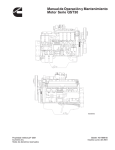

Download LeeBoy Cummins B3.9 & B5.9 Engine Manuals

Transcript