Download SERVICE MANUAL

Transcript

Commercial Air Conditioning

SERVICE MANUAL

Models

AB122ACERA

AC122ACERA

AD122ALERA

AU122AEERA

Features

High energy efficiency

Can be connected with the universal outdoor unit AU122AEERA

Infrared control type or wired control type

Low ambient cooling kit (optional) and low ambient heating kit (optional)

New friendly refrigerant R410a, environment protection

Advanced technology, DC inverter control function

Weekly timer (standard)

Group control function

Auto restart function

Room card function

Manual code: SYJS-020-07REV.0

Edition: 2007-05-15

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

CONTENTS

Contents………………………………………………………...2

1. Description of products & features………………………..3

2. Specification…………………………………………………7

3. Safety precaution…………………………………………..10

4. Net dimension………………………………………………12

5. Installation instructions………..…………………………...14

6. Parts and functions…………………………………………30

7. Controller functions…………………………………………32

8. Refrigerant circuit…………………………………………...33

9. Electrical control functions…………………………………34

10. Electrical data………………………………………………49

11. Troubleshooting …………….....………………………….57

12. Noise level.....................................................................61

2

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

1.DESCRIPTION OF PRODUCTS & FEATURES

1.1. Products code explanation

A

C 12 2

A C

E R

A

Climate type: T1 (see table 1)

Design number (R stands for design sequence, DC inverter

frequency type)

Product type: A stands for heat pump type, refrigerant is R22

B stands for heat pump type, refrigerant is R407C

E stands for heat pump type, refrigerant is R410a

Q stands for cool only type, refrigerant is R410A

Outlook appearance

Product series: A stands for 1 to 1

Applicable voltage: 2 stands for 220~230V/50Hz,

4 stands for 220V/60Hz,N stand for 380~400VAC/50Hz

Cooling / Heating capacity, 12=12000BTU/h

Product type : “B” stands for cassette type, “C” stands for

convertible type, ”D” stands for duct, “S” stands for wall

mounted type, ”Q” stands for chiller system, "E" stands for

ceiling concealed type, “U” stands for outdoor unit

Air Conditioner

1.2 Brief Introduction for T1、T2、T3 working condition

Climate type

Type

of

Conditioner

Air

T1

T2

T3

Cooling Only

18 ℃~43℃

10℃~35℃

21℃~52℃

Heat pump

-7℃~43℃

-7℃~35℃

-7℃~52℃

Electricity Heating

~43℃

~35℃

~52℃

1.3 Operating Range of Air Conditioners

Temp.

Mode

Indoor

Cooling

Outdoor

Indoor

Heating

Outdoor

Rated

Maximum

Minimum

DB

℃

27

32

15

WB

℃

19

23

14

DB

℃

35

43

-5

WB

℃

24

26

6

DB

℃

20

27

10

WB

℃

14.5

---

--

DB

℃

7

23

-10

WB

℃

6

18

---

3

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

1.4 Product features

Adopt the much friendlier refrigerant R410a

The air conditioner system adopts the greatly friendly refrigerant R410a, which is protective for the

ozone layer and is good to avoid the earth getting warmer. Benefit for the environment.

Adopt the advanced DC inverter technology

The system adopts the advanced DC inverter technology, which can consume less power energy to

realize the equal efficiency, saving money for you.

Smart newly designed infrared remote controller

The cassette and convertible unit can be controlled by the infrared remote controller YR-H71, the remote

controller can be fixed with a remote controller holder.

Auto–restart function (optional)

All indoor units have auto-restart function. When the power supply cut off suddenly, the unit will

automatically recover the previous running mode once the power supply is on.

Long-life& high efficiency air purify filter

Low temperature cooling realized, super low temperature heating

realized.

Low ambient cooling kit (optional)

Group control function (with a group controller YR-E12)

Central control function, if connected with a central controller

YCZ-A001

Weekly timing function, if connected with a weekly timer YCS-A001

4

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

1.5 New friendly refrigerant R410A introduction:

■R410A

The working pressure of R410A is approximately 1.6 times higher than R22. Because the oil in the

refrigerant is different, please do not mix them.

Refrigerant

R22 (single)

R410A (mixed)

R407C (mixed)

Oil

Mineral oil (SONTEX 200LT)

Synthetic oil (POE oil)

Synthetic oil (POE oil)

Pressure ratio

1

Approx. 1.6

Approx. 1.1

■Operation flow

prepare work schedule

refrigerant inspection

1. Always inspect the used refrigerant

2. Always use the specified refrigerant

operation chart preparation

indoor unit installation

refrigerant piping work

1. Use piping material of the specified thickness

2. Do not use dirty pipe

3. Always flow nitrogen during welding work

drain piping work

duct work

insulation work

remote controller installation

electric wiring work

1. Do not connect the power supply

outdoor unit foundation work

outdoor unit installation

refrigerant piping connection

leakage test

evacuation and drying

additional refrigerant charging

1. Charge the nitrogen to the set pressure

2. 24 hours later,check if the pressure in the pipe

has reduced

1. Air purging by refrigerant is prohibited seriously

2. Use a special vacuum pump with reverse check

mechanism

1. Calculate the refrigerant additional charging

amount, and charge a suitable amount.

gas leakage check

maintenance panel installation

trial running and adjustment

hand over

5

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

■Piping material

1. Use the correct refrigerant piping and materials for R410A

2. For the pipe wall thickness, see the table below:

Pipe diameter

Φ6.35

Φ9.52

Φ12.7

Φ15.88

Φ19.1

Pipe wall thickness

0.8

0.8

0.8

1.0

1.2

Note: Always observe and comply with the local regulations when installing the refrigerant piping.

■Tools

R410A work requires a number of special tools (* symbol). Since the tools used in R22 work

cannot be used for R410A, provide the tools separately.

Tool name

Process and application

Pipe cutter

Piping cutting

*Flaring tool

Pipe flaring work

*Torque wrench

Flare nut connection

Expander

Expansion at pipe connection

Pipe bender

Pipe bending work

Nitrogen gas

Pipe oxidation prevention

Welder

Pipe brazing

*Gauge manifold

Vacuum

*Charging hose

charging operation check

Refrigerant piping work

evacuation

and

Air tightness test

refrigerant

Air tightness test

Refrigerant

additional

charging

*Vacuum

pump

(with

Vacuum drying

adapter)

Electronic scale

Gas leakage detector

Refrigerant

additional

charging

Gas leakage test

■Work precautions

Refrigerant check: Before work, check the used refrigerant and prepare materials matched to the

refrigerant.

Refrigerant piping: Observe the basics of refrigerant piping to avoid the unnecessary problems. In

addition, when performing the welding work, seal in the nitrogen gas to the pipes, and prevent it

from the oxidation.

Leak pressure detection: Perform seal detection and make sure there is no refrigerant leakage.

Vacuum drying: If the vacuum pump has not the reverse flow check mechanism, use the pump

together with a reverse flow check adapter.

Additional refrigerant: Charge a suitable amount of refrigerant with a special R410A gauge

manifold and charging hose.

6

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

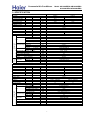

2. SPECIFICATION

Panel

Indoor unit

item

Function

Capacity

Sensible heat ratio

Total power input

Max. power input

EER or COP

ENERGY CLASS

Dehumidifying capacity

Power cable

Power source

Running

Start Current

Circuit breaker

Unit model (color)

Type × Number

Speed(H-M-L)

Fan

Fan motor output power

Air-flow(H-M-L)

Type / Diameter

Heat exchanger Total Area

Temp. scope

External

(L×W×H)

Dimension

Package

(L×W×H)

Drainage pipe (material , I.D./O.D.)

Control type (Remote /wired)

Fresh air hole dimension

Noise level

(H-M-L)

Weight

(Net / Shipping)

External

(L×W×H)

Dimension

Package

(L×W×H)

Weight

(Net / Shipping)

Indoor unit

Item

Function

Capacity

Sensible heat ratio

Total power input

Max. power input

EER or COP

Dehumidifying capacity

Power cable

Power source

Running

Start Current

Circuit breaker

Unit model (color)

Type × Number

Speed(H-M-L)

Fan

Fan motor output power

Air-flow(H-M-L)

Type / Diameter

Heat exchanger Total Area

Temp. scope

External

(L×W×H)

Dimension

Package

(L×W×H)

Drainage pipe (material , I.D./O.D.)

Control type (Remote /wired)

Noise level

(H-M-L)

Weight

(Net / Shipping)

Mode

AB122ACERA

cooling

3.52(0.9--4.4)

0.71

1250(280---1650)

1650

2.81(C)

kW

W

W

W/W

heating

4.4(1.0---4.8)

1210(280--1650)

1650

3.64(A)

1.6

1.5

3×2.5

1, 220--230, 50

6.0(1.4--8.0)A/8A

6.0(1.4--8.0)A/8A

3

3

13

13

AB122ACERA(BLACK)

Centrifugal fan*1

795/690/550±50

0.065

700/620/520

inner grooved pipe/φ7

0.272

2-7

570×570×260mm

718×680×380mm

PVC 26/32

Remote

95

45/40/32

18.5/23

700×700×60mm

740×750×115mm

3.5/4.5

10‐³×m³/h

N, V, Hz

A/A

A

A

r/min

kW

m³/h

mm

m²

℃

mm×mm×mm

mm×mm×mm

mm

mm

dB(A)

kg / kg

mm×mm×mm

mm×mm×mm

kg / kg

Model

AC122ACERA

cooling

4.1(0.9--4.6)

0.71

1270(280---1650)

1650

3.23(A)

kW

W

W

W/W

10‐³×m³/h

heating

4.4(1.0---5.1)

1210(280--1650)

1650

3.64(A)

1.6

3×2.5

1, 220--230, 50

6.0(1.4--8.0)A/8A

6.0(1.4--8.0)A/8A

3

3

13

13

AC122ACERA(WHITE)

Centrifugal fan*2

1200/1080/880

0.09

750/650/550

inner grooved pipe/φ7

0.20

2-7

1090×655×199

1150×750×300

PVC 18/20

Remote

46/44/42

28.3/34.3

N, V, Hz

A/A

A

A

r/min

kW

m³/h

mm

m²

℃

mm×mm×mm

mm×mm×mm

mm

dB(A)

kg / kg

7

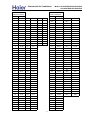

Commercial Air Conditioner

Indoor unit

Item

Function

Capacity

Sensible heat ratio

Total power input

Max. power input

EER or COP

Dehumidifying capacity

Power cable

Power source

Running

Start Current

Circuit breaker

Unit model (color)

Type × Number

Speed(H-M-L)

Fan

Fan motor output power

Air-flow(H-M-L)

Type / Diameter

Heat exchanger Total Area

Temp. scope

External

(L×W×H)

Dimension

Package

(L×W×H)

Drainage pipe (material , I.D./O.D.)

