Download Solutions for your difficult soldering needs.

Transcript

/13%ffi

Information & Instruction Manual for

American Beauty@ Resistance Soldering Equipment

Solutions for your difficult soldering needs.

When it comes to soldering equiprnen! American Beauty@ has been

a trusted name in industry forwell over one hundred years.

Information & Instruction Manual for

Arnerican Beauty@ Resistance Soldering Equipment

ffi

Manufacturers of American Beauty@

Quality Soldering Tools

Table of Contents

Section Title

Page

1.0 lntroduction

2.0 Description

2.1 The Science of Electricity

3.0 Safety-General

3.1 Safety-Heat Related

3.2 Safety-Ventilation Related

3.3 Safety- Electrical Current

4.0 Resistance Soldering Equipment Uses

5.0 Basic System Configuration

5.1 Ghoosing the Correct Handpiece

5.2 Handpiece Recommendations

5.3 Choosing the Gorrect Power Unit

5.4 Power Unit Recommendations

6.0 System Set-up nstructions

7.0 Developing Your Soldering Process

7.1 Determining Appropriate Pgwer Levels

f

7.2

8.0

3

3

4

5

'|

5

5

5

6

6

6

7

8

I

9

9

10

Maximum Operating Parameters

10

Troubleshooting Your Equipment

11

+EF

Intbrmatron & Instruction Manual for

Ilanufacturers of .\ms:-: l:'

Quality Soldeine l:.: -.

:

1.0 Introdueion

Ifyou have only recently become aware ofResistance Soldering'Equipment and its various

tind it interesting to note that this is actually not a new concept. The American Beautf

i

uses you ma)'

line ofResistance

Soldering and Thermal Wirestripping equipment has been manufactured and available for over fifty years.

The entire line of American Beaun! soldering equipment'is developed and manufactured exclusively by

Assembly Technologies Intemational Inc.* located here in suburban Detroit. Michigan.

As the manufacturer ofthe largest assortment ofpower units, handpieces and related accessories available

anywhere, we pride ourselves in being the worlds leader in the design and development ofresistance based

soldering equipment. Each item that we manufacture is being continuously evaluated and improved upon so

that we may offer you the highest performance along with the safest, most efficient. user tiiendll equipmenr

available for any Resistance Soldering or Thermal Wirestripping applications that.!'ou ma1 t'e ;..ns:oe::;rg

All American Beaut-v'' products are manufactured using the highest quality of materials thar.ue:re:l:bie

and are assembled with -sreat care so thel r'ill consistentlv conform to our exacting qualiq spe;:r:;ail.'ns

This is why we are able to offer our Industr_r'Best -Three Year Warranty Policy" $hich ma1 ie rlesei

any time on our Web-Site at uuv'.americanbeauqtools.com under the Support heading.

We are certain that with proper care and maintenance, all of the American Beaut-v! Resistan.'e Stldenng

and Thermal Wirestripping equipment.vou have purchased will provide a long and reliable sen ice lit'e.

This manual has been developed to address manv ofthe specific questions and concems llru ma] have that

relate to the Principles of Resistance Soldering, Thermal Wirestripping and other applicarrlins r\here the use

ofan intense localized heat may be beneficial. We will cover general operating procedures. insrructions and

helpful guidelines as well as some very basic safet_v issues and concems that ma)'be a-.s..ciared uith the use

of this type of equipment. You will also find helpful information within the Support 3rii rlltrur \\-eb-Site.

We are confidant that you rvill find the intbrmation that is being presented uirhin thrs manual to be helptul

and informative, horvever if vou har e questions that are beyond the scope of s hat this manual covers please

take a moment to call us toll tiee ar I 80tl ) 550-25 10.

Yoa will frnd that we arc alw'u;-s happy to help provide "Solufions

for

Your Dilficuh Soldning .\eedr ".

2,0 Description

All soldering applications require the introduction ofenough heatto activate the t'lux and t'lou the solder.

Whenever tools that are being used ttr pertbrm a soldering application take too long to achieve the required

process temperature, tle potential tirr thermal damage exists. Resistance Soldering Equipment gives a user

the ability to manufacture an intense level of heat that can be regulated and localized rvithin the intended

solder joint in a more efficient manner lhan most other available methods. This means a faster soldering

process and less time for dissipative heat to cause any thermal damage to the components that are being

soldered or any materials or components that may be within the immediate area sunounding the intended

solder

joint.

Resistance Soldering is accomplished bl producing a safe (lorv-voltagerhigh-amperage) AC current which

is then passed through special electrc.des (manufactured out ofhigh resistance metal allols or other resistive

materials) to generate an intense level of available heat. A closed loop circuit is required so that the current

can be passed from one resistive electrode directly through the base metals that are being soldered and into

the other electrode back to the po*er unit. An isolated transformer is used so that the current does not stra]

or leak into unwanted areas. but talies the most direct path from one electrode to the other rvhich completes

the circuit that is required to generate the desired heat. The resistance ofthe special electrodes that are used

creates the majoriqv ofthe heat that is being generated. Anl additional resistance rhat exists at the point of

contact and within the base metals that are being soldered will increase the amounl of available heat that can

be generated within the solderjoint. 81'regulating the output voltage olthe resistance soldering power unit

the heat that is generated can be adjusted to the specific level required tbr the soldering application that is

being performed.

ffie

Information & Instruction Manual for

Amertcan Beauty@Resrstance Soldering Equipment

Manufacturers of American Beauty@

Quality Soldering Tools

2.1 The Science of Electricity

Resistance heat can be developed because ofthe three fundamental forces that control all electrical circuitsl

vol tage. amperage, and resistance.

lbltage

Its scientific name is electromotive lorce lvhich is usually represented in formulas with a capital letter ''E".

