inspection of the filter and drainage of water from the fuel tank Checking the filter element 1 Check if the filter element is dirty If the filter element if dirty 2 replace to a new one. Plug the new filter in and tighten the metal ring If dirt or water is found in the cup, clean the cup throughly 3 Also clean the inside of fuel tank Drain the dirty fuel from the bottom of the tank Drainage of water/dirty fuel from the fuel tank Drain the old fuel from the bottom 1 of fuel tank by loosing the drain bolt Loose the drain bolt again 5 to drain the dirty fuel 2 Place the drain bolt back 6 Pour clean kerosene or alcohol 3 into the fuel tank 4 Shake the fuel tank Place the drain bolt and fuel cap firmly Inspection and cleaning of the flame monitor Observations - When removing the flame monitor, hold it by its main assembly; do not pull out the cord. Remove the burner cover and pull out the 1 flame monitor, and check if sensor is dirty If the sensor is dirty, please wipe the 2 surface of its lens with a soft cloth 3 Place the sensor back into the position Online parts ordering: http://easycleansystems.com/heaters/heater-parts.html Order parts by phone: 800 292-3279 916 638-0828