Control type (Remote /wired)

Noise level

(H-M-L)

Weight

(Net / Shipping)

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Model

AD122ALERA

cooling

3.8(0.9--4.4)

0.71

1260(280--1650)

1650

3.02(B)

kW

W

W

W/W

10‐³×m³/h

heating

4.1(1.0---4.8)

1260(280--1650)

1650

3.25(C)

1.6

3×2.5

1, 220--230, 50

6.0(1.4--8.0)A/8A

6.0(1.4--8.0)A/8A

3

3

13

13

AD122ALERA(GREY)

Centrifugal fan*1

1000/900/800±50

0.05

550/450/400

inner grooved pipe/φ7

0.11

2-7

610×483×220

695×536×265

20/18

wired

35/32/30

14/16

N, V, Hz

A/A

A

A

r/min

kW

m³/h

mm

m²

℃

mm×mm×mm

mm×mm×mm

mm

dB(A)

kg / kg

PIPING

Outdoor unit

Item

Mode

AU122AEERA

3×2.5

Power cable

1, 220-230, 50

Power source

N, V, Hz

3

Start Current

A

Unit model (color)

AU122AEERA(WHITE)

C-6RZ092H1A

Model / Manufacture

Compressor

twin rotary

Type

axial*1

Type × Number

840r/min±50

Speed

r/min

Fan

0.06

Fan motor output power

kW

2500/-/Air-flow(H-M-L)

m³/h

Type / Diameter

mm

TP2M/Φ9.52

Heat exchanger Total area

0.374

m²

43-60

Temp. scope

℃

775x640x245

External

(L×W×H) mm×mm×mm

Dimension

901x341x712

Package

(L×W×H) mm×mm×mm

Refrigerant control method

mm/mm Capillary tube: main φ3×φ1.8×920,assistant φ3×φ1.8×780

Defrosting

auto

55

Noise level

dB(A)

Type of Four way valve

SHF-4-10A

XPE

material of reduce noise

37

crankcase heater power

W

Weight(Net / Shipping)

39/43

kg / kg

R410A 1300

Type / Charge

g

Refrigerant

30

Recharge quantity

g/m

6.35

Liquid

mm

Pipe

12.7

Gas

mm

flared

Connecting Method

MAX.Drop

10

m

Between I.D &O.

MAX.Piping length

20

m

Norminal condition: indoor temperature (cooling): 27 ℃DB/19℃WB, indoor temperature (heating): 20 ℃DB/14.5℃WB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7 ℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter. It is a sound pressure noise level.

8

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter.

It is a sound pressure noise level. The detailed method please refer to the following information:

Installation state: the unit should be placed on the flat floor or be mounted in horizontal

direction.

Testing method:

built-in-ceiling unit:

mounting-on-ceiling unit:

1m

1.4m

1m

duct unit without auxiliary duct:

duct unit with auxiliary duct:

2m

duct

2m

1m

auxiliary duct

auxiliary duct

1.4m

1.4m

1m

outdoor unit:

1.air outlet from side: the noise level is the average sound pressure level measured from front, left, right directions.

2.air outlet from top: the noise level is the average sound pressure level measured from front, back, left, right directions.

measured point:

H ( height to the ground) = (h (unit height) + 1m) /2

and, it is 1m to each side.

1m

1m

1m

h

Note: ⊙ is the real

time analyser

9

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

3. Safety precaution

Carefully read the following information in order to operate the airconditioner correctly.

Below are listed three kinds of Safety Cautions and Suggestions.

WARNING! Incorrect operations may result in severe consequences of death or serious injuries.

CAUTION! Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

INSTRUCTIONS: These information can ensure the correct operation of the machine.

Be sure to conform with the following important Safety Cautions.

The Safety Cautions should be at hand so that they can be checked at any time when needed.

If the conditioner is transferred to the new user, this manual should be as well transferred to the new user.

WARNING!

If any abnormal phenomena is found

(e. g.smell of firing), please cut off the

power supply immediately, and contact

the dealer to find out the handling

method.

Don't dismantle the outlet of the

outdoor unit.

The exposed fan is very dangerous

which may harm human beings.

In such case, to continue using the

conditioner will damage the conditioner,

and may cause electrical shock or fire

hazard.

switch

off

When the unit needs maintenance and

repairment, please call dealer to handle it.

After the unit being used for a long time,

the base should be checked for any

damages.

If the damaged base is not repaired, the

unit may fall down and cause accidents.

1000

Incorrect maintenance and repairment

may cause water leak, electrical shock

and fire hazard.

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

WARNING!

Installed electrical-leaking circuit

breaker.

Nothing or nobody is permitted to

placed on or stand on outdoor unit.

It easily cause electrical shock without

circuit breaker.

The falling of goods and people may

cause accidents.

Air-conditioner can't be installed in

the environment with inflammable

gases because the inflammable gases

near to air-conditioner may cause fire

hazard.

Please let the dealer be responsible for

installing the conditioner.

Don't operate the air-conditioner with

damp hands.

Incorrect installation may cause water

leak, electrical shock and fire hazard.

Otherwise will be shocked.

Call the dealer to take measures to

prevent the refrigerant from leaking.

If conditioner is installed in a small

room be sure to take every measure in

order to prevent suffocation accident

Only use correctly-typed fuse.

even in case of refrigerant leakage.

May not use wire or any other materials

replacing fuse, other-wise may cause

faults or fire accidents.

When conditioner is removed or

reinstalled, dealer should be

responsible for them.

Incorrect installation may cause water

leaking, electrical shock and fire hazard.

Connect earthing wire.

Earthing wire should not be connected to the gas pipe, water pipe,

lightning rod or phone line, in-correct

earthing may cause shock.

Use discharge pipe correctly to ensure

efficient discharge.

Incorrect pipe use may cause water

leaking.

Earthing

11

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

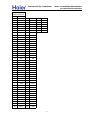

4. Net dimension

4.1 AB122ACERA

:;9

A9

U\MXRIVML LQYZITKM JMZ]MMT ZPM KMQRQTO

ITL ZPM VITMRC ;>SS

VITMR

KMQRQTO

B>

:A9

><>SS 7JMZ]MMT Y[YVMTYQUT VURMY8

NXMYP IQX PURM

>@9SS 7QTLUUX [TQZ LQSMTYQUT8

?>9SS 7KMQRQTO UVMTQTO LQSMTYQUT8

@99SS 7VITMR LQSMTYQUT8

:=9

GFEH D

GFEH D

4.2 AC122ACERA

620

605

600

880

100

655

40

35

35

30

990

12

240

200

199

900

<;9SS

Y[YVMTYQUT PURLMX

:>9SS

@99SS 7VITMR LQSMTYQUT8

OIY VQVM

?>9SS 7KMQRQTO UVMTQTO LQSMTYQUT8

RQW[QL VQVM

>@9SS 7QTLUUX [TQZ LQSMTYQUT8

LXIQTIOM VQVM

?9SS

B9

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

4.3 AD122ALERA

;

>

?

:

A

@

B

= <

9EBG DF=>C

:

45-..47684

1/3

;

03/+1

<

=

>

?

@

A

B

-/-

2-,

.11

-,1

0-3

1,3

..,

4.4 AU122AEERA

23+

6AF;B 8=B=@< 7;B?=@9>

245

-0

1/+

6AF;B 8=B=@<

4=CDB=:ED=A@ 5A>;

0++

13

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

5. Installation Instructions

1. Accessories

Edging

"Edging" for protection of electric wires from an

opening edge.

2. Selection of the place of installation

Select the place of installation satisfying the following conditions and, at the

same time, obtain a consent from the client or user.

Place where air circulates.

Place free from heat radiation from other heat sources.

Place where drain water may be discharged.

Place where noise and hot air may not disturb the neighborhood.

Place where there is not heavy snowfall in the winter time.

Place where obstacles do not exist near the air inlet and air outlet .

Place where the air outlet may not be exposed to a strong wind.

Place surrounded at four sides are not suitable for installation. A 1m or more

of overhead space is needed for the unit.

Mount guide-louvers to place where short-circuit is a possibility.

When installing several units, secure sufficient suction space to avoid short

circuiting.

(1) Open space requirement around the unit

L2

Air

inlet

L3

Air inlet

500

(Servicing

space)

Air outlet

L1

Note :

(1) Fix the parts with screws

(2) Don't intake the strong wind directly to the

outlet air-flow hole.

(3) A one meter distance should be kept from the

unit top

(4) Don't block the surroundings of the unit with

sundries

Unit: mm

Case

Distance

I

L1

II

III

open

open

500

L2

300

0

open

L3

150

300

150

NO

Wind direction

(2) Installation where the area with strong winds.

Install the unit so that the air outlet section of the unit must NOT be faced

toward wind direction.

14

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

5.1 Installation of outdoor unit

Installation

Fix the unit in a proper way according to the condition of a place where it is

installed by referring to the following .

(a) Concrete foundation

(b) Foundation anchor

Unit

Unit

Anchor bolt

Concrete foundation

Concrete foundation

To fix by bolts

Anchor bolt

Install the unit so that the angle of inclination must be less than 3 degrees.

