Download User manual - Wassermann Dental

Transcript

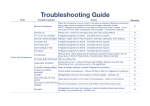

User manual Vacuum mixers WAMIX – 2 / 2M / 2M(S) WAMIX – 3M Fig. 2: WAMIX-2 Fig. 1: WAMIX-2M Fig. 3: WAMIX-3M Die Basis für Ihr Labor - 1- Dear customer, Thank you for choosing a product from the Wassermann range. Wassermann dental equipment incorporates the highest standards of quality and the latest technology. In order to enjoy maximum performance and years of trouble-free operation, please read this user manual carefully before you start work, and operate the unit according to the recommended guidelines. Keep this user manual on hand for ready reference. Company address: Wassermann Dental-Maschinen GmbH Rudorffweg 15-17 D-21031 Hamburg Germany Tel.: +49 (0)40/730 926-0 Fax.: +49 (0)40/730 37 24 email: info @ wassermann-dental.com URL: http: // www. wassermann-dental.com - 2- Contents CONTENTS.......................................................................................................................2 1 FEATURES................................................................................................................3 2 FOR YOUR SAFETY .................................................................................................3 2.1 2.2 2.3 YOUR USER MANUAL ............................................................................................3 SAFETY GUIDELINES .............................................................................................4 RESPONSIBILITY FOR OPERATION OR DAMAGE.......................................................4 3 AREA OF APPLICATION..........................................................................................5 4 BEFORE YOU START ..............................................................................................5 4.1 4.2 UNPACKING / TRANSPORT ....................................................................................5 LOCATION / STORAGE ...........................................................................................6 5 START-UP.................................................................................................................7 6 OPERATION..............................................................................................................8 6.1 6.2 6.3 VACUUM MIXING (ALL WAMIX MODELS)............................................................8 PRESSURE EMBEDDING (WAMIX-3M ONLY) .................................................9 VIBRATOR (WAMIX-2M ONLY)...........................................................................9 7 TROUBLESHOOTING.............................................................................................10 8 MAINTENANCE ......................................................................................................11 8.1 8.2 8.3 8.4 8.5 9 CLEANING..........................................................................................................11 SERVICING.........................................................................................................11 WARRANTY ........................................................................................................11 SPARE PARTS AND ACCESSORIES ........................................................................12 REPAIRS ............................................................................................................13 TECHNICAL DATA .................................................................................................13 9.1 9.2 9.3 9.4 171994 WAMIX-3M KOMBI VACUUM MIXER ......................................................13 171995 WAMIX-2M(S) VACUUM MIXER ..............................................................14 171996 WAMIX-2M VACUUM MIXER ...................................................................14 171998 WAMIX-2 VACUUM MIXER......................................................................15 10 EC CONFORMITY CERTIFICATE.......................................................................16 - 3- 1 Features The WAMIX range of vacuum mixers range can be used for mixing all types of plaster, embedding and silicone-based materials, and vacuum-washing of models