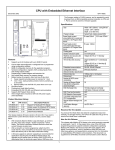

Download VersaMax PLC User`s Manual, GFK-1503C

Transcript