~9@9>7 r?>>53D9?>

u<1B5 3?>>53D9?>

f`G1I F1<F5

v1C @9@5

x>4??B

->9D

}ED4??B

E>9D

z9AE94

@9@5

e`G1I F1<F5

u<1B5 3?>>53D9?>

]d^ s9=5>C9?> ?6 3?>>53D9>7 @9@5

v1C @9@5

deaj==

z9AE94 @9@5

iafh==

u9D D85 >ED ?>

1>4 61CD5>

90 + 0.5

]e^ ,85 =1H9=E= <5>7D8 1>4 4B?@ 85978D ?6 3?>>53D9>7 @9@5

,85 =1H9=E= <5>7D8 9C ec=

,85 =1H9=E= 4B?@ 85978D 9C 15m

,? 5>CEB5 D85 5669395>3I _~9@5C C81<< 25 1C C8?BD 1C @?CC92<5a

r1ED9?>C 6?B @9@9>7 3?>>53D9?>

y?9>D

+@1>>5B

s? >?D DG9CD ?B 456?B= D85 3?>>53D9>7 @9@5a

s? >?D =9H 4ECDCa

,85 25>49>7 B149EC C81<< 25 1C <1B75 1C @?CC92<5a

q?D8 71C @9@5 1>4 <9AE94 @9@5 C81<< 25 851D 9>CE<1D9?>a

|? <51;175 9> D85 6<1B5a

15

+@1>>5B

|ED

Commercial Air Conditioner

2

¡

16

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Electric wiring

WARNING!

DANGER OF BODILY INJURY OR DEATH

TURN OFF ELECTRIC POWER AT CIRCUIT BREAKER OR POWER

SOURCE BEFORE MAKING ANY ELECTRIC CONNECTIONS.

GROUND CONNECTIONS MUST BE COMPLETED BEFORE MAKING

LINE VOLTAGE CONNECTIONS.

(1) Selection of size of power supply and interconnecting wires.

Precautions for Electric wiring

Electric wiring work should be conducted only by authorized personnel.

Do not connect more than three wires to the terminal block. Always use round

type crimped terminal lugs with insulated grip on the ends of the wires.

Use copper conductor only.

Select wire sizes and circuit protection from table below. (This table shows 20 m

length wires with less than 2% voltage drop.)

Circuit breaker

Item

Model

AU122AEERA

PhaseSwitch breaker

(A)

1

Overcurrent

protector

40

Power

source wire

size

2.5 mm2

26

Earth leakage breaker

Switch

break

Leak

curren

40A

30mA

(2) Wiring connection

Make wiring to supply power to the outdoor unit, so that the power for the indoor

unit is supplied by terminals.

For the detailed wiring connection with the indoor units, see the corresponding

indoor operation and instruction manual.

To Indoor Unit

OUTDOOR UNIT

TERMINAL BLOCK

1 2 3

Y/G

WARNING!

INTERCONNECTING WIRES MUST BE WIRED ACCORDING TO FIG.1

INCORRECT WIRING MAY CAUSE EQUIPMENT DAMAGE.

17

Commercial Air Conditioner

t

5.2 Indoor unit ins allation

5.2.1 AB122ACERA

Jhmn[ff[ncih niifm

Tb_ chmn[ff[ncih niifm fcmn_^ ch nb_

`iffiqcha mb__n ][h \_ om_^ [m l_kocl_^2

52 S]l_q ^lcp_l

62 I[]em[q

72 Elcff qcnb [ ^c[g_n_l i` :4gg

82 Jhh_l b_r[aih mj[hh_l0mbc`ncha

mj[hh_l

92 Sj[hh_l -580 5;0 5=06806;gg.

:2 Pcj_ ]onn_l

;2 Pcj_ _rj[h^_l

<2 Khc`_

=2 Pch]_lm

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

52S_f_]ncih i` Jhmn[ff[ncih Pf[]_

-5. Pf[]_ [\ip_ nb_ ]_cfcha qb_l_ b[p_ _hioab mj[]_ ni [ll[ha_

nb_ ohcn2

-6. Pf[]_ qb_l_ nb_ ^l[ch[a_ jcj_ ][h \_ [ll[ha_^ q_ff2

-7. Pf[]_ qb_l_ chf_n [h^ ionf_n [cl i` ch^iil [h^ ion^iil ohcn qcff hin

\_ \fi]e_^2

-8. Ei hin _rjim_ nb_ ohcn ni nb_ jf[]_ qcnb b_[ps icf il gicmnol_

-_2a2ecn]b_h [h^ qilembij.2

-9. Ei hin m_n nb_ ohcn ch nb_ jf[]_ qb_l_ ^_mnlo]ncp_ a[m -mo]b [m

mof`olc] []c^ a[m. il joha_hn a[m -nbchh_l [h^ a[mifch_. ]ih]_hnl[n_m

[h^ l_n[chm2

-:. Pf[]_ mnliha _hioab ni mojjiln nb_ ohcn q_cabn2

-;. Ni _rj_hmcp_ [lnc]f_m mo]b [m n_f_pcmcih [h^ jc[hi \_fiq

ch^iil ohcn2

-<. Fhioab mj[]_ `il g[chn_h[h]_2

-=. Pf[]_ gil_ nb[h 5g [q[s `lig n_f_pcmcih [h^ l[^ci ni [pic^

^cmnol\cha n_f_pcmcih [h^ l[^ci2

-54. F[ms `il g[chn_h[h]_2

H

552 C[h^ n[j_

562 S]l[j_l

0.31m

542 L_[e[a_ ^_n_]nil il mi[js q[n_l

572 R_`lca_l[hn icf

Sn[h^[l^ []]_mmilc_m

6

R_gin_ ]ihnliff_l

C[nn_ls

Qns2

5

Air outlet

1.5m

1.5m

2.5m Over

62Jhmn[ff[ncih Pl_j[l[ncih

-5. Pimcncih i` ]_cfcha ij_hcha \_nq__h ohcn [h^ momj_h^cha \ifn

-`lihn pc_q i` ohcn.2

6

7

Wcl_ ]f[gj

8

8

I_[n

jl_m_lp[ncih

mf__p_

5/5

9

S]l_q

6/8

Indoor unit 570mm

5

B]]_mmils j[lnm

Air inlet

Ceiling opening 650mm

Ni2

Air outlet

Ornament panel 700mm

Tb_ `iffiqcha j[lnm g_hncih_^ ch nbcm

g[ho[f [l_ nb_ chmn[ff[ncih []]_mmilc_m

q_ jl_j[l_^2

Distance between

suspending bolts 535mm

Indoor unit 570mm

Ceiling opening 650mm

5

Ornament panel 700mm

Overlap between ceiling and

ornament panel shall be 25mm

Suspending bolts

150mm

R_gin_

]ihnliff_l

\l[]e_n

5/5

Ceiling

Ornament panel

320mm

;

S]l_q ][j

60mm

:

-6. Pl_j[l_ [ff jcjcha -l_`lca_l[hn0q[n_l ^l[ch[a_ .[h^ qcl_m

-]ihh_]ncih qcl_ i` l_gin_ ]ihnliff_l0 ch^iil ohcn ]ihh_]ncih qcl_m.

ni nb_ ch^iil ohcn \_`il_ chmn[ff[ncih ch il^_l ni ]ihh_]n ch^iil ohcn

cgg_^c[n_fs [`n_l chmn[ff[ncih2

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

-7. Jhmn[ff [ momj_h^cha \ifn

Ti mojjiln nb_ ohcn q_cabn 0[h]bil \ifn mbiof^ \_ om_^ ch nb_ ][m_ i` [fl_[^s _rcmnm ]_cfcha2 Giq h_q ]_cfcha0

om_ `fomb1ch nsj_ \ifn0 \ocfn1ch nsj_ \ifn il j[lnm jl_n[l_^ ch nb_ `c_f^2

C_`il_ aicha ih chmn[ffcha0 [^domn mj[]_ ni ]_cfcha2

Rii`

Bh]bil \ifn

Liha hon il nbl_[^

Somj_h^cha \cfn M54

D_cfcha

Nin_> Bff nb_ [\ip_ g_hncih_^ j[lnm mb[ff \_ jl_j[l_^ ch `_cf^0

nb_ ^c[g_n_l i` momj_h^cha \ifn cm M54

72 Jhmn[ff[ncih i` ch^iil ohcn

@Jhmn[ff[ncih Fr[gjf_A

Jh ][m_ i` hi ]_cfcha

Jhmn[ff ohcn n_gjil[lcfs

Pon momj_h^cha \l[]e_n ih nb_ momj_h^cha \ifn ni b[ha nb_ ohcn oj2 C_ mol_ ni om_ hon [h^ q[mb_l [n \inb _h^

i` nb_ \l_[e_n ni m_]ol_ `clgfs2

B`n_l chmn[ff[ncih ih nb_ ]_cfcha

-5. B^domn ohcn ni cnm lcabn jimcncih -R_`_l ni jl_j[l[ncih `il chmn[ff[ncih1-5..

-6.Db_]e nb[n ohcn cm biltihn[f2

W[n_l jogj [h^ `fi[ncha mqcn]b cm chmn[ff_^ chmc^_ ch^iil ohcn0]b_]e `iol ]ilh_lm i` nb_ ohcn `il cnm f_p_l omcha

bilctihn[f ]igj[l[nil il PVD no\_ qcnb q[n_l2-J` ohcn cm ncfncha [a[chmn nb_ ^cl_]ncih i` q[n_l ^l[ch[a_0jli\f_g

g[s i]]ol ih `fi[ncha q[n_l f_[e[a_2.

Jh nb_ ][m_ i` ]_cfcha [fl_[^s _rcmnm

-5.Jhmn[ff ohcn n_gjil[ffs

Pon momj_h^cha \l[]e_n ih nb_ momj_h^cha \ifn ni b[ha nb_

ohcn oj2C_ mol_ ni om_ hon [h^ q[mb_l [n \inb _h^ i` nb_

\l[]e_n ni m_]ol_ cn `clgfs2

-6.B^domn nb_ b_cabn [h^ jimcncih i` nb_ ohcn2

-7.Pli]__^ qcnb jli]_^ol_ -8. i` + Jh nb_ ][m_ i` hi ]_cfcha +

Non -Pl_j[l_ ch `_cf^.

W[mb_l -Pl_j[l_^ ch `_cf^.

Somj_h^cha \ifnm

G[mn_h -^io\f_ honm.