for special dental procedures. There are separate power units for vacuum generation and mixing. A timer is used to switch the mixers on and off without breaking the vacuum. Until changed, the set mixing time (up to 240 seconds) becomes the default. An audible signal indicates the end of the mixing process. The mixing beakers on these units are held to the flange only by vacuum, guaranteeing air is excluded. The mixers are supplied for wall-mounting but can readily be converted for tabletop operation at any time (for accessories, see 8.4). The WAMIX-3M also features a pressure chamber, allowing you to achieve a more homogeneous, blister-free texture by hardening materials under pressures above atmospheric. The WAMIX-2M also has a vibrator for preparing single spoonfuls, for example. 2 For your safety 2.1 Your user manual You should read and follow carefully the instructions in this user manual for setting up and operating the unit. The unit is intended only for the specified purpose. Especially important points are highlighted as follows: Warning! This is a warning of risk situations and dangers. Failure to observe ! this warning could be life-threatening. These warnings must be observed. - 4- Information This symbol draws your attention to specific features which must be i observed. 2.2 Safety guidelines • ! This equipment is designed to operate at 230V / 50Hz. Make sure it is always connected to the appropriate power supply. • Always remove the plug from the power socket before undertaking maintenance or cleaning work. • A locking plate underneath each unit prevents it coming loose once it has been mounted in the bracket. • Allow the condensors to discharge before opening the unit. • A valve on the pressure chamber opens automatically if the pressure exceeds 7 bar (WAMIX-3M only). 2.3 Responsibility for operation or damage The responsibility for operating the unit lies exclusively with the owner or user if said unit is incorrectly serviced, maintained or altered by persons not employed by an authorised dealer or if the unit is used in a manner contrary to its specified purpose. The unit must be maintained and operated in accordance with this user manual. Wassermann Dental-Maschinen GmbH is not responsible for damage arising from the non-observance of these instructions. Guarantee and responsibility provisions contained in the sales and supply conditions of Wassermann Dental-Maschinen GmbH are not extended by these instructions. - 5- i Ensure that this user manual is accessible at all times and has been read and understood. 3 Area of application WAMIX mixers are used for mixing under vacuum all types of plaster, embedding and silicone-based materials. They can also be used for vacuum-washing models for special dental procedures. The insulating layer between the model and the prosthesis does not peel off prematurely, because the model is kept moist better than when washed in a pressure embedder. The WAMIX-3M can also produce more dense material using pressures above atmospheric. When materials (embedding and silicone-coated materials) are hardened under pressure, any residual air in the mix is compressed, resulting in a more homogeneous, blister-free material. This is the best basis for smooth casts. The WAMIX-2M has a vibrator which also allows you to prepare single spoonfuls, for example. 4 Before you start 4.1 Unpacking / Transport − Remove the packing materials and place the unit on a firm, level surface or use the supplied bracket to mount it on the wall. Check that all items have been supplied (see 8.4). − Before transporting the unit, ensure that it has been unplugged from the power socket. damage. Make sure that it is packed correctly in order to avoid accidental - 6- 4.2 Location / storage − Set the unit up on a level surface or mount it on the wall. − If mounting it on the wall, check first that the wall can take the weight. Mark out the hole template by removing the bracket from the unit and using it as a guide for drilling the 8 mm ∅ wall plugs. Leave a free area of at least 25 - 30 cm under the unit. − Always ensure that the work area is large enough for easy operation (allow for the unit’s size) – do not set the unit up out of doors! − If the unit is to be stored for an extended period, protect it from moisture and dust. − Connect the following before you turn the unit on: 1. Plug the power cord into the socket, making sure that the mains voltage matches the mixer. 