Download Service Manual

Transcript

&KDQJHIRU/LIH

6HUYLFH0DQXDO

02'(/ *:+0%.'1$.

*:+0%.'1$.

*:+0%.'1$.

*:+0%.'1$.

*:+0%.'1&.

*:+0%.'1&.

*:+0%.'1(.

*:+0%.'1(.

5HIULJHUDQW5$

*5(((/(&75,&$33/,$1&(6,1&2)=+8+$,

7DEOHRI&RQWHQWV

7DEOHRI&RQWHQWV

6XPPDU\DQG)HDWXUHV 6DIHW\3UHFDXWLRQV 6SHFL¿FDWLRQV 8QLW6SHFL¿FDWLRQV 2SHUDWLRQ&KDUDFWHULVWLF&XUYH &DSDFLW\9DULDWLRQ5DWLR$FFRUGLQJWR7HPSHUDWXUH 1RLVH&ULWHULD&XUYH7DEOHVIRU%RWK0RGHOV 2SHUDWLRQ'DWD &RQVWUXFWLRQ9LHZV ,QGRRU8QLW 2XWGRRU8QLW 5HIULJHUDQW6\VWHP'LDJUDP 6FKHPDWLF'LDJUDP

(OHFWULFDO'DWD

(OHFWULFDO:LULQJ

3ULQWHG&LUFXLW%RDUG )XQFWLRQDQG&RQWURO 5HPRWH&RQWURO2SHUDWLRQV 'HVFULSWLRQRI(DFK&RQWURO2SHUDWLRQ ,QVWDOODWLRQ0DQXDO 1RWLFHVIRU,QVWDOODWLRQ ,QVWDOODWLRQ'UDZLQJ ,QVWDOO,QGRRU8QLW ,QVWDOO2XWGRRU8QLW &KHFNDIWHU,QVWDOODWLRQDQG2SHUDWLRQ7HVW ,QVWDOODWLRQDQG0DLQWHQDQFHRI+HDOWK\)LOWHU 7DEOHRI&RQWHQWV

([SORGHG9LHZVDQG3DUWV/LVW ,QGRRU8QLW 2XWGRRU8QLW 7URXEOHVKRRWLQJ 0DOIXQFWLRQ$QDO\VLV )ODVKLQJ/('RI,QGRRU2XWGRRU8QLWDQG3ULPDU\-XGJHPHQW +RZWR&KHFN6LPSO\WKH0DLQ3DUW 5HPRYDO3URFHGXUH 5HPRYDO3URFHGXUHRI,QGRRU8QLW 5HPRYDO3URFHGXUHRI2XWGRRU8QLW 6XPPDU\DQG)HDWXUHV

6XPPDU\DQG)HDWXUHV

,QGRRU8QLW

*:+0%.'1$.,

*:+0%.'1$.,

*:+0%.'1$.,

*:+0%.'1$.,

*:+0%.'1&.,

*:+0%.'1&.,

*:+0%.'1(.,

*:+0%.'1(.,

2XWGRRU8QLW

*:+0%.'1$.2

*:+0%.'1$.2

5HPRWH&RQWUROOHU

<%)$

MODE

ON /OFF

FA N

C LOCK

TIMER ON

X-F AN

T EMP

TIMER OF F

T URBO

SLEEP

LIGH T

6DIHW\3UHFDXWLRQV

6DIHW\3UHFDXWLRQV

,QVWDOOLQJVWDUWLQJXSDQGVHUYLFLQJDLUFRQGLWLRQHUFDQEH

KD]DUGRXVGXHWRV\VWHPSUHVVXUHHOHFWULFDOFRPSRQHQWVDQG

HTXLSPHQWORFDWLRQHWF

2QO\WUDLQHGTXDOL¿HGLQVWDOOHUVDQGVHUYLFHSHUVRQQHODUH

DOORZHGWRLQVWDOOVWDUWXSDQGVHUYLFHWKLVHTXLSPHQW

8QWUDLQHGSHUVRQQHOFDQSHUIRUPEDVLFPDLQWHQDQFHIXQFWLRQV

VXFKDVFOHDQLQJFRLOV$OORWKHURSHUDWLRQVVKRXOGEH

SHUIRUPHGE\WUDLQHGVHUYLFHSHUVRQQHO

:KHQKDQGOLQJWKHHTXLSPHQWREVHUYHSUHFDXWLRQVLQWKH

PDQXDODQGRQWDJVVWLFNHUVDQGODEHOVDWWDFKHGWRWKH

HTXLSPHQW)ROORZDOOVDIHW\FRGHV:HDUVDIHW\JODVVHVDQG

ZRUNJORYHV.HHSTXHQFKLQJFORWKDQG¿UHH[WLQJXLVKHUQHDUE\

ZKHQEUD]LQJ

5HDGWKHLQVWUXFWLRQVWKRURXJKO\DQGIROORZDOOZDUQLQJVRU

FDXWLRQVLQOLWHUDWXUHDQGDWWDFKHGWRWKHXQLW&RQVXOWORFDO

EXLOGLQJFRGHVDQGFXUUHQWHGLWLRQVRIQDWLRQDODVZHOODVORFDO

HOHFWULFDOFRGHV

5HFRJQL]HWKHIROORZLQJVDIHW\LQIRUPDWLRQ

:DUQLQJ ,QFRUUHFW KDQGOLQJ FRXOG UHVXOW LQ

SHUVRQDOLQMXU\RUGHDWK

&DXWLRQ ,QFRUUHFW KDQGOLQJ PD\ UHVXOW LQ

PLQRULQMXU\RUGDPDJHWRSURGXFW

RUSURSHUW\

Ɣ0DNHVXUHWKHRXWGRRUXQLWLVLQVWDOOHGRQDVWDEOHOHYHO

VXUIDFHZLWKQRDFFXPXODWLRQRIVQRZOHDYHVRUWUDVK

EHVLGH

Ɣ0DNHVXUHWKHFHLOLQJZDOOLVVWURQJHQRXJKWREHDUWKH

ZHLJKWRIWKHXQLW

Ɣ0DNHVXUHWKHQRLVHRIWKHRXWGRRUXQLWGRHVQRWGLVWXUE

QHLJKERUV

Ɣ)ROORZDOOWKHLQVWDOODWLRQLQVWUXFWLRQVWRPLQLPL]HWKHULVN

RIGDPDJHIURPHDUWKTXDNHVW\SKRRQVRUVWURQJZLQGV

Ɣ$YRLGFRQWDFWEHWZHHQUHIULJHUDQWDQG¿UHDVLWJHQHUDWHV

SRLVRQRXVJDV

Ɣ$SSO\VSHFL¿HGUHIULJHUDQWRQO\1HYHUKDYHLWPL[HGZLWK

DQ\RWKHUUHIULJHUDQW1HYHUKDYHDLUUHPDLQLQWKH

UHIULJHUDQWOLQHDVLWPD\OHDGWRUXSWXUHDQGRWKHUKD]DUGV

Ɣ0DNHVXUHQRUHIULJHUDQWJDVLVOHDNLQJRXWZKHQ

LQVWDOODWLRQLVFRPSOHWHG

Ɣ6KRXOGWKHUHEHUHIULJHUDQWOHDNDJHWKHGHQVLW\RI

UHIULJHUDQWLQWKHDLUVKDOOLQQRZD\H[FHHGLWVOLPLWHG

YDOXHRULWPD\OHDGWRH[SORVLRQ

Ɣ.HHS\RXU¿QJHUVDQGFORWKLQJDZD\IURPDQ\PRYLQJ

SDUWV

Ɣ&OHDUWKHVLWHDIWHULQVWDOODWLRQ0DNHVXUHQRIRUHLJQ

REMHFWVDUHOHIWLQWKHXQLW

Ɣ$OZD\VHQVXUHHIIHFWLYHJURXQGLQJIRUWKHXQLW

:DUQLQJ

$OOHOHFWULFZRUNPXVWEHSHUIRUPHGE\DOLFHQVHGWHFKQLFLDQ

DFFRUGLQJWRORFDOUHJXODWLRQVDQGWKHLQVWUXFWLRQVJLYHQLQWKLV

PDQXDO

Ɣ%HIRUHLQVWDOOLQJPRGLI\LQJRUVHUYLFLQJV\VWHPPDLQ

HOHFWULFDOGLVFRQQHFWVZLWFKPXVWEHLQWKH2))SRVLWLRQ

7KHUHPD\EHPRUHWKDQGLVFRQQHFWVZLWFK/RFNRXWDQG

WDJVZLWFKZLWKDVXLWDEOHZDUQLQJODEHO

Ɣ1HYHUVXSSO\SRZHUWRWKHXQLWXQOHVVDOOZLULQJDQGWXELQJ

DUHFRPSOHWHGUHFRQQHFWHGDQGFKHFNHG

Ɣ7KLVV\VWHPDGRSWVKLJKO\GDQJHURXVHOHFWULFDOYROWDJH

,QFRUUHFWFRQQHFWLRQRULQDGHTXDWHJURXQGLQJFDQFDXVH

SHUVRQDOLQMXU\RUGHDWK6WLFNWRWKHZLULQJGLDJUDPDQGDOO

WKHLQVWUXFWLRQVZKHQZLULQJ

Ɣ+DYHWKHXQLWDGHTXDWHO\JURXQGHGLQDFFRUGDQFHZLWK

ORFDOHOHFWULFDOFRGHV

Ɣ+DYHDOOZLULQJFRQQHFWHGWLJKWO\/RRVHFRQQHFWLRQPD\

OHDGWRRYHUKHDWLQJDQGDSRVVLEOH¿UHKD]DUG

$OOLQVWDOODWLRQRUUHSDLUZRUNVKDOOEHSHUIRUPHGE\\RXUGHDOHU

RUDVSHFLDOL]HGVXEFRQWUDFWRUDVWKHUHLVWKHULVNRI¿UHHOHFWULF

VKRFNH[SORVLRQRULQMXU\

&DXWLRQ

Ɣ1HYHULQVWDOOWKHXQLWLQDSODFHZKHUHDFRPEXVWLEOHJDV

PLJKWOHDNRULWPD\OHDGWR¿UHRUH[SORVLRQ

Ɣ0DNHDSURSHUSURYLVLRQDJDLQVWQRLVHZKHQWKHXQLWLV

LQVWDOOHGDWDWHOHFRPPXQLFDWLRQFHQWHURUKRVSLWDO

Ɣ3URYLGHDQHOHFWULFOHDNEUHDNHUZKHQLWLVLQVWDOOHGLQD

ZDWHU\SODFH

Ɣ1HYHUZDVKWKHXQLWZLWKZDWHU

Ɣ+DQGOHXQLWWUDQVSRUWDWLRQZLWKFDUH7KHXQLWVKRXOGQRWEH

FDUULHGE\RQO\RQHSHUVRQLILWLVPRUHWKDQNJ

Ɣ1HYHUWRXFKWKHKHDWH[FKDQJHU¿QVZLWKEDUHKDQGV

Ɣ1HYHUWRXFKWKHFRPSUHVVRURUUHIULJHUDQWSLSLQJZLWKRXW

ZHDULQJJORYH

Ɣ'RQRWKDYHWKHXQLWRSHUDWHZLWKRXWDLU¿OWHU

Ɣ6KRXOGDQ\HPHUJHQF\RFFXUVWRSWKHXQLWDQGGLVFRQQHFW

WKHSRZHULPPHGLDWHO\

Ɣ3URSHUO\LQVXODWHDQ\WXELQJUXQQLQJLQVLGHWKHURRPWR

SUHYHQWWKHZDWHUIURPGDPDJLQJWKHZDOO

6SHFL¿FDWLRQV

6SHFL¿FDWLRQV

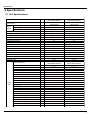

8QLW6SHFL¿FDWLRQV

Rated Voltage

V~

GWH09MB-K3DNA2K

GWH09MB-K3DNA3K

CB181005700

CB171007600

220-240

Rated Frequency

Hz

50

Model

Product Code

Power

Supply

Phases

Power Supply Mode

GWH12MB-K3DNA2K

GWH12MB-K3DNA3K

CB181005800

CB171007700

220-240

50

1

1

Indoor

Indoor

Cooling Capacity (Min~Max)

W

2700(600~3200)

3500(600~3900)

Heating Capacity (Min~Max)

W

2800(800~3600)

4000(880~4400)

Cooling Power Input (Min~Max)

W

870(185~1300)

1170(185~1400)

1200(250~1550)

Heating Power Input (Min~Max)

W

900(220~1400)

Cooling Power Current

A

3.8

5.2

Heating Power Current

A

3.92

5.3

Rated Input

W

1400

1600

Rated Current

A

6.69

7.8

Air Flow Volume(SH/H/M/L/SL)

3

600/500/400/300/-

580/500/400/300/-

Dehumidifying Volume

m /h

L/h

0.8

1.2

EER

W/W

3.10

2.99

COP

W/W

3.11

3.33

SEER

W/W

5.6

6.1

SCOP

W/W

3.8

4.0

m2

12-18

GWH09MB-K3DNA2K/I

GWH09MB-K3DNA3K/I

16-24

GWH12MB-K3DNA2K/I

GWH12MB-K3DNA3K/I

Application Area

Model of Indoor Unit

Fan Type

Diameter Length(DXL)

mm

Φ92X645

Φ92X645

Fan Motor Cooling Speed (SH/H/M/L/SL)

r/min

1260/1050/900/690/-

1290/1070/900/690/-

Fan Motor Heating Speed (SH/H/M/L/SL)

1280/1050/980/920/-

r/min

1320/1200/1000/910/-

Output of Fan Motor

W

20

20

Fan Motor RLA

A

0.1

0.1

Fan Motor Capacitor

μF

1.0

1.0

Input of Heater

W

-

-

Aluminum Fin-copper Tube

Aluminum Fin-copper Tube

Evaporator Form

Indoor

Unit

Pipe Diameter

Coil Length (LXDXW)

mm

Φ7

Φ7

mm

2-1.4

2-1.4

mm

636X25.4X267

636X25.4X267

MP24AA

MP24AA

Swing Motor Model

Output of Swing Motor

W

2

2

Fuse

A

3.15

3.15

Sound Pressure Level (SH/H/M/L/SL)

dB (A)

41/39/34/28/-

42/40/35/30/-

Sound Power Level (SH/H/M/L/SL)

dB (A)

54/50/45/40/-

54/51/45/42/-

mm

845X275X180

845X275X180

Dimension (WXHXD)

Dimension of Carton Box (LXWXH)

mm

915X255X355

915X255X355

Dimension of Package (LXWXH)

mm

918X258X370

918X258X370

Net Weight

kg

9

9

Gross Weight

kg

12

12

6SHFL¿FDWLRQV

Model of Outdoor Unit

GWH09MB-K3DNA3K/O

GWH12MB-K3DNA3K/O

ZHUHAI LANDA COMPRESSOR ZHUHAI LANDA COMPRESSOR

CO., LTD.

