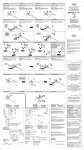

Download ADP/ADS Series Two dry pumps

Transcript