Jhm_ln

f_p_f_l

W[mb_l `crcha j[^

-jl_j[l_^ ch `_cf^.

X m_]ol_ nb_ q[mb_l `clgfsY

Pifsnb_h_ jcj_

4. Installation of water drainage pipe

(1) Install water drainage pipe

Pipe diameter shall be equal or larger than that of connecting pipe (Pipe of polythene; size: 25mm;

O.D.: 32mm )

Drainpipe should be short, with a downward slope at least 1/100 to prevent air bag from forming.

If downward slope of drainpipe cannot be made,lifting pipe shall be installed.

Keep a distance of 1-1.5m between suspending bolts, to make water hose straight.

19

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

1-1.5m

slope over 1/100

Use the drainage hose and clip provided with unit.

Insert water pipe into water plug until it reaches the white tape.

Tighten the clip until head of the screw is less than 4mm from hose.

Wind the drainage hose to the clip using seal pad for heat insulation.

Insulate drainage hose in the room.

Large size seal pad

(accessory)

Clip

Tape(white)

Clip

Draingage hose

4mm below

5. Cautions for the water drainage lifting pipe

Installation height of water drainage lifting pipe shall be less than 280mm

Clip

220mm

500mm below

220

Water drainage

lifting pipe

Drainage hose

500mm below

300mm below 1-1.5m Suspending bracket

280mm unter

Drainage hose

75mm below

There should be a right angle with unit ,300mm from unit.

< Note >

The slope of water drainage hose shall be within 75mm , make the drainage plug not to bear

excessive force.

100mm ¸over

If several water hoses join together, of as per following procedures.

Slope below 1/100

Connection drainage hose with a T-joint

Specifications of the selected drainage hoses shall meet the requirements for the unit running

6. Installation of Ornament Panel

Install ornament panel on indoor unit

(1) Check whether indoor unit is horizontal with leveler or polythene pipe filled with water , and

check that the dimension of the ceiling opening is correct. Take off the lever gauge before

installing the ornament panel.

(2) Fasten the screws to make the height difference between the two sides of indoor unit less than

5mm.

(3) Firstly fix it with screws temporarily.

(4) Fasten the two temporarily fixing screws and other two, and tighten the four screws.

(5) Connect the wires of synchro-motor.

(6) Connect the wire of signal.

(7) If no response of remote controller,check whether the wiring is correct,restart remote controller

10 seconds after shut off power supply.

20

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Electric control box

Panel limitation board installation

(1)Install the panel board in the direction shown in the figure.

(2)The incorrect direction will result in water leakage,meanwhile swing and signal receiving are displayed

that cannot be connected.

21

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

5.2.2 AC122ACERA

Wrap the insulation around the drain hose

connection.(Fig.6)

INSTALLATION PROCEDURE

Install the room air conditioning unit as follows:

(Fig. 6)

PREPARING INDOOR UNIT INSTALLATION

Drain pan

FIRST REMOVE THE INTAKE GRILL

A. FLOOR MOUNTING

Insulation

(Drain hose)

Drain hose

(AC36/42 only suitable for

exposed ceiling mounting)

1. DRILLING FOR PIPING

The piping and drain can exit the

unit in two directions as shown

below in (Fig. 2)

rear

Be sure to arrange the drain hose correctly as shown

in Fig. 7 so that it is lower than the drain hose

connecting point of the indoor unit, if condensate

pump is not fitted to system.

Fig. 7

OK

NO

NO

(Fig. 2)

down

The drain hose must be connected to the right side as

shown in (Fig.3).

Arrange the drain hose

lower than this portion.

(Fig. 3)

Drain hose

CAUTION!

Ensure that the unit is fixed level. Height ‘A’ must be less

than 5 mm.(Fig.8)

Drain hose (Right side)

After the piping and drainage exit has been selected,

drill a 7 cm dia. hole through the wall so that the

hole is slanting downward toward the outside to

ensure good drainage. When the pipe is led out from

the rear, make a hole as Fig.4, at the position shown.

(Fig. 4)

Wall

6mm

Drain hose

A

B. UNDER CEILING MOUNTING

Using the installation template, drill holes for piping

and anchor bolts(for holes).(Fig.9)

7cm

Indoor unit

(Fig. 10)

200mm

2. INSTALLING DRAIN HOSE

The drain hose must be connected to the right side of

the unit (Fig.3)

Insert the drain hose into the drain pan, then secure

the drain hose with a nylon fastener. (Fig.5)

(Fig. 5)

900mm

outdoor unit

Installation

template

Drilling position

for anchor bolt

Ceilling

Wall

Drilling position

for piping

1. DRILLING FOR PIPING

Select piping and drain directions. (Fig.10)

Drain pan

Nylon fastener

(supplied by others)

Fig 10

Drain hose

22

Rear (Install the drain hose

in this direction.)

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

4. INSTALLING INDOOR UNIT

Reset the hex bolts as shown in Fig.14.

CAUTION

Install the drain hose at the rear; it should not be

installed on the top or right side.

After the piping and drainage exit has been selected,

drill 80mm and 50mm or 150mm dia. hole through the

wall. So that the hole is slanting downward toward the

outside for smooth water flow if a condensate pump is

not fitted to system. Wall

Fig. 14

Hex bolt

8 to 13mm

Indoor unit

6mm

2. DRILLING HOLES FOR ANCHOR BOLTS AND

INSTALLING THE ANCHOR BOLTS

using a masonry drill, drill four 12.5 mm dia.

Holes.(Fig.11)

Apply the indoor unit to the brackets.(Fig.15)

Fig. 15

Fig. 11

Fig. 11

Bracket

Bolt

Indoor unit

12.5mm

Insert the anchor bolts into the drilled holes, and drive

the pins completely into the anchor bolts with a

hammer. (Fig. 12)

Now, securely tighten the hex bolts in both sides.

Fig. 12

5. INSTALL THE DRAIN HOSE

The drain hose will be connected to the right side.(Fig.3)

Insert the drain hose into the drain pan, then secure the

drain hose with a nylon fastener.(Fig.5)

Wrap the insulation (drain hose)around the drain hose

connection. (Fig.9)

Be sure to arrange the drain hose correctly so that it is

lower than the drain hose connecting port of the indoor

unit (Fig.16) if condensate pump is not fitted to system.

3. INSTALLING BRACKETS

Install the brackets with nuts, washers and spring

washers.(Fig. 13)

Fig. 16

Remove the hole cover.

Fig. 13

Arrange the drain hose

lower than this portion

Spring washer

OK

Bracket

Special nut

381

26.5

16 21 28

5

4-R

7.5

68

18

10

2-R2.5

232

232

26.5

10

18

26.5

7.5

2-R2.5

5

4-R

26.5

28 21 16

68

381

23

Drain hose

NO

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Wiring

(2) Pull out the electrical component box.

ELECTRICAL WIRING

Fig. 27

CAUTION

(1) Match the terminal block numbers and connection

cable colours with those of the outdoor unit.

Incorrect wiring may cause damage to the electrical

parts.

(2) Connect the connection cables firmly to the terminal

block. Incorrect installation may result in a fire.

Electrical component box

(3) Always fasten the outside covering of the connection

cable with the cable clamp.(If the insulation is chafed,

a short curcuit may occur.)

(3) Remove the electrical component box cover.

Fig. 28

(4) Always connect the earth wire.

1. INDOOR UNIT SIDE

(1) Remove the electrical component box.

Base

Fig. 25

Electrical component box cover

Remove the three tapping screws

CAUTION

Be careful not to pinch the wiring

between the electric component box

and base.

Electrical component box

(4) Wiring

See wiring diagrams for indoor unit.

ELECTRICAL WIRING

INDOOR UNIT SIDE

Fig. 26

WARNING

Electrical component box

(1) Ensure all wiring complies with current regulations.

(2) It is recommended that a MCB of the correct rating is used

to protect the system.

(3) Always use a circuit breaker that can trip all the poles of the

wiring is fitted and has an isolation distance of at least 3mm

between the contacts of each pole.

CUSTOMER GUIDANCE

Explain the following to the customer in accordance with

the operating manual:

(1) Starting and stopping method, operation switching,

temperature adjustment, timer, air flow switching, and

other remote control unit operations.

(2) Air filter removal and cleaning, and how to use air

louvres.

(3) Give the operating and installation manuals to the

customer.

Remove the four self

tapping screws.

CAUTION

Do not remove the screws. If the screws

are removed, the electrical component

box will fall.

24

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

5.2.4 AD122ALERA

GbghU``Uh]cb gdUWY

Q\Y ]bXccf ib]h g\U`` VY ]bghU``YX Uh `cWUh]cbg k\YfY Wc`X UbX \ch U]f Wci`X YjYb`m W]fWi`UhYX2

Q\Y Zc``ck]b[ `cWUh]cbg g\ci`X VY Ujc]XYX>

M`UWYg k]h\ f]W\ gU`h -gYUg]XY UfYU.2

M`UWYg k]h\ d`Ybhm cZ [Ug gi`Z]XYg -aU]b`m ]b kUfa gdf]b[ UfYUg k\YfY h\Y WcddYf hiVY UbX VfUnY kY`X

]g YUgm hc Wcffcg]cb.2

IcWUh]cbg k]h\ aiW\ c]` -]bW`iX]b[ aYW\Ub]WU` c]`. UbX ghYUa2

IcWUh]cbg ig]b[ cf[Ub]W gc`jYbhg2

M`UWYg k\YfY h\YfY UfY aUW\]bYg [YbYfUh]b[ FD Y`YWhfcaU[bYh]W kUjYg2

Mcg]h]cbg UX^UWYbh hc Xccf cf k]bXck ]b WcbhUWh k]h\ \][\1\ia]X]hm YlhYfbU` U]f2 -CUgm hc [YbYfUhY XYk.2

IcWUh]cbg ZfYeiYbh`m ig]b[ gdYW]U` UYfcgc`g2

Q\Y Zc``ck]b[ dc]bhg g\ci`X VY hU_Yb WUfY cZ>

52 PY`YWh gi]hUV`Y d`UWYg h\Y cih`Yh U]f WUb VY gYbh hc h\Y

Ybh]fY fcca0 UbX WcbjYb]Ybh hc `Um cih h\Y WcbbYWh]cb

d]dY0 WcbbYWh]cb k]fY UbX h\Y XfU]bU[Y d]dY hc cihXccf2

62 Q\Y WY]`]b[ ghfiWhifY aigh VY ghfcb[ Ybci[\ hc giddcfh

h\Y ib]h kY][\h2

72 Q\Y WcbbYWh]b[ d]dY0 XfU]b d]dY UbX WcbbYWh]cb k]fY

w*~ t

g\U`` VY UV`Y hc [c h\ci[\ h\Y Vi]`X]b[ kU`` hc WcbbYWh

VYhkYYb h\Y ]bXccf UbX cihXccf ib]hg2

82 Q\Y WcbbYWh]b[ d]dY VYhkYYb h\Y ]bXccf UbX cihXccf ib]hg Ug kY`` Ug h\Y XfU]b d]dY g\U`` VY Ug g\cfh

Ug dcgg]V`Y2 -PYY D][ifY 5.

