Download dpl plc controlling system - DPL

Transcript

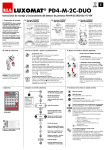

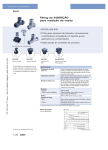

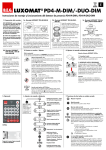

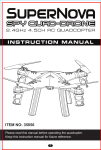

PLC Control System DPL 10188/ 10189 Instruction Manual. Danish Process Light PLC Control System DPL: 10188/10189: DPL Industri A/S introduces a new UV Controlsystem based on PLC technique. This new control system have full control over the UV lamp, Ballast, Chiller and the light sources. DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 1 PLC Control System DPL 10188/ 10189 Instruction Manual. 1. Installation The PLC control system DPL 10188/10189 is a part of the DPL “plug & play” UV system. The UV system is very user friendly to install and use. Control cable: Connect all the control cables to the PLC with the standard “SUB D cables” by following the Sign on the PLC box, and connect the cable to the chiller, ballast and UV lamp. Power Cable: Connect the ballast and PLC main power cables to the power section of the printing machine. Important! The main power to the chiller had always to be connected to main power in order to protect the reflectors. (Cool down). Remote Cable: The simple version of remote control, is just a switch to start the curing activation.( Switch application mode). The switch and cable is standard accessories. 2. Start up the UV system: The basic set-up is made by DPL, in order to protect the UV-lamp system. The set-up is blocked by a pass-word only for distributors and factory set-up. 3. Input Select: Input select is set up by DPL for your application, but it is possible to change to other input type. By Input select means different possibility to control the UV curing power. Tacho Input: The tacho generator on the printing machine, regulate the curing power. ( Speed power control ) Switch Application 0-10V The curing will be started by a switch, and the curing power will be regulated by 0-10 V Dc on the remote Input/output. Switch application The curing will be started by a switch, and the curing power will be set manually on the screen. Clock input: The PLC will be in Slave mode. Only together with a Master with tacho input. DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 2 PLC Control System DPL 10188/ 10189 Instruction Manual. 4. Light Source select: The PLC control system monitors the light sources lifetime, by effective control of start/stop sequence and burning-hours Light source select is necessary, because there is different Lifetime for different Types. Mercury Lamp: By select this Lamp, the lifetime counter will be preset to 2000 hours. This is the typical lifetime for a mercury lamp. Ion-Doped Lamp: By select this lamp, the lifetime counter will be preset to 1000 hours. This is a typical lifetime for a Iondoped lamp. Galium- Doped Lamp: By select this lamp, the lifetime counter will be preset to 1200 hours. This is the typical lifetime for a Galium-doped lamp 5. Counter Reset: By replacing the UV-Lamp, it is very important to reset ( preset) the lifetime counter. In some application, with low UV Power, the lifetime can be more than the typical value. Reset (preset) the counter again, and use the next periode before replacing the UV-Lamp. Lifetime of the lamp, will be 1 hours shorter by start/stop of the Lamp. Therefore keep the lamp in Stand-by, and only stop the lamp by longer machine-stop. DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 3 PLC Control System DPL 10188/ 10189 Instruction Manual. 6. Manual Start UV Lamp: With Manual/Remote setting in: Manual Position. Press “Lamp Power” On The PLC controller start the chiller. ( can take up to 30 second ) When the water flow is ok, “UV-Lamp On” will indicate that UV Lamp is started. The UV Lamp power meter indicate the stand-by level 20% The UV Lamp heath-up after 30 sec. and wait for indication of “UV lamp ready for Curing” The UV System is ready for Curing. 