Download Contact Information

Transcript

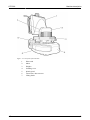

GB MANUAL HTC 500 Translation of manual in original language Contact Information HTC Sweden AB Box 69 SE-614 22 Söderköping - Sweden Tel: +46 (0) 121-294 00 Fax: +46 (0) 121-152 12 You can find addresses for our retailers and service partners on our website: www.htc-floorsystems.com Always specify the model and serial number when asking questions about your product. Trademarks HTC is a trademark owned by HTC Sweden AB. Other names and products mentioned in this manual may be registered trademarks owned by the relevant companies. © 2007 HTC Sweden AB. All rights reserved. EC Declaration of conformity Manufacturer: HTC Sweden AB Box 69 SE-614 22 Söderköping Sweden +46 (0)121-29400 Type of equipment: Grinding machine Make: HTC Model: HTC 500 Year of manufacture: See machine name plate Serial number: See machine name plate As the manufacturer, we hereby declare under our sole responsibility that the above product with serial numbers from 2004 onward conforms to the applicable regulations in directives MD 2006/42/EC, EMC 2004/108/EC and LVD 2006/95/EC. The following standards have been used as a basis: ISO 5349-1:2001, ISO 5349-2:2001, ISO 20643:2005, ISO 3741. This product was CE-marked in 1997. The technical documentation is available from the manufacturer. Original of the EC declaration of conformity (Swedish). Other languages are translations of the original of the EC declaration of conformity. Söderköping, 01-01-2010 Peter Lundgren Development Manager, HTC Sweden AB Kåre Kilgren Product Manager, HTC Sweden AB HTC 500 Table of contents 1 2 3 Introduction 1 1.1 General ............................................................................ 1.2 Responsibility .................................................................. 1.3 Manual ............................................................................. 1.3.1 Safety instructions – Explanation of symbols ..... 1.4 Transportation ................................................................. 1.5 On delivery ...................................................................... 1.6 Unpacking the machine ................................................... 1.7 Machine name plate ........................................................ 1.8 Handling and storage ...................................................... 1.9 Vibration and noise .......................................................... 1.9.1 Hand and arm vibrations .................................... 1.9.2 Sound pressure level .......................................... 1 1 1 1 2 2 2 3 3 3 4 4 Safety 5 2.1 General Information ......................................................... 2.2 Warnings ......................................................................... 2.3 Notes ............................................................................... 5 5 6 Machine description 8 3.1 General machine description ........................................... 8 3.2 Description of controls – Control panel ........................... 10 4 Usage 12 4.1 4.2 4.3 4.4 4.5 12 12 13 14 15 16 17 17 18 19 19 19 19 20 4.6 4.7 4.8 4.9 General Information ......................................................... Handle settings ................................................................ Handling weights ............................................................. Access to grinding tools .................................................. Fitting and replacing grinding tools .................................. 4.5.1 Fitting grinding tools ........................................... 4.5.2 Changing grinding tools ...................................... Preparations for dry grinding ........................................... Preparations for wet grinding .......................................... Operation ......................................................................... 4.8.1 Standby .............................................................. 4.8.2 Emergency stop switch ...................................... 4.8.3 Starting the machine .......................................... Making operation easier .................................................. i Table of contents 5 6 HTC 500 Maintenance and repairs 21 5.1 5.2 5.3 5.4 5.5 5.6 5.7 21 21 21 21 22 22 22 General Information ......................................................... Cleaning .......................................................................... Daily ................................................................................ Every week ...................................................................... Every month (or 100 hours) ............................................. Repairs ............................................................................ Spare parts ...................................................................... Faultfinding 23 6.1 General Information ......................................................... 