The electromotive tbrce or electrical pressure that moves an electrical cunent through a conductive material

is measured in units that are called volts. One lolt is equal to the amount ofelectromotive force necessary to

force one ampere ofcurrent to flou through a resistance ofone ohm. Generally a higher voltage means that

more current will flow and a louer voltage means that less cunent will tlos through an electrical circuit.

he used lo measure the amount ofvoltage (electrical pressure)

A voltmetet can

in the circuit

Amperage

The scientific reference is intensitl Lrlcurrent flow usually represented in formulas with a capital letter "I".

The rate at which an electrical cunent u ill l'lorv through a conductive material can be measured in units that

are called amperes. One ampere equals a tlon of6.25 x 1023 electrons (called one coulomb) per second.

Using the water flowing through a pipe analogl to describe the way that current florvs along a conductor,

current rvill flow more readill through a short thick conductor than through a long nanorv conductor.

,4n ammeter can be used to measure the amounl of ct nent that

Although

a greater amount

is

Jlowiilg through a circuit

nill flou-alone a conductor,

also be dependant upon the amount of resistance encountered.

ofvoltage can increase the amount ofcunent that

the actual amount ofcunent that florvs lr

ill

Resistance

Resistance is the property ofa material which resists or opposes the flow ofan electrical cunent through it.

The actual resistance (R) of a material is dependant upon its resistivity (p) which can be different for each

nraterial, along with its physical characteristics tsuch as the materials overall length and cross-sectional

area).

This can generally be shown as R: pLlA, rvhere R is the resistance in Q (ohms). p is the known resistivity

of the conductive material, L is the length ofthe conductor and A the cross sectional area ofthe conductor.

Resistivity (p): is unique to each material being soldered.

Length (L): A greater length increases the amount of resistance and a shorter lengh decreases resistance.

Area (A): A greater area decreases the amount of resisrance and a smaller area increases the resistance.

An ohmmelet

q4

be used to measare the omount of rcsistance that eyists

in a conductive material

Resistance Heat

Resistance heat is the heat that is developed as an electrical cunent is passed through a conductive material

because ofthat conductive material's resistance (or opposirirrn) to the cunent that is being passed through it.

Whenever an electrical cunent (l) flows through a conductive material with resistance (R), electrical energ;is converted to heat at a rate ofpower (P) that may be calculated as P: I? R, where P is the polver measured

in watts, I is the cunent measured in amperes and R is the resistance measured in O lohms).

The heating eflect of resistance is often considered undesirable in the transmission of current tbr most

electrical applications and must be minimized, but it is verl useful tbr intentionally generating electrical

heat tbr a variety of uses, in this case Resistance Soldering. Understanding that some materials have a

higher level ofresistivity than others and that the actual amount ofresistance can be altered by changing the

physical characteristics of the material is an important part ol us creating and utilizing resistance heat tbr

various soldering applications.

+ffiF

\Ianufacturers of .{rne:::a: 3=.-;.

Quality Solder:r:g li: -.

-1.0

Safety-Generol

'

,

.{ll of the American Beautyi

resistance soldering or thermal wirestripping equipment that is manufactured

b."- Assembly Technologies Intemational Inc.* should be operated in complete compliance with all federal.

state and local regulations that exisr pertaining to the varioqs uses for this type of equipment. This includes

actual use, storage, safe handling and disposition ofanv materials, components. tools or other products that

may be used in conjunction rvith this equipment. Consult the manufacturers of the solders, fluxes, cleaning

agents and other products that might be used along rvith this equipment and request a copy oftheir current

Material Safety Data Sheets t\lSDSs.l or other available information, documentation or specific wamings

regarding each of their individual products. It is important to become familiar with all MSDSs. operations

manuals, information and instruction sheets, stickers, labels, inserts and other related material or documents

that are currently (or that become) available regarding our products and any other materials ..r equipment

that may be used in conjunction with them.

3.

I

Safety-Heat Related

As previously stated, all soldering applications will require the introduction of some ier el ..f helt :.. i,e

flux and melt and flou.the solder. It is important to exercise caution $hen rperaring anr

products or equipment that are used to manutacture or generate the required heat. The devekipment of satt

operating practices and proper training procedures rvill help eliminate the possibilir."" of an1 .rc;idental bums

or other potential hazards. All operating personnel must be aware ofthe proper handling pr..cedures for any

combustible or flammable materials that might be required for your specific soldering appiicatierns.

Systems should be tumed offwhenever the) eue not in use or they are going to be lett temporarilv unattended in order to help prevent any accidental actuations.

able to activate the

3.2 Safety-Ventilation

Related

Proper ventilation is a signiticant consideration lor any type ofmanufacturing and pr..cessrng environment.

This fact is especialll'true rrhere there is a potential for smoke, fumes. vapors or other irriranls and airbome

contaminanb that exist or develop. There are a rvide variety of sizes, sr_'-les and rypes .ri r entilatron. exhaust

and air tiltering s) stems availaL,le rr hich have been specifically designed for the remtrr al .rf oft-ensive odors

and potentialll" harmful smoke. fumes trr vapors that may be given offduring variLrus srrldering applications.