7. Remote Start of UV Lamp: With Manual/Remote setting in: Remote Position. Activate “Start UV lamp” on remote connector JP40 pin 1. active low The PLC controler start the chiller. ( can take up to 30 second ) When the water flow is ok, “UV-Lamp On” will indicate that UV Lamp is started. The UV Lamp power meter indicate the Stand-by level 20% The UV Lamp heath-up after 30 sec. and wait for indication of “UV lamp ready for Curing” The UV System is ready for Curing. DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 4 PLC Control System DPL 10188/ 10189 Instruction Manual. 8. Curing activation: The curing activation is only possible by the remote connector JP40 Pin 9 active low or by a switch between Pin 9 and GND Pin 8. By using tacho or clock input, the curing activation is generated by the tacho speed. By Curing activation: The UV lamp shutter will open, and the indicator be active. The default UV-Lamp curing power, will be applied to the UV-Lamp The UV Lamp power can be set from 0-100% power by press on button down/Up. By activating the switch, the Power meter is moving from Stand-by 20%, to 100% if the curing power is regulated to 100%, with the up/down button. Printing Machine C ontrol PLC ( Remote ) 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 Start UV Lamp Output signal Activ e Low Start Curing Output signal Activ e Low Optional 0-10V Analog output PWM Regulation Output 1-5 kHz Ready f or curing Input signal Activ e High Common Failure Input signal Activ e High Water Flow Failure Input signal Activ e high. UV Lamp Temp Failure input signal Activ e High Shutter Failure input signal Activ e high Light Source exchange input signal Activ e High Ballast Failure input signal Activ e High Sy stem Failure Input signal, Activ e higk UV Lamp Failure signal input Activ e High Analog GND Digital GND Start UV Lamp SW2 SW1 Start C uring Activating DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 5 PLC Control System DPL 10188/ 10189 Instruction Manual. Remote Control Connection: Printing Machine Controller with Isolated Input/Output + 0-10V Curing regulation. Output R 1 5 2 Input Active Low to DPL PLC controller Max sink curent 4-7mA. 2 Optocoplers Start UV Lamp Output signal Activ e Low Start Curing Output signal Activ e Low Optional 0-10V Analog output Optional PWM Regulation Output 1-5 kHz Ready f or curing Input signal Activ e High Common Failure Input signal Activ e High Water Flow Failure Input signal Activ e high. UV Lamp Temp Failure input signal Activ e High Shutter Failure input signal Activ e high Light Source exchange input signal Activ e High Ballast Failure input signal Activ e High Sy stem Failure Input signal, Activ e higk UV Lamp Failure signal input Activ e High Analog GND Digital GND GND Input 5 R 1 8 Output Activ High from DPL PLC controller Max. 20mA Led curent. 8 Optocopler 4 ISO1 OPTO ISOLATOR2 2 Standard 1 5 P ins Sub D C able to D P L P L C c ontroller 1 0 1 8 8 /1 0 1 8 9 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 2 4 ISO2 OPTO ISOLATOR2 GND 0-10V DC C uring regulation output V Analog GND 10V DC Remote Control description: PIN Type 1 Active Low Input 24V/0V 2 Linear Input 0-10V DC 3 4 5 6 7 8 9 10 11 12 13 14 15 Active High Output 0V/24V Active High Output 0V/24V Active High Output 0V/24V Active High Output 0V/24V Active High Output 0V/24V Digital Ground Active low Input 24V/0V PWM Input 0-24V 1-5kHz Function Start UV Lamp Input 0-10 V Power Regulation Input Ready for Curing Output Water Failure Output Shutter Failure Output Lamp Driver failure Output UV Lamp Failure Output Digital Gnd Start Curing Input PWM Regulation Input Note 5,0 mA Sink Machine Input/ Output Open Collector Output 0-10V DC Output 6,0mA Source 6,0mA Source 6,0mA Source 6,0mA Source 6,0mA Source Opto-koppler input with Resistor