CO., LTD.

QXA-A091zE190A

QXA-A091zE190A

Compressor Manufacturer/Trademark

Compressor Model

Compressor Oil

Compressor Type

L.R.A.

A

FVC 68EP

FVC 68EP

Rotary

Rotary

16.5

16.5

Compressor RLA

A

4.9

4.9

Compressor Power Input

W

950

950

1NT11L-6233

1NT11L-6233

Overload Protector

Throttling Method

Electron expansion valve

Electron expansion valve

Operation temp

ºC

16~30

16~30

Ambient temp (Cooling)

ºC

-7~43

-7~43

Ambient temp (Heating)

ºC

Condenser Form

Pipe Diameter

mm

-7~24

-7~24

Aluminum Fin-copper Tube

Aluminum Fin-copper Tube

Φ7

Φ7

mm

1-1.4

2-1.4

Coil Length (LXDXW)

mm

710X19.05X508

695X38.1X506

Fan Motor Speed

rpm

900/650

900/650

Output of Fan Motor

Outdoor Fan Motor RLA

Unit

Fan Motor Capacitor

Air Flow Volume of Outdoor Unit

W

30

30

A

0.15

0.15

μF

-

-

3

m /h

1800

1800

mm

Φ400

Φ400

Automatic Defrosting

Automatic Defrosting

T1

T1

I

I

IP24

IP24

MPa

4.3

4.3

MPa

2.5

2.5

Fan Type

Fan Diameter

Defrosting Method

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating Pressure

for the Discharge Side

Permissible Excessive Operating Pressure

for the Suction Side

Sound Pressure Level (H/M/L)

dB (A)

51/-/-

53/-/-

Sound Power Level (H/M/L)

dB (A)

63/-/-

63/-/-

mm

776X540X320

776X540X320

Dimension (WXHXD)

Dimension of Carton Box (LXWXH)

mm

848X360X580

848X360X580

Dimension of Package (LXWXH)

mm

851X363X595

851X363X595

Net Weight

kg

28.0

29.0

Gross Weight

kg

Refrigerant

Refrigerant Charge

Length

Gas Additional Charge

Connectio Outer Diameter Liquid Pipe

n Pipe Outer Diameter Gas Pipe

kg

32.0

33.0

R410A

R410A

0.7

0.85

m

5

5

g/m

20

20

mm

Φ6

Φ6

Φ9.52

mm

Φ9.52

Max Distance Height

m

10

10

Max Distance Length

m

15

15

7KHDERYHGDWDLVVXEMHFWWRFKDQJHZLWKRXWQRWLFH3OHDVHUHIHUWRWKHQDPHSODWHRIWKHXQLW

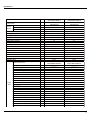

6SHFL¿FDWLRQV

Rated Voltage

V~

GWH09MB-K3DNC9K

GWH09MB-K3DNE1K

CB145003600

CB143001300

220-240

Rated Frequency

Hz

50

Model

Product Code

Power

Supply

Phases

Power Supply Mode

GWH12MB-K3DNC9K

GWH12MB-K3DNE1K

CB145003700

CB143001400

220-240

50

1

1

Indoor

Indoor

Cooling Capacity (Min~Max)

W

2700(600~3200)

3500(600~3900)

Heating Capacity (Min~Max)

W

2800(800~3600)

4000(880~4400)

Cooling Power Input (Min~Max)

W

870(185~1300)

1170(185~1400)

1200(250~1550)

Heating Power Input (Min~Max)

W

900(220~1400)

Cooling Power Current

A

3.8

5.2

Heating Power Current

A

3.92

5.3

Rated Input

W

1400

1600

Rated Current

A

6.69

7.8

Air Flow Volume(SH/H/M/L/SL)

3

600/500/400/300/-

580/500/400/300/-

Dehumidifying Volume

m /h

L/h

0.8

1.2

EER

W/W

3.10

2.99

COP

W/W

3.11

3.33

SEER

W/W

5.6

6.1

SCOP

W/W

3.8

4.0

m2

12-18

GWH09MB-K3DNC9K/I

GWH09MB-K3DNE1K/I

16-24

GWH12MB-K3DNC9K/I

GWH12MB-K3DNE1K/I

Application Area

Model of Indoor Unit

Fan Type

Diameter Length(DXL)

mm

Φ92X645

Φ92X645

Fan Motor Cooling Speed (SH/H/M/L/SL)

r/min

1260/1050/900/690/-

1290/1070/900/690/-

Fan Motor Heating Speed (SH/H/M/L/SL)

1280/1050/980/920/-

r/min

1320/1200/1000/910/-

Output of Fan Motor

W

20

20

Fan Motor RLA

A

0.1

0.1

Fan Motor Capacitor

μF

1.0

1.0

Input of Heater

W

-

-

Aluminum Fin-copper Tube

Aluminum Fin-copper Tube

Evaporator Form

Indoor

Unit

Pipe Diameter

Coil Length (LXDXW)

mm

Φ7

Φ7

mm

2-1.4

2-1.4

mm

636X25.4X267

636X25.4X267

MP24AA

MP24AA

Swing Motor Model

Output of Swing Motor

W

2

2

Fuse

A

3.15

3.15

Sound Pressure Level (SH/H/M/L/SL)

dB (A)

41/39/34/28/-

42/40/35/30/-

Sound Power Level (SH/H/M/L/SL)

dB (A)

54/50/45/40/-

54/51/45/42/-

mm

845X275X180

845X275X180

Dimension (WXHXD)

Dimension of Carton Box (LXWXH)

mm

915X255X355

915X255X355

Dimension of Package (LXWXH)

mm

918X258X370

918X258X370

Net Weight

kg

9

9

Gross Weight

kg

12

12

6SHFL¿FDWLRQV

Model of Outdoor Unit

GWH09MB-K3DNA3K/O

GWH12MB-K3DNA3K/O

ZHUHAI LANDA COMPRESSOR ZHUHAI LANDA COMPRESSOR

CO., LTD.

CO., LTD.

QXA-A091zE190A

QXA-A091zE190A

Compressor Manufacturer/Trademark

Compressor Model

Compressor Oil

Compressor Type

L.R.A.

A

FVC 68EP

FVC 68EP

Rotary

Rotary

16.5

16.5

Compressor RLA

A

4.9

4.9

Compressor Power Input

W

950

950

1NT11L-6233

1NT11L-6233

Overload Protector

Throttling Method

Electron expansion valve

Electron expansion valve

Operation temp

ºC

16~30

16~30

Ambient temp (Cooling)

ºC

-7~43

-7~43

Ambient temp (Heating)

ºC

Condenser Form

Pipe Diameter

mm

-7~24

-7~24

Aluminum Fin-copper Tube

Aluminum Fin-copper Tube

Φ7

Φ7

mm

1-1.4

2-1.4

Coil Length (LXDXW)

mm

710X19.05X508

695X38.1X506

Fan Motor Speed

rpm

900/650

900/650

Output of Fan Motor

Outdoor Fan Motor RLA

Unit

Fan Motor Capacitor

Air Flow Volume of Outdoor Unit

W

30

30

A

0.15

0.15

μF

-

-

3

m /h

1800

1800

mm

Φ400

Φ400

Automatic Defrosting

Automatic Defrosting

T1

T1

I

I

IP24

IP24

MPa

4.3

4.3

MPa

2.5

2.5

Fan Type

Fan Diameter

Defrosting Method

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating Pressure

for the Discharge Side

Permissible Excessive Operating Pressure

for the Suction Side

Sound Pressure Level (H/M/L)

dB (A)

51/-/-

53/-/-

Sound Power Level (H/M/L)

dB (A)

63/-/-

63/-/-

mm

776X540X320

776X540X320

Dimension (WXHXD)

Dimension of Carton Box (LXWXH)

mm

848X360X580

848X360X580

Dimension of Package (LXWXH)

mm

851X363X595

851X363X595

Net Weight

kg

28.0

29.0

Gross Weight

kg

Refrigerant

Refrigerant Charge

Length

Gas Additional Charge

Connectio Outer Diameter Liquid Pipe

n Pipe Outer Diameter Gas Pipe

kg

32.0

33.0

R410A

R410A

0.7

0.85

m

5

5

g/m

20

20

mm

Φ6

Φ6

Φ9.52

mm

Φ9.52

Max Distance Height

m

10

10

Max Distance Length

m

15

15

7KHDERYHGDWDLVVXEMHFWWRFKDQJHZLWKRXWQRWLFH3OHDVHUHIHUWRWKHQDPHSODWHRIWKHXQLW

6SHFL¿FDWLRQV

2SHUDWLRQ&KDUDFWHULVWLF&XUYH

Cooling

Heating

8

10

9

7

8

6

12K

12K

7

5

Current(A)

Current(A)

6

09K

5

4

3

Condition

Indoor:DB 27 WB19

Indoor air flow: Turbo

Pipe length:5m

Voltage:230V

2

09K

4

3

Condition

Indoor:DB 20

Indoor air flow:Turbo

Pipe length:5m

Voltage:230V

2

1

1

0

0

0

20

40

60

80

100

0

120

20

Compressor Speed(rps)

40

60

80

100

120

Compressor Speed(rps)

&DSDFLW\9DULDWLRQ5DWLR$FFRUGLQJWR7HPSHUDWXUH

Heating

110

120

100

100

90

80

Capacity ratio(%)

Capacity ratio(%)

Cooling

80

70

60

Condition

Indoor:DB27℃ WB19℃

Indoor air flow: Turbo

Pipe length:5m

50

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

Outdoor temp. (°C)

60

40

Condition

Indoor:DB20℃

Indoor air flow: Turbo

Pipe length:5m

20

0

-7

-5

0

5

10

Outdoor temp. (°C)

6SHFL¿FDWLRQV

1RLVH&ULWHULD&XUYH7DEOHVIRU%RWK0RGHOV

Indoor side noise when blowing

Outdoor side noise when Compressor speed changed

45

55

Noise/dB(A)

Noise/dB(A)

40

35

30

High

Middle

Low

12K

50

45

20

25

Supper High

09K

30

Indoor fan motor rotating speed

40

50

60

70 75

Compressor Speed(rps)

2SHUDWLRQ'DWD

&RROLQJ

7HPSHUDWXUH

FRQGLWLRQć 0RGHOQDPH

,QGRRU 2XWGRRU

.

.

6WDQGDUG

SUHVVXUH

303D

a

+HDWH[FKDQJHUSLSHWHPS

7&

WR

WR

7&

WR

WR

,QGRRUIDQ

PRGH

2XWGRRUIDQ &RPSUHVVRU

PRGHUSP UHYROXWLRQUSV

785%2

+HDWLQJ

7HPSHUDWXUH

FRQGLWLRQć 0RGHOQDPH

,QGRRU 2XWGRRU

.

.

6WDQGDUG

SUHVVXUH

303D

a

+HDWH[FKDQJHUSLSHWHPS

7&

WR

WR

7&

WR

WR

,QGRRUIDQ

PRGH

2XWGRRUIDQ &RPSUHVVRU

PRGHUSP UHYROXWLRQUSV

785%2

37KHDLUSLSHSUHVVXUHJDVYDOYHVLGHSUHVVXUHFRQQHFWWRLQGRRUDQGRXGRRUXQLW

7,QOHWDQGRXWOHWSLSHWHPSHUDWXUHRIHYDSRUDWRU

7,QOHWDQGRXWOHWSLSHWHPSHUDWXUHRIFRQGHQVHU

127(6

0HDVXUH VXUIDFH WHPSHUDWXUH RI KHDW H[FKDQJHU SLSH DURXQG FHQWHU RI KHDW H[FKDQJHU SDWK 8 EHQW

7KHUPLVWRUWKHPRPHWHU

&RQQHFWLQJSLSLQJFRQGLWLRQP

&RQVWUXFWLRQ9LHZV

&RQVWUXFWLRQ9LHZV

,QGRRU8QLW

Φ55

Φ55

143

80

2XWGRRU8QLW

714

320

776

286

540

257

510

8QLWPP

5HIULJHUDQW6\VWHP'LDJUDP

5HIULJHUDQW6\VWHP'LDJUDP

INDOOR UNIT

OUTDOOR UNIT

4-Way valve

HEAT

EXCHANGER

(EVAPORATOR)

Accumlator

Compressor

HEAT

EXCHANGER

(EVAPORATOR)

Strainer Electron expansion valve Strainer

COOLING

HEATING

5HIULJHUDQWSLSHGLDPHWHU

/LTXLGPP

*DVPP

6FKHPDWLF'LDJUDP

6FKHPDWLF'LDJUDP

(OHFWULFDO'DWD

0HDQLQJRIPDUNV

6\PERO

&RORU6\PERO

6\PERO

2*

25$1*(

:+

<(

5'

<(*1

%1

%8

%.

:+,7(

<(//2:

5('

<(//2:*5((1

%52:1

%/8(

%/$&.

3DUWV1DPH

3527(&7,9(($57+

&203

6$7

<9

;7

&2035(6625

29(5/2$'

:$<9$/9(

7(50,1$/%/2&.