Be sure that you have obtained. read and fullv understand all ofthe available documentation regarding the

proper use, storage and sale handline .rf anv materials and equipment that you ma]' be intending to use with

your soldering applications. This should include any requirements for protective cltthing shielding or other

apparatus that may be_speci{igd

3.

3

Safety-Eledrie*l

-C u rr e nt

Resistance Soldering equipment consists ofvarious electrical devices that are intended for use in soldering

applications to help improve the saliq . qualiry and effrciency of many of.vour current soldering processes.

This equipment must be used in ctrmplete compliance with all of the applicable sal'e operating procedures,

local ordinances and other guidelines and regulations that exist for the locations shere thel are being used.

Failure to follow the specific instructirrns. procedures and guidelines can result in the possibilitl ofinjuries

to your operating personnel or damage to equipment which could otherwise have been avoided.

The output that is produced bv all rrfthe American Beauty Resistance Soldering Pelser Lnits is a very safe

low-voltage AC cunent this equipment operates on standard 1 10-120 or 220-2-10 .A.C line voltage. However.

opening the Power Unit enclosure can expose an operator or individual to the possibiliq ofvarious electrical hazards. Any troubleshotrting practices and maintenance procedures that mal be required should be

attempted by qualified personnel onll'.

Information & Instruction Manual for

American Beauty@ Resistance Soldering Equipmenr

4.0

#o

Manufacturers of American Beauty

Quality Soldering Tools

Resistance Soldering Equipment L'ses

Because ofthe abiliqv to very rapidh produce an intense level'ofcontrolled, localized heat. directll'u.her

it is needed tbr soldering .vou rvill t'ind tha aimtrst anv soldering metlod or process that currentll' exists ca

be improved upon uith the use of resistancr sLrldenng equipment. The wide variety of available handpiecr

manuihctured tbr use with various poser unrts ranging ih maximum outputs of 100 to 3000 watts give

_v-o

the abilitl lqr pertbrm a virtuallf intlnite number ol soldering applications that can range from very sma

electronic components all the wav up to 3'- diameter thin wall metal pipes or other tubing that is used in

varietl of plumbine. retiieeration and H\'.{C applications.

$'ith the conectll contigured s)stems )rru rrill aluals be able to produce the higher temperatures that at

required for various hard solders and er en manl of rhe lotv to mid-temperature brazing materials that exis

Resistance soldering equipment is ernen the pert'ect choice tbr applications involving temperature sensitil

components that are either being s..ldered themselves or are located within close proximity to the materia

that are being soldered. For this qpe lf soldering applications it is very important to be able to apply a hig

enough temperature to the correcl iocallon and for the shortest amount of time possible in order to minimiz

the amount of heat that travels as a1 rrrm the solder joint. This is one of the primary reasons for choosin

resistance soldering equipment over sL) manv ofthe other types ofsoldering tools dnd equipment that exis

Some of the other reasons for resistarce scrlderins rue more consistent repeatability and improved qualiq

throughput and effrciencl . .{s 1 our operators gain more experience the number of uses is sure to increase.

Thermal Wirestripping is another npe of application that resistance soldering equipment may be used fo

This is best accomplished bl using one of the manl specially designed handpieces that have been develope

specifically for thermal wirestripping applicatitns along rvith the conect resistance soldering power unit.

Using the cotect equipment

5.0

fot

a4' ptocess grcatb' affects the quality and elficiency level you achieve.

Basic System ConJigaration

When configuring the basic resistance soldering system that will be required for any applicatior

your three primary components will be a handpiece. a power unit and a footswitch. There are a wid

variety of American BeautyD resistance soldering handpieces and several power units available to choos

from along with various accessories rvhich migtrr ais,. be recommended or required for more specialize

applications. It is important to properl] match the handpiece and power unit to the intended solderin

applications when configuring a s-vstem. in order tt be .rble to marimize the full range of benefits that ca

be obtained with the use of resistance soldering equrFment. You should determine the most appropriat

handpiece to use for the application first and then rq.g srll be better able to decide on the power unii th:

will give you the w-idestpossible working range and rersatility. Ifyou are considering using resistanc

soldering equipment for more than one applicatitrn. ) ou rna) find it beneficial to evaluate the requiremenl

of the largest application first. This approach can decre.::e ]our total cost of ownership by purchasing

single power unit to work in conjunction with multiple h.rndpieces.

5.1 Choosing the Correct Handpiece

When you are deciding on the most appropriate handpiece ro use for an application you should consider th

process that is being developed along with the size. shape and tlpe ofthe materials that are being solderec

The handpiece style that is being chosen for a specific apphcarron should allow for proper placement ofth

electrodes to the work based on the accessibility to the srrlder_roint area along with any special horizontal c

vertical orientation of the handpiece that may be required ttr ,'trmibrtably perform the soldering task. Th

electrodes size requirement will help determine the required handpiece size. The electrodes size should b

properly matched to the work requirements, because a grearer area of contact between the electrode an

work surfaces will help to increase the overall efficiencl rri the thermal transfer that will be taking plact

Even though electrodes can be modified in order to maximize rheir effrciency. you should choose the typ

and size that will most appropriately match the intended application prior to these modifications bein

made.

