Download TGGE Manual

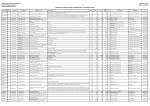

Transcript