92 GZ ]hg bYWYggUfm hc UX^igh h\Y Z]``]b[ Uacibh cZ h\Y fYZf][YfUbh0 d`YUgY fYZYf hc h\Y ]bghU``Uh]cb aUbiU`

UhhUW\YX k]h\ h\Y cihXccf ib]h2

:2 Q\Y WcbbYWh]b[ Z`Ub[Y g\ci`X VY dfcj]XYX Vm h\Y igYf \]agY`Z2

;2 Q\Y ]bXccf ib]h \Ug hkc kUhYf cih`Yhg cbY cZ k\]W\ ]g cVghfiWhYX Uh h\Y ZUWhcfm -k]h\ U fiVVYf WUd.2 Lb`m

h\Y cih`Yh bch cVghfiWhYX -`]ei]X ]b`Yh UbX cih`Yh g]XY. k]`` VY [YbYfU``m igYX Xif]b[ ]bghU``Uh]cb2 GZ

Udd`]WUV`Y0 Vch\ h\Y cih`Yhg g\ci`X VY igYX hc[Yh\Yf2

KchY> Q\Y UWWYgg \c`Y aigh VY dfcj]XYX Xif]b[ ]bghU``Uh]cb cZ ]bXccf ib]h Zcf aU]bhYbUbWY2

8?K>I J>C><KBE@ KA> BEJK;CC;KBFE JG;<>6| GIF<>>= KA> ?FCCFMBE@ JK>GJ7

74 Djadd Y `gd] af l`] oYdd Yf\ afk]jl l`] [gff][laf_ hah] Yf\ oaj] l`jgm_` Y PVC oYdd3

l`jgm_` lmZ] hmj[`Yk]\ dg[Yddq4 T`] oYdd `gd] k`Ydd Z] oal` Y gmloYj\ \gof kdgh] g^ Yl

d]Ykl 757664 /S]] Fa_mj] 80

84 B]^gj] \jaddaf_ [`][c l`Yl l`]j] ak fg hah] gj j]af^gj[af_ ZYj bmkl Z]`af\ l`] \jaddaf_

hgkalagf4 Djaddaf_ k`Ydd Ynga\ Yl hgkalagfk oal` ]d][lja[ oaj] gj hah]4

94 Mgmfl l`] mfal gf Y kljgf_ Yf\ `gjargflYd Zmad\af_ jgg^4 I^ l`] ZYk] ak fgl ^aje2 al oadd

[Ymk] fgak]2 naZjYlagf gj d]YcY_]4

:4 Smhhgjl l`] mfal ^ajedq4

;4 C`Yf_] l`] ^gje g^ l`] [gff][lagf hah]2 [gff][lagf oaj] Yf\ \jYaf hah] kg l`Yl l`]q

[Yf _g l`jgm_` l`] oYdd `gd] ]Ykadq4

25

Fa_ 8

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

CUW\ cZ h\Y U]f gYbX]b[ XiWh UbX U]f fYhifb XiWh g\U`` VY Z]lYX cb h\Y dfYZUVf]WUhYX dUbY` cZ h\Y Z`ccf

Vm h\Y ]fcb VfUW_Yh2

Q\Y fYWcaaYbXYX X]ghUbWY VYhkYYb h\Y YX[Y cZ h\Y U]f fYhifb XiWh UbX h\Y kU`` ]g cjYf 594aa2

Q\Y [fUX]Ybh cZ h\Y WcbXYbgUhY kUhYf d]dY g\U`` _YYd cjYf 5,2

Q\Y WcbXYbgUhY kUhYf d]dY g\U`` VY h\YfaU` ]bgi`UhYX2

T\Yb ]bghU``]b[ h\Y WY]`]b[ AcbWYU`YX hmdY ]bXccf ib]h0 h\Y U]f fYhifb XiWh aigh VY XYg][bYX UbX

]bghU``YX -Ug Z][ifY g\ckb.2

@i]`X]b[ fccZ cZ ]bghU``Uh]cb

U]f fYhifb Vcl

?]f cih`Yh [f]``Y

524a -igY k\]hY achcf d`i[.

924a-igY fYX achcf d`i[.

?]f gidd`m

v

WY]`]b[

ib]h

U]f fYhifb Vcl

U]f fYhifb

U]f gidd`m

Q\YfY g\ci`X VY

bc cVghUW`Yg

k]h\]b 5a

ib]h

U]f fYhifb

KchY> T\Yb WcbbYWh]b[ h\Y g\cfh XiWhg0 igY h\Y `ck ghUh]W hYfa]bU`g0 k\]W\ Wc`cf ]g k\]hY2

Q\Y X]ghUbWY I Zfca h\Y U]f cih`Yh cZ h\Y XiWh hc h\Y U]f cih`Yh cZ h\Y g]f WcbX]h]cbYf g\U`` VY bc acfY h\Ub 5 a2

PigdYbX]b[ \cc_

BfU]b d]dY

?]f cih XiWh

?]f fYhifb XiWh

QfUbg]h]cb XiWh

?]f fYhifb V`]bX

Q]Y1]b cZ U]f

X]ghf]VihUfm

?]f X]ghf]VihUfm

Q\Y g_YhW\ aUd cZ `cb[ XiWh

KchY> T\Yb WcbbYWh]b[ h\Y `cb[ XiWhg0 igY h\Y a]XX`Y ghUh]W hYfa]bU`g0 k\]W\ Wc`cf ]g fYX2

Q\Y X]ghUbWY I Zfca h\Y U]f cih`Yh cZ h\Y XiWh hc h\Y U]f cih`Yh cZ h\Y g]f WcbX]h]cbYf g\U` VY bc acfY h\Ub 9 a2

J< k]XY YldUbg]cb Vc`h

J< gigdYbXYf gWfYk

?]f WcbX]h]cbYf

J< k]XY `cW_ kUg\Yf

J< gWfYk bih

GbghU``Uh]cb cZ ]bXccf ib]h XiWh

52 GbghU``Uh]cb cZ U]f gYbX]b[ XiWh

Q\]g ib]h igYg fcibXYX XiWh0 h\Y X]UaYhYf cZ h\Y XiWh ]g 5<4aa2

Q\Y fcibXYX XiWh bYYXg hc UXX U hfUbg]h]cb XiWh hc WcbbYWh k]h\ h\Y U]f1gYbX]b[ XiWh cZ ]bXccf ib]h0

h\Yb WcbbYWh k]h\ fYgdYWh]jY gYdUfUhcf2 ?g D][2 5 g\ckb0 U`` h\Y ZUb gdYYX cZ Ubm cZ h\Y gYdUfUhcfrg

U]f cih`Yh g\U`` VY UX^ighYX Uddfcl]aUhY`m h\Y gUaY hc aYYh h\Y fYei]fYaYbh Zcf h\Y fcca U]f WcbX]h]cbYf2

GbXccf ib]h

Z`Yl]V`Y ^c]bh

QfUbg]h]cb XiWh

OcibXYX XiWh

Q]Y1]b cZ U]f

X]ghf]VihUfm

?]f X]ghf]VihUfm

D][2 5

Rb]h> aa

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

62 GbghU``Uh]cb cZ U]f fYhifb XiWh

RgY f]jYh hc WcbbYWh h\Y U]f fYhifb XiWh cb h\Y U]f fYhifb ]b`Yh cZ h\Y ]bXccf ib]h0 h\Yb WcbbYWh h\Y ch\Yf YbX k]h\

h\Y U]f fYhifb V`]bX2 ?g D][2 6 g\ckb2

?]f fYhifb V`]bX

?]f fYhifb XiWh

GbXccf ib]h

f]jYh

D][2 6

7 Q\YfaU` ]bgi`Uh]cb cZ XiWh

?]f1gYbX]b[ XiWh UbX U]f fYhifb XiWh g\U`` VY h\YfaU``m ]bgi`UhYX2 D]fgh gh]W_ h\Y [`iYm bU]` cb h\Y XiWh0 h\Yb

UhhUW\ h\Y \YUh dfYgYfjUh]cb Wchhcb k]h\ U `UmYf cZ h]bZc]` dUdYf UbX igY h\Y [`iYm bU]` WUd hc Z]l2 D]bU``m igY

h\Y h]bZc]` UX\Yg]jY hUdY hc gYU` h\Y WcbbYWhYX dUfh2 ?g D][2 7 g\ckb2

[`iYm

[`iYm \YUh dfYgYfjUh]cb

h]bZc]` bU]` WUd

Wchhcb

bU]`

UX\Yg]jY hUdY

D][2 7

GbghU``]b[ h\Y gigdYbg]cb gWfYk>

RgY J< cf J54 gigdYbg]cb gWfYkg -80dfYdUfYX ]b h\Y Z]Y`X.-k\Yb h\Y gigdYbg]cb gWfYk\Y][\h YlWYYXg 42=a0

J54 g]nY ]g h\Y cb`m W\c]WY.2Q\YgY gWfYkg g\U`` VY ]bghU``YX Ug Zc``ckg k]h\ gdUWY UXUdh]b[ hc U]f WcbX]h]cbYf

cjYfU`` X]aYbg]cbg UWWcfX]b[ hc h\Y cf][]bU` Vi]`X]b[ ghfiWhifYg2

TccXYb ghfiWhifY

? geiUfY kccX g\U`` VY giddcfhYX Vm h\Y VYUag UbX h\Yb gYh h\Y gigdYbg]cb gWfYkg2