2. WAMIX-2 and WAMIX-3M only: Connect a compressed-air hose in accordance with the technical specifications. In the case of long hoses, make sure that the hose ID is at least 6 mm. Provide a monitoring unit for each air hose and use a pressure gauge to keep the pressure constant. i Accidental mixing is not possible because the motor starts only after the beaker is held by vacuum to the flange, even if a mixing time has been set. Before you use the vacuum mixer, check that the lock plate (under ! the unit) has been turned through 90° (it should protrude beyond the housing). Tighten the screw on the plate to prevent the unit coming loose accidentally. - 7- 5 Start-up − Turn on the green switch (vacuum mix) ( all WAMIX models) − Open the compressed-air supply (WAMIX-2 and WAMIX-3M only) − WAMIX-2 only: When you use the unit for the first time, you will have to adjust the vacuum using the regulator knob. A pressure of at least 5 bar is recommended. The regulator knob is located under the pressure gauge. Open the valve slowly, until the arrow moves from zero into the green range. The best vacuum is obtained in the middle of the range, not when the valve is fully open. Re-adjustment is only necessary if the compressed-air supply changes in some way. − WAMIX-3M only: Use the regulator (black knob to the left of the vacuum flange) to set the pressure for embedding – max. 7 bar (safety valve). Pull and turn the knob to set the desired pressure. The initial pressure will be the maximum sealing pressure. Push the knob in again. NOTE: If you want to set a lower pressure, first turn the unit off (vent the unit), because the tank pressure is kept constant by a non-return valve. Then set the desired pressure on the gauge by turning up the regulator. i WAMIX-2: If, when you are setting the pressure, the arrow on the pressure gauge does not enter the green range, there is too little flow to the unit. Check the compressed-air supply (see also 4.2). i If the unit is not to be used for an extended period, disconnect the compressed-air supply and turn the mixer off. - 8- 6 Operation i All instructions for using the unit, whether verbal, written or in the form of practical guidance, are based on individual experience and experimentation and can only be regarded as guidelines. 6.1 VACUUM MIXING (all WAMIX models) 1. Set the mixing time (up to 240 seconds) (automatic operation). This time is used until a new time is set. For manual operation, turn the timer to 0, but set the desired mixing time only after a vacuum has been obtained. 2. Add the material to be mixed to the beaker. 3. Add the liquid and mix manually until the powder and the liquid are well combined. 4. Seal the beaker with the lid. 5. Insert the beaker into the mixer from below. This will start the vacuum suction. Hold the beaker until a vacuum is obtained. 6. The mixer will switch on automatically for the set time. An audible signal will indicate when mixing has finished. 7. Hold the beaker firmly before turning off the switch (vacuum). The beaker will be released from the mixer as the vacuum drops. i The sealing surfaces between the beaker and the cover must be clean – likewise the rotor mounting spigot and the top of the beaker cover – to ensure trouble-free operation. i Fill the beaker only to the Max. mark. Otherwise, too much material will be drawn into the system by the vacuum. - 9- i After the vacuum has dropped, the beaker will come away by itself. To avoid damaging the seal, never pull on the beaker. 6.2 PRESSURE EMBEDDING (WAMIX-3M ONLY) 1. Set the time on the timer (up to 60 minutes). 2. Open the black latched door (turn in the opposite direction to the arrow) – do not try to pull it open! 3. Insert the items - max. 3 large muffle rings. 4. Close the pressure chamber and activate the green switch (embedding). 5. The pressure will rise to the set level (pressure gauge). 