Manufacturers of .{m*cs

Quality Soldering :\

5.2 Handpiece

Recommendations

3eri !

:

,

The handpiece styles that are currently available include single electrode (used rvith a lead for current

return) dual electrode stationary, dual electrode tweezers, dual electrode pliers. dual electrode forks and a

variety of handpieces designed especialll for thermal wire stripping. All of the handpiece styles that are

listed here are available in a varietv of sizes in order to best meet the specific application requirements that

might exist.

Single Electrode Handpieces give -vou the ability to direct the heat to a specific point of contact in the

same manner as you would with a conventional soldering iron but with a much higher thermal capaciry

available. Using a lead for cunent retum will be necessary with the use of this st1{e of handpiece in order

to complete the required current path. The most appropriate handpiece size to choose is directll related tt

the electrode that will work best for the application that is being considered. Choose the ele.'trode :ize ;n ihc

same manner as you would when choosing a soldering iron tip size. Match the electrode diameler l.' :he

area being soldered.

Stationary Dual Electrode Handpieces sere initially developed for the highl."- repetitile sricer:ng of

similar sized terminations (terminal strips. multiple termination buss bars, etc.). The] ma1 be used on

applications similar to those where single electrode handpieces might be considered but the] do not require

the use of a lead for cunent retum to operate properly. The electrode tips are positioned in :r ;lose proximiry'

to one another and will complete the cunent path b)- passing current through the surface ofthe material that

is to be heated. With minor adjustments or modit'ications to the electrodes (bending. grinding. etc.) they can

be positioned in a manner appropriate to the requirements ofthe application that the] are intended fbr.

Tweezer Style Dual Electrode Handpieces will allow you to direct the heat ttr a specific area while

actually holding the component in place during a soldering application. After florving the solder .v-ou can

deactivate the footswitch while continuing to hold the component in place to cool. This helps to eliminate

cold solder joints that might be caused by agitation of the joint while it is cooling. The metal electrodes

being used in these handpieces can be bent to improve the ergonomic teel of rhe handpiece and the

electrode tips can be contoured to custom fit the work surface improving the thermal ransfer tiom the

electrodes into the work.

Pliers St-vle Dual Electrode Handpieces are similar in design to tweezer s4le handpieces but

were

developed for heavier applications and can obtain much higher operating temperatures. These handpieces

incorporate carbon block electrtrdes that allorv you to operate at temperature levels shich could actually

melt the metal allol electrrrdes rhat are used in the tweezer style handpieces. Carbon block electrodes have

increased lrork surtbces and can be contoured to increase the surface contact area of the electrodes to the

work even further. Ths inerea-ied crrntact area will greatly improve the thermal transfer that talies place

during soldering. _ .

Fork Style Dual Electrode Handpieces are similar in design to the largest

heav-v-dutv pliers-stvle

handpieces. These handpieces incLrrporate an entirely different type of adapter and electrode configuration

allowing for an increased level of versatilit-v. Because the electrodes are rods and the adapters can be

swiveled for more specific orientation of the electrode tips to the required surface area of the work many

applications may be performed nith an increased level ofefficiency and control.

Thermal Wirestripping Handpieces have been developed primarily for the purpose of thermally stripping

the insulation from wires to help minimize the hazard of nicking scoring or othenvise damaging the

conductors. These handpieces have closed loop elements which will begin to heat as soon as the power unit

is activated. The output ofthe ptser unit should be adjusted only high enough to allot the elements ofthe

handpiece to reach the temperarure required for melting through the insulation $ ithout buming it. The nvo

basic types ofthermal uirestripping handpieces that are cunently manufactured are the nveezer st-vle and

the V-notch style. The trveezer srlle handpieces are designed for stripping smaller gauge wires and the Vnotch style are designed for stripping the larger gauge wires.

Soller Reflow Tools

are similar in design to the V-notch stvle rvirestripping handpieces and although thel'

maybeusedforwirestrippingthe;-neredevelopedforawidevarietl

olotherapplicationswhichinclude

solder reflow, wax sculpting, lvood buming, trimming plastics. stained glass work and much more.

*ffip

Information & Instruction Manual for

Manufacturers of American Beauty@

QualitY Soldering Tools

American Beauty@ Resistance Soldering Equicment

5.3 Choosingthe Correct Power

L:nit

'

tbr an application the.final decision should be based not

when deciding on the correct po$er unit tcr bt used

for

applicaiion but also the temperatwe that is required

trrat

tor

chosen

naiu..n

ttat

onlv on the handpiece

brazing materials which

various

and

h*d..olders

ib,

is-especiatt',*.

*.a.1trtt

a

to flow and wet properly' You should aSvays consider

require signiticantll- greater f.u.ii oi tt."t rn trider

determined,to be required for the

hive

you

what

than

or,pu,

unuiinUi.

tign.,

u

has

no\\.er unir rhat

continuous

rnis rvitt give 1:uru assurance that the power unit will not require

increase the output

to

ability

the

have

you

that

insure

ivill

also

operation ar irs marimum *rpuir.n.i. ittis

the operators become more proficient with a soldering

oower level arld lower the reiuired clcle times as

is planning ahead and allowing tbr potential

;il'r;il;;;ii-u.

ilil:#

il;r.

iowth

#r=;;;;"J.

ffi#.';;;;i";';."il;;;.fil;.*'ia.'uiion

into larger applications a' the need mal anse'

5.4 Power Unit Recommendations

include infinitely variable-''selectively variable

The variety of power unit lpes thar are ;unentlyavailable

type ofpower unit listed,here is manufactured

specific

each

rhat

r.iil

irnd

i-.*

and multiple output models.

shown below are based upon

recommendations

All

;f.the

t.t.tr.