Opto-koppler input with Resistor Opto-koppler input with Resistor Opto-koppler input with Resistor Opto-koppler input with Resistor Direct connected Digital GND Open Collector Output Open Collector Output 5,0 mA Sink 7,0 mA Source Active High Output 0V/24V Common Failure Output 6,0mA Source Active High Output 0V/24V UV Lamp Temp Failure 6,0mA Source Active High Output 0V/24V Light Source Exchange Output 6,0mA Source Active High Output 0V/24V System Failure Output 6,0mA Source Analog Ground (0-10V input Analog Gnd ) DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Opto-koppler input with Resistor Opto-koppler input with Resistor Opto-koppler input with Resistor Opto-koppler input with Resistor Direct Connected Analog GND Instruction manual 10188 1a Side 6 PLC Control System DPL 10188/ 10189 Instruction Manual. 9. UV System Errors: All UV system failure will be displayed in the Control and Status information display. All failure will stop the UV-lamp, and the failure be displayed. By UV System Failure: UV lamp Power ON/OFF will return to OFF. UV Lamp On indication dissapears UV Lamp system Failure: indication for failure 10. Help Function: Press Help to get a failure hint. 11. Start again after UV system failure The PLC controller latch all fail information. To reset the failure press “UV Lamp OFF”. The UV System is ready to start again. If the failure come back, try to solve the problem Or contact DPL Industri A/S for Help. 12. PLC Connection Diagram: DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 7 PLC Control System DPL 10188/ 10189 Instruction Manual. Tacho Encoder ( Printing Speed ) Hengstler Encoder RI 58 0 1 6 2 7 3 8 4 9 5 +24V DC Supply Output A OC Tacho Encoder Input Cable Output B OC Digital Ground Printing Machine Control PLC ( Remote ) 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 Printing Machine Control Cable ( Remote ), 15 Pin Standard SUB D 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 Start UV Lamp Output signal Active High Start Curing Output signal Active High Optional 0-10V Analog output PWM Regulation Output 1-5 kHz Ready for curing Input signal Active High Common Failure Input signal Active High Water Flow Failure Input signal Active high. UV Lamp Temp Failure input signal Active High Shutter Failure input signal Active high Light Source exchange input signal Active High Ballast Failure input signal Active High System Failure Input signal, Active higk UV Lamp Failure signal input Active High Analog GND Digital GND Ballast Nedap 3 kW JS31 JP31 1 2 3 4 5 6 7 8 3kW Ballast Cable + Screen 1 14 2 15 3 16 4 17 5 18 6 19 7 20 8 21 9 22 10 23 11 24 12 25 13 1 2 3 4 5 6 7 8 PWM Input 1-5 kHz Lamp Driver failure OC Active High Remote ON/OFF High= ON System Failure Output OC Active High Lamp ON-Ready Output OC Active low Lamp Failure Output OC Active High Output power supply 14V Common Return See 3 kW Electronic Lamp Driver Manual 6kW Ballast Cable + Screen JS61 UV Lamp Control Cable, 15 Pin SUB D JS4 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 White Black S1 SW SPDT 1 2 3 4 5 6 7 8 9 10 Ballast Connector JP 36 Nedap 3kW Lamp Driver Nedap 6kW Lamp Driver UV Lamp Shutter & Thermoswitch cirquit JS3 Ballast Nedap 6 kW JP61 1 2 3 4 5 6 7 8 9 10 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 1 6 2 7 3 8 4 9 5 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 Powerset 0-10V Analog Input ( Optionaly ) Powerset Return ( Analog GND ) PWM Input 1-5kHz Remote ON/OFF Input High=ON Output Internal Power Supply 14V/25mA System failure OC Output Active Low Lamp Failure OC Output Active Low Lamp Driver Failure OC Output Active Low Lamp ON-Ready OC Output Active low Common Return See 6 kW Electronic Lamp Driver Manual Shutter Motor Green + S2 Grey SW SPDT A Earth Phase Cooling Machine Control Neutral - Yellow Red 1 6 2 7 3 8 4 9 5 TSW 1 Thermoswitch 1 6 2 7 3 8 4 9 5 GND Neutral Alarm OFF Delay RELAY SPDT 11 24V 15 K4 K3 A2 18 JP4 JP3 Start Cool Cooling Machine Control Cable. 