(OHFWULFDO:LULQJ

Ɣ,QGRRU8QLW

TUBE

TEM.SENSOR

θ

θ

RT1

RT2

DISPLAY

L1

AP1

CN1 CN2

L1

N

ROOM

DISP-1 DISP-2

TUBE

COM-OUT

POWER

BN

YEGN

BU

XT1

W1BU

N(1)

W2BK

2

W3BN

CAP

AP2

AC-L

L-OUT

K4

JUMP

3

W4YEGN

L

N

BU

BK

BN

YEGN

OUTDOOR UNIT

ROOM

TEM.SENSOR

EVAPORATOR

PE

PGF PG

SWING-UD

HEALTH-LHEALTH-N

M

M

RD

BU

COOL PLASMA

GENERATOR

YEGN

FAN MOTOR

SWING MOTOR(U.D)

PE

6FKHPDWLF'LDJUDP

Ɣ2XWGRRU8QLW

TUBE OUTROOM EXHAUST

TEM.SENSOR TEM.SENSOR TEM.SENSOR

RT1 RT2 RT3

4YV

θ θ θ

YEGN

PE

I

N

D

O

O

R

U

N

I

T

BU

BK

BN

YEGN

XT

N(1)

2

3

PE

CN2

CN1

CN3

AP1

L1 BU

BK

L1 BN

EKV

L3

BU BN

LX1-1 LX1-2

CN1

AC-L2

4V

AC-L3

AP2

N

COM-OUT N1 BU

AC-L

L

AC-L1 BN

BN

AC-N1

AC-N2 BU

AC-N

AC-L

OFAN

OVC-COMP

U V W

PE

BU YE RD L4

MID.ISOLATION SHEET ELECTRIC BOX

PE

PE

L2

YEGN

SAT

RD

M

L2 L2

NOTE:

FAN

Motor ground only

BU YE RD

applies to the

YEGN

V

U

iron shell motor.

YEGN

W

COMP.

PE

E

COMP

7KHVHFLUFXLWGLDJUDPVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFHSOHDVHUHIHUWRWKHRQHVXSSOLHGZLWKWKHXQLW

6FKHPDWLF'LDJUDP

3ULQWHG&LUFXLW%RDUG

,QGRRU8QLW

TOP VIEW

Solid-state relay

Port of neutral wire

Auto button Feedback of indoor fan

Live wire of health function

Port of indoor fan

Port of motor for vertical swing

Port of motor for

horizontal swing

Protective

tube

Buzzer

Port of indoor ambient

temp sensor

Port of indoor pipe

temp sensor

Power of

switch

Port of display

High-frequency transformer

Communication port

Main chip

BOTTOM VIEW

6FKHPDWLF'LDJUDP

2XWGRRU8QLW

Ɣ7239,(:

inductance pin1

inductance pin2

fan neilsbed

four-way valve

compressor

electric heater

chassis

electric heater

10-core

communication cable

compressor

Ɣ%277209,(:

temp. sensor

overload protection

electric expansion valve

)XQFWLRQDQG&RQWURO

)XQFWLRQDQG&RQWURO

5HPRWH&RQWURO2SHUDWLRQV

1

ON/OFF

Press it to start or stop operation.

2

MODE

Press it to select operation mode (AUTO/COOL/DRY/FAN/HEAT).

3

+

Press it to increase temperature setting.

4

Press it to decrease temperature setting.

5

2

1

FAN

Press it to set fan speed.

6

3

4

6

5

11

12

13

TIMER ON

Press it to set auto-on timer.

7

9

10

Press it to set swing angle.

7

8

TIMER OFF

Press it to set auto-off timer.

8

9

14

CLOCK

Press it to set clock.

10

X-FAN(X-FAN is the alternative expression of BLOW for the purpose

of understanding.)

11

12

13

14

TEMP

TURBO

SLEEP

LIGHT

Press it to turn on/off the light.

25

24

23

22

21

15

16

20

17 18 19

15

MODE icon:

If MODE button is pressed, current operation mode icon

(AUTO),

( COOL),

(DRY),

(FAN) or

(HEAT is only for heat

pump models) will show.

16

SLEEP icon :

is displayed by pressing the SLEEP button. Press this button again to clear the display.

17

TEMP icon:

Pressing TEMP button,

(set temperature),

(indoor ambient temperature),

(outdoor ambient temperature) and blank is

displayed circularly.

18

Up & down swing icon:

is displayed when pressing the up & down swing button. Press this button again to clear the display.

)XQFWLRQDQG&RQWURO

19

LIGHT icon:

is displayed by pressing the LIGHT button.Press LIGHT button again to clear the display.

20

LOCK icon:

is displayed by pressing "+" and “-” buttons simultaneously.Press them again to clear the display.

21

SET TIME display:

After pressing TIMER button, ON or OFF will blink.This area will show the set time.

22

TURBO icon:

23

DIGITAL display:

is displayed when pressing theTURBO button.Press this button again to clear the display.

This area will show the set temperature. During defrosting operation, “H1” will be displayed.

24

X-FAN icon:

25

FAN SPEED display:

is displayed when pressing the X-FAN button. Press this button again to clear the display.

Press FAN button to select the desired fan speed setting(AUTO Low-Med-High).Your selection will be displayed in the LCD windows,

except the AUTO fan speed.

1

ON/OFF:

Press this button to turn on the unit. Press this button again to turn off the unit.

2

MODE:

Each time you press this button,a mode is selected in a sequence that goes from AUTO, COOL,DRY, FAN, and HEAT *, as the

following:

AUTO COOL DRY FAN

HEAT*

*Note: Only for models with heating function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on the LCD, and the unit will

automatically select the suitable operation mode in accordance with the room temperature to make indoor room comfortable.

3

+:

Press this button to increase set temperature. Hold it down for above 2 seconds to rapidly increase set temperature. In AUTO mode,

set temperature is not adjustable.

4

-:

Press this button to decrease set temperature. Hold it down for above . 2 seconds to rapidly decrease set temperature. In AUTO

mode, set temperature is not adjustable.

5

FAN :

This button is used for setting fan speed in the sequence that goes from AUTO,

,

,

to then back to Auto.

AUTO

Low speed

Medium speed

High speed

6

Press this button to set up & down swing angle, which circularly changes as below:

OFF

This remote controller is universal. If any command

indicates the guide louver swings as:

,

or

is sent out, the unit will carry out the command as

)XQFWLRQDQG&RQWURO

7

TIMER ON:

Press this button to initiate the auto-ON timer. To cancel the auto-timer program, simply press this button again. After pressing this

button,

disappears and "ON" blinks . 0 0:00 is displayed for ON time setting. Within 5 seconds, press + or - button to adjust the

time value. Every press of either button changes the time setting by 1 minute. Holding down either button rapidly changes the time

setting by 1 minute and then 10 minutes. Within 5 seconds after setting, press TIMER ON button to confirm.

8

TIMER OFF:

Press this button to initiate the auto-off timer. To cancel the auto-timer program, simply press the button again.TIMER OFF setting is

the same as TIMER ON.

9

CLOCK :

Pressing CLOCK button,

blinks. Within 5 seconds, pressing + or - button adjusts the present time. Holding down either button

above 2 seconds increases or decreases the time by 1 minute every 0.5 second and then by 10 minutes every 0.5 second. During

blinking after setting, press CLOCK button again to confirm the setting, and then

10

will be constantly displayed.

X-FAN:

Pressing X -FAN button in COOL or DRY mode,the icon

is displayed and the indoor fan will continue operation for 10 minutes in

order to dry the indoor unit even though you have turned off the unit.

After energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO, FAN or HEAT mode.

11

TEMP:

Press this button, could select displaying the indoor setting temperature or indoor ambient temperature.When the indoor unit firstly

power on it will display the setting temperature, if the temperature's displaying status is changed from other status to"

",displays

the ambient temperature, 5s later or within 5s, it receives other remote control signal that will return to display the setting temperature. if the users haven't set up the temperature displaying status,that will display the setting temperature.

12

TURBO:

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in the shortest

time. In COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the unit will blow strong heating air

at super high fan speed.

13

SLEEP:

Press this button to go into the SLEEP operation mode. Press it again to cancel this function. This function is available in COOL,

HEAT (Only for models with heating function) or DRY mode to maintain the most comfortable temperature for you.

14

LIGHT:

Press LIGHT button to turn on the display's light and press this button again to turn off the display's light. If the light is turned on ,

is displayed. If the light is tunrned off,

disappears.

15 Combination of "+" and "-" buttons: About lock

Press "+ " and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked,

case, pressing any button,

is displayed. In this

blinks three times.

16 Combination of "MODE" and "-" buttons:About switch between Fahrenheit and Centigrade At unit OFF, press "MODE" and "- "

buttons simultaneously to switch between ℃ and ℉.

Replacement of Batteries

1.Remove the battery cover plate from the rear of the remote controller.

(As shown in the figure)

2.Take out the old batteries.

3.Insert two new AAA1.5V dry batteries, and pay attention to the polarity.

4. Reinstall the battery cover plate.

★Notes:

●When replacing the batteries, do not use old or different types of batteries.

Otherwise, it may cause malfunction.

●If the remote controller will not be used for a long time,

please remove batteries to prevent batteries from leaking.

●The operation should be performed in its receiving range.

●It should be kept 1m away from the TV set or stereo sound sets.

●If the remote controller does not operate normally, please take the

Sketch map for

replacing batteries

batteries out and reinsert them after 30 seconds. If it still can't operate

properly, replace the batteries.

)XQFWLRQDQG&RQWURO

'HVFULSWLRQRI(DFK&RQWURO2SHUDWLRQ

1. Temperature Parameters

Indoor preset temperature (Tpreset)

Indoor ambient temperature (T amb.)

2. Basic Functions

Once energized, in no case should the compressor be restarted within less than 3 minutes. In the situation that memory

function is available, for the first energization, if the compressor is at stop before de-energization, the compressor will be

started without a 3-minute lag; if the compressor is in operation before de-energization, the compressor will be started with

a 3-minute lag; and once started, the compressor will not be stopped within 6 minutes regardless of changes in room

temperature;

(1)COOL mode

The condition and process of cooling

If Tamb. ≥Tpreset COOL mode will act, the compressor and outdoor fan will run, and the indoor fan will run at the set speed.

If Tamb. ≤Tpreset-2 , the compressor will stop, the outdoor fan will delay 30 seconds to stop, and the indoor fan will run at the set speed.

If Tpreset-2

≤Tamb ≤Tpreset , the unit will keep running in the previous mode.

In this mode, the reversal valve will not be powered on and the temperature setting range is 16

~30 .

Start cooling

Tamb.

Tpreset

Original operating status

Tpreset –2 ˚C

≥ 6 min.

≥ 3 min.

≥ 6 min.

Stop cooling

Compressor

Outdoor fan

Setting fan speed

Indoor fan

Run

Protection function

Overcurrent protection

Stop

If total current is high, the compressor will run in limited frequency. If total current is too high, the compressor will stop, the

outdoor fan will delay 30 seconds to stop, indoor unit will display E5 and outdoor yellow light will blink 5 times.

Antifreezing protection

When the antifreezing protection is detected, the compressor will stop, the outdoor fan will stop after 30 seconds, and the

indoor fan and swing motor will keep running in the original mode. When antifreezing protection is eliminated and the

compressor has stopped for 3 minutes, the compressor will resume running in the original mode.

During antifreeze protection

min

Compressor

Outdoor fan

Preset speed

Indoor fan

Run

Stop

(2) Dehumidifying Mode

Working conditions and process of dehumidifying

If T amb. T preset, the unit will enter cooling and dehumidifying mode, in which case the compressor and the outdoor fan will

operate and the indoor fan will run at low speed.

If T preset -2

T amb. T preset, the compressor remains at its original operation state.

If T amb.< T preset -2 , the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will

operate at low speed.

Protection

Protection is the same as that under the cooling mode.

)XQFWLRQDQG&RQWURO

+($70RGH

ķ :RUNLQJFRQGLWLRQVDQGSURFHVVRIKHDWLQJ

,I7DPE7SUHVHW&WKHXQLWHQWHUVKHDWLQJPRGHLQZKLFKFDVHWKHIRXUZD\YDOYHWKHFRPSUHVVRUDQGWKHRXWGRRUIDQZLOO

RSHUDWHVLPXOWDQHRXVO\DQGWKHLQGRRUIDQZLOOUXQDWSUHVHWVSHHGLQWKHFRQGLWLRQRISUHVHWFROGDLUSUHYHQWLRQ

,I7DPE7SUHVHW&WKHFRPSUHVVRUZLOOVWRSWKHRXWGRRUIDQZLOOVWRSZLWKDWLPHODJRIVDQGWKHLQGRRUIDQZLOOVWRSDIWHU

VHFRQGEORZDWORZVSHHG

,I7SUHVHW&7DPE7SUHVHW&WKHXQLWZLOOPDLQWDLQLWVRULJLQDORSHUDWLQJVWDWXV

8QGHUWKLVPRGHWKHIRXUZD\YDOYHLVHQHUJL]HGDQGWHPSHUDWXUHFDQEHVHWZLWKLQDUDQJHRI&7KHRSHUDWLQJV\PEROWKH

KHDWLQJV\PERODQGSUHVHWWHPSHUDWXUHDUHUHYHDOHGRQWKHGLVSOD\

ĸ &RQGLWLRQDQGSURFHVVRIGHIURVW

:KHQGXUDWLRQRIVXFFHVVLYHKHDWLQJRSHUDWLRQLVPRUHWKDQPLQXWHVRUDFFXPXODWHGKHDWLQJWLPHPRUHWKDQPLQXWHVDQG

RQHRIWKHIROORZLQJFRQGLWLRQVLVUHDFKHGWKHXQLWZLOOHQWHUWKHGHIURVWPRGHDIWHUPLQXWHV

7RXWGRRUDPELHQW ˚ &7RXWGRRUWXEH&

&7RXWGRRUDPELHQW ˘ &7RXWGRRUWXEH&

&7RXWGRRUDPELHQW ˘ &7RXWGRRUWXEH&

&7RXWGRRUDPELHQW ˘ &7RXWGRRUWXEH7FRPSHQVDWRU\7RXWGRRUDPELHQW&

7RXWGRRUDPELHQW ˘ &7RXWGRRUWXEH7FRPSHQVDWRU\7RXWGRRUDPELHQW&

DIWHU HQHUJL]LQJ7 FRPSHQVDWRU\ & GXULQJ WKH ILUVW GHIURVWLQJ LI LW LV QRW WKH ILUVW GHIURVWLQJ7 FRPSHQVDWRU\ LV FRQILUPHG E\

