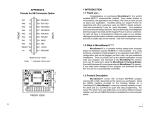

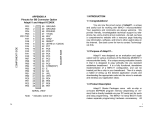

Download TALRIK JUNIOR USERS MANUAL

Transcript