Download SERVICE MANUAL

Transcript

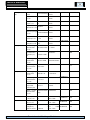

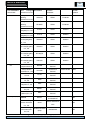

SERVICE MANUAL 03D Series SERVICE MANUAL Order No. Front Load Washing Machine MODEL: L614WD13 WARNING This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or products dealt with in this service information by anyone else could result in serious injury or death ©2011 Front Load Haier Washing Machine All rights reserved. Unauthorized copying and distribution is a violation of law. Front Load Washing Machine SERVICE MANUAL 2 03D Series 21 21 21 22 Front Load Washing Machine SERVICE MANUAL 3 03D Series 22 23 23 24 9 28 10 Washing process table 33 Front Load Washing Machine 03D Series Front Load Washing Machine SERVICE MANUAL 5 03D Series Front Load Washing Machine 03D Series L614WD13 300 800 6 1400 1 2050 850X525X595 67 60 78 <0.5 <0.5 Front Load Washing Machine SERVICE MANUAL 7 03D Series Chapter 3 Appearance brief introduction 3-1. Name of parts 52 5 850 L614WD13 595 Front Load Washing Machine SERVICE MANUAL 8 03D Series Chapter 4 Operational Guidance Quick Wash Pre-Wash Mix Cotton Standard Delicate Eco Rinse Synthetic Wool Power Spin Dry Delay 90 1400 60 1000 40 20 Temp. L614WD13 800 400 Speed Intense Dry Start/Pause Dry . . ¬Control panel lock function: Press the "Delay" and the "Start/Pause" buttons simultaneously for 3 seconds after starting a program.Button Functions and wash cycle will be unable to be changed. To unlock press the "Delay" and "Start/Pause" buttons again for 3 seconds. Front Load Washing Machine SERVICE MANUAL 9 03D Series K Press this button ,the "dry" indicator light will illuminate.When you select the washing programe first, and then press this button,the machine will perform the washing and drying function. ¬To cancel a program Press the "Start/Pause" button, then switch off the power and the program is automatically cancelled. Turn on the power and use the program selector again to choose another program. ¬To cancel audible alarm Alarm sound can be cancelled if it is required (not recommended) Switch on the washing machine and turn the program knob to Spin/Drain cycle, then press the "Delay" and "Dry” button, hold on for 3 seconds. The message "bEEP OFF” will be displayed on the screen, indicating that the alarm sound has been cancelled. ¬To reinstate audible alarm Switch on the washing machine and turn the program knob to Spin/Drain cycle, then press the "Delay" and "Extra rinse"button, hold on for 3 seconds.The "bEEP On" message will be displayed on the screen, indicating that the alarm sound has been reinstated. ¬Power-off memory function In case of abrupt power failure or the need to cut off the power during a program cycle, the present settings will be saved and the preset operation will resume when the power is on again. Front Load Washing Machine SERVICE MANUAL 10 03D Series Chapter 5 Wiring circuit Front Load Washing Machine SERVICE MANUAL 11 03D Series l l l l ll ll l l AC l l l l l l ll 1.How to start Press the “Temp.” and “Speed” button, at the same time, put plug in the socket, then LED will be on.Press“start/pause” button, it will enter the model of the machine, then press the “start/pause” button again, it will implement the test function. 2.Test item 1)Door switch is closed for 3 seconds, “88:88” will display. If the door switch is open, “Err1” will display. 