@YUa

PeiUfY kccX

KYk WcbWfYhY g`UV

Qc gYh k]h\ YaVYXXYX dUfhg0ZcibXUh]cb Vc`hg YhW2

PigdYbg]cb gWfYk

Gfcb fY]bZcfWYaYbh

DcibXUh]cb Vc`h

Hb]ZY YaVYXXYX dUfh

Ei]XY d`UhY YaVYXXYX dUfh

M]dY gigdYbg]cb ZcibXUh]cb Vc`h

Lf][]bU` WcbWfYhY g`UX

xz,~*,~ {-+1

RgY \c`Y \]b[Y0\c`Y d`ib[Yf cf \c`Y Vc`h2

PhYY` fY]bZcfWYaYbh ghfiWhifY

RgY ghYY` Ub[`Y cf bYk giddcfh ghYY` Ub[`Y X]fYWh`m2

y20.},0*-, 0|/}3

27

y2..-/1 01}}+ z,~+}

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

FUb[]b[ cZ h\Y ]bXccf ib]h

DUghYb h\Y bih cb h\Y gigdYbg]cb gWfYk UbX h\Yb \Ub[ h\Y gigdYbg]cb gWfYk ]b h\Y Q g`ch cZ h\Y gigdYbg]cb

dUfh cZ h\Y ib]h2 ?]XYX k]h\ U `YjY` aYhYf0UX^igh `YjY` cZ h\Y ib]h k]h\]b 9aa2

5 9;LKBFE

Gb cfXYf hc XfU]b kUhYf bcfaU``m0 h\Y XfU]b d]dY g\U`` VY dfcWYggYX Ug gdYW]Z]YX ]b h\Y

]bghU``Uh]cb aUbiU` UbX g\U`` VY \YUh ]bgi`UhYX hc Ujc]X XYk [YbYfUh]cb2 GadfcdYf \cgY

WcbbYWh]cb aUm WUigY ]bXccf kUhYf `YU_U[Y2

OYei]fYaYbhg

Q\Y ]bXccf XfU]b d]dY g\U`` VY h\YfaU` ]bgi`UhYX2

Q\Y WcbbYWh]cb dUfh VYhkYYb h\Y XfU]b d]dY UbX h\Y ]bXccf ib]h g\U`` VY ]bgi`UhYX gc Ug hc dfYjYbh XYk

[YbYfUh]cb2

Q\Y XfU]b d]dY g\U`` VY g`Ubh XckbkUfXg -[fYUhYf h\Ub 53544.2 Q\Y a]XX`Y dUfh g\U`` bch VY cZ P hmdY Y`Vck0

ch\Yfk]gY UVbcfaU` gcibX k]`` VY dfcXiWYX2

Q\Y \cf]ncbhU` `Yb[h\ cZ h\Y XfU]b d]dY g\U`` VY `Ygg h\Ub 64 a2 Gb WUgY cZ `cb[ d]dY0 giddcfhg g\U`` VY

dfcj]XYX YjYfm 529 q 6a hc dfYjYbh kUjm Zcfa2

AYbhfU` d]d]b[ g\U`` VY `U]X cih UWWcfX]b[ hc h\Y Zc``ck]b[ Z][ifY2

QU_Y WUfY bch hc Udd`m YlhYfbU` ZcfWY cbhc h\Y XfU]b d]dY WcbbYWh]cb dUfh2

529ao6a

Piddcfh

Gbgi`Uh]cb

Bckb g`cdY

-gidd`]YX Vm h\Y igYf. UVcjY 53544

P hmdY Y`Vck

TU``

Qc h\Y `Uf[Ygh -Udd2 54Wa.

Lihg]XY

SM74

Bckb g`cdY UVcjY 53544

P`Ubh

M]dY UbX ]bgi`Uh]cb aUhYf]U`

M]dY

O][]X MSA d]dY SM7529aa -]bhYfbU` X]UaYhYf.

BfU]b d]dY -gidd`]YX

Vm h\Y igYf.

Gbgi`Uh]cb DcUaYX MC k]h\ h\]W_bYgg UVcjY ; aa

FcgY

BfU]b d]dY g]nY> -738+. MSA d]dY

Q\Y \cgY ]g igYX Zcf UX^igh]b[ h\Y cZZ1WYbhYf UbX Ub[`Y cZ h\Y f][]X MSA d]dY2

B]fYWh`m ghfYhW\ h\Y \cgY hc ]bghU`` k]h\cih aU_]b[ Ubm XYZcfaUh]cb2

Q\Y gcZh YbX cZ h\Y \cgY aigh VY ZUghYbYX k]h\ U \cgY W`Uad2

FcgY

FcgY W`Uad

M`YUgY Udd`m h\Y \cgY cb \cf]ncbhU` dUfh

Gbgi`Uh]cb hfYUhaYbh>

TfUd h\Y \cgY UbX ]hg W`Uad ibh]` hc h\Y

]bXccf ib]h k]h\cih Ubm W`YUfUbWY k]h\

]bgi`Uh]b[ aUhYf]U`0 Ug g\ckb ]b h\Y Z][ifY2

PiVg]X]Ufm ]bgi`Uh]cbu

BfU]b WcbZ]faUh]cb

Gbgi`Uh]cb

O][]X MSA d]dY

Bif]b[ hf]U` fib0 W\YW_ h\Uh h\YfY ]g bc `YU_U[Y Uh h\Y d]dY WcbbYWh]cb dUfh Xif]b[ kUhYf XfU]b]b[ YjYb ]b k]bhYf2

?``ckUV`Y d]dY `Yb[h\ UbX Xfcd

Q\YgY dUfUaYhYfg X]ZZYf UWWcfX]b[ hc h\Y cihXccf ib]h2 PYY h\Y ]bghfiWh]cb aUbiU` UhhUW\YX k]h\ h\Y cihXccf

ib]h Zcf XYhU]`g2

28

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

t784=6

t<49;

SUWiia diad]b[

T]h\ U jUWiia diad0WfYUhY jUWiia Zfca h\Y ghcd jU`jY cZ h\Y cihXccf ib]h2

Cadhm]b[ k]h\ fYZf][YfUbh gYU`YX ]b h\Y cihXccf ib]h ]g UVgc`ihY`m ZcfV]XXYb2

LdYb U`` jU`jYg

LdYb U`` h\Y jU`jYg cb h\Y cihXccf ib]h2

EUg `YU_U[Y XYhYWh]cb

A\YW_ k]h\ U `YU_U[Y XYhYWhcf cf gcUd kUhYf h\Uh ]Z h\YfY ]g [Ug `YU_U[Y Uh h\Y d]dY WcbbYWh]cbg

UbX VcbbYhg2

Gbgi`Uh]cb hfYUhaYbh

LdYfUhY ]bgi`Uh]cb hfYUhaYbh cb Vch\ h\Y [Ug g]XY UbX `]ei]X g]XY cZ d]dYg fYgdYWh]jY`m2

Bif]b[ Wcc`]b[ cdYfUh]cb0Vch\ h\Y `]ei]X UbX [Ug g]XYg UfY Wc`X UbX h\ig g\U`` VY ]bgi`UhYX

gc Ug hc Ujc]X XYk [YbYfUh]cb2

Q\Y ]bgi`Uh]b[ aUhYf]U` Uh [Ug g]XY g\U`` VY fYg]ghUbh hc U hYadYfUhifY UVcjY 564 XY[fYY2

Q\Y ]bXccf ib]h d]dY WcbbYWh]cb dUfh g\U`` VY ]bgi`UhYX2

Q\Y bchW\ idkUfX-?hhUW\YX XYhU]` j]Yk.

D]Y`X d]d]b[ g]XY

GbXccf ib]h

PiVg]X]Ufm ]bgi`Uh]cb hiVY

8<<>JJFIN ;J ?FCCFM7

Kc2

5

6

7

?WWYggcfm dUfhg

T]fY W`Uad

FYUh

]bgi`Uh]cb

g\YUh\]b[

PWfYk WUd

Nhm2

6

5/5

5/5

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

6. Parts and Functions

6.1 AB122ACERA

F_RWP UX]^NZ

+9RZ OUX_ MRZNL\RXW LJW KN JMS][\NM K` ][RWP

\QN FI?B> K]\\XW XW \QN ZNVX\N LXW\ZXUUNZ,

CYNZJ\RWP :XW\ZXU DJWNU

9RZ ?WUN\ >ZRUUN

9RZ =RU\NZ

+?W[RMN XO \QN ?WUN\ >ZRUUN,

CYNZJ\RWP :XW\ZXU DJWNU

a ENVX\N ZNLNR^NZ

b :XVYZN[[XZ @JVY

c G?A<E @JVY

:CAD G?A<E

d CD<E9G?CB @JVY

CD<E DCI<E <A<E

e DX_NZ @JVY

a

b

c

d

e

f <VNZPNWL` [_R\LQ

f

6.2 AC122ALERA

10

1

11

POWER

OPER

TIMER

3

9

8

30

COMP

7

EMER

2

Fig.2

3

Fig.1 Indoor Unit

1

2

3

4

5

6

7

8

9

10

11

Fig.1

4

5

6

Operating Control Panel (Fig.2)

Emergency switch

Remote Control Signal Receiver

Power Indicator Lamp (Red)

OPERATION Indicator Lamp (Green)

TIMER Indicator Lamp (Yellow)

Compressor Run Lamp (Green)

Intake Grill

Air Filter

UP/DOWN Air Direction Flaps

RIGHT/LEFT Air Direction Louvers

(behind UP/DOWN Air Direction Flaps)

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

6.3 AD122ALERA

Electrical components Case

Air outlet frame

Evaporator

Drain pan

6.4 AU122AEERA

Air inlet

Air outlet

Compressor

(Inside of unit)

31

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

7. Controller functions

Mg_jZj^] \hgljhee^j YS<LB@

B

Wired controller YR-E12

A

E

V

U

Q

QJJ

SEMP

ON

OFF

RUING

FAN

;=34

50<

0BA=

0BA=

50< =<:F

7867

RLEEP

;43

>?4-740A

3?F

740A

A4@

:=D

345?=@A

HEALSH

FQERH

CLOCK

740:A7

27429

@D8<6

B<8A <=.

