Download WK 420 140 Pilot operated pressure relief valve type

Transcript

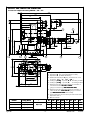

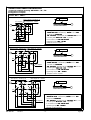

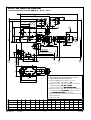

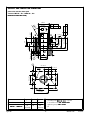

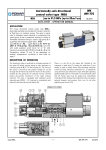

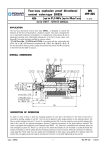

Pilot operated pressure relief valve type DB WK 420 140 NS10, 20, 30 up to 35 MPa up to 650 dm3/min DATA SHEET - SERVICE MANUA MANUAL NUA L 07.2011 APPLICATION Pressure relief valves type DB... serve to limit pressure in a hydraulic system or in its part, while in version DBW... with pilot valve it is also used to unload pressure in a system. Application example: •DB... for setting up maximum pressure in a system •DBW... for actuation of a pump without pressure The valve is complied with the regulations of directive 2006/95/WE for the following voltages: voltages •50 50 – 250 V for AC •75 75 – 250 V for DC DESCRIPTION OF OPERATION DB20 - 2 - 52/100 10 2 6 3 5 Y 11 7 1 4 9 X P Pilot operated pressure relief valve type DB... consists of the pilot valve (2) and the main valve (1). Pressure in a system through line P affects the lower side of the spool (4) and via jets (9), (10), (11) also affects its upper side and the poppet (6) of the pilot valve. At standstill, the pressure is equal on both sides of the spool. A spring (7) holds the spool (4) in the starting position. Lines P and T are separated from each other. If pressure in a system reaches the value set by the position of the Type DB T adjustment element (5) and tension of the spring (3) of the pilot valve, the pilot poppet (6) opens and fluid flows via jets (9) and (10) and opened pilot valve (2) to a tank. The flow of control stream causes pressure drop at jets (9) and (10). In effect pressure acting on the lower side of the spool (4) is greater and the spool moves upwards, what allows excess fluid to be drained to a tank and pressure in a system to be limited to the set value. -1- WK 420 140 07.2011 DESCRIPTION OF OPERATION DBW20...A - 2 - 52/100 8 6 2 5 10 3 Y 11 7 1 4 9 X P T Pressure relief valve is also available in version with forced (electrically) pressure unloading. Pilot valve (8) in form of a directional valve shuts off drain line before the pilot poppet in its starting position. The valve functions as described before. After switching directional valve (9) the chamber before the pilot WK 420 140 07.2011 poppet is connected to drain line (connected to a tank). The unloaded spool (4) moves upwards opening connection between P and T. The valve is available in two versions depending on the pilot valve (8): closed in de-energized position – version DBW…A A… or opened in de-energized position – version DBW…B B… . -2- Type DB TECHNICAL DATA Hydraulic fluid mineral oil Req Required fi f iltrat ltr ati ation up to t o 1 6 µm Recommended filtration up to 10 µm Nominal fluid viscosity 37 mm 2/s at temperature 55 C Viscosity range 2,8 up to 380 mm 2/s o recommended 40 oC up to 55 C max -20 oC up to +70 oC -20 oC up to +70 oC version DB... Fluid temperature range (in a tank) Ambient temperature range Maximum imum operat operati ating press pres sure Maximum imum press pres sure in lines nes Y , T Minimum imum setti sett ing press pres sure Maximum imum setting pres pressure Maximum imum fl f low rate rate Weight Type of a d direct irectiional valve irect (only for versions DBW... ; DBW...G; DBWC...) Nomi ominal supply upply voltage ltage for f or solen lenoid o -20 oC up to +50 oC version DBW... 3 5 MP a versiion DB... vers 31, 5 MPa versi ersion DBW... 2 1 MPa 0,5 0, 5 MPa 3 5 MP a 25 2 50 dm 3 / mi m in 500 dm 3/ mi m in 3 65 6 50 dm / mi m in version NS1 NS10 NS2 NS20 NS3 NS 30 nomi ominal size nominal size DB... NS10 NS20 3,1 kg 4,0 kg NS30 4,9 kg DBG... DBW... 4,9 kg 4,7 kg 4,7 kg 5,6 kg 5,4 kg 6,5 kg DBWG... DBC... DBWC... 6,5 kg 6,3 kg 7,0 kg 1,5 kg 1,5 k g 1,5 kg 3,1 kg 3,1 kg 3,1 kg WE6... according to data sheet WK 499 502 AC (plug-in connector with rectifier) DC 12 V 24 V Supply voltage tolerance ±10% Power requirement (DC) 30 W Insulati ation Temperature of solenoid coil IP I P 65 max 150 oC 11 0V 2 30 V - 5 0 Hz 11 0 V - 5 0H z ASSEMBLY AND APPLICATION REQUIREMENTS 1. Only valve working properly and suitably installed may be connected to an electric system. Only skilled workers are allowed to connect and disconnect electric system. 2. Ground connection ( ) must be connected with protective earth wire ( PE) PE in supply system according to appropriate instructions. 3. It is forbidden to apply the valve if the supply cable in the gland of plugplug-in connector is not properly tightened. Type DB -3- 4. It is forbidden to apply the valve if the plugplug-in connector is not properly tightened to the solenoid socket and is not secured by screwing bolt tightly. 5. Due to heating solenoid coil, coil, the valves should be placed in order to eliminate the possibility of incidental touch while using, or, they should be equipped with the coil covers (in accordance with the European standards PN - EN ISO 1373213732-1 and PN - EN 982). WK 420 140 07.2011 OVERALL AND CONNECTION DIMENSIONS versions for subplate mounting: DB10...; 20...; 30... 7 3 160 46 123 stroke 50,5 S 22 S 6 S 24 S 22 O O 36 G1/4 depth 12 stroke 4 32 115 L4 18 4 100 Y 79 6 6 4 16 O T 27 P X 3 1 2 5 4 O O B2 B1 D2 - 4 spotfaces D1 - 4 holes X T P Y L2 L3 4 L1 1 - Adjustment 1 (handknob) 2 - Adjustment 2 (set screw with hexagon socket) 3 - Adjustment 3 (lockable handknob) 4 - Additional external port Y (plug G1/4 does not occur in versions: DB.../...Y... ; DB.../...XY...) 5 - Sealing ring o-ring -rin g - 2 pcs/kit (P, T) - according to table 6 - Sealing ring o-ring -rin g - 1 pcs/kit (X) - according to table 7 - Space required to remove the key from the lock of the adjustment item 3 o-ri -ring item 5 versi vers ion DB10... DB10... 17,1 7, 1 x 2,6 2,6 DB20... DB2 0... 28,2 8, 2 x 3,5 3,5 DB30... DB30... 34,5 4, 5 x 3,5 3,5 WK 420 140 07.2011 o-ri -ring item 6 8,3 8, 3 x 2,4 2,4 -4- B1 78 B2 φ D1 L1 L2 L3 20 φ D2 14 54 90 54 23,5 100 70 26 18 117 67 34 107 115 82,5 29 20 148 89 41,5 128 L4 93,5 Type DB OVERALL AND CONNECTION DIMENSIONS versions for subplate mounting: DBW10...; 20...; 30... 3 162 206 15 15 L4 50,5 4 G1/4 depth 12 2 10 9 46 S 22 S 6 32 Y 79 S 22 T P 6 O 5 P B1 B2 X OO 6 1 4 stroke 3 8 T 1 - Adjustment 1 (handknob) 2 - Adjustment 2 (set screw with hexagon socket) 3 - Adjustment 3 (lockable handknob) 4 - Additional external port Y (plug G1/4 does not occur in versions: DBW.../...Y... DBW.../...XY...) 5 - Sealing ring o-ring - 2 pcs/kit (P, T) - according to table 6 - Sealing ring o-ring - 1 pcs/kit (X) - according to table 7 - Dimension for the valve with electrical connection of a directional valve 12V, 24 24V, 110V DC (plug-in connector type DIN 43650/ISO 4400) 8 - Dimension for the valve with electrical connection of a directional valve 110V, 230V AC (plug-in connector type DIN 43650/ISO 4400 with rectifier) 9 - Space required to remove the key from the lock of the adjustment item 3 10 - Manual override Y D1 - 4 holes D2 - 4 spotfaces L3 4 S 24 stroke 27 X 4 16 4 7 Type DB O O 146 36 184 191 18 L2 L1 versi vers ion o-ri -ring item 5 DBW1 DBW10... 