2)”77:77” will display, if the level of water reach the first level following these steps: firstly, the water is from the pre wash valve for 5 seconds, secondly , the water is form the main wash valve for 5 seconds, thirdly, the water is from the hot water valve for 5 seconds(if there is not hot water, this step ignores), then the water is from the soft water valve (in the mean, the main wash valve and the prewash valve work at the same time) until the first level. “Err5” will dispaly, if the first level does not reach after 2 minutes.(“Err8”will dispaly, if the first level indicates before the water coming from the valve, or it showesreaching the overflown level). 3) The Heater works for 10 seconds, ”66:66” will display. 4) When the water runs out, “55:55” will be on. If there is water after 2 minutes, “Err2” will be on. 5) Drain Pump keep working, at the same time, the washing machine works 10s at the speed of 400rpm, then it keep 10s at the speed of 1400rpm,“44:44” will be on. Please press the “start/pause” botton or turn off the power when it need stop the program. If there is something wrong, please deal with the trouble following the indication. 1.Press the “Speed” button, at the same time, put plug in the socket,then it will enter the model of the washing machine. 2. “1490” dispalys on the screen, then press “Speed” button to choose the correct speed 1490/1480/1470/ 1460/14501290/1280/1270/1260/1250/1090/1080/1070/1060/1050 ” will be display by turn. In order to save the right model, please press the “Temp.” button. Finally, please cut off the power when the washing work is over. Finally, please cut off the power when the washing work is over. 3. “1460” is the original edition before you choose the model. 4. The model will change as following “1490/1480/1470/1460/1450/1290/1280/1270/1260/1250/1090/1080/ 1070/1060/1050 when you choose the model for the first time (from the lager number to the little).The model can not change after you set up. 5. For the model “L614WD13” Please choose “ 1460 ” SERVICE MANUAL 12 03D Series Chapter 7 Error Display and troubleshooting 7-1 d Front load Washing Machine SERVICE MANUL 13 03D Series 7-2. Error Display Error message:Door is not properly shut 20s after program is started. Troubleshooting: Shut the door properly Pushing the door to Check Whether Door is properly shut or not N Y Cut off the power and then turn on again. Check the voltage between brown wire and blue wire of door lock, is it between AC 220-240V? Door lock is broken and need replacing, then make sure wire is connected properly. Y N Check if the wire connecting door lock and PCB is loose Connect the wire properly Y N Replace PCB Check the voltage between X1-2 and X2-2 of PCB, is it between AC 220-240V? N Error message: Drainage error, water not emptied within 6 min. Troubleshooting: Check if the pipe connected to the water level sensor is jammed, If it is, clean the pipe. If not, replace PCB Check if water is emptied Y N Check if drain pump acts by touching pump position Y N Check if drain pump or drain pipe is jammed, And open the filter and clean Cut off the power and choose spin program to start ,then check the import voltage of drain pump, is it between AC 220-2240 V? Y N Cut off power and pull out water level pressure switch wire connection. Set spin program to start. Check the export voltage to drain pump, is it between AC 220-240V? Y N Replace drain pump The wire between PCB and drain pump is not connected properly. Replace the wire. Replace PCB Haier Front Load Washing Machine SERVICE MANUL 14 03D Series Error message:Temperature sensor is not properly connected or damaged. Troubleshooting: Cut off power and measure the resistance of temperature sensor by multimeter, is it between 5-14k ? NTC exist open circuit. Replace it N Y Check if NTC is connected properly Connect NTC well N Y Check the