34;0<3

;0<B0:

A8;4?

RES

HIGH4RO

FILSEQ

HEAS

QERES

CODE

LIGHS

2:=29 B>

*

+

A4;>

740:A7

2:=29

@4A A4;>.

A8;4?

@4A

?42=C4?F

27429

58:A4?

?4@4A

3=D< C4<A8:0A8=<

0BA=

=55

?42=C4?F

<=?;0:

=</=55

LOCK

32

@D8<6

50<

?==; A4;>.

=<

308:F

SIMEQ

58:A4?

58E

@[email protected].

;=34

@A0<31F

2==:

24<.033.

MODE

24<A?0:

=>4?0A8=<

defrost

temp.

sensor

Te

outdoor

ambient

temp.

sensor

Tao

condenser

condenser air-inlet temp.

sensor Tci

check

valve

discharge

temp.

sensor

Td

4-way

valve

assistant

capillary

check

valve

one-way valve

main

capillary

cooling

low pressure

switch

high pressure

switch

muffle

compressor

heating

2-way stop valve

(liquid side)

3-way stop

valve (air side)

indoor

coil

temp.

sensor

Tc

evaporator

indoor

ambient

temp.

sensor

Tai

33

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Commercial Air Conditioner

8. Refrigerant circuit

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

9. Electrical Control Functions

9.1. Outdoor electric control functions

System main functions

Definition of sensor sign: Tnh=indoor ambient temp., Twh=outdoor ambient temp., Tpg=indoor coil,

Ttc=discharge, Tcs= outdoor coil, Txr=suction.

1.1 Outdoor running frequency and the control procedure

1.1.1 Outdoor running frequency control

Outdoor running frequency range:

Compressor max. running frequency in cooling mode:

outdoor ambient temp.

~15

15~38

38~

Max. running frequency Hz(E)

60

100

80

Compressor min. running frequency in cooling mode:

outdoor ambient temp.

~38

38~

Min. running frequency Hz(E)

16

16

Compressor max. running frequency in heating mode:

outdoor ambient temp.

~0

0~15

15~

Max. running frequency Hz(E)

120

100

80

Compressor min. running frequency in heating mode:

outdoor ambient temp.

~10

10~

Min. running frequency Hz(E)

30

30

1.1.2 Compressor startup

When compressor startup for the first time, compressor running frequency must be stay at 60Hz(E)

and 80Hz(E) for 1 minutes (At outdoor discharg temp. overhigh protection and compressor overcurrent

protection, the frequency will be reduced), and then rise up to the target frequency. After the unit is in

normal, the above procedure is not available.

1.2.3 Heating mode, cooling mode

After performing the compressor startup procedure, the unit will run according to the indoor

frequency.

2 minutes later, the unit will compensate the running frequency due to the relative condition.

1.2.4 Compressor frequency rising/reducing speed

Rapid rising/reducing frequency speed 1----1Hz/second

Slow rising/reducing frequency speed 2----1Hz/10 seconds

Slow reducing frequency speed 3----2Hz/second

1.2 Outdoor motor control

Note: When the outdoor motor needs to change the class, there will be 45-second interval to avoid

the fan speed changing frequently. 4 pulse for each circuit.

1.2.1 Fan motor speed class has 7 steps, the rotation and class is as follow:

Class-0

Stop

Class-1

250

Class-2

400

Class-3

550

Class-4

650

Class-5

850

Class-6

900

Class-7

950

1.2.2 Blowing remain heat after compressor shuts off

In cooling mode, when compressor shuts off, outdoor motor will enter speed Class-5 automatically,

and will shut off after blowing remaining heat for 30 seconds.

1.2.3 Outdoor motor control in cooling/dry mode

Fan motor locked rotor: When fan motor is requested to work, if fan speed is measured to be below

50RPM and keep for 10 seconds, the compressor will stop, but 3 minutes later, it will re-start up again.

If within 10 minutes, the condition occurs 3 times, the unit will stop and alarm.

When compressor starts up, the unit will adjust automatically in 3 minutes according to the outdoor

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

ambient temperature, and 3 minutes later, the unit will adjust according to the outdoor ambient

temperature and compressor running frequency.

Fan speed chart in 3 minutes after compressor starts up:

Ambient temp.

~10

10~25

25~

Cool

Class-3

Class-5

Class-6

heat

Class-6

Class-5

Class-3

Fan speed chart in 3 minutes after compressor runs due to the ambient temp. and compressor

frequency:

Compressor frequency in cooling

Twh

40Hz≤F<50Hz

50≤F

Over 28℃

Class-3

Class-5

Class-6

Below 28℃

Class-1

Class-3

Class-5

F<40Hz

40Hz≤F<50Hz

50≤F

Over 15℃

Class-1

Class-3

Class-4

Below 15℃

Class-3

Class-5

Class-6

Compressor frequency in heating

Twh

F<40Hz

● Low temp. cooling mode:

Outdoor temp. To

DC fan speed

To <0

0≤To <5

5≤To <10

10≤To <15

Class-1

Class-2

Class-3

Class-4

Rated running mode:

Outdoor fan motor runs in class-7(DC motor) in rated mode.

1.2.4 Fan motor speed control when outdoor select inverter moter

Select fan motor by SW4 on the outdoor small indicate board, ON means DC motor, OFF means

inverter motor.

Blowing remain heat function: In cooling mode, when compressor shuts off, outdoor motor will run in

low speed, and will shut off after 30 seconds.

Fan speed chart in 3 minutes after compressor starts up:

●

Ambient temp.

Cool

Ambient temp.

heat

~15

15~25

25~

Low speed

High speed

High speed

~10

10~20

20~

High speed

High speed

Low speed

Fan speed chart in 3 minutes after compressor runs due to the ambient temp. and compressor

frequency:

Compressor frequency in cooling

Twh

~25

25~45

Over 28℃

Low speed

High speed

High speed

Below 28℃

Low speed

Low speed

High speed

~25

25~45

Over 15℃

Low speed

Low speed

High speed

Below 15℃

Low speed

High speed

High speed

Compressor frequency in heating

Twh

45~

45~

Remark: 1. There are 45 seconds delay when changing fan speed;

2. When in non-heating mode, if outdoor ambient temp. is lower than 15℃, the fan will run in low

speed;

3. When in heating mode, if outdoor ambient temp. is lower than 20℃, the fan will run in low

speed.

1.3 Outdoor electronic expansion valve (EEV) control

1.3.1 Movement of EEV

Full-close, full-open, open angle upper limitation, open angle lower limitation, open/close valve speed.

35

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Initialize movement: 600 pulse close, then 50 pulse open, that is stop at 50 pulse at last;

Full-open: 480 pulse open(E);

Upper/lower limitation of open angle: 480---50 pulse;

Driving speed: open direction: 30.3 PPS; close direction: 83.3 PPS;

Electrify initialize movement: act as full-close;

The movement of valve after compressor startup/shut off ;

Compressor startup: the compressor will startup after the open angle of valve has reached the

fiducial open angle;

Compressor shut off: valve begin to full-close after the compressor has stopped.

1.3.2 Enter the fiducial open angle after compressor startup(no matter 2 minutes later or 2 minutes ago), 4

minutes later adjust automatically according to the target over-heat value, 10 minutes later begin to modify

the over-heat value and open angle of valve.

Cool

~22℃

Outdoor temp.

22℃~

Compressor frquency

~50

50~80

80~

~50

50~80

80~

PMV open angle

230

220

240

260

250

280

Heat

~6℃

Outdoor temp.

6℃~

Compressor frquency

~50

50~80

80~

~50

50~80

80~

PMV open angle

200

180

220

240

230

260

1.3.3 Confirmation of over-heat degree

Standarded over-heat degree

Actual running Hz

~20

~30

~40

~50

~60

~70

~80

~90

90~

TXRH0

(℃)

Cool, dry

2

2

1

1

1

1

1

2

2

heat

2

2

1

1

1

1

1

1

1

When discharging temp. Td is too high or too low, modify the EEV angle

Mode

Modification angle

Max. modification

Cooling

Ttc>100℃, standarded over-heat degree -1 degree / 2 minutes

90℃< Ttc<100℃, keep the angle

Ttc<90℃, +1 degree / 2 minutes, and plus to 0 degree gradually

Max. -5

Cooling

Ttc<35℃, standarded over-heat degree +1 degree / 2 minutes

35℃< Ttc<40℃, keep the angle

Ttc>40℃, -1 degree / 2 minutes, and reduce to 0 degree gradually

Max. +5

Heating

Ttc>100℃, standarded over-heat degree -1 degree / 2 minutes

90℃< Ttc<100℃, keep the angle

Ttc<90℃, +1 degree / 2 minutes, and plus to 0 degree gradually

Max. -5

Heating

Ttc<35℃, standarded over-heat degree +1 degree / 2 minutes

35℃< Ttc<40℃, keep the angle

Ttc>40℃, -1 degree / 2 minutes, and reduce to 0 degree gradually

Max. +5

1.4 4-way valve control

The 4-way valve control in defrosting: refer to the defrosting procedure.

4-way valve control in other modes:

In heating mode, 4-way valve will open in 15 seconds after compressor starts up. When compressor

not startup or in non-heating mode, 4-way valve will close to ensure the compressor has stopped for at

least 2 minutes.

36

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

1.5 Outdoor defrosting control

1.5.1 Enter condition

In heating mode, if the compressor has run for 10 minutes continuously and run for 45 minutes in

all(clear the compressor accumulative operation time when defrost over or enter cooling mode), the system

will measure the defrosting temp. sensor Tcs(check the frosting condition of outdoor heat exchanger) and

outdoor ambient temp. sensor Ta, if the below condition can be met for continous 5 minutes, the unit will

enter defrosting operation:

Tcs≤C×Ta-α

Herein: C: Ta<0℃, C=0.8(E)

Ta≥0℃, C=0.6(E)

Set α= 8 according to the data of EEPROM.