6.1.1 The machine will not start ................................... 6.1.2 The machine vibrates or wears the tool unevenly ............................................................. 6.1.3 The machine is grinding at an angle .................. 6.1.4 The machine stops during operation .................. 6.1.5 The fuses trip frequently ..................................... 6.1.6 The machine cannot cope .................................. 23 23 Electronic error codes 25 7.1 General Information ......................................................... 7.2 Hitachi SJ200 .................................................................. 7.2.1 Resetting the frequency converter ..................... 7.2.2 Checking the last error code .............................. 7.3 Omron MX2 ..................................................................... 7.3.1 Resetting the frequency converter ..................... 7.3.2 Checking the last error code .............................. 25 25 26 26 26 27 27 8 Technical data 28 9 Environment 30 7 10 Warranty and CE marking 23 23 23 24 24 31 10.1 Warranty .......................................................................... 31 10.2 CE marking ...................................................................... 31 ii HTC 500 Introduction 1 Introduction 1.1 General HTC 500 is a grinder that can be used to grind, strip, clean and polish concrete, natural stone and terrazzo floors. The machine's area of application depends on the choice of tool. Read the manual carefully, so you are totally familiar with the machine before you start to use it. Contact your local retailer for further information. For contact information, see Contact Information at the start of the manual. 1.2 Responsibility Even though every effort has been made to make this manual as complete and accurate as possible, we bear no responsibility for incorrect or missing information. HTC reserves the right to change descriptions in this manual without giving prior notice. This manual is protected by the Copyright Act and no part of it may be copied or used in any other way without the written approval of HTC. 1.3 Manual In addition to the general functions, this manual deals with the areas of application and the maintenance of the grinder. 1.3.1 Safety instructions – Explanation of symbols A number of symbols are used in the manual to highlight the most important sections, see below. In order to avoid both personal injury and material damage as far as possible, it is extremely important to read and understand the text next to these symbols particularly carefully. There are other symbols indicating practical tips. These are to help you use the machine in the easiest and most effective way. The following symbols are used in the document to indicate where special attention is needed. Warning! This symbol means Warning! and indicates that incorrect use can result in material damage to the machine or accessories. If you see this symbol next to a section of text, you must be particularly careful when reading through the text and not carry out any stages of which you are unsure. This is to protect you and other users and to avoid damaging the machine or other equipment. 1.0 1 Introduction HTC 500 Note! This symbol means Note! and indicates that material damage can occur if the machine or its accessories are used incorrectly. If you see this symbol next to a section of text, you must be particularly careful when reading through the text and not carry out any stages of which you are unsure. This is to avoid damage to the machine or other equipment. Tip! This symbol means Tip! and indicates that you can get tips and advice on ways to make operating your machine or associated equipment easier, and to avoid wear. When you see this symbol you should read the accompanying text to facilitate your work and increase the service life of the machine. 1.4 Transportation The machine is best transported securely fastened to a pallet. 1.5 On delivery The following items are included in the delivery. Contact you retailer if anything is missing. 1.6 • Grinding machine • Manual • Locking key for control cabinet • Hammer EZ system • Splash guard Unpacking the machine Warning! Read through the safety instructions and the manual carefully before use. • • 2 Check carefully to see if the packaging or machine has been damaged during delivery. If there is any sign of damage, contact your retailer and report it. Report packaging damage to the transport company as well. Check that the delivery matches the order. If there are any discrepancies, contact your retailer. 1.0 HTC 500 1.7 Introduction Machine name plate The machine name plate provides the following information. The model and serial number must be specified when ordering spare parts for the machine. Figure 1-1. Machine name plate 1.8 1. Model 2. Model number 3. Serial number 4. Year of manufacture 5. Power (kW) 6. Voltage (V) 7. Current (A) 8. Frequency (Hz) 9. Rotational speed (r.p.m.) 10. Weight (kg) 11. Address field Handling and storage The machine should be stored in a dry, warm location when not in use. Otherwise it may become damaged by condensation and coldness. 