*tpur

in a va'iety of ma,ximum

appropriate equipment for

most

the

"trituUt.

determine

guide

to

as a basic

broad speculation *o rt outi o-nti: JG.o

your potential requirements'

Infinitely variable Power Lnits incorptrrate a solid

the

state voltage regulating device in order to allow

po$er

hnest level of adjustment to their output

:

This tr-pe of power unit is available tn eilher

rl05A3powerunitsarecapableofproducinguptol00wattsofporverandmaybeusedtosolder

materials and components that do not ex;eed

o

I

3" diameter'

watts of power and may be used to solder

I05Al2 power units are capable of prtducing up to 250

materials and components that do not excsed

I

-1" diameter'

power f nits incorptrare an ergtrr-i8) position tap switch along with an off center

Selectively variable

high'

unrr-erght Oiint.nt output selections at each of the

tapped transform.. r..onOury.-Ciiing th.'por..,

from.

choose

to

selections

furpur

medium and low levels of output po\ir or i-l specitic

ThLst,-peofpowerunitis.availaibineirherll00uanor:\'lrrnximumavailableoutputs'

l0582powerunitsare-capableofproducinguptollt.x-.\\attsofpowerandmaybeusedtosoldermaterials

diameter'

and components that do not exceed 1/2"

l05Clpowerunitsarecapableofproducinguptols0r-r$3nSr]fpowerandmaybeusedtosoldermaterials

and components that do not exceed a 1" diameter'

ilIultiple output Power Units incorporate

an

offcenter npped transformer secondaq to all!l\\

high, medium and low levels ofoutput power'

watt or

This type ofpower unil is available in either 1800

30(10

vdn

t-or either

available outpttts'

'l'L\nnnl

trfpolver and may be used to solder materials

rvatts

1800

to

up

ofproducing

105c2 power units are capable

recommendations.

tubing

Nall

thin

diameter

that do not or..o ttt. 3"

-J.-orripon.no

materials

up to 3000 $atts trf polver and may be used to solder

105D1 power units are capable of producing

recommendations.

rubing

wall

thin

"

Aiu*it.r

f

that do not exceeO

-J.o-,npon.n,,

t.

#

lv{anufacturers of Amer:cg: 3r

Quality Soldering T:.:

r

-.

60

Sy'stem Set-up

Instrudions

.

The first thing to do is fit the three prong 5-15 NEMA plug that is attached to the porver unit cord into rhe

receptacle portion of the piggy-back si1-le plug that is attached to the footswitch cord assembly and then t'ir

the plug portion of the footswitch into anl properl-v grounded 120 VAC outlet. with the power unit at the

lowest setting and tumed on, activate the footsrvitch. The light on the power unit should come on, indicating

that the power unit and footswitch are both functioning. When the footswitch is released the light should go

out as there is no longer anv current being supplied to the power unit. Attach the handpiece connections to

the appropriate taper pin receptacles or threaded posts that are located on the front or top ofthe power unit.

Single electrode style handpieces rill require the use ofan appropriate lead for current return to provide the

required closed circuit in order to achieve proper curent flow and generate heat.

The power units produce a sale low voltage,

altenartng (AC) cufient

so therc is no concern

lot polatil'-

Heavy-Duty handpieces that have been developed tbr the higher power ranges are manutacrur.d *l'i'i -: S"

ring terminals fbr a more perrnanent and mechanical connection to the threaded posts thar arc imFi.)ed L1n

the higher output pol\'er unis. This minimizes the electrical resistance that may exist at this itrn.n€Jritifl ud

helps eliminate the possibiliS ofthe handpiece connection loosening over time. Handpieces rhar nave been

developed for the lower po\\er ranges are manufachrred with specially designed taper pin rerrnlnations for

quick connection to the custom receptacles that are employed on the lower output pouer unirs. This gives

users the ability to quickly change back and tbnh between the variety of handpieces thar ma) be required

for a specific process. For connection you simpll push the taper pin into the receptacle tuming clockwise

until it is snug.

Converting your Taper Pin connectors to Ring Terminals:

When a process is developed involving the lorver output power units, uhich does nert require changing

handpieces the mechanical connection as mentioned above can be implemented. Thrs is done bl removing

the taper pins from the handpiece and anaching l14" ring terminals in their place. The handpiece can then

be attached to the pouer unit uith the use of3/-1" length l/4-20 brass bolts. because the receptacles are

alread) tapped to accept the 1 J-10 bolts.

7.0 Developing I'our Soldering Process

With the equipment pr.rperll selup as described above it is time to develop lour resistance soldering

process. Devellrptng the srlJenng prlrcess using resistance soldering equipment is quite simple and rvill be

ver) eas) to mliter. i'n.. \.'u rulh understand the basic principles ofelectriciq that are involved in the

development r.ircts.ten;rlrai lJtrs manual should answer the majoritl of lour questions and get.vou on

the right track.