wire between NTC and PBC, are they connected well? Connect all wires well N Y Disconnect the two black wires from PCB , and measure if the resistance between the two black wires of PCB, is it infinite? Replace wire Y N Replace PCB Error message:The heater may be broken(dispiay at the end of a program). Troubleshooting: Check if overload laundry. Reduce the laundry Y N Cut off power, check the resistance of two pins of heater element by multimeter, is it between 27-30 ? N Heater element must be broken, please replace it Y The control wire may be broken, Otherwise the PCB must be broken; Please replace the broken. Haier Front Load Washing Machine SERVICE MANUL 15 03D Series Error message: The required water level is not reached within 8 min. Troubleshooting: Connect it well. Check if water is leaking from washer bottom. Inlet pipe. drain pipe or other pipe connection Y N Check if tap is closed or water pressure is too low (usual between 0.03 -1 MPa) Y Open the tap or wait for normal water pressure to use N Clean inlet valve Check if inlet valve is jammed Y N Draw out the dispenser and check if water is entering Y N Turn on power, and set pre-wash mode, then start. Check the import voltage of electromagnetic valve by multimeter is it between AC 220-240V? Y Observe if the height of drain pipe not reach 80 cm. If water level sensor and the hose is leaking gas Electromagnetic valve must be broken, please replace it. N The wire connected PCB and inlet valve is not properly. Please reconnect it or replace it. Check if export voltage from PCB to electromagnetic valve is it between AC 220-240V? Y N Replace PCB Haier Front Load Washing Machine SERVICE MANUL 16 03D Series Error message. Motor speed is abnormal. Troubleshooting: Cut off power and check if motor wires are connected well Reconnect well N Y N Switch on the power and check the voltage(9 or 10 of motor connector) is between 220-240V? Replace the PCB Y The motor is broken, replace it. Haier Front Load Washing Machine SERVICE MANUL 17 03\D Series Error message. Water level exceeds protection value. TroubTroubleshooting: leshooting: Troubleshooting: Unfold the pipe connected Check if the pipe connected to the Y water level sensor is folded. to the water level sensor N Check if the pipe connected to the water level sensor is jammed. Clean the pipe connected Y to the water level sensor N Without power ,connect inlet pipe to inlet valve, then open the tap and observe if water is entering in dispenser Replace inlet valve Y N Without starting but electrifying, measure the import voltage of inlet valve, is it between AC 220-240V? Haier Y Front Load Washing Replace PCB Machine SERVICE MANUL 18 03D Series dry heating element error check the resistance of dry heating tube by mulitimeter,is it between 2730 check the import voltage of dry heating tube by mulitimeter,is it between 220240V Haier Front Load Washing Machine SERVICE MANUL 19 03D Series Error message dry motor error Troubleshooting Cut off power and check if drying motor wires are connected well Reconnect well Replace the drying motor Haier Front Load Washing Machine SERVICE MANUL 20 03D Series Error message The PCB and the motor can not communicate Troubleshooting Are the lines between PC board and drive board ok? Please connect the lines or replace them. Can the indicator light on the drive board flash? replace the drive board replace the PC board Haier Front Load Washing Machine SERVICE MANUL 21 03D Series 7-3. 