6. When the set time expires, the pressure chamber will vent automatically, and the items can be removed. The pressure-embedding process can be interrupted at any time by turning off the switch (embedding), that is, the pressure chamber will be vented. i If the pressure drops in the compressed-air supply hose while the mixer is running, the non-return valve will keep the pressure at the level already reached. Open the pressure chamber only when the pressure has fallen to i zero. Opening the chamber prematurely can tear the rubber ring from its groove and damage it. 6.3 VIBRATOR (WAMIX-2M only) 1. Press the white switch (vibrator). 2. The vibrator rod and rubber ball vibrate. 3. Hold single spoons (or small moulds) against the rubber ball and add the mixed material (plaster and similar) in small amounts. This allows you to use the one mixer for smaller jobs. - 10 - 7 Troubleshooting Problem Mixer will not start Vacuum too low No vacuum Pressure does not increase in pressure chamber (WAMIX-3M) Likely cause Blown fuse Likely solution Replace fuse and determine cause. If necessary, contact Service. Timer on 0 Set mixing time Filter (vacuum) blocked Check filter – clean and/or change (see 8.2) Faulty seal on vacuum flange for mixing beaker Replace seal Beaker filled beyond Max. Clean system, ie, contact Service mark, so mixing material in system Faulty vacuum pump Contact Service Faulty cover seal O-ring Check and/or replace Oring Pressure regulator set to 0 Check and/or set pressure (pressure gauge) Vacuum set with regulator too low (WAMIX-2) i Timer on 0 Set time Pressure too low in air hose Check compressed-air supply (min. 5 bar) If the above recommendations do not solve the problem, contact your dental depot or our Service department. - 11 - 8 Maintenance 8.1 Cleaning The unit should be cleaned at regular intervals to ensure problem-free operation. It requires only normal cleaning (sponge, damp cloth, mild detergent). Do not use chemical additives. Solvents must not be used to clean the mounting plate! Keep the beaker clean. When not in use, fill with water to just below the stirrer. The model plate must always be legible and should not be removed. 8.2 Servicing i Allow the condensors to discharge before you open the mixer. Our vacuum mixers do not require servicing. Just make sure that the unit is kept clean and that the flange seal is not damaged. Changing the filter: Undo the knurled screw (on the right, near the mixer on the vacuum flange on the underside of the unit). The filter swings loose at the forward end of the screw. After changing the filter, do up the screw finger-tight (do not forget the O-ring). 8.3 Warranty The warranty period for our instruments is 6 months. If faults occur within the warranty period, contact your dental depot or get in touch directly with our Service department. Vacuum mixers should only be operated in perfect condition. If faults occur which - 12 - could harm operators or third parties, the unit should not be used until it has been fixed. The warranty does not cover damage caused by improper use, external mechanical causes, transport damage or interference with the unit by unauthorised persons. 8.4 Spare parts and accessories Spare parts Item number 171219 171226 171411 171416 180005 291008 380018 380023 380026 380032 392026 560107 560108 560111 560112 582029 610025 610028 Description Filter screw Locating plate Vibrator rod (WAMIX-2M only) Vibrator ball, complete (WAMIX-2M only) Muffle mount (WAMIX-3M only) Conical knob (WAMIX-3M only) O-ring 9.75 x 1.78 O-ring 8 x 1.9 Seal D56 x D48 x 3, black, self-sealing one side O-ring 166.4 x 3.8 (WAMIX-3M only) Flexible pad D8 - H1.6 (WAMIX-3M only) Knob, black (WAMIX-2 only) Cover for knob, black (WAMIX-2 only) Cover for knob, black with stripe, white Knob, black with stripe, white Fuse 3.15 A T 250V - D5x20 Sinter filter (vacuum unit) Sound absorber (WAMIX-2 only) Accessories Item number 171106 171112 171126 171210 171212 171230 171237 171269 171275 171283 Description Wall bracket ( WAMIX-2M or 2M(S) Table stand ( WAMIX-2M or 2M(S) (not supplied) Fastener set (WAMIX-2M only) Wall bracket (WAMIX-2 only) Table stand (WAMIX-2 only) (not supplied) Beaker, small, complete, 200 ml (not supplied) Beaker, large, complete, 600 ml (not supplied) Beaker, extra large, complete, 1000 ml (not supplied) Vacuum washing beaker, 600 ml (not supplied) Beaker, medium, complete, 350 ml - 13 - 171290 171295 171299 171412 171424 171427 320026 Fastener set ( WAMIX-2 or 2M(S)) Beaker, extra small, complete, 75 ml (not supplied) Adapter for “Inceram“ (VITA) (not supplied) Wall bracket (WAMIX-3M only) Table stand (WAMIX-3M only) (not supplied) Fastener set (WAMIX-3M only) High-pressure air hose, blue, D8 x 6 ( 2 m) (WAMIX-2 or 3M) 8.5 Repairs Servicing or repairs to the unit must only be carried out by trained technicians. Only original spares are to be used. Responsibility for the product is voided if it is altered by unauthorised persons or if inappropriate components are installed. 9 Technical data 9.1 171994 WAMIX-3M KOMBI vacuum mixer with motorised pump and compressor Voltage: Power consumption: Output: Speed: Mixing time: Vacuum: Compressed air: Safety class: Pressure chamber: Overall size: Weight: 230 V / 50 Hz 1.8 A 230 W 350 rpm up to 240 sec., adjustable approx. 970 mbar min. 3.5 bar IP 44 interior 130 mm high, 250 mm deep Capacity: 3 muffles Operating pressure: max. 7 bar Width 475 mm Height 255 mm Depth 395 mm 29.4 kg - 14 - 9.2 171995 WAMIX-2M(S) vacuum mixer with motorised pump, without vibrator Voltage: Power consumption: Output: Speed: Mixing time: Vacuum: Safety class: Overall size: Weight: 9.3 230 V / 50 Hz 1.8 A 230 W 350 rpm up to 240 sec., adjustable approx. 970 mbar IP 44 Width 350 mm Height 190 mm Depth 370 mm 16.1 kg 171996 WAMIX-2M vacuum mixer with motorised pump and vibrator Voltage: Power consumption: Output: Speed: Mixing time: Vacuum: Safety class: Overall size: Weight: 230 V / 50 Hz 2.2 A 300 W 350 rpm up to 240 sec., adjustable approx. 970 mbar, IP 44 Width 350 mm Height 190 mm Depth 370 mm 17.5 kg - 15 - 9.4 171998 WAMIX-2 vacuum mixer with injector Voltage: Power consumption: Output: Speed: Mixing time: Vacuum: Compressed air: Safety class: Overall size: Weight: 230 V / 50 Hz 1.6 A 190 W 350 rpm up to 240 sec., adjustable approx. 950 mbar min. 5 bar IP 44 Width 245 mm Height 155 mm Depth 300 mm 12.5 kg Vacuum mixer noise emission ≤70 dB(A) i We reserve the right to make technical changes. - 16 - 10 EC CONFORMITY CERTIFICATE in accordance with 73/23/EWG (low-voltage guidelines) modified by 93/68/EWG and 89/336/EWG (EMV guidelines) and 89/392/EWG (Machinery guidelines), with modifications Product description : Manufacturer W A S S E R M A N N : Dental-Maschinen GmbH Rudorffweg 15 - 17 D-21031 Hamburg Machine model: Vacuum mixer for dental applications WAMIX-3M Kombi with motorised pump and compressor WAMIX-2M(S) with motorised pump, without vibrator WAMIX-2M with motorised pump and vibrator WAMIX-2 with injector Applicable standards: (171994) (171995) (171996) (171998) EN 61010-1:1993 + A2:1995 EN 50081-1 + EN 50082-1 Pressure container ordinance (WAMIX-3M Kombi only) DIN 45635 Part 1 Hiermit wird bestätigt, daß die oben bezeichnete Maschine den genannten EG-Richtlinien entspricht. Diese Erklärung wird ungültig, falls die Maschine ohne unsere Zustimmung verändert wird. This is to confirm that the above-mentioned machine complies with the described EC rules. This declaration becomes invalid if the machine is modified without our approval. Cette machine est conforme aux normes en vigueur de la Communauté Européene. Cet avis est nul et non avenant si cette machine est modifiée sans notre accord. Esta máquina, anteriormente mencionada, cumple con los limites requeridos por el reglamento EC. Ahora bien, esta declaración quedará invalidada en caso de realizar modificaciones al aparato sin nuestra aprobación. Hiermee wordt bevestigd dat bovengenoemde machine voldoet aan de voorgeschreven EU normen. Deze verklaring verliest geldigheid als er zonder onze uitdrukkelijke toestemming wijzigen aan de machine worden aangebracht. Company stamp : Place, date: Hamburg, den 10.Apr.2003 Signed: ________________________ Wilfried Wassermann (Managing Director) - 17 - - 18 - WASSERMANN Dental-Maschinen GmbH Rudorffweg 15 – 17, D-21031 Hamburg Tel.: + 49 (0)40 / 730 926 – 0 Fax: +49 (0)40 / 730 37 24 e-mail: [email protected] Internet: http://www.wassermann-dental.com