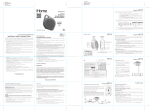

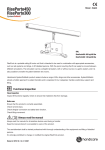

Download Information Manual AirTEP

Transcript