7RXWGRRUWXEHRITXLWWLQJODVWGHIURVWLQJDZKHQ7RXWGRRUWXEH ˚ &7FRPSHQVDWRU\ &EZKHQ7RXWGRRUWXEH&7

FRPSHQVDWRU\ &

$WWKDWWLPHWKHLQGRRUIDQVWRSVDQGWKHFRPSUHVVRUVWRSVDQGDIWHUVHFRQGVWKHRXWHUIDQZLOOVWRSDQGWKHQDIWHUVHFRQGV

WKHIRXUZD\YDOYHZLOOVWRS$IWHUVHFRQGVWKHFRPSUHVVRULVLQLWLDWHGIRUUDLVLQJWKHIUHTXHQF\WRGHIURVWIUHTXHQF\

:KHQ WKH FRPSUHVVRU KDV RSHUDWHG XQGHU GHIURVW PRGH IRU PLQXWHV RU7 RXWGRRU DPELHQW ı & WKH FRPSUHVVRU ZLOO EH

FRQYHUWHG WR +] RSHUDWLRQ$IWHU VHFRQGV WKH FRPSUHVVRU ZLOO VWRS$QG DIWHU DQRWKHU VHFRQGV WKH IRXUZD\ YDOYH ZLOO

EH RSHQHG DQG DIWHU VHFRQGV WKH FRPSUHVVRU DQG WKH RXWHU IDQ ZLOO EH VWDUWHG WKH LQGRRU IDQ ZLOO UXQ XQGHU SUHVHW FROG DLU

SUHYHQWLRQFRQGLWLRQVDQG+ZLOOEHGLVSOD\HGDWWHPSHUDWXUHGLVSOD\DUHDRQWKHGLVSOD\SDQHO'HIURVWIUHTXHQF\LV+]

Ĺ 3URWHFWLRQ

ƹ &ROGDLUSUHYHQWLRQ

7KHXQLWLVVWDUWHGXQGHUKHDWLQJPRGHWKHFRPSUHVVRULV21

ķ ,QWKHFDVHRI7LQGRRUDPE&LI7WXEH&DQGWKHLQGRRUIDQLVDWVWRSVWDWHWKHLQGRRUIDQZLOOEHJLQWRUXQDWORZVSHHG

ZLWKDWLPHODJRIPLQXWHV:LWKLQPLQXWHVLI7WXEH!&WKHLQGRRUIDQDOVRZLOOUXQDWORZVSHHGDQGDIWHUPLQXWHRSHUDWLRQ

DWORZVSHHGWKHLQGRRUIDQZLOOEHFRQYHUWHGWRRSHUDWLRQDWSUHVHWVSHHG:LWKLQPLQXWHORZVSHHGRSHUDWLRQRUPLQXWHQRQ

RSHUDWLRQLI7WXEH!&WKHIDQZLOOUXQDWSUHVHQWVSHHG

ĸ ,QWKHFDVHRI7LQGRRUDPE&LI7WXEH&WKHLQGRRUIDQZLOOUXQDWORZVSHHGDQGDIWHURQHPLQXWHWKHLQGRRUIDQZLOO

EHFRQYHUWHGWRSUHVHWVSHHG:LWKLQRQHPLQXWHORZVSHHGRSHUDWLRQLI7WXEH!&WKHLQGRRUIDQZLOOEHFRQYHUWHGWRSUHVHW

VSHHG

1RWH7LQGRRUDPELQGLFDWHGLQ

ķ DQG

ĸ UHIHUVWRXQGHULQLWLDOO\KHDWLQJPRGHWKHLQGRRUDPELHQWWHPSHUDWXUHEHIRUHWKH

FRPPDQG WR VWDUW WKH FRPSUHVVRU LV SHUIRUPHG DFFRUGLQJ WR WKH SURJUDP RU DIWHU WKH XQLW LV ZLWKGUDZQ IURP GHIURVW WKH LQGRRU

DPELHQWWHPSHUDWXUHEHIRUHWKHGHIURVWV\PEROLVFOHDUHG

ƹ 7RWDOFXUUHQWXSDQGIUHTXHQF\GRZQSURWHFWLRQ

,IWKHWRWDOFXUUHQW,WRWDO$IUHTXHQF\ULVHZLOOEHDOORZHGLI,WRWDO$IUHTXHQF\ULVHZLOOQRWEHDOORZHGLI,WRWDO$WKHFRPSUHVVRU

ZLOOUXQDWUHGXFHGIUHTXHQF\DQGLI,WRWDO$WKHFRPSUHVVRUZLOOVWRSDQGWKHRXWGRRUIDQZLOOVWRSZLWKDWLPHODJRIV

)DQ0RGH

8QGHUWKHPRGHWKHLQGRRUIDQZLOOUXQDWSUHVHWVSHHGDQGWKHFRPSUHVVRUWKHRXWGRRUIDQWKHIRXUZD\YDOYHDQGWKHHOHFWULF

KHDWHUZLOOVWRS

8QGHUWKHPRGHWHPSHUDWXUHFDQEHVHWZLWKLQDUDQJHRI&

$8720RGH

ķ :RUNLQJFRQGLWLRQVDQGSURFHVVRI$872PRGH

D:KHQ7DPELHQW&WKHXQLWZLOORSHUDWHLQ&RROPRGH7KHVHWWHPSHUDWXUHLV&

E:KHQ7DPELHQW&WKHKHDWSXPSXQLWZLOORSHUDWHLQ+HDWPRGHVHWWHPSHUDWXUHEH&WKHFRROLQJRQO\XQLWZLOORSHUDWH

LQ)DQPRGHVHWWHPSHUDWXUHEH&

F:KHQ&7DPELHQW&WKHXQLWZLOORSHUDWHLQWKHSUHYLRXVVWDWH,ILWLVHQHUJL]HGIRUWKH¿UVWWLPHLWZLOORSHUDWHLQ)DQ

PRGH

G8QGHUDXWRPRGHLILWVFRROLQJPRGHRSHUDWLRQIUHTXHQF\LVVDPHDVWKDWXQGHUFRROLQJPRGHLILWVKHDWLQJPRGHRSHUDWLRQ

IUHTXHQF\LVVDPHDVWKDWXQGHUKHDWLQJPRGH

)XQFWLRQDQG&RQWURO

ĸ 3URWHFWLRQ

D,QFRROLQJRSHUDWLRQSURWHFWLRQLVWKHVDPHDVWKDWXQGHUWKHFRROLQJPRGH

E,QKHDWLQJRSHUDWLRQSURWHFWLRQLVWKHVDPHDVWKDWXQGHUWKHKHDWLQJPRGH

F:KHQDPELHQWWHPSHUDWXUHFKDQJHVRSHUDWLRQPRGHZLOOEHFRQYHUWHGSUHIHUHQWLDOO\2QFHVWDUWHGWKHFRPSUHVVRUZLOO

UHPDLQXQFKDQJHGIRUDWOHDVWPLQXWHV

&RPPRQ3URWHFWLRQ)XQFWLRQVDQG)DXOW'LVSOD\XQGHU&22/+($7'5<DQG$8720RGHV

ķ 2YHUORDGSURWHFWLRQ

7WXEHPHDVXUHGWHPSHUDWXUHRIRXWGRRUKHDWH[FKDQJHUXQGHUFRROLQJPRGHDQGPHDVXUHGWHPSHUDWXUHRILQGRRUKHDWH[FKDQJHU

XQGHUKHDWLQJPRGH

&RROLQJRYHUORDG

D,I7WXEH&WKHXQLWZLOOUHWXUQWRLWVRULJLQDORSHUDWLRQVWDWH

E,I7WXEH&IUHTXHQF\ULVHLVQRWDOORZHG

F,I7WXEH&WKHFRPSUHVVRUZLOOUXQDWUHGXFHGIUHTXHQF\

G,I7WXEH&WKHFRPSUHVVRUZLOOVWRSDQGWKHLQGRRUIDQZLOOUXQDWSUHVHWVSHHG

+HDWLQJRYHUORDG

D,I7WXEH&WKHXQLWZLOOUHWXUQWRLWVRULJLQDORSHUDWLRQVWDWH

E,I7WXEH&IUHTXHQF\ULVHLVQRWDOORZHG

F,I7WXEH&WKHFRPSUHVVRUZLOOUXQDWUHGXFHGIUHTXHQF\

G,I7WXEH&WKHFRPSUHVVRUZLOOVWRSDQGWKHLQGRRUIDQZLOOEORZUHVLGXHKHDWDQGWKHQVWRS

ĸ ([KDXVWWHPSHUDWXUHSURWHFWLRQRIFRPSUHVVRU

,IH[KDXVWWHPSHUDWXUH&IUHTXHQF\LVQRWDOORZHGWRULVH

,IH[KDXVWWHPSHUDWXUH&WKHFRPSUHVVRUZLOOUXQDWUHGXFHGIUHTXHQF\

,IH[KDXVWWHPSHUDWXUH&WKHFRPSUHVVRUZLOOVWRS

,IH[KDXVWWHPSHUDWXUH&DQGWKHFRPSUHVVRUKDVVWD\HGDWVWRSIRUDWOHDVWPLQXWHVWKHFRPSUHVVRUZLOOUHVXPHLWVRSHUDWLRQ

Ĺ &RPPXQLFDWLRQIDXOW

,IWKHXQLWIDLOVWRUHFHLYHFRUUHFWVLJQDOVIRUGXUDWLYHPLQXWHVFRPPXQLFDWLRQIDXOWFDQEHMXVWL¿HGDQGWKHZKROHV\VWHPZLOOVWRS

ĺ 0RGXOHSURWHFWLRQ

8QGHU PRGXOH SURWHFWLRQ PRGH WKH FRPSUHVVRU ZLOO VWRS :KHQ WKH FRPSUHVVRU UHPDLQV DW VWRS IRU DW OHDVW PLQXWHV WKH

FRPSUHVVRUZLOOUHVXPHLWVRSHUDWLRQ,IPRGXOHSURWHFWLRQRFFXUVVL[WLPHVLQVXFFHVVLRQWKHFRPSUHVVRUZLOOQRWEHVWDUWHGDJDLQ

Ļ 2YHUORDGSURWHFWLRQ

,IWHPSHUDWXUHVHQVHGE\WKHRYHUORDGVHQVRULVRYHU&WKHFRPSUHVVRUZLOOVWRSDQGWKHRXWGRRUIDQZLOOVWRSZLWKDWLPHODJRI

VHFRQGV,IWHPSHUDWXUHLVEHORZ&WKHRYHUORDGSURWHFWLRQZLOOEHUHOLHYHG&

ļ '&EXVYROWDJHSURWHFWLRQ

,IYROWDJHRQWKH'&EXVLVEHORZ9RURYHU9WKHFRPSUHVVRUZLOOVWRSDQGWKHRXWGRRUIDQZLOOVWRSZLWKDWLPHODJRI

VHFRQGV:KHQYROWDJHRQWKH'&EXVUHWXUQVWRLWVQRUPDOYDOXHDQGWKHFRPSUHVVRUKDVVWD\HGDWVWRSIRUDWOHDVWPLQXWHVWKH

FRPSUHVVRUZLOOUHVXPHLWVRSHUDWLRQ

Ľ )DXOWVRIWHPSHUDWXUHVHQVRUV

2WKHU&RQWUROV

212))