7-3-1. Examination & Troubleshooting Display nothing Troubleshooting: Repair power supply Measure the power supply ,is it exists 220V-240V AC voltage ? N Y Press the power switch Is power switch on? N Y Press power switch and check the voltage between L port and N port of the filter. Is there 220-240V AC voltage? The filter is broken, replace the filter N Y Cut off power and check if plugs are connected well by pulling the plug of PCB. Insert the plug well and test N Y Check if PCB exists 220V-240V AC voltage at the import pin Replace PCB N 7-3-2. No water inletting Troubleshooting: Is the tap shut off or the water pressure too low? Y Open tap or wait for normal water pressure N Check if water is leaking from washer connection, especially between inlet pipe and tap. to make sure of no bends. Y Reconnect inlet pipe. N Check if filter of electromagnetic valve is jammed Clean filter Y N Choose pre-wash program and start, Check if there is 220-240V at import pin of electromagnetic valve Replace electromagnetic valve N Y Is there open circuit between electromagnetic valve and PCB? Reconnect the wire N Y Choose pre-wash program and start, then check if there is 220-240V at export pin of electromagnetic valve Haier N Front Load Washing Replace PCB Machine SERVICE MANUL 22 03D Series 7-3-3. No draining Troubleshooting: Is the height of drain pipe too high? Adjust the height of drainpipe to 80-100 cm Y N Turn filter anticlockwise, check if filter is jammed open and Clean and tighten filter clockwise. Y N Check if hose-connecting cylinder to pump is bent or jammed Arrange hose and clean Y N Turn on power and choose spin program to start. Measure if import voltage of drain pump is 220-240V Replace drain pump Y N Cut off and check if the connection between drain pump and PCB is open Y Replace the wire . N Replace PCB Turn on and select spin program to start, Measure export voltage of PCB to the drain pump, is it 220-240V? 7-3-4. N Abnormal noise and vibration Troubleshooting: Is the pack screws dismantled? N Dismantle the screws Y Clean Y Is there foreign material in the washer ? N Adjust adjustable feet Is washer in balance? N Y Replace it Is belt loose or worn? Y N Remove belt and turn belt pulley by hand, and then check if there is different noise Dismantle triangle and check the bearing. If it is broken, replace it. Y N Turn on power and set spin program, then start, check if there is different noise from motor Haier Replace motor Y Front Load Washing Machine SERVICE MANUL 23 03D Series 7-3-5. Water leaking Troubleshooting: Check if water is leaking from the inlet pipe or the tap Readjust it Y N Is drain pipe broken? Y Replace drainpipe N Check if there is foreign material nipped between cushion of sight window and sight window Y Remove clothes N Check if all tubes and tie-in is leaking water, including the connecting of tube and valve, dispenser, tube and dispenser, outer cylinder-cushion of sight windowhose and outer cylinder, drain Y Reassemble or repair N Replace outer cylinder Is cushion of sight window broken? Y N Is water leaking from outer cylinder? 7-4. Parameter of primary electronic appliance The rated voltage , current and frequency of motor The rated voltage of motor is 220~240V,rated current of motor is 6A,rated frequency of motor is 50/60Hz, 2 3-4K Heater Haier Front Load Washing Machine SERVICE MANUAL 24 03D Series 8 Front Load Washing Machine SERVICE MANUAL 25 03D Series Front Load Washing Machine SERVICE MANUAL 26 03D Series Dismantle the motor Release the two screws on the Motor bracket. Pull the motor along the arrowhead, then take off the motor. Dismantle shock absorber Pull out the pin of shock absorber, then take off the bolt and washer of on the cabinet The pins can not be used again. shock absorber