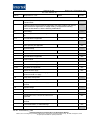

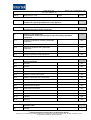

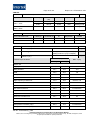

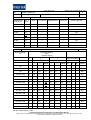

Download Test report_GZ12100571

Transcript