All ofthe American Beaun r

resistance soldering power units have a specialll developed transformer that

converts your standard I l0-110 \'.{C input line voltage into a completell safe (lo$ voltage,rhigh amperage)

AC electrical cunent. When this sate. l!r$' voltage current gets passed through a resistive material an intense

amount of heat can be developed u ithin the immediate area of resistance. This immediate area of resistance

exists within the intended solderjoint area ofthe base materials located benveen rhe tips ofthe electrodes.

Resistive heat will be developed because of the resistance that an electrical current encounters when being

passed through the electrodes and the base metals. A closed circuit is required in order to maintain the path

for proper current flo* . The am.runt of heat produced is determined b;- the output current being supplied b-uthe power unit. It is imponanl tlr determine the output current that is required to produce the correct level of

heat for the process that is beine developed. Your primary goal should be lo establish the shortest dwell

time in which you can comtirnabl)' create good qualitv solder joints. In the beginning this must be

accomplished by trial and error. houever as you become more accustomed to the resistance soldering

equipment you rrill become bener able to predict the required du'ell times and the most efficient output

settings with a far greater level of accuracy and consistency.

Information & Instruction Manual for

American Beauty@ Resistance Soldering Equiprnent

ffip

Manufacturers of American Beauty@

Quality Soldering Tools

In the beginning stages ofyour nel\'process derelopment it is often very beneficial for

-vou to use dummy

components or scrap pieces of similar size and material to the ach-al components that you will be soldering.

This should help you to establish the most elficient porver unit output to be used without causing unwanted

damage to any expensive materials or compLrnents during the initial process development stages.

Whenever a soldering application involves joining togethei pieces ofvastly different sizes, or components

that mav be highl-"" sensitive to thermal damage. ]ou may want to consider pre-tinning the pieces separately

and then joining them together by re-flowing the solder and adding enough new solder to complete the joint.

7.1 Daermining Appropriote Power Levels

Establish a good contact with the base materials (close to the intended solderjoint area) and both electrodes

(or the single electrode and retum hamess clip) and activate the footswitch. Apply solder to thejoint area as

it is heating, then release the tbotssitch once the solder has properly flowed. Because there is no longer any

current being supplied to the handpie.'e. 1ou will be able to hold the components in place while allowing the

solderjoint to cool undisturbed until the solder has finished setting.

Upon completion of the first solder joint l ou should be able to evaluate the results that have been achieved.

Based upon this evaluation 1ou should be able to determine whetier there are any adjustments that might be

recommended or even required to improve the soldering process. You should be especially concemed about

the amount of dwell time thar is required in order to properly flow the solder. Remember that your goal is

to estalrlish the shortest dnell time

solder joint.

in which )'ou can comfortably and efficientlv create a quality

If the output of the power unit is set too high \Lru ian prlrduce dt'ell times so shon that lou will have little

or no measure ofcontrollability. Dtell times that nlie iess than one second are generalll:not recommended

without the use of a precision timer unit. Ilthe dlell time is too short and a precision timer unit is not going

to be used you should adjust the ouput olthe po\\er unit to a lower level (this will increase the dwell time

and improve the level ofprocess controllabilin r and rhen attempt the soldering process again.

Ifthe output ofthe power unit is set too los ltu .an Fr!)duce dwell times that are too long which increases

the time available for heat to travel a\\'a] tiom the st'iJer joint and into unwanted areas. Longer dwell times

increases the chances of causing damage to thermalll sensitive components or materials that are being used.

lfthe dwell time is longer than necessary'1ou should increase the output ofthe porver unit to a higher level

(this decreases dwell time and the possibilitv ofthermal damage) and attempt the soldering process again.

7.2 Maximum Operating PAiameterc

if

All ofthe resistance sotieting power units have a recomniended 50% duty-cycle. What this means is rhat

a power unit is being operated at levels above 50?ir oftheir r.rml available output power the dwell (heating)

and idle (cooling) time must be regulated in equal measure. It is important for the idle (cooling) time to be

equal to, or greater than the dwell (heating) time that is required for soldering. Ifit takes l0 seconds for the

solder to florv properly you must allow a minimum of l0 seconds of cooting time befbre proceeding to the

next solderjoint. You should also monitor the handpiece cables tbr excessive heat buildup during soldering.

If you find excessive heat building up in the cables 1ou shc.uld funher lengthen the required cooling time.

To prevent darnage to the equipment you must never operate pol\'er units for longer than 20 seconds on any

setting lvhile soldering. Ifyou have reached the marimum available output ofthe power unit and cannot get

the solder to flow within this amount of time you should malie sure there is no problem with the equipment

set-up and then verif good electrical contact between the elecrodes and the base materials or components.

Once you have verified the equipment set-up and the electrical contact the next area for consideration is the

power unit and handpiece configuration you have chosen for the application being attempted. The specific

application that you are trying to perform may require a higher output power unit and a dilTerent handpiece

to achieve the desired results. Although this segment does not apply to thermal rvirestripping applications,

the handpiece cables should still be monitored for excessive thermal buildup.

"-"tffifi

-.-l Improve Your Process l;l/ith

a

,""1f

: :'.,'..'.'

precision Timer Module

'{tier 1ou have properly set up.a.resistance soldering syster

have determined the correct operarlng

parameters to be used you should immediatell begin to notice the

improvements in qualit-v and consistencv.

once you have had an opportunitl' to e'aluate all olrhe benefits that are achieved

*iti, tf,e ur.

soldering systems you may decide to impro'e the repeatabillty and consistency

ori.oripio."r. further still.