3UHVVWKHUHPRWHEXWWRQ212))WKHRQRIIVWDWHZLOOEHFKDQJHGRQFHHDFKWLPH\RXSUHVVWKHEXWWRQ

0RGH6HOHFWLRQ

3UHVVWKHUHPRWHEXWWRQ02'(WKHQVHOHFWDQGVKRZLQWKHIROORZLQJZD\V$872&22/'5<)$1+($7$872

7HPSHUDWXUH6HWWLQJ2SWLRQ%XWWRQ

(DFKWLPH\RXSUHVVWKHUHPRWHEXWWRQ7(03RU7(03WKHVHWWLQJWHPSHUDWXUHZLOOEHXSRUGRZQE\&5HJXODWLQJ

5DQJHa&WKHEXWWRQLVXVHOHVVXQGHUWKH$872PRGH

7LPH6ZLWFK

<RXVKRXOGVWDUWDQGVWRSWKHPDFKLQHDFFRUGLQJWRWKHVHWWLQJWLPHE\UHPRWHFRQWURO

6/((36WDWH&RQWURO

,QFRROLQJPRGH

:KHQWKHLQLWLDOVHWWHPSHUDWXUHLV&WKHWHPSHUDWXUHZLOOULVH&E\HYHU\KRXUDIWHUVOHHSIXQFWLRQLVVHWWKHWHPSHUDWXUH

ZLOOQRWFKDQJHDIWHUULVLQJ&DIWHUUXQQLQJIRUKRXUVWKHWHPSHUDWXUHZLOOGHFUHDVH&DQGLWZLOOQRWFKDQJHDIWHUWKDW

)XQFWLRQDQG&RQWURO

:KHQWKHLQLWLDOVHWWHPSHUDWXUHLV&WKHWHPSHUDWXUHZLOOULVH&E\HYHU\KRXUDIWHUVOHHSIXQFWLRQLVVHWWKHWHPSHUDWXUH

ZLOOQRWFKDQJHDIWHUULVLQJ&DIWHUUXQQLQJIRUKRXUVWKHWHPSHUDWXUHZLOOGHFUHDVH&DQGLWZLOOQRWFKDQJHDIWHUWKDW

:KHQWKHLQLWLDOVHWWHPSHUDWXUHLV&WKHWHPSHUDWXUHZLOOULVH&E\HYHU\KRXUDIWHUVOHHSIXQFWLRQLVVHWWKHWHPSHUDWXUH

ZLOOQRWFKDQJHDIWHUULVLQJ&DIWHUUXQQLQJIRUKRXUVWKHWHPSHUDWXUHZLOOGHFUHDVH&DQGLWZLOOQRWFKDQJHDIWHUWKDW

:KHQ WKH LQLWLDO VHW WHPSHUDWXUH LV & WKH XQLW ZLOO NHHS RQ UXQQLQJ DW WKLV WHPSHUDWXUH DIWHU UXQQLQJ IRU KRXUV WKH

WHPSHUDWXUHZLOOGHFUHDVH&DQGLWZLOOQRWFKDQJHDIWHUWKDW

5HODWLRQVKLSEHWZHHQVHWWHPSHUDWXUHDQGUXQQLQJWLPH

,QLWLDO7HPS

VWDUW

5XQQLQJWLPH7

,QKHDWLQJPRGH

:KHQWKHLQLWLDOVHWWHPSHUDWXUHLV&WKHXQLWZLOONHHSRQUXQQLQJDWWKLVWHPSHUDWXUH

:KHQWKHLQLWLDOVHWWHPSHUDWXUHLV&WKHWHPSHUDWXUHZLOOGHFUHDVH&E\HYHU\KRXUDIWHUVOHHSIXQFWLRQLVVHWWKH

WHPSHUDWXUHZLOOQRWFKDQJHDIWHUGHFUHDVLQJ&

:KHQWKHLQLWLDOVHWWHPSHUDWXUHLV&WKHWHPSHUDWXUHZLOOGHFUHDVH&E\HYHU\KRXUDIWHUVOHHSIXQFWLRQLVVHWWKH

WHPSHUDWXUHZLOOQRWFKDQJHDIWHUGHFUHDVLQJ&

:KHQWKHLQLWLDOVHWWHPSHUDWXUHLV&WKHWHPSHUDWXUHZLOOGHFUHDVH&E\HYHU\KRXUDIWHUVOHHSIXQFWLRQLVVHWWKH

WHPSHUDWXUHZLOOQRWFKDQJHDIWHUGHFUHDVLQJ&

5HODWLRQVKLSEHWZHHQVHWWHPSHUDWXUHDQGUXQQLQJWLPH

,QLWLDO7HPS

VWDUW

5XQQLQJWLPH7

,QGRRU)DQ&RQWURO

7KH,QGRRU)DQFDQEHVHWDV+,*+0('/2:E\UHPRWHFRQWURODQGWKH,QGRRU)DQZLOOEHUHVSHFWLYHO\UXQDWKLJKPHGLXPORZ

VSHHG,WZLOODOVREHVHWDV$872DQGWKH,QGRRU)DQLVDVWKHIROORZLQJVDWWKHDXWRPDWLFZLQGVSHHG

)XQFWLRQDQG&RQWURO

ķ &RROLQJPRGHLQDXWRFRROLQJPRGHRUQRUPDOFRROLQJPRGHWKHDXWRIDQVSHHGZLOOUXQDWEHORZPRGH

D:KHQ7DPE7SUHVHW&WKHLQGRRUIDQZLOOUXQDWKLJKVSHHG

E:KHQ7SUHVHW7DPE7SUHVHW&WKHLQGRRUIDQZLOOUXQDWPLGGOHVSHHG

F7DPE7SUHVHWWKHLQGRRUIDQZLOOUXQDWORZVSHHG

6ZLWFKHV EHWZHHQ KLJK VSHHG DQG PLGGOH VSHHG PLGGOH VSHHG DQG ORZ VSHHG KLJK VSHHG DQG ORZ VSHHG UXQQLQJ WLPH RI PLQXWHVPXVWEHHQVXUHG

ĸ +HDWLQJPRGHLQDXWRKHDWLQJPRGHRUQRUPDOKHDWLQJPRGHWKHDXWRIDQVSHHGZLOOUXQDWEHORZPRGH

D:KHQ7DPE7SUHVHW&WKHLQGRRUIDQZLOOUXQDWKLJKVSHHG

E:KHQ7SUHVHW&7DPE7SUHVHW&WKHLQGRRUIDQZLOOUXQDWPLGGOHVSHHG

F7DPE7SUHVHW&WKHLQGRRUIDQZLOOUXQDWORZVSHHG

6ZLWFKHV EHWZHHQ KLJK VSHHG DQG PLGGOH VSHHG PLGGOH VSHHG DQG ORZ VSHHG KLJK VSHHG DQG ORZ VSHHG UXQQLQJ WLPH RI PLQXWHVPXVWEHHQVXUHG

)DQPRGHLVWKHVDPHDVFRROLQJPRGH

%X]]HU&RQWURO

7KHEX]]HUZLOOVHQGD³'L´VRXQGZKHQWKHDLUFRQGLWLRQHULVSRZHUHGXSRUUHFHLYHGWKHLQIRUPDWLRQVHQWE\WKHUHPRWHFRQWURORU

WKHUHLVDEXWWRQLQSXWWKHVLQJOHWXEHFRROHUGRHVQWUHFHLYHWKHUHPRWHFRQWURO21VLJQDOXQGHUWKHPRGHRIKHDWLQJPRGH

$XWREXWWRQ

,IWKHFRQWUROOHULVRQLWZLOOVWRSE\SUHVVLQJWKHEXWWRQDQGLIWKHFRQWUROOHULVRIILWZLOOEHDXWRPDWLFUXQQLQJVWDWHE\SUHVVLQJWKH

EXWWRQVZLQJRQDQGOLJKWRQDQGWKHPDLQXQLWZLOOUXQEDVHGRQWKHUHPRWHFRQWUROLIWKHUHLVUHPRWHFRQWURORUGHU

8SDQG'RZQ6ZLQJLQJ&RQWURO

:KHQSRZHURQWKHXSDQGGRZQPRWRUZLOO¿UVWO\PRYHWKHDLUGHÀHFWRUWRFRXQWHUFORFNZLVHFORVHWKHDLURXWOHW$IWHUVWDUWLQJWKH

PDFKLQHLI\RXGRQWVHWWKHVZLQJLQJIXQFWLRQKHDWLQJPRGHDQGDXWRKHDWLQJPRGHWKHXSDQGGRZQDLUGHÀHFWRUZLOOPRYHWR

'FORFNZLVHXQGHURWKHUPRGHVWKHXSDQGGRZQDLUGHÀHFWRUZLOOPRYHWR/,I\RXVHWWKHVZLQJLQJIXQFWLRQZKHQ\RXVWDUWWKH

PDFKLQHWKHQWKHZLQGEODGHZLOOVZLQJEHWZHHQ/DQG'7KHDLUGHÀHFWRUKDVVZLQJLQJVWDWHV/RFDWLRQ//RFDWLRQ$/RFDWLRQ

%/RFDWLRQ&/RFDWLRQ'/RFDWLRQ/WR/RFDWLRQ'VWRSDWDQ\ORFDWLRQEHWZHHQ/'WKHLQFOXGHGDQJOHEHWZHHQ/a'LVWKHVDPH

7KHDLUGHÀHFWRUZLOOEHFORVHGDW/RFDWLRQDQGWKHVZLQJLQJLVHIIHFWXDORQO\RQFRQGLWLRQWKDWVHWWLQJWKHVZLQJLQJRUGHUDQGWKH

LQQHUIDQLVUXQQLQJ7KHLQGRRUIDQDQGFRPSUHVVRUPD\JHWWKHSRZHUZKHQDLUGHÀHFWRULVRQWKHGHIDXOWORFDWLRQ

heating angle

O(0 )

R

cooling angle

R

O(0 )

L

A

B

C

L1

A1

B1

C1

D1

D

'LVSOD\

ķ 2SHUDWLRQSDWWHUQDQGPRGHSDWWHUQGLVSOD\

$OOWKHGLVSOD\SDWWHUQVZLOOGLVSOD\IRUDWLPHZKHQWKHSRZHURQWKHRSHUDWLRQLQGLFDWLRQSDWWHUQZLOOGLVSOD\LQUHGXQGHUVWDQGE\

VWDWXV:KHQWKHPDFKLQHLVVWDUWE\UHPRWHFRQWUROWKHLQGLFDWLRQSDWWHUQZLOOOLJKWDQGGLVSOD\WKHFXUUHQWRSHUDWLRQPRGHWKHPRGH

OLJKWLQFOXGHV&RROLQJKHDWLQJDQGGHKXPLGLI\,I\RXFORVHWKHOLJKWNH\DOOWKHGLVSOD\SDWWHUQVZLOOFORVH

ĸ'RXEOHGLVSOD\

$FFRUGLQJWRWKHGLIIHUHQWVHWWLQJRIUHPRWHFRQWUROWKHQL[LHOLJKWPD\GLVSOD\WKHFXUUHQWWHPSHUDWXUHWKHWHPSHUDWXUHVFRSHLVIURP

&WR&DQGLQGRRUDPELHQWWHPSHUDWXUH7KHVHWWHPSHUDWXUHGLVSOD\HGLQDXWRFRROLQJDQGIDQPRGHLV&DQGWKHVHW

WHPSHUDWXUHGLVSOD\HGLQDXWRKHDWLQJPRGHLV&8QGHUKHDWLQJPRGHQL[LHWXEHGLVSOD\V+RUKHDWLQJLQGLFDWRULVRIIVDQG

EOLQNVVLQGHIURVWLQJ,I\RXVHWWKHIDKUHQKHLWWHPSHUDWXUHGLVSOD\WKHQL[LHOLJKWZLOOGLVSOD\DFFRUGLQJWRIDKUHQKHLWWHPSHUDWXUH

3URWHFWLRQIXQFWLRQDQGIDLOXUHGLVSOD\

()UHH]HSURR¿QJSURWHFWLRQ(([KDXVWLQJSURWHFWLRQ(2YHUFXUUHQWSURWHFWLRQ

(&RPPXQLFDWLRQIDLOXUH+2YHUORDGSURWHFWLRQ

),QGRRUDPELHQWVHQVRUVWDUWDQGVKRUWFLUFXLWFRQWLQXRXVO\PHDVXUHGIDLOXUHLQ6

)XQFWLRQDQG&RQWURO

),QGRRUHYDSRUDWRUVHQVRUVWDUWDQGVKRUWFLUFXLWFRQWLQXRXVO\PHDVXUHGIDLOXUHLQ6

)2XWGRRUDPELHQWVHQVRUVWDUWDQGVKRUWFLUFXLWFRQWLQXRXVO\PHDVXUHGIDLOXUHLQ6

)2XWGRRUFRQGHQVHUVHQVRUVWDUWDQGVKRUWFLUFXLWFRQWLQXRXVO\PHDVXUHGIDLOXUHLQ6DQGGRQWPHDVXUHZLWKLQPLQXWHV

DIWHUGHIURVWHG

)2XWGRRUH[KDXVWLQJVHQVRUVWDUWDQGVKRUWFLUFXLWFRQWLQXRXVO\PHDVXUHGIDLOXUHLQ6DIWHUWKHFRPSUHVVRURSHUDWHGPLQXWHV

+2YHUORDGSURWHFWLRQRIFRPSUHVVRU+0RGXOHSURWHFWLRQ

3++LJKYROWDJHSURWHFWLRQ3//RZYROWDJHSURWHFWLRQ

31RPLQDOFRROLQJDQGKHDWLQJ30D[LPXPFRROLQJDQGKHDWLQJ

30HGLXPFRROLQJDQGKHDWLQJ30LQLPXPFRROLQJDQGKHDWLQJ

'U\LQJ)XQFWLRQ

<RXPD\VWDUWRUVWRSWKHGU\LQJIXQFWLRQXQGHUWKHPRGHVRIFRROLQJDQGGHKXPLGLI\DWWKHVWDUWLQJVWDWXV7KHPRGHVRIDXWRPDWLVP

KHDWLQJDQGDLUVXSSO\GRQRWKDYHGU\LQJIXQFWLRQ:KHQ\RXVWDUWWKHGU\LQJIXQFWLRQDIWHUVWRSWKHPDFKLQHE\SUHVVLQJWKHVZLWFK

EXWWRQ\RXVKRXOGNHHSUXQQLQJWKHLQQHUIDQVIRUPLQXWHVXQGHUORZDLUGDPSHU7KHVZLQJZLOORSHUDWHDVWKHIRUPHUVWDWXVZLWKLQ

PLQXWHVFRROLQJLQGLFDWRULVRQIRUVDQGWKHQRIIIRUVLQGU\LQJDQGRWKHUORDGLVVWRSSHGWKHQVWRSWKHHQWLUHPDFKLQH

:KHQ \RX VWRS WKH GU\LQJ IXQFWLRQ SUHVV WKH VZLWFK EXWWRQ ZLOO VWRS WKH PDFKLQH GLUHFWO\ :KHQ \RX VWDUW WKH GU\LQJ IXQFWLRQ