1.9 Vibration and noise Warning! Always use ear muffs when using the machine. 1.0 3 Introduction 1.9.1 HTC 500 Hand and arm vibrations Hand and arm weighted vibration level [m/s²] for HTC 500 have been measured with equipment approved according to ISO 5349-1:2001. The measurement uncertainty for the measurement apparatus has been measured as +/- 2%. The machine has been tested in accordance with ISO 5349-2:2001 and ISO 20643:2005 in order to identify the operations that contribute to the most frequent vibration exposures. At vibration levels > 2.5 m/s², the exposure time should be limited in accordance with the table below. For vibration levels > 5 m/s², immediate measures should be taken by the employer to ensure that the exposure time does not exceed the time specified in the table below. Identified work conditions Measured values [m/s²] Daily permitted exposure (number of hours) 1.9.2 Grinding/polishing 2,76 unlimited Floor preparation (T-rex) 5,4 5,12 Sound pressure level This machine has been tested for noise in accordance with ISO 3741. For information on sound pressure levels, see the table in chapter Technical data, page 28. 4 1.0 HTC 500 Safety 2 Safety 2.1 General Information This chapter contains all the warnings and notes that should be considered for HTC 500 . 2.2 Warnings Warning! The machine may only be used or repaired by personnel who have received the requisite theoretical and practical training and who have read the user manual. Warning! Never use the machine in an environment with a risk of explosion or fire. Familiarise yourself with the fire-protection instructions for the working area and follow them. Warning! Secure the area around the working area. No unauthorised persons should be allowed within a 15-metre radius of the machine. If a loose object were to catch under the grinding head, this could be flung out and cause personal injury. Warning! Use protective equipment such as safety shoes, safety goggles, protective gloves, breathing mask and ear muffs. Warning! The machine must only be started with the grinding head down. The rotating disc must be touching the floor and the correct tool must be fitted. Warning! Read through the safety instructions and the manual carefully before use. Warning! Always use ear muffs when using the machine. Warning! During grinding, the tools become very hot. Tip the machine back and allow it to stand for a short while. Use protective gloves when removing the tools. Warning! Disconnect the electrical supply, when changing tools or repairing the machine. 1.0 5 Safety HTC 500 Warning! The machine must only be used and moved on level surfaces. There is a risk of crushing if the machine starts to roll. Warning! Connect the machine to an earth fault breaker. Warning! Do not clean the machine using a high-pressure washer. Otherwise moisture may penetrate electrical elements and damage the machine’s drive system. Warning! The machine may only be used when the splash guard is fitted. 2.3 Notes Note! The machine may only be used to grind and polish natural stone, terrazzo, concrete, or other materials stated in this manual or that are approved by HTC. Note! Only original tools and spare parts from HTC may be used for the machine. Otherwise neither the CE marking nor the warranty will be valid. Note! For the CE marking to be valid, the instructions in this manual must be followed. Note! The machine should be stored in a dry, warm (plus degrees) location when not in use. Note! If the machine is stored in a cold (minus degrees) location, it must be placed in a warm (plus degrees) location for at least two hours before use. Note! The appropriated dust extractor must be used when dry grinding. Contact HTC for model recommendation. 6 1.0 HTC 500 Safety Note! The dust extractor's suction hose must be connected to the appropriate socket on the machine. Adjust the dust extractor to match the grinder's capacity. Note! Do not use the emergency stop switch to stop the machine, except in emergencies. Note! As long as the emergency stop switch is pressed in, the machine cannot be started. Reset by turning the switch 45° clockwise so that it pops out again. The machine can then be restarted. Note! After removing glue and wet grinding, always lift up the grinding heads so that they do not stick to the floor and damage machine components and the floor when restarting. Note! When wet grinding, the water tank must be filled with water. Only use cold water with no chemical additives. 