The next level of improvement to \ our soldenne process is easily accomplisrt.a

ur: ti^prv rcorporatlng an

American BeautyD Model l05PT\l tlrecisron iimer rtoauley into the present

resisrance soldering system.

-a iu

;;;;j;;"

The Model l05PTM is a self conrained. drgrrai LCD. multi-function, precision

timing control device" that has

been specifically developed tbr use sith manr of rhe.{merican Beauty8 ..rir,""".

loia..,"_n systems and

power units that are currentlv available Thrs trmer module gives you ihe

ability to establish consistent and

repeatable dwell times that are accurate to s:thrn a hundredih ofa second.

fftis i111p-..J ,.neatabilur. :ei:s

eliminate the need for relying on an operators abrlrrr ro consistentlv respond to the

sold.r,"g;;;..r'.,r.. ,

being perlormed

-The

follorving set-up steps shos hos eas) :r is ro incorporate the timer module into your soije:-::::

>.,::e::

The precision timer module should be pluegec ,lrrecrlv into any standard

5-l5R NEMA I l0-i:.;.1-,-,..;

The footswitch plugs rnto the lorr voltage -i 5mm t'em;le jack on the lower front panel

of the rrme: :::o,ruie.

The American BeautyE resistance

poser units ilug into the 5-l5R NEMA re..piu.i.

,, .tro

-soldeiing

located on the lower front panel olthe

timer mo,lule. Thi l0-519 Footswitch with the pig!r:-ia.i snle plug

receptacle is not required because the prectsion timer module has its

own low voltage fol'tss lcn supplied.

.",

Carelully read all of the documentation included u'ith the timer module in

order to properll Jerermine the

appropriate function that should be used for 1-our specific resistance soldering

application ,.qu,r.-"ntr.

Each ofthe various functions that are available can be chosen by adjusting

tte ortpui rot. t.r.ctor to the

appropriate letter designator' The time range mode and time value are useJ to

determrne :he inten.al senine.

. This ltem is svailable in 220 ,'-lC upon requesl

High

Capaci$

Preckion

Timer

.llodule

l)lodel

|LSHCPTM)

is availablefor use virh C and D seiles power units.

'

' Alwals veilrt'ilre output mode ond the processing time selections are coieu before operaing

q'stem

).our sotdering

Sffis

Information & Instruction Manual for

American Beauty@ Resistance Soldering Equipment

Manufacturers of American Beauty@

Quality Soldering Tools

8.0 Troubleshooting Yow Equipment

Only authorized persons that have received training in tt. propi, servicin! ofelectrical equipment should

attempt to diagnose or malie repairs tJ an1 ol1'our American Beautyr'registance soldering equipment.

You rvill find that the most importail tool to have available when troubleshooting your risistance so.ldering

equipment will be a standard Ap v#-mrter or a multi-meter *rat has a setting forreadir:g the AC voltage.

.\'ever aftemDt to service yo,tf

anB

4'resista

the troubleshooting

stepilo follo\r nssuming that you have properly set up )-our soldering slsten

--,F'

t{ propQll pertbrm the soldering process before any problems have der.eloped.

Ifthe proper AC voltage ca4lnt be terified at each ofthe steps listed below, continue on with the next step

Th_ese are

and have already been able

1. Verifr that the proper.\c

'olrage

is being conducted into the handpiece's electrodes.

If proper AC voltage is available

at the eleCtrodes but no heat is being developed they may require cleanin5

where they make contact s'ith the'!ate metals. Contamination, dirt and bumt flux may encumber the curren

ilorv that is required from the crrnla!'t suriaces ofthe electrodes and through the base metals.

2. Veril],

that the proper AC voltage is being conducted to the electrode adapters.

Ifproper AC voltage is available rvithin the electrode adapters but unavailable from the electrodes be sure

that their contact surfaces have not become .onlaminated and that the electrodes have not become loosened

lvlalie sure that any set-scJ9ws tbat belong in rhe adapters are still in place and are properly tightened.

3. Verif,thattheproperACvolrageisbeingc.uducredtiomthepouerunit'soutputreceptacles.

tf proper AC voltage is aV$able at the power unit rrutput but is unavailable at the electrodes and adapters

be sure the handpiece is sgiurely connected to the poser unit and check the electrodes and adapters again.

If proper AC voltage is siill unavailable at the elecrrtrdes or the adapters the handpiece may ha-ve devilopec

a short in the cables, or ong ofthe wire conneclirrns mal have become loose. Ifyou are unable to determine

the source ofthe problent you may wish to rerum r..ur handpiece to the factory for an evaluation and repair

,

4. Verifothattheproporl20VAClinevoltageisarailablefromthereceptacleofthefootswitch'spig$.back plug assembly whgrl thq footsrvitch is beine depressed.

Ifproper line voltage is qvailable from the receptacle ..fthe footswitch's piggy-back plug assembly.but the

proper output is unavallaple from the porver unit. be sure that the power unit is tumed on and rhat the circuil

breaker has not been tripped. Ifthe circuit brealier has nlrr been tripped the problem may exist inside ofthe

power unit and you iiray wish to retum it to the facroq tbr an evaluition and repair.

5. Verifothattheproperl20VAClinevoltageisavailablefromthemainpowersupplyreceptaclethatthe

fbotswitch's piggy-back plug assembly was plugged inro.

