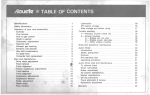

Download MS320 User`s Manual

Transcript