1.0 7 Machine description 3 Machine description 3.1 General machine description HTC 500 In relation to its size, the HTC 500 is a very efficient machine with a high capacity, which makes it suitable for use in both small and large spaces. It is used to grind, coarse grind, prepare and polish concrete, natural stone and terrazzo floors or other materials specified in this manual or material recommended by HTC. The machine is a perfect choice for removing coverings and for grinding concrete floors according to the HTC Superfloor method, which is an environmentally-friendly method for grinding and polishing concrete floors The machine is constructed from a number of main components, see Figure 3-1, page 9 and Figure 3-2, page 10. It can be combined with weights for adjusting the grinding pressure, which makes the machine perfect for those with high demands for flexibility. The handle can be set at several different angles, select a position that suits you best. The grinding cover has two connections for an external vacuum cleaner hose for use during dry grinding. The machine can easily be equipped with a large number of tools, depending on the material to be ground. For the different tools, see HTC’s Product Catalogue under the Grinding Guide tab. 8 1.0 HTC 500 Machine description Figure 3-1. The front of the machine 1.0 1. Water tank 2. Motor 3. Weights 4. Grinding cover 5. Splash guard 6. Connection, dust extractor 7. Lifting frame 9 Machine description HTC 500 Figure 3-2. The machine's rear 3.2 1. Control panel 2. Filter 3. Tap for wet grinding 4. Wheels 5. Electrical connection 6. Control cabinet 7. Handle lock 8. Handle Description of controls – Control panel The picture below shows the machine's control panel: 10 1.0 HTC 500 Machine description Figure 3-3. Control panel 1.0 1. EM-STOP - Emergency stop switch: Press the switch in an emergency to cut the power to the machine. 2. SPEED - Rotation speed: Regulates the rotational speed of the machine’s grinding discs. 3. ON/OFF - Start/stop the machine's functions: Turn the knob to "ON", to activate the machine's functions and to prepare for starting. Turn the knob to "OFF", to switch off the machine's functions. 4. REW/FWD - Start/stop the grinding discs' rotation and direction of rotation. Turn the knob to "0", to stop the rotation. 5. RESET - Resetting the electronics: If the machine experiences an error, it can be reset by pressing and holding the button in for two seconds. Any error code is shown on the frequency converter's display inside the electrical cabinet, see Figure 3-2, page 10. For error codes, see Electronic error codes, page 25. 6. DUTY - Standby indicator: Indicates that the machine's functions have been activated. Lights when the ON/OFF knob is turned to "ON". 11 Usage HTC 500 4 Usage 4.1 General Information The following section describes how to change tools and how to operate the grinding machine. This section does not deal with the technical aspects of grinding, such as selection of grinding tools, etc. For choice of tools, see HTC’s Product Catalogue under the Grinding Guide tab. Warning! The machine may only be used or repaired by personnel who have received the requisite theoretical and practical training and who have read the user manual. Warning! Never use the machine in an environment with a risk of explosion or fire. Familiarise yourself with the fire-protection instructions for the working area and follow them. Warning! Secure the area around the working area. No unauthorised persons should be allowed within a 15-metre radius of the machine. If a loose object were to catch under the grinding head, this could be flung out and cause personal injury. Warning! Use protective equipment such as safety shoes, safety goggles, protective gloves, breathing mask and ear muffs. Warning! The machine must only be started with the grinding head down. The rotating disc must be touching the floor and the correct tool must be fitted. Warning! The machine must only be used and moved on level surfaces. There is a risk of crushing if the machine starts to roll. Tip! Check the minimum recommended cable area before using an extension cord. You will find the recommended cable area under Technical data, page 28. 4.2 Handle settings The appropriate working height is set with the help of the adjustable handle. Release the handle, by pulling the locking pin on the handle lock, see Figure 3-2, page 10. 12 1.0 HTC 500 Usage Adjust the handle to the desired position and secure it, by inserting the locking pin again. Figure 4-1. Handle settings 1. The forward position - used, for instance, for transportation, as the machine takes up significantly less space. 2. Rear position - used for tipping the machine to make tool replacement easier. 3. Working position - the working height can be adjusted to two positions using the machine’s adjustable handle. 4.3 Handling weights The machine can be equipped with three weights to make it easy to change the machine's grinding pressure, seeFigure 4-2, page 14. When all three weights are mounted, they provide additional grinding pressure that increases the grinding effect. When using a tool with a high removal rate, such as T-Rex™, we recommend a low grinding pressure. Note! Too high a grinding pressure combined with an incorrect grinding tool may cause damage to both the machine and the floor. 