Download Agatec G.C.P.V. User's Manual

Transcript

4/01ErNs511502

GasFiredCookers

\@'9,-4

lnstallationlnstructionsfor

Aga Gas PowerVent FiredRange

Models:G.C.P.V.(2 Oven)N.G.and L.P'G.

G.E.P.V.(4 Oven)

(.e]

For U.S.and CandianMarkets

ANDTHEUSER

BELEFTVMTHTHEAPPLIANCE

SHOULD

INSTRUCTIONS

NOTE:THESEINSTALLATION

REFERENCE.

FORFUTURE

TO RETAIN

fof

can be made,the siteis inspected

TheGasfiredrangesarc deliveredunassembledBeforeinstallation

codes

local

installation

wiih

conform

to

whefenecessary

andcorrected

.uiLuirltyby i" AifllorisedAga Distributor

or in the absenceof localcodeswith:

ln Canada:

codes

installation

TheCANiCGA-B149

ln U.S.:

The NationalFuelGas CodeANSI2223 1-latestedition

andsafety'

ensurecorrectperformance

on siteby the sameAga Distributorto

Assemblyis undertaken

INSTALLATION

the

It is essentialthatthe baseor hearthon whichthe rangestandsshouldbe leveland strongenoughto support

weightof the rangeweights:

Approximate

G.C.- 406k9(900|b)

l\4odels

G.E.- 585k9(12901b)

materialfor a minimumthicknessof 12mm(1/2)and

Thetop faceof the heanhmustbe of non-combustible

co'nplywithtl-ecunentBuildingRegulaoas and Na onalFlreLaws

aroundthe range

The locationmustalsopfovideadequatespacefor servicingandaif circulation

W A L LT I L I N G

shouldthetiles

lfthe cookeris to standin a fecessor againsta wallwhichis to be tiled,in no circLlmstances

overlapthe rangetop plate.

GAS SUPPLY- U.S.PIPETHREADS

LOCATIONlN THEGASPIPE

lN AN ACCESSIBLE

NOTE:A [4ANUALVALVElllUSTBE INSTALLED

oF GASTo rHE

oNoR SHUTTING

oFTURNING

FoRTHEPURPoSE

Eiienrni io rne nppLrANcE

APPLIANCE.

ALL GASCONTROLSMUSTBE U.S.PIPETHREADS.

Btu/h)

Heatlnput4.4kW(15,000

Maximum

The maximumgas inletpressureat the appliancemustnotexceed1o inchesw.g.for NaturalGas,14 inchesw-g

inches

mustbe5 inchesw g NaturalGasand11

gasinletpressrlrc

at theappliance

forL.P. Gas.TFeminimum

be

obtained

to

wg. L.P.Gasto enablethe correctmanifoldPressure

fromthe gas supplypipingsystemduring

shut-offvalvemustbe disconnected

and its individual

Theappliance

in excessof 1/2 psig(3.skPa).Theappliancemustbe

anv o;essuretestinqofihat svstemat testpressures

duing any pressure

manualshut-offvalve

isoijteafromtne ga1supplypipingsystemby closingits Individual

psi

(3

skPa)

1/2

prcsstre

less

than

equal

to

or

pi6lng

gas-suppli

at

te.t

syiteh

t;atingof the

and purge.Leaktestingofthe applianceshallbe conducted

for soundness

testthe gas installation

on completion

instuctions.

accordingto manufactureis

to ensurethereare no gas leaks

NOTE:Usesoapywatersolutionon newgasconnections

AIRSUPPLY

Kitchenor IntemalAi. SUPPIY

in forcebut in anyeventthe

ii'" ipptilncacan ontybe initilled in a roomwhichmeetsventilaiionregulations

(5

2

2

sin

area

36cm

ventof minimumfreeair

)

roommusthavea permanent

willbe requircd

ventllation

In the eventof an extractorfan beingflttedin the vacinityofthe range,compensatory

flue

conditions

and

efficiency

combustion

influencing

to satisfythe demandsofthe fan wit-hout

ELECTRICAL

1'10/l2oV6oHz,loAN4PFLEX|BLEcoRDANDPLUGPAMLLELTYPE.Theapp|iancewheninsta||ed,m

groundedin accordance

withlocalcodesor, in the absenceof localcodes,w1hthe Na6onalElectrical

ete;11ically

70.

CodesANSI/NFPA

to the

socketmustbe providedwithin6 feetofthe LH sideofthe applianceand easilyaccessible

An etectrical

Do not positionsocketabovethe appliance.

userto disconnect.

