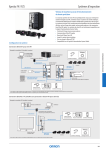

Download Vision Sensor FZ4 Series

Transcript