1.0 13 Usage HTC 500 Note! Always dismantle the weights when you change tools, to make tipping the machine easier. Warning! There is a risk of crush injuries when handling the weights, as these are heavy. Therefore, the weights should always be handled with great care. Figure 4-2. Handling weights 4.4 Access to grinding tools Warning! Always remove the weights before changing tools, to prevent the machine from tipping back. Warning! The tool becomes very hot during use. Tip the machine back and allow it to stand for a short while. Use protective gloves when removing the tools. Warning! Disconnect the electrical supply, when changing tools or repairing the machine. 14 1.0 HTC 500 Usage 1. Set the handle to the rear position - see Figure 4-1, page 13 2. Removing the weights. 3. Tip the machine backwards carefully so that it rests on the floor. 4.5 Fitting and replacing grinding tools Warning! Disconnect the electrical supply, when changing tools or repairing the machine. Warning! The tool becomes very hot during use. Tip the machine back and allow it to stand for a short while. Use protective gloves when removing the tools. As the machine is equipped with the patented EZchange tool system, fitting and replacing grinding tools is quick and easy. The tool system consists of wings on which diamond grinding tools are fitted without the need for screws. 1.0 15 Usage 4.5.1 HTC 500 Fitting grinding tools 1. Slide the grinding tool diagonally, from above, down into the appropriate guide slot on the tool holder, see Figure 4-3, page 16. Then push the tool fully into the guide slot. Figure 4-3. Fitting grinding tools 2. Lock the grinding tool into the tool holder by giving it a few light taps with a rubber hammer - see Figure 4-4, page 16. Figure 4-4. Locking grinding tools 16 1.0 HTC 500 4.5.2 Usage Changing grinding tools 1. Remove the grinding tool by giving it a few light taps with a rubber hammer so the locking mechanism releases, see Figure 4-5, page 17. Then draw the tool up out of the guide slot. Figure 4-5. Removing grinding tools 2. Slide the grinding tool diagonally, from above, down into the appropriate guide slot on the tool holder, see Figure 4-3, page 16. Then push the tool fully into the guide slot. 3. Lock the grinding tool into the tool holder by giving it a few light taps with a rubber hammer - see Figure 4-4, page 16. 4.6 Preparations for dry grinding Warning! Check that the splash guard is fitted. 1.0 17 Usage HTC 500 1. Connect a dust extractor to the machine. For dust extractor models, see under the Suction System tab in the HTC Product Catalogue. Note! The dust extractor's suction hose must be connected to the appropriate socket on the machine. Adjust the dust extractor to match the grinder's capacity. 2. Inspect the floor carefully and remove any objects sticking up, such as reinforcement rods or bolts, and any debris that could get caught in the machine. 3. Attach the appropriate tool to the machine, see under Fitting grinding tools, page 16 4. Set the handle to the working position, see Figure 4-1, page 13. 4.7 Preparations for wet grinding Warning! Check that the splash guard is fitted. 1. Always use liquid suction when wet grinding. Tip! Never use a dust extractor, as blockages may develop in the dust extractor's suction hose and filter. 2. Inspect the floor carefully and remove any objects sticking up, such as reinforcement rods or bolts, and any debris that could get caught in the machine. 3. Attach the appropriate tool to the machine. 4. Set the handle to the working position, see Figure 4-1, page 13. Warning! Only use cold water with no chemical additives. 5. Fill the tank with cold water. 6. Turn the tap on the left side of the machine to the open position. 7. Turn the tap to the closed position once wet grinding is finished. 18 1.0 HTC 500 4.8 Usage Operation The machine's functions can be controlled using the control panel - see Figure 3-3, page 11. During operation, the operator pushes the grinder forwards over the floor surface. 4.8.1 Standby To activate the machine's functions, turn the ON/OFF knob to the right. When the knob is in this position, the green Standby light (DUTY) is lit, indicating that the machine is in standby mode. 4.8.2 Emergency stop switch The emergency stop switch, (EM-Stop) must only be used in an emergency. When the switch is pressed, all electrically-powered equipment on the machine are turned off. Note! Do not use the emergency stop switch to stop the machine other than in emergencies, as it decreases the lifespan of the machine's electrical components. Note! As long as the emergency stop switch (EM-Stop) is pressed, the machine cannot be started. Reset by turning the switch 45° so that it pops out again. The machine can then be restarted. 4.8.3 Starting the machine For a description of the control panel, see Figure 3-3, page 11. 1. Make sure the emergency stop switch is not activated. 2. Insert the cable. 3. Start the dust separator if dry grinding is to be done. 4. Turn the ON/OFF knob to the right. 5. Start the grinding discs rotation, by turning the REW/FWD knob to the desired direction of rotation. 