pin Dismantle the door lock Take off the tightening ring of rubber cushion, release the twe screws of door lock. Pull out thewire connecting the lock, then take the lock out. Front Load Washing Machine SERVICE MANUAL 27 03D Series Front Load Washing Machine SERVICE MANUAL 28 03D Series Chapter 9 Componenten Einzelteil Hersteller Typ/Modell Technische Daten Geprüft nach Object/part No. Manufacturer/ trademark Type/model Technical data Standard Prüfzeichen Mark(s) of conformity see separate sheet PCB 1.PCB ASSEMBLY Haier Interlligent 0021800059 ˄display˅ Electronics Co.Ltd. 220-240V / Test with 50Hz/60Hz appliance Changzhou 2. PCB Aohong Electronics Co., Ltd KB-6160 KunShan china thrive circuit board KB-616XS ǃ SN-L4 ǃ FR-4-86-PY/UV co.ltd Block FR-4-86 2.Transformer Shenzhen meikai T1 Electronics Stock E303981 UL E227809 UL E239832 UL FR-4 FR-4 BCK-1941/2250 2mH±10% Co.,Ltd. Qingdao Jingshi BCK-25-2521 Electronics 2mH±10% E353025 UL 2mH±10% E341237 UL Co.,LTD. Jiangsu Taichang BCK-EI22-09208 Electronics Co.,LTD. 3.X2 CX2 Capacitor Pilkor Electronics Co.Ltd IEC/EN132400 VDE X2,0.1UF 275VAC IEC/EN132400 VDE EPCOS(Zhuhai B32922C3104M2 X2,0.1UF 305VAC IEC/EN132400 ENEC FTZ)Co., Ltd 89 X2,0.1UF 275VAC IEC/EN132400 VDE X2,0.1UF 275VAC IEC/EN132400 VDE Jimson Electronics MKP104K/275VA X2,0.1UF 275VAC IEC/EN132400 VDE IEC/EN132400 ENEC PCX2 337F60104 X2,0.1UF 275VAC Xiamen Faratronic MKP61 Co.,Ltd. Okaya electric industries Co., Ltd. Nistronics (Jiangxi) Co.,Ltd LE104-M MPRC 0275K104M0000 035 (Xiamen)Co.,Ltd C P15 Ultra Tech Xiphi HQX104K275I15 X2,0.1UF 275VAC Enterprise Co.Ltd Front SNY Load Washing Machine SERVICE MANUAL 29 03D Series 4.X2Capacitor Pilkor Electronics CX1 Co.Ltd PCX2 337J60334 IEC/EN132400 ENEC IEC/EN132400 VDE IEC/EN132400 VDE IEC/EN132400 ENEC IEC/EN132400 VDE IEC/EN132400 VDE IEC/EN132400 VDE IEC/EN61810 VDE 5A/250VAC IEC/EN61810 VDE 10A125VAC IEC/EN61810 TUV 5A/250VAC IEC/EN61810 TUV 12A/7A250VAC IEC/EN61810 TUV IEC/EN61810 VDE 10A/250VAC,5A/2 IEC/EN61810 VDE X2,0.0047UF 275VAC Xiamen Faratronic MKP61 X2,0.0047UF Co.,Ltd. 275VAC EPCOS(Zhuhai B32921C3473K2 X2,0.0047UF FTZ)Co., Ltd 89 Okaya electric industries Co., Ltd. Nistronics (Jiangxi) Co.,Ltd 305VAC LE104-M MPRC X2,0.0047UF 275VAC X2,0.0047UF 0275K472000000 275VAC 35 Jimson Electronics MKP472K/275VA X2,0.0047UF (Xiamen)Co.,Ltd C P10 275VAC Ultra Tech Xiphi HQX472K275F15 X2,0.0047UF Enterprise Co.Ltd 5. Relay K1 Xiamen SNY 275VAC 5A 250VAC Hongfa Electroacoustic JZC-32F/012-HS 5A 30VDC Co.,Ltd. Tyco Electronics (shenzhen) Co., OJE-SH-112DM Ltd Anhui Mingguang Life Electronic BJ-SS-112DM 5A250VAC/30VDC Co.,Ltd Xiamen Song Chuan Precision 307-1AH-C Co., LTD. Relay K2,K3,K4 Anhui Mingguang Life Electronic 15A125VAC BRD-SS-112L Co.,Ltd Xiamen Song 10A/8A/277VAC Chuan Precision 812H-1C-V Co., LTD. Omron Electronic Components G5LA-14 50VAC (Shenzhen) Ltd. Xiamen Hongfa Electroacoustic Co.,Ltd. 6. Varistor RV1ˈ IEC/EN61810 VDE IEC/EN61051 VDE IEC/EN61051 VDE 1200A IEC/EN61051 VDE 10A/250VAC HF3FD-012-ZSTF (245) EPCOS (Zhuhai B72214S2351K5 Imax˖8000A FTZ) Co., Ltd. 02 V1mA˖560V (Zhuhai B72207S2271K1 Imax˖1200A 7.Varistor RV2ˈRV3 EPCOS FTZ) Co., Ltd. 01 V1mA˖430V Thinking (Changzhou) Imax Electronic Co Ltd Front TVR07431 Load ˖ V1mA˖430V Washing Machine SERVICE MANUAL 30 03D Series 1.PCB ASSEMBLY Haier Interlligent 0021800052 ˄drive board˅ Electronics Co.Ltd. 2.PCB 220-240V / Test with 50Hz/60Hz appliance Changzhou UL Haihong KB-5150 CEM-1 E166702 Electronics Co.Ltd. Changzhou UL Haihong ZD-95GF CEM-1 E166702 S3155 CEM-1 E56334 S3116 CEM-1 E56334 Electronics Co.Ltd. HT Circuits (Qingdao) Co.,Ltd. HT Circuits (Qingdao) Co.,Ltd. HT UL UL UL Circuits(Qingdao) KB5150 CEM-1 E56334 Co., Ltd. HT UL Circuits(Qingdao) KB5150 CEM-1 E56334 Co., Ltd. HT UL Circuits(Qingdao) ZD-95(G)F CEM-1 E56334 Co., Ltd. HT UL Circuits(Qingdao) DS7106 CEM-1 E56334 Co., Ltd. 3. C9 EPCOS Electronic Components S.A. . Okaya electric industries Co., Ltd. Pilkor Electronics Co.Ltd Nistronics (Jiangxi) Co.,Ltd ultra tech xiphi enterprise co., ltd Xiamen Faratronic Co.,Ltd. Jimson Electronics (Xiamen)Co.,Ltd 5. Relay K1,K2,K3 OMRON X2,0.047UF X2,0.047UF X2,0.047UF Hongfa Electroacoustic Co.,Ltd. Front X2,0.047UF HQX IEC/EN132400 ENEC IEC/EN132400 VDE IEC/EN132400 VDE IEC/EN132400 VDE IEC/EN132400 VDE 275VAC X2,0.047UF MKP61 275VAC X2,0.047UF MKP 275VAC NO:10A/250VAC,N IEC/EN61810 C:5A/250VAC NO/NC:10A/8A/277 HF3FD-012-ZSTF (245) Load ENEC 275VAC Co., Ltd. Xiamen IEC/EN132400 275VAC MPR 812H VDE 275VAC PCX2 Xiamen Song IEC/EN132400 305VAC LE473M G5LA-1 Chuan Precision X2,0.047UF B3292# Washing VDE IEC/EN61810 VDE VAC IEC/EN61810 10A/250VAC Machine VDE SERVICE MANUAL 31 03D Series Others(universal) VDE AC 250V, 16A, DIN VDE 0620 VDE AC 250V; 13A BS1363 BSI AC250V 13A BS1363 KEMA AC250V 13A BS 1363 ASTA 230V 1800W IEC/EN 60335-1 VDE 250V 16Aˈ167ć IEC/EN 60691 230V 1800W IEC/EN 60335-1 VDE G5 250V 16Aˈ184ć IEC/EN 60691 VDE G4 250V 10Aˈ184ć IEC/EN 60691 VDE NW84TF 230V 1800W IEC/EN 61770 VDE SW-120T 250V 10A , 167ć IEC/EN 60691 VDE PS2SP-B1 DC5.0V IEC/EN 60335 Tested with appiance DC5.0V IEC/EN 60335 Tested with appiance AC 220-240V, IEC/EN 60730 Tested appiance Various H05VV-F 3G*1.5mm 2.Power Plug Various Various Chau’s 2 DIN VDE 0281 1.Power Cord Electrical BS-01 Company Limited LEONI Cabel CW3201 (Changzhou) Co., Ltd Fund Resources BS-01J Electric Industry Co.,Ld.Shanghang 3.Heating Element Hangzhou (double fuse) Thermal link Kawai WACDD5141 Electric Co.;Ltd (in Emerson heater) G5 VDE Electric(Shenzhen) Co.,Ltd. 4.Heating Element Zoppas (double fuse ) Industries RW8TF Hangzhou Ltd.(ZIH) Thermal link (in Emerson heater) Electric(Shenzhen) Co.,Ltd. Alternative Emerson Electric(Shenzhen) Co.,Ltd. 5.Heating Element Zoppas (double fuse) Hangzhou Ltd Thermal link (in Sung Woo heater) Industrial Co. 6. Water Industries level Hangzhou sensor Kambayashi Electrics Co.,Ltd. Dongguan Ark-les ST-545 Elec.Components Co.,Ltd. 7.Water inlet valve Hangzhou 0024000274 Kambayashi FCF-22-B6 50/60Hz, Electrics Co.,Ltd. Front Load Washing Machine with SERVICE MANUAL 32 03D Series 8. Micro-delay door Dongguan Ark-les ZV-446 Electric switch 250V 16(6)A, IEC/EN 60730 VDE IEC/EN 60730 ENEC IEC60939 SEMKO T85 Components Co.,Ltd ROLD DA 250V 16(6)A, T85 9. Filter DNF06-Q˄RALA˅ 12A,250VAC. Aerodev Electromagnetic 50/60hz.25/085/21 Tech.Inc L: 2x(ı4mH) /EN133200 C: (0.68+0.47)UF (X2) 2x4700pF(Y) 10. Zheijiang Water Inlet Hose Dongyang XG 3/4” 70嘙C IEC/EN 61770 VDE XG-1 3/4” 25嘙C IEC/EN 61770 VDE 70嘙C PVC; IEC/EN 61770 VDE 3/4” 25嘙C IEC/EN 61770 VDE GJS-150CXH 3/4” 90ć IEC/EN 61770 VDE GJS-FL-115H 10bar 90ć MAX IEC/EN 61770 VDE Yidan,Electron Make Co.,Ltd. Zheijiang Dongyang Yidan,Electron Make Co.,Ltd. Taizhou Hualong V70D Outside 16mm; Household thread 3/4'' Appliance Accessory Co., Ltd. Wuxi Jinhua GJS-150CX Electrical controlling Equipments factory Wuxi Jinhua Electrical controlling Equipments factory Mechanical Valve Wuxi Jinhua with hose set Electrical IEC/EN 60730 controlling Equipments factory Alternative Eltek S.p.A. 100269... 