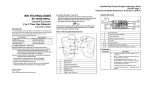

Download MicroDock II

Transcript