WARNING

EleciiicalGroundingInstiuctions

Thisapp|ianceisequippedwitha(three-prong)groundingp|ugforyourprotectionagainstashockhaza

plug

snouldbe pluggeddirbitlyintoa properreceptaaleDo notcut or removethe groundingprongfromthis

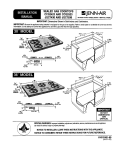

VENTSYSTEM

whichcanreachupto 6

ventpipe50mm(2in)diameter

discharge

is bya fanpowered

Products

of combustion

of 6 x 90' bendsor I metres(29ft)withonebendExitsfromthe

metres(19.5fr)

in lengththrough

a Faximum

sides,fromtherearcentreor fromtheunderside(Figs.2 & 3).

appliance

canbefromrearL.H.or-R.H.

wallfixingplateby25mm( 1in)Fig.1

theoutsrde

Theventpipeshouldexitthrough

D E S N5 1 1 1 8 9

F I G 1,

DESN511126

rtt

el ffic{lrhl ||!$ru

]

EL

S|l'E

i

gx

!t

o

I

I

f,ffi

tHtt^tsl

al'lr:

ml

\rrfir ntr{N

off xtE||n/rdr*l

L,'1: lSilr$d€l,M

nE|,|n& !3r t'

ffi.TD

Carejts|*

t &€lrUrids ldar & *xs{ra$hn

vArft !*hr&fig donlr6b. Wdng r.rq$

rawF ]rrpr.fllr qrd d!ng4|qf cp!|q!rj

\is|ly frsrnl {rr'ldrrt als $dr6s.

{3i

l-*\o.

E

I

i

n

TERMINALPOSITION

'1.The rangemustbe installedso thattheventterminalis exposedto the externalair andterminal

clearancecomDlvwith:

In l.r.s.:The NationalFuelGas CodesANSI22231 latesteditionSection7.7

installation

code.

In Canada:CAN/CGA-8149

2. Termination

shouldbe on a clearexpanseofwall,the terminalbeingpreferablynotlessthan

355mm(14in)awayfroma corner,recessof projection'1.5"frominsideto outsidefaceof

3. A holemustbe cutthroughan outsidewallwiththe holefalling

Openingsin thewallsbehindor on the floorobelowthe appliancemustbe sealedusingthe closureplateand

sealantprovided.

DONOTinstalltheterminaiunderthe followingconditions:

(a)Wthin 300mm( 12in)measuredvedicallyfromthe bottomof an openablewindow,air ventor any

other ventilating

opening.

(b)\Mthin300mm(12in)aboveadjacentgroundlevel.

(c)Wthin 600mm(24in)ofanysurfacefacingthe terminal.

beloweavesor balcony

(d)Wthin355mm(14in)(U.S.)or 300mm(12in)(Canada)

guard(supplied)

installedovertheterminalto prevent

Theterminalmustbe protectedby the terminalprotective

(See

unauthofised

contactwiththe hotteminal surfaces.

E4L1).

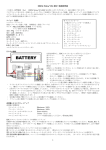

TechnicalSpecification

GCandGE

L.P.G

NaturalGas

rG

e Model

ain BurnerInjecto.

tir

PilotBurner

Iniector

t,-

GasValve

Combination

BvpassScrew

sas BurnerPrcssure

:ombinationGasValve

Piiot

s.t.T.EUROSTT

JOHNSONS

t-il

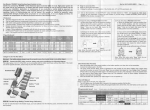

GCPV12ovElrtsl

f*l]--';o,*o*o,

qarsEo

lrDsWHEN

I i!

I

-T

'r 4Se#"1r'

I

,i

ti

I

rrtlr4tN,|

I

I

tF=:

I

I

Bl

|

I

I

|

I|

t4-:il

|

I

L-_

I

|lrilLlh=

H

l'

l" Hil

- T l|

f

lt

r-,---J

l

t--

-

lF

tLI&::L=FJ

+t l I

'Yr'

I

.,-N

)n-,1*

*1r1e-----*

v#i?#..'-"-

Tl

---J

IINT PIPE

V

,, / ./,/ / / / ,/ ,1"// ,/ ,/ ,/ ,/j/ / / , _*

^'cg::='t-Uil

I| l"

/\

| I

P,]

//'="'\'l

?.

I

\t

I// ,

t

urlsi=ffilbr

vEr.rT

PrPE

ll

\

6l l{,

j|l' )lW

I

\"-// \=d/

II l"

Z

I

"l| V , t l.

|

I

I

tr::::

=::!#1--Vl----l' (/ |

--*

\DOoh'N .;.

|I

OvEr,l

f,

'1.1,/.

oPEN

PosrTroN

- - ; - { I/

t

""--1+B

.ir

Eq

lt, I

I

II

r\tfl,

Llt --- i--!l',,i tI

T./lT----l--Tl

:+

i

I

r11i,/

x{ --1v ,IE-

| 4,,HVll

\//

").,

Llt. stDEvEw

Fno$rv|gw

w

/,2GASCONt{EgflON

n H.

+S

t*-

R'K SDEVIIW

PtAtrluEw

c

mm 987 967 851

l''t