10bar 90嘙C MAX (mechanical VALVE) Front Load Washing Machine IEC/EN 60730 VDE SERVICE MANUAL 33 03D Series 11. PUMP Jiangmen Hanyu B20-6A Electrical Co., IEC/EN 60335 TUV IEC/EN 60335 VDE AC 220-240Vˈ50HZ IEC/EN 60335 VDE IEC/EN 60730 VDE IEC/EN 60730 VDE IEC/EN 60730 VDE IEC/EN 60730 KEMA IEC/EN 60730 VDE IEC/EN 60730 KEMA IEC/EN 60730 KEMA IEC/EN 60730 VDE IEC/EN 60730 VDE AC 220-240Vˈ50HZ Ltd. Askoll (China) S3000 220-240V,50HZ Motor 25W,0.2A Technologies Co., Ltd Changzhou Leshi Leili Motor Co.,Ltd BPX2-34 Protector for Hanyu Chang zhou City KW-90 pump 85~95 ć Tong Li Electronic Co., Ltd. Jiangsu BR-A90 Changsheng AC 250V Electric 85~95 ć Appliance Co., Ltd Changzhou KW-A2 changshengTong AC250V Li Electronic 85~95 ć Co., Ltd. Protector for Askoll Sensata pump 7AM037 Technologies 150ć Holland,B.V. Tyco Electronics CP17AM150 Sensata 17AMC 150 Technologies 150ć 150ć Holland,B.V. Jiangsu 17AM-D150 Changsheng Electric 150ć Appliance Co., Ltd Sensata 3MP* Technologies 145ć for S3000 Tyco Electronics CP17AM145A 145ć ˄for S3000˅ Protector for Leshi Changzhou Ainuo pump Electronics KW-105 AC220V 105ºC IEC/EN 60730 VDE BR-A AC250V 105ºC IEC/EN 60730 VDE Technical Co.,Ltd. Jiangsu Changsheng Electric Appliance Co.,Ltd. Front Load Washing Machine SERVICE MANUAL 34 03D Series Toneluck 12.Aqua proof 0.1A 125/250VAC Electro-Mechanics L50 13.Protector for Chwen-Der haier motor Thermostat & temperature 145± Co.,Ltd. 5ºC CD79 AC250V, operating IEC/EN 60730 17AM216A5 AC250V, operating IEC/EN 60730 Technologies ,Holl temperature 145± and,B.V. 5ºC 14.Protector for Sensata weiling motor Technologies ,Holl temperature 145± and,B.V. 5ºC 15.Heating Element to dryer 17AM216A5 Kawai ENEC 1E5,40T85 (Huizhou) Co., Ltd. Sensata IEC/EN 61058 AC250V, operating IEC/EN 60730 VDE ENEC ENEC 0024000223 AC 220V, 1200W IEC/EN 60335 Test with appliance 36T Off:160f8ć IEC/EN 60730 VDE Off:130f4ćˈ IEC/EN 60730 VDE 16.Non Emerson Electrical self-resetting (Shenzhen) thermal cut-off Co.,Ltd. 17.Self-resetting Emerson Electrical 36T thermal limiter (Shenzhen) On:103f6ć Co.,Ltd. Panasonic 18.capacitor drying fan motor 451series 450V 50/60Hz 1.5uFf5% IEC/EN 60252 TUV CBB65A-1 450V 50/60Hz 1.5uF IEC/EN 60252 VDE IEC60335 CE for Electrical (Jiangmen) Co.,Ltd. Alternative Anhui Feida Industry Stock Co.,Ltd. Ebm-papst 19. Drying Motor R2E133-BE49-C 230VAC 50Hz 2300 Mulfingen GmbH&Co..,Ltd Front 05 Load ˄r/min˅ 1.5uf Washing Machine SERVICE MANUAL 35 03D Series 10 Washing process table * Water Supply : W·S Rinse Washing C Y Pre Main C 3 60 60 15 16 17 18 19 20 21 22 23 24 25 26 D·T 14 Spin 13 W · S Rinsing 12 I · S Drain MIN 120 60 11 Drain 10 I · S W · S Rinsing 9 4 Drain 8 I · S W · S Rinsing 7 1 Drain 600 120 240 120 6 Rinsing 5 I · S W · S Spin Rinse + 2 Drain 4 Drain 3 W · S Rinsing 2 W · S Heating I · S Washing Drain (SEC) Normal Washing Staycooling Washing C O U R S E L W S E · S T E P 1 Time 120 * Intermittent Spin : I·S 27 28 29 * Disentangle : D·T A U D E T R N O Normal Y D O Working F Time F (Hour:Minute) 20 20 180 120 240 60 180 120 240 60 180 120 240 60 180 120 240 60 MIN 60 30 30 Pre-wash cotton ~ About 1:22 Standrard cotton ~ About 1:20 Eco cotton ~ About 1:06 Synthetic ~ About 1:08 Wool ~ About 1:05 Quick Wash ~ About 0:15 Mix About 1:14 Delicate About 0:44 Rinse About 0:23 Spin About 0:12 Dry About 2:20 * Basic Cycle * Optional Cycle * Pre-Setting Time : Water Supply - 120 sec. Drain - 60 sec. * ~ Time for varies as the temperature or the amount of laundry * Basic time is minute in washing chart * The actual program time can be varied with the load amount, water temperature or ambient temp erature If the laundry is heavily soiled, “Pre Wash” course is effective. Pre Wash is available in Cotton . If you want to prevent crease, select this button with spin speed. Front Load Washing Machine