17,1 7,1 x 2,6 2, 6 DBW2 DBW20... 28,2 8, 2 x 3,5 3,5 DBW3 DBW30... 34,5 4, 5 x 3,5 3,5 o-ri -ring item 6 8,3 8,3 x 2,4 2, 4 -5- B1 78 B2 φ D1 L1 L2 L3 20 φ D2 14 54 90 54 23,5 100 70 26 18 117 67 34 107 115 82,5 29 20 148 89 41,5 128 WK 420 140 L4 93,5 07.2011 OVERALL AND CONNECTION DIMENSIONS versions for subplate mounting: DB, DBW10...; 20...; 30... portiing pat port p attern attern on subpl ubplate versi vers ions: DB10... DB1 0... ; DBW1 DBW10... O O 7 depth 6 r 14,7 (max) - 2 holes (P,T) 0,01/100 mm 0,63 M12 depth 22 - 4 holes 2 1 X P T 54 80 O 6 1 - Porting pattern on subplate according to: •CETOP- RP 121H - identified by CETOP 4.4.2-2- R06 nominal size CETOP R06 •PN - ISO 6264 - identified by PN - ISO 6264 -06-09-1-97 mounting bolts M12 x 50 - 10.9 0. 9 - 4 pcs/kit in accordance with PN - EN ISO 4762 tightening torque Md = 12 1 20 Nm 2 - Subplate surface required 22,2 47,6 21,5 54 88 versi ersions: DB20... DB2 0... ; DBW2 DBW 20... O r 23,4 (max) - 2 holes (P,T) M16 depth 26 - 4 holes 0,01/100 mm 0,63 1 P T 2 69,8 100 O X 6 O 11,1 33,3 55,6 23,8 66,7 134 1 - Porting pattern on subplate according to: •CETOP- RP 121H - identified by CETOP 4.4.2-2- R08 nominal size CETOP R08 •PN - ISO 6264 - identified by PN - ISO 6264 -0 -08-13-1-97 mounting bolts M16 x 50 - 10.9 0.9 - 4 pcs/kit in accordance with PN - EN ISO 4762 tightening torque Md = 31 310 Nm 2 - Subplate surface required 7 depth 6 25,8 versi ersions: DB30... DB3 0... ; DBW3 DBW 30... O 32 (max) - 2 holes (P,T) M18 depth 26 - 4 holes 1 r 0,01/100 mm 0,63 P T 6 12,5 44,5 76 89 120,6 158 WK 420 140 07.2011 2 82,5 120 O X O 22 1 - Porting pattern on subplate according to: •CETOP- RP 121H - identified by CETOP 4.4.2-2- R10 nominal size CETOP R10 • PN - ISO 6264 - identified by PN - ISO 6264 -1 -10-17-1-97 7 depth 7 mounting bolts M18 x 50 - 10.9 0. 9 - 4 pcs/kit in accordance with PN - EN ISO 4762 tightening torqueMd = 43 4 30 Nm 2 - Subplate surface required -6- Type DB OVERALL AND CONNECTION DIMENSIONS versions for threaded connection: DB10...G...; 20...G...; 30...G... 5 3 160 46 123 S6 4 stroke 56 S 24 O 20 O 41 36 S 22 stroke 20 S 22 32 115 50,5 G1/4 depth 12 18 4 Y 2 H2 T 1 3 O G1/4 depth 12 4 L4 L3 L2 D1 - 2 holes B1 O 22 depth 1 P O O H3 H1 X H4 D2 depth 1 2 spotfaces D3 depth T1 - 2 holes 4 Y L1 L5 3 1 - Adjustment 1 (handknob) 2 - Adjustment 2 (set screw with hexagon socket) 3 - Adjustment 3 (lockable handknob) 4 - External port Y (plug G1/4 does not occur in versions: DB...G.../...Y... DB...G.../...XY...) 5 - Space required to remove the key from the lock of the adjustment item 3 H1 H2 H3 H4 L1 L2 L3 L4 L5 T1 34 G 1/2 27 126 10 62 85 14 62 31 90 14 9 47 G1 27 126 10 62 85 14 62 31 90 18 11 61 G 1 1/2 42 139 13 64 100 18 72 36 99 22 B1 DB10... DB1 0...G 0... G... 63 9 DB20... DB2 0...G 0... G... 63 DB30... DB3 0...G 0... G... 70 Type DB φ D2 φ D3 φ D1 versi vers ion -7- WK 420 140 07.2011 OVERALL AND CONNECTION