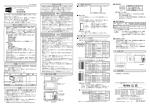

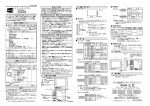

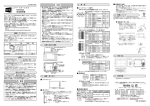

Download SMART TERMINAL EST-Z Series User`s Manual

Transcript