1.0 19 Usage HTC 500 6. Set the speed for the grinding discs using the Speed knob. 7. The machine has now started. 4.9 Making operation easier In order to keep the suction hose for the dust extractor and the power cable out of the working area and/or path of the machine, the hose and cable can be arranged as shown in the picture below. Figure 4-6. Making operation easier Tip! By arranging the hose and cable as shown in the picture, you avoid disruptive stoppages caused by having to re-position the cable and hose. 20 1.0 HTC 500 Maintenance and repairs 5 Maintenance and repairs 5.1 General Information We recommend regular inspections of all seals. Warning! Disconnect the electrical supply, when changing tools or repairing the machine. Warning! Use protective equipment such as safety shoes, safety goggles, protective gloves, breathing mask and ear muffs. 5.2 Cleaning Warning! Do not clean the machine using a high-pressure washer. Otherwise moisture may penetrate electrical elements and damage the machine’s drive system. 5.3 • Vacuum the electrical cabinet, if required. • Always clean the machine after use with a damp sponge or cloth. Daily • Wash the machine if it is used for wet grinding. • Check for wear to the grinding tool – abnormal or uneven wear may indicate a damaged grinding holder. Check the tool holder and grinding holder to ensure that no damage or cracks have arisen. Replace the parts if there is any damage. • 5.4 Every week • Wash the machine. • Check the grinding holders. Remove the tools and run the machine in mid air at the slowest speed. If the grinding holders oscillate or wobble significantly, they are damaged. Check that the upper belt is whole, by turning the large disc in one direction or the other. If there is resistance the belt is whole, if the disc rotates freely the belt is broken. • 1.0 21 Maintenance and repairs HTC 500 Tip! Recondition all the grinding holders at the same time. 5.5 5.6 Every month (or 100 hours) • Tighten anything that may have vibrated loose. • Remove the grinding cover and check that it is undamaged. • Check the upper belt and replace if necessary. • • Check the seals on the shafts on which the upper belt runs and replace if necessary. Scrape and vacuum-clean the parts shielded by the grinding cover. • Test run and listen for any dissonance from the bearings. • Clean or, if necessary, replace the filter to the electrical cabinet. Repairs Any repairs that may be required must be carried out by a HTC Service Centre, which has trained service personnel and uses HTC original parts and accessories. Contact your retailer if your machine requires servicing. For contact information, see Contact Information at the start of the manual. 5.7 Spare parts To ensure rapid delivery of spare parts, always specify the model, the machine's serial number and the spare part number when ordering. Information on the model and serial number can be found on the machine's name plate. Information on spare part numbers can be found in the machine's spare parts list which is available to read or print out from the accompanying digital media or HTC's website: www.htc-floorsystems.com Only original tools and original spare parts from HTC may be used. Otherwise neither the CE marking nor the warranty will be valid. 22 1.0 HTC 500 Faultfinding 6 Faultfinding 6.1 General Information This chapter describes some of the faults that may occur and how to deal with these faults. If the fault cannot be dealt with, or if there are other faults, contact your nearest retailer. See Contact Information at the front of the manual. 6.1.1 The machine will not start • • • • 6.1.2 • • • Check the condition of the grinding holders. If the grinder holders need reconditioning, contact HTC for information about spare parts. Recondition the grinding holder. See under The machine vibrates or wears the tool unevenly, page 23. Check that the upper belt is undamaged. Try to turn the large disc in one direction or the other, there should be resistance. If it turns freely, the belt is broken and must be replaced. The machine stops during operation • 1.0 Check that there is movement between the chassis and grinding head. If necessary, loosen one of the two pins in order to increase the play between the chassis and the grinding head. Check the belts, replace if necessary. The machine is grinding at an angle • 6.1.4 Check the error code on the frequency converter's display. For corrective measures, see Electronic error codes, page 25. The machine vibrates or wears the tool unevenly • 6.1.3 Check if the emergency stop switch on the control panel is pressed. Reset the switch by turning it 45°. Check if the power connection is correct. Check that there is full voltage available on the supply's phase/phases. Check the fuses and contactors in the electrical cabinet. Check the error code in the display on the frequency converter, see Electronic error codes, page 25. 