DIMENSIONS versions for threaded connection: DBW10...G...; 20...G...; 30...G... 3 206 15 15 162 50,5 G1/4 depth 12 4 2 1 7 46 S 22 S 6 H5 32 O 36 18 O 20 39,5 H2 125 48 8 Y stroke S 24 4 S 22 4 stroke T P L2 3 6 B1 O L4 D1 L3 H3 23 depth 1 G1/4 depth 12 H1 5 O 4 D2 depth 1 2 spotfaces D3 depth T1 - 2 holes H4 O X O 1 - Adjustment 1 (handknob) 2 - Adjustment 2 (set screw with hexagon socket) 3 - Adjustment 3 (lockable handknob) 4 - External port Y (plug G1/4 does not occur in versions: DBW.../...Y... DBW.../...XY...) 5 - Dimension for the valve with electrical connection of a directional valve 12V, 24 24V, 110V DC (plug-in connector type DIN 43650/ISO 4400) 6 - Dimension for the valve with electrical connection of a directional valve 110V, 230V AC (plug-in connector type DIN 43650/ISO 4400 with rectifier) 7 - Space required to remove the key from the lock of the adjustment item 3 8 - Manual override Y L1 L5 versi vers ion B1 DBW1 DBW10...G 0... G... 63 φ D 1 φ D2 φ D3 9 34 G 1/2 H1 H2 H3 H4 H5 L1 L2 L3 L4 L5 27 210 10 62 217 85 14 62 31 90 T1 14 DBW2 DBW20...G 0... G... 63 9 47 G1 27 210 10 62 217 85 14 62 31 90 18 DBW3 DBW30...G 0... G... 70 11 61 G 1 1/2 42 225 13 64 232 100 18 72 36 99 22 WK 420 140 07.2011 -8- Type DB OVERALL AND CONNECTION DIMENSIONS pilot valve without the main spool - version DBC... pilot valve with the main spool - versions: DBC10...; 30... 3 160 46 123 stroke 115 stroke 4 7 18 4 50,5 S 24 S 22 O 36 42 O 41 29 20 Y 32 S 22 S 6 G1/4 depth 12 6 8,4 - 4 holes Y X Y 1 3 10 (16) 13 2 4 32 O 5 44 58 8 9 4 51 - Adjustment 1 (handknob) - Adjustment 2 (set screw with hexagon socket) - Adjustment 3 (lockable handknob) - External port Y (plug G1/4 does not occur in versions: DBC.../...Y... ; DBC.../...XY...) 5 - Sealing ring o-r o -ri -ring 27,3 7, 3 x 2,4 2, 4 6 - Sealing ring o-ri -ring 9,2 9, 2 x 1,8 1,8 - szt. 2/komplet (X, Y) 7 - Space required to remove the key from the lock of the adjustment item 3 8 - Dimension for version DBC... (pilot valve without the main spool) 9,10 - Dimensions only for versions DBC10...; DBC30... (pilot valve with the main spool) 1 2 3 4 Type DB -9- WK 420 140 07.2011 OVERALL AND CONNECTION DIMENSIONS pilot valve without the main spool - version DBWC... pilot valve with the main spool - versions: DBWC10...; 30... 3 206 15 15 162 50,5 G1/4 depth 12 125 48 S 22 46 S6 132 11 12 18 4 32 4 stroke stroke 42 S 22 O O 36 39,5 29 20 Y 9 58 O 5 6 2 1 - Adjustment 1 (handknob) - Adjustment 2 (set screw with hexagon socket) - Adjustment 3 (lockable handknob) - Additional external port Y (plug G1/4 does not occur in versions: DBWC.../...Y...; DBWC.../...XY...) 5 - Sealing ring o-ri -ring 27,3 7, 3 x 2,4 2,4 6 - Sealing ring o-ri -ring 9,2 9, 2 x 1,8 1,8 - 2 pcs/kit (X, Y) 7 - Dimension for the valve in version DBWC... (pilot valve without the main spool) with electrical connection of a directional valve 12V, 24V, 110V DC (plug-in connector type DIN 43650/IS /I SO 4400) 8 - Dimension for the valve in version DBWC... (pilot valve without the main spool) with electrical connection of a directional valve 110V, 230V AC (plug-in connector type DIN 43650/IS /ISO 4400 with rectifier) 9,10 - Dimension for the valve in version DBWC10...; DBWC30... (pilot valve with the main spool) 11 - Space required to remove the key from the lock of the adjustment item 3 12 - Manual override 1 2 3 4 4 Y 4 WK 420 140 07.2011 8 Y X 13 3 10 16 8,4 - 4 holes 44 32 7 51 - 10 - Type DB OVERALL AND CONNECTION DIMENSIONS pilot valve with the main spool versions: DBC10...; 30...; DBWC10...; 30... dimen dime nsions of the t he valve ca c avity 0,008 0,05 B A Y 0,63 25,5 D3 u 34 17 2,5 32 ±0,1 1 24 D1 O u 55 ±0,2 16 0,2 4,2 X Y M8 depth 13 4 holes 51 ±0,1 φ D1 φ D2 φ D3 DBC1 DBC10... ; DBWC DBW C10... 