Herein: when C×Ta-α exceed the range of -12℃≤C×Ta-α≤-6℃,

If C×Ta-α<-12℃, regard it as equal to -12℃; if C×Ta-α>-6℃, regard it as equal to -6℃.

1.5.2 Defrost interval time

When C×Ta-α>-12℃, compressor defrost accumulative operation time is 45 minutes;

When C×Ta-α≤-12℃, compressor defrost accumulative operation time is 45 minutes

1.5.3 Defrost operation

when defrost begins, compressor will stops for 1 minute, outdoor fan runs, after 50 seconds, 4-way

valve OFF.

Outdoor fan stops when compressor starts up, compressor running frequency must be stay at 60Hz

(E) for 1 minute, and then rise up to the target frequency 88Hz.

Compressor current and discharge protections are valid during defrost, when compressor stops

because of protection or failure in defrost mode, resume after stopping for 3 minutes, accumulative

operation time will not be cancelled. Enter defrost when the continuous operation time is met.

When enter defrost, quit defrost only when 2 minutes of the compressor min. operation time is met.

1.5.4 Quit condition

When any of the following condition is met, change defrost to heating mode.

(1): Outdoor heat exchanger temp. over 10℃ last for 60 senconds contineously;

(2): Outdoor heat exchanger temp. over 14℃ last for 30 senconds contineously;

(3): Defrost for 9 minutes contineously.

1.6 PTC output control

When outdoor unit is electrified, PTC output is 0, 3 seconds later, it is 1.

1.7 Heater control

When compressor stops and outdoor ambient temp. less than 26℃, heater will work, or stop it.

1.8 auto-checking function(pre-set)

Auto-checking function: When first short-circuit CJ601 then electrified, enter auto-checking. The

process is as following: failure lamp LED001---PTC---4-way valve---heater---high speed---low speed--expansion valve(A—B—C—D)---LED lamp board(LED5—LED4—LED3—LED2—LED1—compulsory

cooling—compulsory heating—DC fan motor—inverter fan motor)

Compulsory cooling when SW5-2 on LED lamp board is “ON”, LED5, LED4, LED3, LED2 and LED1

are all light, or all are black out.

Compulsory heating when SW5-1 on LED lamp board is “ON”, LED5, LED4, LED3 and LED2 are all

light, LED1 is black out, or all are black out.

DC fan motor when SW5-4 on LED lamp board is “ON”, LED5, LED4, LED3 and LED1 are all light,

LED2 is black out.

Inverter fan motor when SW5-4 on LED lamp board is “OFF”, LED5, LED4 and LED3 are light, LED2

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

and LED1 are black out.

1.9 Time shorting function

Time shorting function: If the time shorting port is in short circuit after electrifying CJ601, the unit will

perform a 1/60 time shorting control.

1.10 Additional functions

1.10.1 The interval between compressor stop and startup again is 3 minutes, which can protection

compressor. If being electrified for the first time, compressor will start up only when the valve opens to the

normal operation angle.

1.10.2 Ttc high temperature protection

Ttc discharg temp. over-heat protection can be executed once the unit is ON, but the discharge temp.

sensor can only alarm after the compressor has started up for 4 minutes.

114℃

quick reduce FQY 2HZ/S

Discharging temp. Ttc

111℃

quick reduce FQY 1HZ/S

108℃

slow reduce FQY 1HZ/10S

105℃

keep FQY

95℃

slow rise FQY 1HZ/10S

90℃

If Ttc>=115 keeping for 10s, the discharge temp. over-heat protection excutes and unit stops,

resumable after quit the protection. If in 60 minutes the protection occurs for 3 times, the failure can be

sent to indoor unit.

1.10.3 In heating indoor Tc high temperature protection

Indoor heat exchanger temp. sensor will check the indoor coil temperature, if it is over 55℃, the unit

will reduce the compressor motor speed to perform the indoor heat exchanger temp. overhigh protection.

If it is below 48℃, the unit will resume to be normal control.

P: reduce at the speed of 1Hz/10s

Q: remain the previous value

R: rise at the speed of 1Hz/10s

TC

P

reduce slowly

Q

remaining

R

rise slowly

55℃

52℃

48℃

1.10.4 Over current protection:

38

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

The compressor will stop and alarm if current exceed 11A for 3 seconds contineously during

compressor startup, the compressor can re-start up after 3 minutes. but the compressor will stop and

alarm and confirm the failure if it stop abnormally 3 times in 60 minutes, the system will work continued

after been power-off.

Over current reducing frequency(FQY) protection

When current exceed (B)A, the compressor will reduce FQY at 1HZ/S, if current is less than (B)A and

more than (B-1)A, stop reducing FOY and then rise FQY at 1HZ/10S, when current is less than (B-A)A,

reaume to the target FQY. (B is setted in the EEPROM)

Compressor power protection

1) In dry and cooling mode, when compressor power over (a)W, the compressor will reduce FQY

1HZ/S, if compressor power over (b)W, the compressor will reduce FQY 0.1HZ/S, when compressor

power over (c)W, rise the compressor FQY is forbidden, when compressor power over (d)W, the

compressor will rise FQY 0.1HZ/S.

2) In heating mode, when compressor power over (a1)W, the compressor will reduce FQY 1HZ/S, if

compressor power over (b1)W, the compressor will reduce FQY 0.1HZ/S, when compressor power over

(c1)W, rise the compressor FQY is forbidden, when compressor power over (d1)W, the compressor will

rise FQY 0.1HZ/S.

Remark: a, b, c, d and a1, b1,c1,d1 are written in EEPROM, can be adjusted according to different

system.

1.10.5 High, low pressure protection

High pressure protection: high pressure switch will not detect when in standby, detect after

compressor has started for 3 minutes.

Low pressure protection: low pressure switch will detect after compressor has started for 3 minutes,

and will shield during defrost or 6 minutes after defrost.

1.10.6 Sensor management: the detect time for sensor short-circuit or open-circuit is 4.5s, 3 minutes is

needed for resume if failure is detected, the unit will work normally when the failure is cancelled.

Discharge temp. sensor will not detect if it short-circuit or open-circuit, detect when compressor has

started for 3 minutes.

When the AD value of all sensor is less than 3, regard as the outdoor temp. too low and all sensor

failtures will not alarm.

Outdoor add high temp. protection

Te

quick reduce FQY 1HZ/S, when Te>=70℃, quick reduce FQY 1HZ/S, and stop the unit

62℃

if it lasts for 10 senconds

59℃

remaining

55℃

slow reduce FQY 1HZ/10S

1.10.7 Indoor heat exchanger anti-freezed protection

Anti-freezed in cooling mode

39

Commercial Air Conditioner

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

normal control

11℃

slow rise FQY 1HZ/10S

9℃

remaining

6℃

slow reduce FQY 1HZ/10S

1.10.8 Rated operation(the value can be setted by EEPROM)

● Rated cooling:

When receiving the indoor rated operation command, the unit will enter rated cooling operation.

● Rated cooling:

When receiving the indoor rated operation command, the unit will enter rated heating operation.

1.10.9 Outdoor compulsory operation(select by the outdoor dip switch)

● Compulsory heating operation

Dial SW1 of the outdoor small indicate board in ON state, set the heat exchanger temp. from indoor

unit 16℃, each protection is available, FQY(20—120Hz), fan speed(inverter: high/middle/low; DC motor:

class 1—7) and expansion valve(10—400) can be manual adjusted.

● Compulsory cooling operation

Dial SW2 of the outdoor small indicate board in ON state, set the heat exchanger temp. from indoor

unit 16℃, each protection is available, FQY(20—120Hz), fan speed(inverter: high/middle/low; DC motor:

class 1—7) and expansion valve(10—400) can be manual adjusted.

Note: the dip switches for compulsory cooling and compulsory heating can not be setted ON

synchronously.

1.10.10 Failure code and troubleshooting

The outdoor lamp will flash if there is failure, the flash FQY is 1HZ, the flash time is according to the

following table, the lamp will off for 3 seconds after one flash circuit, meanwhile, the lamps on LED board

will light in 5-bit binary system(light is 1, LED1-LED5 from low bit to high bit).

Alarm lamp is always light when there is no failure.

1.10.11 Special funtions

1) Power operation

When receiving the Power operation signal from indoor, the unit will operate as the set frequency by

EEPROM. Fan speed will depend on the ambient temperature and the frequency. When the Power signal

is cancelled by indoor, the Power operation will stop.

2) Soft operation

When receiving the Soft operation signal from indoor, the unit will operate as the set frequency by

EEPROM. Fan speed will depend on the ambient temperature and the frequency. When the Soft signal is

cancelled by indoor, the Soft operation will stop.

3) Time shorting operation

After receiving the time shorting signal, the unit will perform the 1/60 time shorting operation.

4) Compulsory cooling/heating operation

Controlled by the buttons on the outdoor small board, only indoor heat exchanger protection is invalid,

all the other protections are valid.

40

Commercial Air Conditioner

Trouble description

Display of

LED borad

LED 5-4-3-2-1

Model: AU122AEERA AB122ACERA

AC122ACERA AD122ALERA

Analyze and diagnose

Flash times

of LED on

mainborad

IPM failure

00001

IPM failure

1

Abnormal of DC moter

00010

Jam of DC motor or motor failure

2

00011

Communication fail over 4min

3

00100

Compressor discharging tempreature over 120

centigrade

4

00101

Current of spdu / ISPM module over limit

5

Communication error between

indoor and outdoor unit

Compressor discharging

temprerture protection

Spdu / IPM module over

current protection

Abnormal of outdoor ambient

sensor

Abnormal of piping sensor

00111

Outdoor ambient sensor short-circuit or

open-circuit last 60 sec

Piping sensor short-circuit or open-circuit last

60 sec

High pressure protection

01000

System high pressure over 4.5Mpa

8

01001

Compressor discharge sensor short-circuit or

open-circuit last 60 sec

9

01010

The power supply is not the 50Hz

10

Module PWM select circuit error

01011

Module PWM select wrong circuit

11

Detect PFC over-current

01100

The current of PFC circuit is too high

12

Module error

01101

Module error

13