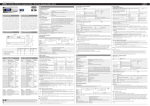

Download Gefran 600 PID controller: User Manual & Installation Guide

Transcript