10 40 10 DBC3 DBC30... ; DBWC DBW C30... 30 (nominal) 45 30 (nominal) versi vers ion Type DB 10 ±0,2 44 ±0,1 O 2 P OO M4 6 (min) 2 - 45 v O T 40 0,1 B 2 2 - 45 v nr 28,6 +0,2 X 0,01/100 0,02 A 30 eaO +0,1 32H7 42 +0,05 48 D2 1,25 2,5 OO v O M5 depth 6 1 - Porting pattern on end face of the valve seat mounting bolts M8 x 40 -1 -10.9 - 4 pcs/kit in accordance with PN - EN ISO 4762 tightening torque Md = 37 Nm 2 - Jet - 11 - WK 420 140 07.2011 SCHEMES Deta Det ailed and simpl implified ified symbo symb ols for comple mplet lete valv alves - versi ersions DB. DB... detai deta iled symbo symb ol simpl implified ified symbo symb ol version DB.../... P X P X T Y T version DB.../...X... P X T P Y X T version DB.../...Y... P X P X T T Y Y version DB.../...XY... P P X T WK 420 140 T Y 07.2011 - 12 - X Y Type DB SCHEMES Deta Detailed and simpl implified ified symbo symb ols for co comple mplet lete valv alves - versi ersions DBW DBW... detai deta iled symbo symb ol simpl implified ified symbo symb ol versi vers ion of directi direct ional valve version DBW.../... DBW...A.../... (normally closed) P X P DBW...B.../... (normally opened) X T Y T version DBW.../...X... DBW...A.../...X... (normally closed) P X P DBW...B.../...X... (normally opened) T Y X T version DBW.../...Y... DBW...A.../...Y... (normally closed) P X P DBW...B.../...Y... (normally opened) X T Y T Y version DBW.../...XY... DBW...A.../...XY... (normally closed) P X P DBW...B.../...XY... (normally opened) T Type DB Y T X - 13 - Y WK 420 140 07.2011 SCHEMES Graph raphic symbo symb ols for f or pi p ilot va v alves DBWC versi versions: DBC... DB C... ; DBWC versi vers ion DBC... versi vers ion DBWC... DBWC... versi vers ion of direct ional valve DBWC...A.../... (normally closed) P P T DBWC...B.../... (normally opened) X X T PERFORMANCE CURVES o measured at viscosity ν = 41 mm 2/s and temperature t = 50 C Operating pressure p in relation to the flow Q for valves NS1 NS10 40 p [MPa] 30 20 10 0 WK 420 140 50 07.2011 150 10 0 3 Q [dm /mi /min] 2 00 - 14 - 250 Type DB PERFORMANCE CURVES o measured at viscosity ν = 41 mm 2/s and temperature t = 50 C Operating pressure p in relation to te flow Q for valves NS2 NS20 40 p [MPa ] 30 20 10 10 0 0 30 0 2 00 4 00 50 0 [dm 3/mi /min] Q Operating pressure p in relation to te flow Q for valves NS3 NS30 40 p [MPa ] 30 20 10 0 10 0 20 0 Q 30 0 40 0 500 60 0 [dm 3/mi /min] Minimum settable pressure p min in relation to the flow Q 2 NS10 NS 10 NS20 NS2 0 NS30 NS 30 p mi min n [MPa ] 1,5 Cracking pressure of the main valve: standard low (U) 1 0,5 0 Type DB 100 200 300 400 Q [dm 3 /min /min] 500 - 15 - 600 650 WK 420 140 07.2011 HOW TO ORDER DB Version without pressure unloading with pressure unloading = no designation =W Design version complete valve pilot valve with the main spool state nominal size NS10 or NS30 in the next step pilot valve without the main spool do not state nominal size in the next step = no designation = C ... =C Nominal size (NS) NS10 NS20 NS30 = 10 = 20 = 30 