Download CP-SP-1293E - Azbil Corporation

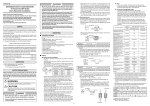

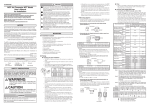

Transcript