23 Faultfinding 6.1.5 The fuses trip frequently • • 6.1.6 HTC 500 The load is too high on the distribution box to which the machine is connected. Use a different socket or reduce the speed of the machine. Check the tools. Ensure that the correct tools are used, that they are in working order and that they are correctly fitted. The machine cannot cope • • • • Heavy load. Press the handle down slightly so that the grinding head eases slightly away from the surface being ground. Sticky coating on the surface being ground. Run half of the machine on the surface to be cleaned and half on the clean surface. This removes any residue from the tools. Check the tools. Ensure that the correct tools are used, that they are in working order and that they are correctly fitted. Voltage drop. Check that the cable area meets HTC’s recommendations. Tip! Check the minimum recommended cable area before using an extension cord. You will find the recommended cable area under Technical data, page 28. 24 1.0 HTC 500 Electronic error codes 7 Electronic error codes 7.1 General Information In the event of an error, the error code is shown in the display. The most common error codes that may occur on the frequency converter, in the control cabinet, are listed below. In the event of other errors, contact the HTC Service Centre. 7.2 Hitachi SJ200 Error code Cause Action E01 Excess current at constant speed The machine is running too fast or with too great a load. Lower the speed, lower the load by changing the position of the weights and check your tools. Check mechanical inertia, spin the grinding discs. E02 Excess current during deceleration. See E01 E03 Excess current during acceleration. See E01 E04 Excess current under other conditions. See E01 E05 Overload. See E01 E08 Internal EEPROM error due to Open the electrical cabinet and allow to cool. Check the filter overheating or interference and the cooling fans in the cabinet. Let the frequency converter cool down before restarting. E09 Under-voltage. The connection cable is too long, poor connection or too many consumers connected to the mains. Change socket, use shorter cables and lower the speed. E10 Internal current supply error Contact HTC Service Centre. E11 Internal processor fault Reset the electronics using the Reset procedure. E13 Anti-restart switch tripped Check the operation when starting the machine, see Operation, page 19. E14 Earth fault Check the motor's cables and connections. E15 Excess voltage Mains voltage too high or disturbance in the mains supply. Check the supply voltage, change socket. E21 Excess temperature See E08. E22 Internal processor error Contact HTC Service Centre. E30 Internal communications error Contact HTC Service Centre. 1.0 25 Electronic error codes 7.2.1 Resetting the frequency converter • 7.2.2 HTC 500 Press and hold the "RESET" button in for two seconds. Checking the last error code 1. Press FUNC, D01 is shown in the display. 2. Press "arrow up", until D08 is shown in the display. 3. Press FUNC, the error code is shown in the display. 4. Press FUNC again, the current frequency is shown in the display. 5. Press FUNC once again, the motor voltage is shown in the display. 6. Press FUNC once again, the voltage of the DC bus is shown in the display. • 7.3 Press "arrow up", until D09 is shown in the display, in order to see the previous error codes. Omron MX2 Error code Cause Action E01 Excess current at constant speed The machine is running too fast or with too great a load. Lower the speed, lower the load by changing the position of the weights and check your tools. Check mechanical inertia, spin the grinding discs. E02 Excess current during deceleration See E01 E03 Excess current during acceleration See E01 E04 Excess current under other conditions See E01 E05 Overload See E01 E08 Internal EEPROM error due to Open the electrical cabinet and allow to cool. Check the filter overheating or interference and the cooling fans in the cabinet. Let the frequency converter cool down before restarting. E09 Under-voltage The connection cable is too long, poor connection or too many consumers connected to the mains. Change socket, use shorter cables and lower the speed. E10 Internal current supply error Contact HTC Service Centre. E11 Internal processor fault Reset the electronics using the Reset procedure. 26 1.0 HTC 500 Electronic error codes Error code Cause Action E13 Anti-restart switch tripped Check the operation when starting the machine, see Operation, page 19. E14 Earth fault Check the motor's cables and connections. E15 Excess voltage Mains voltage too high or disturbance in the mains supply. Check the supply voltage, change socket. E21 Excess temperature See E08. E22 Internal processor error Contact HTC Service Centre. E30 Internal communications error Contact HTC Service Centre. 7.3.1 Resetting the frequency converter • 7.3.2 Press and hold the "RESET" button in for two seconds. Checking the last error code 1. Press the "Set key" button, D001 is shown in the display. 2. Press the "arrow up" button, until D081 is shown in the display. 