RSHUDWLQJWKHGU\LQJEXWWRQZLOOVWRSWKHLQQHUIDQVDQGFORVHWKHJXLGHORXYHU

0HPRU\IXQFWLRQZKHQLQWHUUXSWLQJWKHSRZHUVXSSO\

0HPRU\FRQWHQWPRGHVZLQJIXQFWLRQOLJKWVHWWHPSHUDWXUHDQGZLQGVSHHG$IWHULQWHUUXSWHGWKHSRZHUVXSSO\WKHPDFKLQHZLOO

VWDUWZKHQUHFRYHULQJWKHSRZHUDFFRUGLQJWRWKHPHPRU\FRQWHQWDXWRPDWLFDOO\,IWKHODVWUHPRWHFRQWUROFRPPDQGKDVQRWVHW

WKHWLPHGIXQFWLRQWKHV\VWHPZLOOUHPHPEHUWKHODVWUHPRWHFRQWUROFRPPDQGDQGRSHUDWHDFFRUGLQJLW,IWKHODVWUHPRWHFRQWURO

FRPPDQGKDVVHWWLPHGIXQFWLRQDQGWKHSRZHUVXSSO\LVLQWHUUXSWHGEHIRUHWKHWLPHGWLPHWKHV\VWHPZLOOUHPHPEHUWKHWLPHG

IXQFWLRQRIWKHODVWUHPRWHFRQWUROFRPPDQGWKHWLPHGWLPHZLOOUHFRXQWHGIRUPSRZHURQ,IWKHODVWUHPRWHFRQWUROFRPPDQGKDV

VHWWLPHGIXQFWLRQWKHWLPHLVRXWDQGWKHV\VWHPLVVWDUWRUVWRSDFFRUGLQJWRWKHVHWWLPHZKHQWKHSRZHUVXSSO\LVLQWHUUXSWHGWKH

V\VWHPZLOOUHPHPEHUWKHRSHUDWLRQVWDWXVEHIRUHWKHSRZHUVXSSO\ZDVLQWHUUXSWHGDQGGRQRWFDUU\RXWWLPHGDFWLRQ7KHWLPHG

FORFNZLOOQRWUHPHPEHUHG

(OHFWULFKHDWLQJEDQGFRQWURORIRXWGRRUXQLW

ķ &RPSUHVVRUHOHFWULFKHDWLQJEDQGFRQWURO

D6WDUWFRQGLWLRQWKHFRPSUHVVRULVLQRIIVWDWXVDQGWKHRXWGRRUDPELHQWWHPSHUDWXUH&

E6WRSFRQGLWLRQWKHEDQGLVRIIZKHQHLWKHURIWKHEHORZFRQGLWLRQLVPHW

7KHFRPSUHVVRULVLQRQVWDWXV

7KHFRPSUHVVRULVLQRIIVWDWXVDQGWKHRXWGRRUDPELHQWWHPSHUDWXUH&

F:KHQRXWGRRUDPELHQWWHPSHUDWXUHVHQVRULVLQPDOIXQFWLRQVWDWXVWKHHOHFWULFKHDWLQJEDQGVWRSVRSHUDWLRQ

ĸ &RQGHQVHUHOHFWULFKHDWLQJEDQGFRQWURO

:KHQ7RXWGRRUDPELHQW&WKHHOHFWULFKHDWLQJEDQGVWDUWVZRUNLQJ

:KHQHQWHUGHIURVWLQJDQGGHIURVWLQJLV¿QLVKHGWKHFKDVVLVHOHFWULFKHDWLQJEDQGVWDUWVZRUNLQJIRUPLQDVWKHFRPSUHVVRU

VWDUWV$IWHUWKHFRPSUHVVRUVWDUWVIRUPLQDQG7RXWGRRUDPELHQW&WKHHOHFWULFKHDWLQJEDQGVWRSVRSHUDWLRQ

:KHQ7RXWGRRUDPELHQW&WKHFRQGHQVHUHOHFWULFKHDWLQJEDQGGRHVQ¶WZRUN

:KHQ&7RXWGRRUDPELHQW&WKHFRQGHQVHUHOHFWULFKHDWLQJEDQGNHHSVWKHSUHYLRXVVWDWXV

:KHQRXWGRRUDPELHQWWHPSHUDWXUHVHQVRULVLQPDOIXQFWLRQVWDWXVWKHHOHFWULFKHDWLQJEDQGVWRSVRSHUDWLRQWKHHOHFWULFKHDWLQJ

EDQGFDQZRUNDJDLQDIWHUPLQRIODVWVWRS

,QVWDOODWLRQ0DQXDO

,QVWDOODWLRQ0DQXDO

1RWLFHVIRU,QVWDOODWLRQ

&DXWLRQ

7KHXQLWVKRXOGEHLQVWDOOHGRQO\E\DXWKRUL]HGVHUYLFHFHQWHUDFFRUGLQJWRORFDORUJRYHUQPHQWUHJXODWLRQVDQGLQFRPSOLDQFHZLWK

WKLVPDQXDO

%HIRUHLQVWDOOLQJSOHDVHFRQWDFWZLWKORFDODXWKRUL]HGPDLQWHQDQFHFHQWHU,IWKHXQLWLVQRWLQVWDOOHGE\WKHDXWKRUL]HGVHUYLFHFHQWHU

WKHPDOIXQFWLRQPD\QRWEHVROYHGGXHWRLQFRYHQLHQWFRQWDFWEHWZHHQWKHXVHUDQGWKHVHUYLFHSHUVRQQHO

:KHQUHPRYLQJWKHXQLWWRWKHRWKHUSODFHSOHDVH¿UVWO\FRQWDFWZLWKWKHORFDODXWKRUL]HGVHUYLFHFHQWHU

:DUQLQJ%HIRUHREWDLQLQJDFFHVVWRWHUPLQDOVDOOVXSSO\FLUFXLWVPXVWEHGLVFRQQHFWHG

)RUDSSOLDQFHVZLWKW\SH<DWWDFKPHQWWKHLQVWUXFWLRQVVKDOOFRQWDLQWKHVXEVWDQFHRIWKHIROORZLQJ,IWKHVXSSO\FRUGLVGDPDJHGLW

PXVWEHUHSODFHGE\WKHPDQXIDFWXUHULWVVHUYLFHDJHQWRUVLPLODUO\TXDOL¿HGSHUVRQVLQRUGHUWRDYRLGDKD]DUG

7KHDSSOLDQFHPXVWEHSRVLWLRQHGVRWKDWWKHSOXJLVDFFHVVLEOH

7KHWHPSHUDWXUHRIUHIULJHUDQWOLQHZLOOEHKLJKSOHDVHNHHSWKHLQWHUFRQQHFWLRQFDEOHDZD\IURPWKHFRSSHUWXEH

7KHLQVWUXFWLRQVVKDOOVWDWHWKHVXEVWDQFHRIWKHIROORZLQJ

7KLV DSSOLDQFH LV QRW LQWHQGHG IRU XVH E\ SHUVRQVLQFOXGLQJ FKLOGUHQZLWK UHGXFHG SK\VLFDO VHQVRU\ RU PHQWDO FDSDELOLWLHV RU ODFN

RIH[SHULHQFHDQGNQRZOHGJHXQOHVVWKH\KDYHEHHQJLYHQVXSHUYLVLRQRULQVWUXFWLRQFRQFHUQLQJXVHRIWKHDSSOLDQFHE\DSHUVRQ

UHVSRQVLEOHIRUWKHLUVDIHW\

&KLOGUHQVKRXOGEHVXSHUYLVHGWRHQVXUHWKDWWKH\GRQRWSOD\ZLWKWKHDSSOLDQFH

,QVWDOODWLRQ6LWH,QVWUXFWLRQV

3URSHULQVWDOODWLRQVLWHLVYLWDOIRUFRUUHFWDQGHI¿FLHQWRSHUDWLRQRIWKHXQLW$YRLGWKHIROORZLQJVLWHVZKHUH

ƔVWURQJKHDWVRXUFHVYDSRXUVÀDPPDEOHJDVRUYRODWLOHOLTXLGVDUHHPLWWHG

ƔKLJKIUHTXHQF\HOHFWURPDJQHWLFZDYHVDUHJHQHUDWHGE\UDGLRHTXLSPHQWZHOGHUVDQGPHGLFDOHTXLSPHQW

ƔVDOWODGHQDLUSUHYDLOVVXFKDVFORVHWRFRDVWDODUHDV

ƔWKHDLULVFRQWDPLQDWHGZLWKLQGXVWULDOYDSRXUVDQGRLOV

ƔWKHDLUFRQWDLQVVXOSKXUHVJDVVXFKDVLQKRWVSULQJ]RQHV

ƔFRUURVLRQRUSRRUDLUTXDOLW\H[LVWV

,QVWDOODWLRQ6LWHRI,QGRRU8QLW

7KHDLULQOHWDQGRXWOHWVKRXOGEHDZD\IURPWKHREVWUXFWLRQV(QVXUHWKHDLUFDQEHEORZQWKURXJKWKHZKROHURRP

6HOHFWDVLWHZKHUHWKHFRQGHQVDWHFDQEHHDVLO\GUDLQHGRXWDQGZKHUHLWLVHDVLO\FRQQHFWHGWRRXWGRRUXQLW

6HOHFWDSODFHZKHUHLWLVRXWRIUHDFKRIFKLOGUHQ

6HOHFWDSODFHZKHUHWKHZDOOLVVWURQJHQRXJKWRZLWKVWDQGWKHIXOOZHLJKWDQGYLEUDWLRQRIWKHXQLW

%HVXUHWROHDYHHQRXJKVSDFHWRDOORZDFFHVVIRUURXWLQHPDLQWHQDQFH7KHLQVWDOODWLRQVLWHVKRXOGEHFPRUPRUHDERYHWKH

ÀRRU

6HOHFWDSODFHDERXWPRUPRUHDZD\IURP79VHWRUDQ\RWKHUHOHFWULFDSSOLDQFH

6HOHFWDSODFHZKHUHWKH¿OWHUFDQEHHDVLO\WDNHQRXW

0DNHVXUHWKDWWKHLQGRRUXQLWLVLQVWDOOHGLQDFFRUGDQFHZLWKLQVWDOODWLRQGLPHQVLRQLQVWUXFWLRQV

'RQRWXVHWKHXQLWLQWKHODXQGU\RUE\VZLPPLQJSRROHWF

,QVWDOODWLRQ6LWHRI2XWGRRU8QLW

6HOHFWDVLWHZKHUHQRLVHDQGRXWÀRZDLUHPLWWHGE\WKHXQLWZLOOQRWDQQR\QHLJKERUV

6HOHFWDVLWHZKHUHWKHUHLVVXI¿FLHQWYHQWLODWLRQ

6HOHFWDVLWHZKHUHWKHUHLVQRREVWUXFWLRQEORFNLQJWKHLQOHWDQGRXWOHW

7KHVLWHVKRXOGEHDEOHWRZLWKVWDQGWKHIXOOZHLJKWDQGYLEUDWLRQ

6HOHFWDGU\SODFHEXWGRQRWH[SRVHWKHXQLWWRGLUHFWVXQOLJKWRUVWURQJZLQG

0DNHVXUHWKDWWKHRXWGRRUXQLWLVLQVWDOOHGLQDFFRUGDQFHZLWKWKHLQVWDOODWLRQLQVWUXFWLRQVDQGLVFRQYHQLHQWIRUPDLQWHQDQFHDQG

UHSDLU

7KHKHLJKWGLIIHUHQFHEHWZHHQLQGRRUDQGRXWGRRUXQLWVLVZLWKLQPDQGWKHOHQJWKRIWKHFRQQHFWLQJWXELQJGRHVQRWH[FHHGP

6HOHFWDSODFHZKHUHLWLVRXWRIUHDFKRIFKLOGUHQ

6HOHFWDSODFHZKHUHWKHXQLWGRHVQRWKDYHQHJDWLYHLPSDFWRQSHGHVWULDQVRURQWKHFLW\

,QVWDOODWLRQ0DQXDO

6DIHW\3UHFDXWLRQVIRU(OHFWULF$SSOLDQFHV

$GHGLFDWHGSRZHUVXSSO\FLUFXLWVKRXOGEHXVHGLQDFFRUGDQFHZLWKORFDOHOHFWULFDOVDIHW\UHJXODWLRQV

'RQ WGUDJWKHSRZHUFRUGZLWKH[FHVVLYHIRUFH

7KHXQLWVKRXOGEHUHOLDEO\HDUWKHGDQGFRQQHFWHGWRDQH[FOXVLYHHDUWKGHYLFHE\WKHSURIHVVLRQDOV

7KHDLUVZLWFKPXVWKDYHWKHIXQFWLRQVRIPDJQHWLFWULSSLQJDQGKHDWWULSSLQJWRSUHYHQWVKRUWFLUFXLWDQGRYHUORDG

7KHPLQLPXPGLVWDQFHEHWZHHQWKHXQLWDQGFRPEXVWLYHVXUIDFHLVP

7KHDSSOLDQFHVKDOOEHLQVWDOOHGLQDFFRUGDQFHZLWKQDWLRQDOZLULQJUHJXODWLRQV

$QDOOSROHGLVFRQQHFWLRQVZLWFKZLWKDFRQWDFWVHSDUDWLRQRIDWOHDVWPPLQDOOSROHVVKRXOGEHFRQQHFWHGLQ¿[HGZLULQJ

1RWH

Ɣ0DNHVXUHWKHOLYHZLUHQHXWUDOZLUHDQGHDUWKZLUHLQWKHIDPLO\SRZHUVRFNHWDUHSURSHUO\

FRQQHFWHG7KHUHVKRXOGEHUHOLDEOHFLUFXLWLQWKHGLDJUDP

Ɣ,QDGHTXDWHRULQFRUUHFWHOHFWULFDOFRQQHFWLRQVPD\FDXVHHOHFWULFVKRFNRU¿UH

(DUWKLQJ5HTXLUHPHQWV

$LUFRQGLWLRQHULVW\SH,HOHFWULFDSSOLDQFH3OHDVHHQVXUHWKDWWKHXQLWLVUHOLDEO\HDUWKHG

7KH\HOORZJUHHQZLUHLQDLUFRQGLWLRQHULVWKHHDUWKLQJZLUHZKLFKFDQQRWEHXVHG

IRURWKHUSXUSRVHV,PSURSHUHDUWKLQJPD\FDXVHHOHFWULFVKRFN

7KHHDUWKUHVLVWDQFHVKRXOGDFFRUGWRWKHQDWLRQDOFULWHULRQ

7KHSRZHUPXVWKDYHUHOLDEOHHDUWKLQJWHUPLQDO3OHDVHGRQRWFRQQHFWWKHHDUWKLQJZLUHZLWKWKHIROORZLQJ

ķ :DWHUSLSHĸ *DVSLSHĹ &RQWDPLQDWLRQSLSH

ĺ 2WKHUSODFHWKDWSURIHVVLRQDOSHUVRQQHOFRQVLGHULVXQUHOLDEOH

7KHPRGHODQGUDWHGYDOXHVRIIXVHVVKRXOGDFFRUGZLWKWKHVLONSULQWRQIXVHFRYHURUUHODWHG3&%

,QVWDOODWLRQ0DQXDO

,QVWDOODWLRQ'UDZLQJ

Space to the ceiling

15cm

Above

Space to the wall

15cm Above

15cm Above

Space to the wall

300cm

cm

Above

Above

Air outlet side

Space to the floor

Space to the obstruction

50cm Above

The dimensions of the space necessary for proper

installation of the unit include the minimum

permissible distances to adjacent parts.

Air inlet side

ov

cm

30cm Above

Ab

e

30

Space to the wall

0

20

cm

o

Ab

ve

Space to the wall

50cm Above

Air outlet side

Schematic diagram being reference only (outdoor unit is with variation),

please refer to real product for authentic information.