If proper 120 VAC line voltage is available from the main porver receptacle but it is unar.ailable liom the

receptacle ofthe footswitch's piggy-back plug assembll )ou ma]'wish to retum vour tbots\ritch assembly

to the factory for an evaluation and repair.

You may find it easier to troubleshoot your resistance soldering system by following the verification steps

that are listed above in the reverse order (similar to the initial set-up procedures) tracing voltage fronr the

source until you reach the point where it becomes unavailable and then determining the exact cause.

You

willfrnd more Troubleshoofing information

available within the Support secfiott

ofour

Web-Site.

All American Beauty Resistance Soldering Systems are proudty manufactured in the U.S.A,, b1

Assembly Technologies rnternational, rnc. we are located at !177 w, Maple Road, ctawson Mi

48017' We can be found on the internet @ WWW.AMERICANBEAUTYTOOLS,COM or via telephone,

toll free at 800.550.2510,

Thank you for your business!

inaane

;

*EE

igfi

x;; isi atf,+ aic;rfg

IIaIiE

E EIE iiE EF Ei;

ae;iFE

5

35EE

1[q

lffi

iE

I;EEI

Eisi$srariF;iara;iiliEiEifr'i[Eiiii

: q

iEli

E =iE

l4 a8-fr

3

m

i

F

H

c)

ss :4 iiB

tH IEl ,EEilrtgl,11gfuaiigggfug1gi1ig1ilggE

2nl

s5

wc

rfl!

Ep

ie

ter

1n

7tF

]lt

a{

HH

az

ilo

2=

d

iel

d='iEil

;n

1

$

{i

Egi

eE is*a E

:**

[-* igi

tila

ro;F

F$''' EfE$3EiHil aI

+' ;e iE$

-iira

Ail $iE E$i

-*frEe

g1

Eg

ga ai

3ai i**

iiE

qs

a *e: $fli E;1 iig i; ii

$6

=s. $ i3

$ai

Fg

;i

I

si.3 ;? ;ii{ 5ad:5 sE tE

3

; a;g;.i* i;fi*;irir agegi

I

F

fi;gglggifl;aaiEfritaAE:

E'i;gE;ii+**iii+i1ii3

,e. K

,68

B e gt

B

;idq

;se

:il

,B

fd

qc Eej

inx

o-o

e;

=fl ;q

A

1

e

qtr iF

3 E

1g fr$ i

riA ;asgi

eFB$* iflnmE

en FEg

: ai

n6.

AFOc

Fc)

9{

mH

FO

2G

oT

ag

a

{

m

3

a

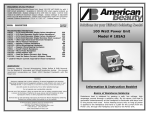

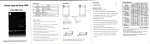

Description of your Product:

100 Watt Infinitely-Variable Power Unit. Input 110-t2A VAC 50/60 Hz, with 1

protection. Available in 220-240 VAC when special ordered as

model 105A3 22A. Output voltage is 0 to 2.65 VAC (no load). Control Knob

reads 0 to 100% of maximum output voltage. Output wattagg is adjustable

from 0 to 100 Watt maximum. Power Unit incdrporates Taper Pin connection

method. Product dimensions-3 3/4" x3 7/8" x 5". Product weight -2.5 lbs.

AMP clicuit

MODEL

DESCRIPTION

MAXIMUM

WATTAGE

Recommended Han d pi eces:

10515 - 3132 Inch Diameter Single Carbon Handpiecex

225

LO572 L/8Inch Diameter Single Carbon Handpiece*

25O

10573 - 3/ 16 Inch Diameter Single Carbon Handpiece*

325

10552 - 5/64 Inch Diameter Single Stainless Steel Handpiece* 1OO

10578 - Ultra-Light Fixed Dual-Electrode Handpiece

225

105133 - Micro-Tweezer Handpiece

30

10541 - Regular Tweezer Handpiece

2OO

105131 - Micro Wirestripping Handpiece

30

tOStT - Regular Wirestripping Handpiece

tOO

10591 - Small V-Notch Handpiece

lOO

105 I23 - Micro Probe Handpiece

SO

105L42 - Solder Reflow Tool

100

10512 - Lead for Return Current-Std. Clamp

25O

10512A - Lead for Return Current-Alligator Clamp

1oo

* Lead for Return Current required for these handpieces

Applications:

Soldering, Heating, Thermal Wirestripping, Solder Reflow & SM D Removal.

Can be adapted to automated and fixtured production tooling. We strongly

recommend incorporating our Model 10519 Standard Footswitch with this

Power Unit.

WARNINGS

Maximum wattage that is shown reflects a 20-second suggested cycle duration.

Operating handpiece beyond suggested wattage or cycle duration can result in heat

damage tO tOOl. A higherwattage may be used when incorporating a shorterdwell (heating) time

Use with caution

to avoid burns, fire or other potential damage

Do not operate near combustible materials

Normal use of this product is likely to expose the user to solders containing lead, which

is known to the State of California to cause cancer and birth defects (or other reproductive harm) or other proposition 65 listed Chemicals.

General Set-up and Operating Instructions for American Beauty Resistance Soldering

Systems are located inside this booklet or on our website.

All American Beauty Soldering Tools are manufactured by

Assembly Technologies International, Inc.

II77 West Maple Road . Clawson Michigan 48017-1059

(248) 280-2810 . (248) 2BO-2878

WWW.AM

E

RICAN BEAUTYTOO LS. CO M