3. Press the "Set key" button, the error code is shown in the display. 4. Press the "arrow up" button, the frequency at the time of the error is shown in the display. 5. Press the "arrow up" button, the motor current during the error is shown in the display. 6. Press the "arrow up" button, the voltage of the DC bus during the error is shown in the display. 7. Press the "arrow up" button, the operating time accumulated up to the time of the error is shown in the display. 8. Press the "arrow up" button, the time accumulated with the voltage connected up to the time of the error is shown in the display. Figure 7-1. "Set key" button For the "Set key" button, see Figure 7-1, page 27. 1.0 27 Technical data 8 HTC 500 Technical data The table below shows the machine’s technical data. HTC 500 EU HTC 500 US HTC 500 US Motor 4.0 kW 4.0 kW 4.0 kW Current 10 A 16 A 22 A Tension 3 x 380-415 V 3 x 200-240 V 2 x 115 V Total machine weight 180 kg 180 kg 180 kg Chassis weight 78 kg 78 kg 78 kg Weight, grinding head 102 kg 102 kg 102 kg Weights 3 x 9.5 kg 3 x 9.5 kg 3 x 9.5 kg Grinding diameter 530 mm 530 mm 530 mm Grinding pressure, with weights 95-105-115-125 kg 95-105-115-125 kg 95-105-115-125 kg RPM 289 - 1301 r.p.m 289 - 1301 r.p.m 289 - 1301 r.p.m Water tank 17 litres 17 litres 17 litres Grinding discs 3 x 230 mm 3 x 230 mm 3 x 230 mm Recommended minimum cable area 2.5 mm² 2.5 mm² 6 mm² Sound pressure level, average value over 94 dBA time according to ISO 3741, measurement uncertainty according to class 1 measuring instruments for sound level meters. 94 dBA 94 dBA HTC 500 JP HTC 500 NO HTC 500 MS Motor 4.0 kW 4.0 kW 4.0 kW Current 16 A 16 A 9A Tension 3 x 200 V 3 x 200-240 V 3 x 380-415 V Total machine weight 180 kg 180 kg 184 kg Chassis weight 78 kg 78 kg 82 kg Weight, grinding head 102 kg 102 kg 102 kg Weights 3 x 9.5 kg 3 x 9.5 kg 3 x 9.5 kg Grinding diameter 530 mm 530 mm 530 mm Grinding pressure, with weights 95-105-115-125 kg 95-105-115-125 kg 100-110-120-130 kg RPM 289 - 1301 r.p.m 289 - 1301 r.p.m 723 r.p.m Water tank 17 litres 17 litres 17 litres Grinding discs 3 x 230 mm 3 x 230 mm 3 x 230 mm Recommended minimum cable area 2.5 mm² 2.5 mm² 2.5 mm² 28 1.0 HTC 500 Technical data HTC 500 JP Sound pressure level, average value over 94 dBA time according to ISO 3741, measurement uncertainty according to class 1 measuring instruments for sound level meters. HTC 500 NO HTC 500 MS 94 dBA 94 dBA Figure 8-1. Height and length of the machine in millimetres Figure 8-2. Width of the machine in millimetres 1.0 29 Environment 9 HTC 500 Environment HTC's products are constructed mainly of recyclable metal and plastic. The main materials used are listed below. Chassis Frame Electro-galvanised steel Handle Plastic covered steel Wheels Polyurethane-filled rubber wheels Cover ABS plastic Motor Aluminium Grinding head Lower cover Aluminium Cover ABS plastic External plate and steel components Electro-galvanised steel Other components Steel Electrical system Control cabinet Stainless steel Cables Copper conductors with PVC covering Plastic components can be recycled by sorting as hard plastics. Electronics can be deposited as electronic waste. The machine or machine components can also be returned to HTC Sweden AB. For recycling and scrapping of components, see the applicable national regulations for each country. 30 1.0 HTC 500 Warranty and CE marking 10 Warranty and CE marking 10.1 Warranty This warranty only covers manufacturing defects. HTC bears no responsibility for damage that arises or occurs during transportation, unpacking or use. In no instance and under no circumstances shall the manufacturer be held responsible for damage and defects caused by incorrect use, corrosion or use outside the prescribed specifications. The manufacturer is not responsible for indirect damage or costs under any circumstances. For complete information on the manufacturer's warranty period, see HTC's current warranty terms. Local distributors may have special warranty terms specified in their terms of sale, delivery and warranty. If there is any uncertainty regarding warranty terms, please contact your retailer. 10.2 CE marking CE marking of a product guarantees its free movement within the EU area in accordance with EU regulations. CE marking also guarantees that the product fulfils various directives (the EMC Directive and other possible requirements in so-called directives for new procedures in accordance with these regulations). This machine carries the CE mark in accordance with the Low Voltage Directive (LVD), the Machinery Directive and the EMC Directive. The EMC Directive states that electrical equipment must not disturb its surroundings with electromagnetic radiation and that it must also be immune to electromagnetic interference in the surroundings. This machine is classified for use in environments such as heavy industry, light industry and homes. See the Manufacturer’s Declaration of Conformity, which shows that the machine is harmonised with the EMC Directive. 1.0 31