,QVWDOODWLRQ0DQXDO

,QVWDOO,QGRRU8QLW

,QVWDOODWLRQRI0RXQWLQJ3ODWH

0RXQWLQJSODWHVKRXOGEHLQVWDOOHGKRUL]RQWDOO\$VWKHZDWHUWUD\VRXWOHWIRUWKHLQGRRUXQLWLVWZRZD\W\SHGXULQJLQVWDOODWLRQWKH

LQGRRUXQLWVKRXOGVOLJKWO\VODQWWRZDWHUWUD\VRXWOHWIRUVPRRWKGUDLQDJHRIFRQGHQVDWH

)L[WKHPRXQWLQJSODWHRQWKHZDOOZLWKVFUHZV

%HVXUHWKDWWKHPRXQWLQJSODWHKDVEHHQ¿[HG¿UPO\HQRXJKWRZLWKVWDQGDERXWNJ0HDQZKLOHWKHZHLJKWVKRXOGEHHYHQO\

VKDUHGE\HDFKVFUHZ

Wall

Above 150 from the ceiling

Wall

Wall

Above

150 from

the wall

Above

150 from

the wall

Φ55

Φ55

Left

)LJ

'ULOO3LSLQJ+ROH

6ODQWWKHSLSLQJKROHĭRQWKHZDOOVOLJKWO\GRZQZDUGWRWKH

RXWGRRUVLGH

,QVHUWWKHSLSLQJKROHVOHHYHLQWRWKHKROHWRSUHYHQWWKHFRQQHFWLRQSLSLQJ

DQGZLULQJIURPEHLQJGDPDJHGZKHQSDVVLQJWKURXJKWKHKROH

Right

Indoor

8QLWPP

Outdoor

Wall pipe

Seal pad

ĭ

,QVWDOODWLRQRI'UDLQ+RVH

&RQQHFWWKHGUDLQKRVHWRWKHRXWOHWSLSHRIWKHLQGRRUXQLW%LQGWKHMRLQWZLWKUXEEHUEHOW

3XWWKHGUDLQKRVHLQWRLQVXODWLQJWXEH

outlet pipe of

indoor unit

rubber belt

outlet pipe of

indoor unit

drain hose

outlet pipe of

indoor unit

:UDSWKHLQVXODWLQJWXEHZLWKZLGHUXEEHUEHOWWRSUHYHQW

WKHVKLIWRILQVXODWLQJWXEH6ODQWWKHGUDLQKRVHGRZQZDUG

VOLJKWO\IRUVPRRWKGUDLQDJHRIFRQGHQVDWH

1RWH7KHLQVXODWLQJWXEHVKRXOGEHFRQQHFWHGUHOLDEO\ZLWK

WKHVOHHYHRXWVLGHWKHRXWOHWSLSH7KHGUDLQKRVHVKRXOGEH

VODQWHGGRZQZDUGVOLJKWO\ZLWKRXWGLVWRUWLRQEXOJHRU

ÀXFWXDWLRQ'RQRWSXWWKHRXWOHWLQWKHZDWHU

drain hose

rubber belt insulating tube

rubber belt

outlet pipe of

indoor unit

connected

bulge

insulating tube

distortion

Flooded

&RQQHFWLQJ,QGRRUDQG2XWGRRU(OHFWULF:LUHV

2SHQWKHIURQWSDQHO

5HPRYHWKHZLULQJFRYHUDQGZLUHFODPS0DNHWKHSRZHUFRQQHFWLRQFRUGSDVV

WKURXJKWKHKROHDWWKHEDFNRILQGRRUXQLW

&RQQHFWDQG¿[WKHSRZHUFRQQHFWLRQFRUGWRWKHWHUPLQDOERDUG$VVKRZQLQ)LJ

)L[WKHSRZHUFRQQHFWLRQFRUGZLWKZLUHFODPSDQGUHLQVWDOOZLULQJFRYHU

5HLQVWDOOWKHIURQWSDQHO

Wiring Cover

N(1)

blue black

2

3

brown

yellowgreen

outdoor unit connection

Fig.2

,QVWDOODWLRQ0DQXDO

127(

$OOZLUHVEHWZHHQLQGRRUDQGRXWGRRUXQLWVPXVWEHFRQQHFWHGE\WKHTXDOL¿HGHOHFWULFFRQWUDFWRU

Ɣ(OHFWULFZLUHVPXVWEHFRQQHFWHGFRUUHFWO\,PSURSHUFRQQHFWLRQPD\FDXVHPDOIXQFWLRQ

Ɣ7LJKWHQWKHWHUPLQDOVFUHZVVHFXUHO\

Ɣ$IWHUWLJKWHQLQJWKHVFUHZVSXOOWKHZLUHVOLJKWO\WRFRQ¿UPZKHWKHULWV¿UPRUQRW

Ɣ0DNHVXUHWKDWWKHHOHFWULFFRQQHFWLRQVDUHHDUWKHGSURSHUO\WRSUHYHQWHOHFWULFVKRFN

Ɣ0DNHVXUHWKDWDOOZLULQJFRQQHFWLRQVDUHVHFXUHDQGWKHFRYHUSODWHVDUHUHLQVWDOOHGSURSHUO\3RRULQVWDOODWLRQPD\FDXVH¿UHRU

HOHFWULFVKRFN

Gas side pipe

,QVWDOODWLRQRI,QGRRU8QLW

Ɣ7KHSLSLQJFDQEHRXWSXWIURPULJKWULJKWUHDUOHIWRUOHIWUHDU

:KHQURXWLQJWKHSLSLQJDQGZLULQJIURPWKHOHIWRUULJKWVLGHRILQGRRUXQLWFXWRIIWKHWDLOLQJV

IURPWKHFKDVVLVZKHQQHFHVVDU\$VVKRZQLQ)LJ

Ł &XWRIIWDLOLQJZKHQURXWLQJWKHZLULQJRQO\

ł &XWRIIWDLOLQJDQGWDLOLQJZKHQURXWLQJERWKWKHZLULQJDQGSLSLQJ

7DNHRXWWKHSLSLQJIURPERG\FDVHZUDSWKHSLSLQJSRZHUFRUGVGUDLQKRVHZLWKWKHWDSH

DQGWKHQPDNHWKHPSDVVWKURXJKWKHSLSLQJKROH$VVKRZQLQ)LJ

+DQJWKHPRXQWLQJVORWVRIWKHLQGRRUXQLWRQWKHXSSHUKRRNVRIWKHPRXQWLQJSODWHDQG

FKHFNLILWLV¿UPHQRXJK$VVKRZQLQ)LJ

7KHLQVWDOODWLRQVLWHVKRXOGEHFPRUPRUHDERYHWKHÀRRU

Tailing 2

Tailing 1

Fig.3

External connection

electric wire

Liquid side piping

Gas side piping

insulation

Liquid side

Piping insulation

Finally wrap it

Water drainage pipe

with tape

Left

েৢ

Left rear

Right

Right rear

Fig.4

Fixing hook

Mounting

plate

Mounting

plate

Fig.5

,QVWDOODWLRQRI&RQQHFWLRQ3LSH

$OLJQWKHFHQWHURIWKHSLSHÀDUHZLWKWKHUHODWHGYDOYH

6FUHZLQWKHÀDUHQXWE\KDQGDQGWKHQWLJKWHQWKHQXWZLWKVSDQQHUDQGWRUTXH

ZUHQFKE\UHIHUULQJWRWKHIROORZLQJ

+H[QXWGLDPHWHU

Ɏ

Ɏ

Ɏ

Ɏ

Ɏ

7LJKWHQLQJWRUTXH1ÂP

̚

̚

̚

̚

̚

127(&RQQHFWWKHFRQQHFWLRQSLSHWRLQGRRUXQLWDW¿UVWDQGWKHQWRRXWGRRUXQLW

+DQGOHSLSLQJEHQGLQJZLWKFDUH'RQRWGDPDJHWKHFRQQHFWLRQSLSH(QVXUHWKDW

WKHMRLQWQXWLVWLJKWHQHG¿UPO\RWKHUZLVHLWPD\FDXVHOHDNDJH

Indoor unit piping

Taper nut Piping

Spanner

Torque

wrench

,QVWDOO2XWGRRU8QLW

(OHFWULF:LULQJ

5HPRYHWKHKDQGOHRQWKHULJKWVLGHSODWHRIRXWGRRUXQLW

7DNHRIIZLUHFODPS&RQQHFWDQG¿[WKHSRZHUFRQQHFWLRQFRUG

WRWKHWHUPLQDOERDUG:LULQJVKRXOG¿WWKDWRILQGRRUXQLW

)L[WKHSRZHUFRQQHFWLRQFRUGZLWKZLUHFODPS

&RQ¿UPLIWKHZLUHKDVEHHQ¿[HGSURSHUO\

5HLQVWDOOWKHKDQGOH

127(

Ɣ,QFRUUHFWZLULQJPD\FDXVHPDOIXQFWLRQRIVSDUHSDUW

Ɣ$IWHUWKHZLUHKDVEHHQ¿[HGHQVXUHWKHUHLVIUHH

VSDFHEHWZHHQWKHFRQQHFWLRQDQG¿[LQJSODFHVRQWKHOHDGZLUH

6FKHPDWLFGLDJUDPEHLQJUHIHUHQFHRQO\SOHDVHUHIHUWR

UHDOSURGXFWIRUDXWKHQWLFLQIRUPDWLRQ

Handle

N(1) 2

3

Brown

Black

Blue

Yellow-green

power connection cord

,QVWDOODWLRQ0DQXDO

Manifold Valve

$LU3XUJLQJDQG/HDNDJH7HVW

&RQQHFWFKDUJLQJKRVHRIPDQLIROGYDOYHWRFKDUJHHQGRIORZSUHVVXUH

YDOYHERWKKLJKORZSUHVVXUHYDOYHVPXVWEHWLJKWO\VKXW

&RQQHFWMRLQWRIFKDUJLQJKRVHWRYDFXXPSXPS

)XOO\RSHQWKHKDQGOHRI/RPDQLIROGYDOYH

2SHQWKHYDFXXPSXPSIRUYDFXXPL]DWLRQ$WWKHEHJLQQLQJVOLJKWO\

ORRVHQMRLQWQXWRIORZSUHVVXUHYDOYHWRFKHFNLIWKHUH

LVDLUFRPLQJLQVLGH,IQRLVHRIYDFXXPSXPSKDV

EHHQFKDQJHGWKHUHDGLQJRIPXOWLPHWHULV7KHQWLJKWHQWKHQXW

.HHSYDFXXPLQJIRUPRUHWKDQPLQVDQGPDNH

VXUHWKHUHDGLQJRIPXOWLPHWHULV;SDFP+J

)XOO\RSHQKLJKORZSUHVVXUHYDOYHV

5HPRYHFKDUJLQJKRVHIURPFKDUJLQJHQGRIORZSUHVVXUHYDOYH

7LJKWHQOLGRIORZSUHVVXUHYDOYH$VVKRZQLQ)LJ

Multimeter

-76cmHg

Manometer

Hi handle

Lo Handle

Charging hose

Low pressure valve

Fig.6

Vacuum pump

2XWGRRU&RQGHQVDWH'UDLQDJHRQO\IRUKHDWSXPSXQLW

'XULQJKHDWLQJRSHUDWLRQWKHFRQGHQVDWHDQGGHIURVWLQJ

ZDWHUVKRXOGEHGUDLQHGRXWUHOLDEO\WKURXJKWKHGUDLQKRVH

,QVWDOOWKHRXWGRRUGUDLQFRQQHFWRULQDĭKROHRQ

WKHEDVHSODWHDQGDWWDFKWKHGUDLQKRVHWRWKHFRQQHFWRU

VRWKDWWKHZDVWHZDWHUIRUPHGLQWKHRXWGRRUXQLWFDQEH

GUDLQHGRXW7KHKROHGLDPHWHUPXVWEHSOXJJHG

:KHWKHUWRSOXJRWKHUKROHVZLOOEHGHWHUPLQHGE\WKHGHDOHUVDFFRUGLQJWRDFWXDOFRQGLWLRQV

Drain-water hole

Bottom frame

Drain connecter

Hose (available commercially,

inner dia. 16mm)

&KHFNDIWHU,QVWDOODWLRQDQG2SHUDWLRQ7HVW

&KHFNDIWHU,QVWDOODWLRQ

,WHPVWREHFKHFNHG

3RVVLEOHPDOIXQFWLRQ

+DVLWEHHQ¿[HG¿UPO\"

7KHXQLWPD\GURSVKDNHRUHPLWQRLVH

+DYH\RXGRQHWKHUHIULJHUDQWOHDNDJH ,WPD\FDXVHLQVXI¿FLHQWFRROLQJKHDWLQJ

WHVW"

FDSDFLW\

,VKHDWLQVXODWLRQVXI¿FLHQW"

,WPD\FDXVHFRQGHQVDWLRQDQGGULSSLQJ

,VZDWHUGUDLQDJHVDWLVIDFWRU\"

,WPD\FDXVHFRQGHQVDWLRQDQGGULSSLQJ

,VWKHYROWDJHLQDFFRUGDQFHZLWKWKH

,WPD\FDXVHHOHFWULFPDOIXQFWLRQRU

UDWHGYROWDJHPDUNHGRQWKHQDPHSODWH" GDPDJHWKHSURGXFW

,VWKHHOHFWULFZLULQJDQGSLSLQJ

,WPD\FDXVHHOHFWULFPDOIXQFWLRQRU

FRQQHFWLRQLQVWDOOHGFRUUHFWO\DQG

GDPDJHWKHSDUW

VHFXUHO\"

+DVWKHXQLWEHHQFRQQHFWHGWRDVHFXUH

,WPD\FDXVHHOHFWULFDOOHDNDJH

HDUWKFRQQHFWLRQ"

,WPD\FDXVHHOHFWULFPDOIXQFWLRQRU

,VWKHSRZHUFRUGVSHFL¿HG"

GDPDJHWKHSDUW

$UHWKHLQOHWDQGRXWOHWRSHQLQJV

,WPD\FDXVHLQVXI¿FLHQWFRROLQJKHDWLQJ

EORFNHG"

FDSDFLW\

,VWKHOHQJWKRIFRQQHFWLRQSLSHVDQG

7KHUHIULJHUDQWFDSDFLW\LVQRWDFFXUDWH

UHIULJHUDQWFDSDFLW\EHHQUHFRUGHG"