9 Pins Sub D Standard Dongle to Factory set-up 5-7 Flow Alarm Fluss Alarm Bürkert 8032 Type: 436473 + DK1904 J6 +12V NC GND Alarm PE 1 2 3 4 5 Cool Unit Kühl-Einheit Phase L1 A1 A1 A2 J4 1 2 3 4 5 16 Brown White Blue Black Grey RELAY SPDT 14 B1 Start signal Nyt 24V Relæ, samt PNP output til GND CON5 DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 8 PLC Control System DPL 10188/ 10189 Instruction Manual. 13. PLC Controlbox Diagram: PLC 001 +24VCC 3 0 mA A1 Start UV Lampe input Act H A2 Start Curing Input Act H Ready For Curing Input Act L A3 A4 3kW lamp driv er f ailure 3 kW Sy stem Failure Input Act A5 H +24VCC 3 kW Lamp Failure Input Act H A6 6 kW Lamp Failure Input Act L A7 6 kW Lamp Driv er Failure InputA8 Act L A9 A10 A11 PWM Output UV Lamp Power regA12 A13 Tacho Cascade Output Start UV lamp Output Act H A14 A15 Shutter Relais Open Act H Start Cooler Output Act H A16 UV lamp Failure Output Act H A17 Sy stem Failure Output Act H A18 A19 Lamp Driv er Failure Output Act H B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14 B15 B16 B17 B18 B19 10k0 Output X1 Output X2 Light Source Exchange Output Act H Shutter Failure Output Act H UV Lamp temp Failure Output Act H Water Failure Output Act H Common Failure Output Act H Ready f or Curing Output Act H JP7 Remote C ontrol C onnec tor 1 5 P in SU B D M ale 1 Start UV Lampe input Act H 9 Start Curing Input Act H 2 0-10V Regulation Input 10 PWM Regulation Input 3 Ready f or Curing Output Act H 0E 11 Common Failure Output Act H R12 0E R21 4 Water Failure Output Act H 0E 12 UV Lamp temp Failure Output Act HR14 0E R15 5 Shutter Failure Output Act H 0E 13 Light Source Exchange Output Act HR16 0E 6 Lamp Driv er Failure Output Act H R17 0E R18 14 Sy stem Failure Output Act H 0E R19 7 UV lamp Failure Output Act H 0E R20 15 8 R30 10k0 R29 10k0 R22 10k0 R23 10k0 R24 10k0 R25 10k0 R26 10k0 R27 10k0 R28 10k0 PLC Plug Ty co CA7 Analog GND +24VCC PWM Output UV Lamp Power reg R8 J1 Start UV Lamp Output Act H 1 2 3 4 5 6 7 8 9 10 11 R9 R10 R11 0E 10k0 0E 10k0 LT3301 Analog Plug Nc Analog Input R7 22k0 R36 Output X1 R38 R37 Analog GND Nc out Output X2 Digital GND Shutter Relais Open Act H R39 NC out +24VCC 0E 10k010k010k0 R3 R2 R1 R6 R5 R4 16 Shutter Closed Input Shutter Open Signal Act H 15 UV Lamp Temp Failure Act: L 14 IC1AULN2004A OUT IN COM IC1BULN2004A OUT IN COM IC1CULN2004A OUT IN COM GND Power 1 9 2 9 JS56 C ooling Water C ontrol I nput/O utput 9 P in Sub D Female +24VCC 3 9 8 +12VCC Water Flow ok Input Act H Start Cooler Output Act H 1 2 3 JP36 1 9 2 10 +12VCC 3 11 K2 4 RELAY DPDT 12 5 13 6 14 7 15 8 +12VCC 22k022k022k0 JP40 U V L amp C ontrol C onnec tor 1 5 P in Sub D Female 0E 22k0 +24VCC Digital GND L amp D river C ontrol C onnec tor 2 5 P in SU B D M ale 1 14 2 3kW lamp driv er f ailure 15 3 16 4 3 kW Sy stem Failure Input Act H 17 5 Ready For Curing Input Act L 18 6 3 kW Lamp Failure Input Act H 19 7 6 kW Lamp Failure Input Act L 20 8 6 kW Lamp Driv er Failure Input Act L 21 9 6 kW Sy stem Failure Input Act L 22 10 23 Powerset 0-10V Analog Output 11 24 12 25 13 0-10V Regulation Input 22k0 T ac ho / D ongle I nput C onnec tor 9 P in SU B D M ale 1 Tacho "A" Input eller slav e 6 Tacho "B" Input 2 7 3 8 Tacho Cascade Output R33 4 R35 9 0E 5 Tacho "A" Input eller slav e Tacho "B" Input PWM Regulation Input UV Lamp Temp Failure Act: L +24VCC 6 kW Sy stem Failure Input Act L Water Flow ok Input Act H Shutter Open Signal Act H Shutter Closed Input JP1 P ower Supply C onnec tor R31 0E R32 10k0 1 6 2 7 3 8 4 9 5 JS26 Serial Resistor 0E = Fuse DPL Industri A/S, Fabriksvangen 1, 3550 Slangerup, Denmark. Instruction manual 10188 1a Side 9

![3.3 Test Report [17 September 2003] PDF](http://vs1.manualzilla.com/store/data/005797517_1-9a96a1d49c489ee795f322ac4fe31348-150x150.png)