Type of unloading (only for versions DBW...; DBW...G...; DBWC...) in de-energized position directional valve closed =A in de-energized position directional valve opened =B Mounting method subplate mounting threaded connection = no designation =G Type of adjustment element handknob set screw with hexagon socket lockable handknob =1 =2 =3 Series number (50-59) - connection and installation dimensions unchanged = 5X series 52 = 52 Settable pressure range up to 5 MPa up to 10 MPa up to 20 MPa up to 31,5 MPa up to 35 MPa WK 420 140 07.2011 = 50 = 100 = 200 = 315 = 350 - 16 - Type DB HOW TO ORDER * Further requirements in clear text (to be agreed with the manufacturer) Sealing NBR (for fluids on mineral oil base) FKM (for fluids on phosphate ester base) = no designation =V Electrical connection (only for versions DBW... DBW...G... DBWC...) Plug-in connector DIN 43650-A/ISO4400 without LED = Z4 Plug-in connector DIN 43650-A/ISO4400 with LED = Z4L Manual override for solenoid (only for versions DBW... DBW...G... DBWC...) solenoid without manual override = no designation solenoid with manual override =N Supply voltage for solenoid (only for versions DBW... DBW...G... DBWC...) 12V DC = G12 24V DC = G24 110V DC = G110 110V AC 50Hz (plug-in connector with rectifier) = W110R 230V AC 50Hz (plug-in connector with rectifier) = W230R Pilot oil supply and pilot oil drain (only for versions DB...; DBW...) internal pilot oil supply, internal pilot oil drain external pilot oil supply, internal pilot oil drain internal pilot oil supply, external pilot oil drain external pilot oil supply, external pilot oil drain = no designation =X =Y = XY Cracking pressure of the main valve (not applicable for wersions DBC...; DBWC... without the main spool) standard = no designation low =U NOTES: The valve should be ordered according to the above coding. The symbols in bold are preferred versions in short delivery time. Coding example: DB10 G2 - 52/100 U Type DB - 17 - WK 420 140 07.2011 SUBPLATES AND MOUNTING BOLTS NOTE: Subplate symbols in bold are preferred versions in short delivery time. Subplates for particular versions of valve should be ordered according to subplate type, taking into the account the size of thread connections given in the table below. Subplates and mounting bolts must be ordered separately. Valve type Subp S ubpl ubplate type Data sheet Thread hread co c onnecti nect ions of the t he subpl ubplate G406/01 WK 470 013 G407/01 WK 470 013 G408/01 WK 450 797 G409/01 WK 450 797 G410/01 WK 470 473 G411/01 WK 470 473 P, T - G 3/8 X - G 1/4 DB10...; DB1 0...; DB W10... DB20...; DB20...; DB W20... DB30...; DB30...; DB W30... P, T - G 1/2 X - G 1/4 P, T - G 3/4 X - G 1/4 P, T - G 1 X - G 1/4 P, T - G 1 1/4 X - G 1/4 P, T - G 1 1/2 X - G 1/4 Mounting ting bo b olts lts M12 x 50 - 10.9 0. 9 - 4 pcs/kit in accordance with PN -E - E N I S O 47 62 tightening torque Md = 120 Nm . M16 x 50 - 10.9 0. 9 - 4 pcs/kit in accordance with PN -E - E N I S O 4 7 62 tightening torque Md = 310 Nm . M18 x 50 - 10.9 0.9 - 4 pcs/kit in accordance with PN -E - E N I S O 47 6 2 tightening torque Md = 430 Nm . EXAMPLE OF APPLICATION IN HYDRAULIC SYSTEM P DBW DBW...A. ...A... .A. .... - 52 5 2/100 100 G24NZ 24N Z4 M T X PONAR Wadowice S.A. ul. Wojska Polskiego 29 34-100 Wadowice tel. +48 33 488 21 00 fax.+48 33 488 21 03 www.ponar-wadowice.pl WK 420 140 07.2011 - 18 - Type DB