2SHUDWLRQ7HVW

%HIRUH2SHUDWLRQ7HVW

'RQRWVZLWFKRQSRZHUEHIRUHLQVWDOODWLRQLV¿QLVKHGFRPSOHWHO\

(OHFWULFZLULQJPXVWEHFRQQHFWHGFRUUHFWO\DQGVHFXUHO\

&XWRIIYDOYHVRIWKHFRQQHFWLRQSLSHVVKRXOGEHRSHQHG

$OOWKHLPSXULWLHVVXFKDVVFUDSVDQGWKUXPVPXVWEHFOHDUHGIURPWKHXQLW

2SHUDWLRQ7HVW0HWKRG

6ZLWFKRQSRZHUDQGSUHVV212))EXWWRQRQWKHUHPRWHFRQWUROOHUWRVWDUWRSHUDWLRQ

3UHVV02'(EXWWRQWRVHOHFWWKH&22/+($71RWDYDLODEOHIRUFRROLQJRQO\XQLW)$1WRFKHFNZKHWKHUWKHRSHUDWLRQLVQRUPDORU

QRW

,QVWDOODWLRQ0DQXDO

,QVWDOODWLRQDQG0DLQWHQDQFHRI+HDOWK\)LOWHU

,QVWDOODWLRQRI+HDOWK\)LOWHU

/LIWXSWKHIURQWSDQHOIURPLWVWZRHQGVDVVKRZQE\WKHDUURZGLUHFWLRQDQG

WKHQUHPRYHWKHDLU¿OWHU$VVKRZQLQ¿JD

Fig.a

Fig.b

$WWDFKWKHKHDOWK\¿OWHURQWRWKHDLU¿OWHU$VVKRZQLQ¿JE

Air filter

Healthy filter

,QVWDOOWKHDLU¿OWHUSURSHUO\DORQJWKHDUURZGLUHFWLRQLQ)LJFDQGWKHQFORVHWKHSDQHO

Fig.c

&OHDQLQJDQG0DLQWHQDQFH

5HPRYHWKHKHDOWK\¿OWHUDQGUHLQVWDOOLWDIWHUFOHDQLQJDFFRUGLQJWRWKHLQVWDOODWLRQLQVWUXFWLRQ'RQWXVHEUXVKRUKDUGWKLQJVWRFOHDQ

WKH¿OWHU$IWHUFOHDQLQJEHVXUHWRGU\LWLQWKHVKDGH

6HUYLFH/LIH

7KHJHQHUDOVHULYHOLIHIRUWKHKHDOWK\¿OWHULVDERXWRQH\HDUXQGHUQRUPDOFRQGLWLRQ$VIRUVLOYHULRQ¿OWHULWLVLQYDOLGZKHQLWVVXUIDFH

EHFRPHVEODFNJUHHQ

Ɣ7KLVVXSSOHPHQWDU\LQVWUXFWLRQLVSURYLGHGIRUUHIHUHQFHWRWKHXQLWZLWKKHDOWK\¿OWHU,IWKHJUDSKLFVSURYLGHGKHUHLQLVGLIIHUHQWIURP

WKHDFWXDOSURGXFWSOHDVHUHIHUWRWKHDWXDOSURGXFW7KHTXDQWLW\RIKHDOWK\¿OWHUVLVEDVHGRQWKHDFWXDOGHOLYHU\

([SORGHG9LHZVDQG3DUWV/LVW

([SORGHG9LHZVDQG3DUWV/LVW

,QGRRU8QLW

*:+0%.'1$.,*:+0%.'1$.,*:+0%.'1$.,*:+0%.'1$.,

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

24

25

3

26

2

27

28

30

29

31

34

38

37

36

33

32

35

39

40

1

([SORGHG9LHZVDQG3DUWV/LVW

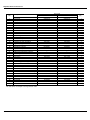

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Description

Product Code

Front Panel

Display Board

Filter Sub-Assy

Electric Box Cover2

Screw Cover

Front Case Sub-Assy

Axile Bush

Guide Louver

Air Louver 1

Air Louver 2

Helicoid tongue

Left Axile Bush

Rear Case assy

Cross Flow Fan

O-Gasket sub-assy of Bearing

Ring of Bearing

Drainage hose

Wall Mounting Frame

Evaporator Assy

Evaporator Support

Cold Plasma Generator Sub-assy

Connecting Cable

Power Cord

Pipe Clamp

Fan Motor

Motor Press Plate

Rubber Plug (Water Tray)

Step Motor

Crank

Electric Box Assy

Electric Box

Terminal Board

Shield cover of Electric Box sub-assy

Electric Box Cover1

Capacitor CBB61

Jumper

Ambient Temperature Sensor

Main Board

Temperature Sensor

Remote Controller

The data above are subject to change without notice.

Part Code

GWH09MB-K3DNA3K/I

CB171N07600

20012548

30565007

1112220403

20122075

24252016

20012139

10542036

10512157

10512156

10512155

26112163

10512037

2220210301

10352017

76512051

26152022

0523001401

01252021

01002424

24212091

/

400205236

400204643

26112164

150120874

26112161

76712012

1521212901

10582070

20402397

2011208201

42011233

01592073

22242135

33010002

4202300102

390000451

30148783

390000591

305100413

GWH12MB-K3DNA3K/I

CB171N07700

20012548

30565007

1112220403

20122075

24252016

20012139

10542036

10512157

10512156

10512155

26112163

10512037

2220210301

10352017

76512051

26152022

0523001401

01252021

01002953

24212091

/

400205236

400204643

26112164

150120874

26112161

76712012

1521212901

10582070

20402396

2011208201

42011233

01592073

22242135

33010002

4202300104

390000451

30148783

390000591

305100413

Qty

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

/

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

([SORGHG9LHZVDQG3DUWV/LVW

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Description

Product Code

Front Panel

Display Board

Filter Sub-Assy

Electric Box Cover2

Screw Cover

Front Case Sub-Assy

Axile Bush

Guide Louver

Air Louver 1

Air Louver 2

Helicoid tongue

Left Axile Bush

Rear Case assy

Cross Flow Fan

O-Gasket sub-assy of Bearing

Ring of Bearing

Drainage hose

Wall Mounting Frame

Evaporator Assy

Evaporator Support

Cold Plasma Generator Sub-assy

Connecting Cable

Power Cord

Pipe Clamp

Fan Motor

Motor Press Plate

Rubber Plug (Water Tray)

Step Motor

Crank

Electric Box Assy

Electric Box

Terminal Board

Shield cover of Electric Box sub-assy

Electric Box Cover1

Capacitor CBB61

Jumper

Ambient Temperature Sensor

Main Board

Temperature Sensor

Remote Controller

Part Code

GWH09MB-K3DNA2K/I

CB181N05700

20022148

30565054

1112220403

20122075

24252016

20012139

10542036

10512157

10512156

10512155

26112163

10512037

2220210301

10352017

76512051

26152022

0523001401

01252021

01002424

24212091

/

400205235

4002046410

26112164

150120874

26112161

76712012

1521212901

10582070

20402761

2011208201

42011233

01592073

22242135

33010002

4202300102

390000451

30148783

390000591

305100413

GWH12MB-K3DNA2K/I

CB181N05800

20022148

30565054

1112220403

20122075

24252016

20012139

10542036

10512157

10512156

10512155

26112163

10512037

2220210301

10352017

76512051

26152022

0523001401

01252021

01002953

24212091

/

400205235

4002046410

26112164

150120874

26112161

76712012

1521212901

10582070

20402761

2011208201

42011233

01592073

22242135

33010002

4202300104

390000451

30148783

390000591

305100413

Qty

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

/

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

The data above are subject to change without notice.

([SORGHG9LHZVDQG3DUWV/LVW

*:+0%.'1&.,*:+0%.'1&.,

36

37

39

38

13

14

12

11

15

10

16

9

8

6

7

17

5

4

18

3

2

20

1

21

24

23

22

25

27

26

28

29

35

30

34

31

33

32

19

([SORGHG9LHZVDQG3DUWV/LVW

12

'HVFULSWLRQ

3URGXFW&RGH

)URQW3DQHO6XE$VV\

)LOWHU6XE$VV\

3DUW&RGH

*:+0%.'1&.,

*:+0%.'1&.,

&%1

&%1

4W\

)URQW&DVH6XEDVV\

*XLGH/RXYHU

$[LOH%XVK

$LU/RXYHU

+HOLFRLG7RQJXH

/HIW$[LOH%XVK

5HDU&DVHDVV\

5LQJRI%HDULQJ

2*DVNHWVXEDVV\RI%HDULQJ

&URVV)ORZ)DQ

(YDSRUDWRU6XSSRUW

(YDSRUDWRU$VV\

0RWRU3UHVV3ODWH

:DOO0RXQWLQJ)UDPH

'UDLQDJH+RVH

)DQ0RWRU

&RQQHFWLQJSLSHFODPS

5XEEHU3OXJ:DWHU7UD\

6WHSSLQJ0RWRU

&UDQN

6FUHZ&RYHU

$LU/RXYHU

(OHFWULF%R[

0DJQHWLF5LQJ

7HUPLQDO%RDUG

(OHFWULF%R[&RYHU

0DLQ%RDUG

&DSDFLWRU&%%

-XPSHU

:LUH&ODPS

6KLHOG&RYHURI(OHFWULF%R[6XEDVV\

/RZHU6KLHOG6XEDVV\RI(OHFWULF%R[

(OHFWULF%R[$VV\

3RZHU&RUG

&RQQHFWLQJ&DEOH

'LVSOD\%RDUG

5HPRWH&RQWUROOHU

7KHGDWDDERYHDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH

([SORGHG9LHZVDQG3DUWV/LVW

*:+0%.'1(.,*:+0%.'1(.,

36

37

39

38

13

14

12

11

15

10

16

9

8

6

7

17

5

4

18

3

2

20

1

21

24

23

22

25

27

26

28

29

35

30

34

31

33

32

19

([SORGHG9LHZVDQG3DUWV/LVW

12

'HVFULSWLRQ

3URGXFW&RGH

3DUW&RGH

*:+0%.'1(.,

*:+0%.'1(.,

&%1

&%1

4W\

)URQW3DQHO$VV\

)LOWHU6XE$VV\

)URQW&DVH6XEDVV\

*XLGH/RXYHU

$[LOH%XVK

$LU/RXYHU

+HOLFRLG7RQJXH

/HIW$[LOH%XVK

5HDU&DVHDVV\

5LQJRI%HDULQJ

2*DVNHWVXEDVV\RI%HDULQJ

&URVV)ORZ)DQ

(YDSRUDWRU6XSSRUW

(YDSRUDWRU$VV\

0RWRU3UHVV3ODWH

:DOO0RXQWLQJ)UDPH

'UDLQDJH+RVH

)DQ0RWRU

&RQQHFWLQJSLSHFODPS

5XEEHU3OXJ:DWHU7UD\

6WHSSLQJ0RWRU

&UDQN

6FUHZ&RYHU

$LU/RXYHU

(OHFWULF%R[

0DJQHWLF5LQJ

7HUPLQDO%RDUG

(OHFWULF%R[&RYHU

0DLQ%RDUG

&DSDFLWRU&%%

-XPSHU

:LUH&ODPS

6KLHOG&RYHURI(OHFWULF%R[6XEDVV\

/RZHU6KLHOG6XEDVV\RI(OHFWULF%R[

(OHFWULF%R[$VV\

3RZHU&RUG

&RQQHFWLQJ&DEOH

'LVSOD\%RDUG

5HPRWH&RQWUROOHU

7KHGDWDDERYHDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH

([SORGHG9LHZVDQG3DUWV/LVW

2XWGRRU8QLW

*:+0%.'1$.2

18

19

20

21

22

23

24

17

26

25

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

([SORGHG9LHZVDQG3DUWV/LVW

12

'HVFULSWLRQ

3URGXFW&RGH

3DUW&RGH

*:+0%.'1$.2

4W\

&%:

)URQW*ULOO

&DELQHW6XEDVV\

$[LDO)ORZ)DQ

&KDVVLV6XEDVV\

&RPSUHVVRUDQG)LWWLQJV

:D\9DOYH$VV\

3

&ODSERDUG6XE$VV\

'UDLQDJH&RQQHFWHU

9DOYH6XSSRUW

&XWRII9DOYH$VV\

*

3

9DOYH

9DOYH6XSSRUW%ORFN

5LJKW6LGH3ODWH6XE$VV\

%LJ+DQGOH

0DJQHW&RLO

0DJQHW&RLO

5HDU*ULOO

(OHFWULF%R[

)LOWHU%RDUG

0DLQ%RDUG

(OHFWULF%R[$VV\

7RS&RYHU6XE$VV\

&RQGHQVHU$VV\

0RWRU6XSSRUW

)DQ0RWRU

6PDOO+DQGOH

7KHGDWDDERYHDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH

([SORGHG9LHZVDQG3DUWV/LVW

*:+0%.'1$.2

18

19

20

21

22

23

24

17

26

25

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

([SORGHG9LHZVDQG3DUWV/LVW

12

'HVFULSWLRQ

3URGXFW&RGH

3DUW&RGH

*:+0%.'1$.2

4W\

&%:

)URQW*ULOO

&DELQHW6XEDVV\

$[LDO)ORZ)DQ

3

&KDVVLV6XEDVV\

&ODSERDUG6XE$VV\

'UDLQDJH&RQQHFWHU

&RPSUHVVRUDQG)LWWLQJV

:D\9DOYH$VV\

9DOYH6XSSRUW

9DOYH6XSSRUW%ORFN

5LJKW6LGH3ODWH6XE$VV\

0DJQHW&RLO

5HDU*ULOO

*

3

&XWRII9DOYH$VV\

9DOYH

%LJ+DQGOH

(OHFWULF([SDQVLRQ9DOYH6XE$VV\

(OHFWULF%R[

)LOWHU%RDUG

0DLQ%RDUG

(OHFWULF%R[$VV\

7RS&RYHU6XE$VV\

&RQGHQVHU$VV\

0RWRU6XSSRUW

)DQ0RWRU

6PDOO+DQGOH

7KHGDWDDERYHDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH

7URXEOHVKRRWLQJ

7URXEOHVKRRWLQJ

0DOIXQFWLRQ$QDO\VLV

1RWH:KHQUHSODFLQJWKHFRQWUROOHUPDNHVXUHLQVHUWWKHZLUHMXPSHULQWRWKHQHZFRQWUROOHURWKHUZLVHWKH

XQLWZLOOGLVSOD\&

The breaker trips at once when it

is set to “ON”.

Air conditioner can not

start up

Trip of breaker or

blow of fuse

The air conditioner does not

react after it is

powered ( after

the plug is

inserted, the

buzzer does not

sound and the

remote startup

has no

response)

The breaker trips in few minutes

when it is set to “ON”.

No power

Check power supply circuit.

Power plug is not well plugged in

and poor connection.

Check if the plug is properly

plugged in and make the loose

contact firm.

Fuse of controller burnt out

Change controller fuse

The transformer connection is

loose or has bad contact or the

transformer has malfunction.

Fasten the wiring; measure the