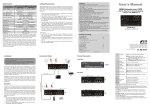

Download Model 210 - Intek, Inc.

Transcript