Download AMS10 and TMS10 Gas Burners 050196 Manual

Transcript

PUBLICATION

DATE:

PUBLICATION

DATE:05-01-96

05-01-96

REVISION03

REVISION

03

EQUIPMENT

mfg.

mfg.by

WAYNEHOME

HOMEEQUIPMENT

by WAYNE

FETZERCOMPANY

A scon

SCOTT FETZER

COMPANY

FORT

WAYNE,INDIANA

INDIANA

FOBTWAYNE,

AMS-10

AMS.10

TMS-10

TMS.10

Installation

Instructions

Installation

&

& Service

ServiceInstructions

AMS-10/TMS-10

Burner

AMS-1orrMS-10 Power

PowerGas

GasBurner

PART

62693-001

PARTNO.

NO.62693-001

INSTALLATION

INSTRUCTIONS

INSTALLATION

INSTRUCTIONS

These instructions

instructionscover

These

cover the

the installation

installationof

Model

of Model

power gas

gas burner.

AMS-10/TMS-10

AMS-1

OfTMS-1 0 power

burner.Safe

and economical

economical

Safe and

operationof

of the

the burner

its service

life is

operation

burnerthroughout

throughoutits

servicelife

is largely

largely

properinstallation

dependentupon

uponproper

installation

furnace.

dependent

in

in the

the furnace.

gas

Burnersare

Burners

are shipped

from the

the factory

factorywith

with natural

naturalgas

shippedfrom

propanegas

gas orifices

orifices

orificesinstalled,

installed,unless

unlesspropane

orificesare

are specified.

specified.

(See carton

carton markings.)

markings.)See

for location

(See

See below

belowfor

locationof

of alternate

alternate

orifices.

orifices.

B.

B . GAS

PIPING

GAS PIPING

pipingshould

in accordance

Gas

be sized

sizedand

and installed

installedin

accordance

Gas piping

shouldbe

with

with local

localcodes

codesand

and utility

regulations.

utilityregulations.

1.

1.

gas line

gas meter

Run

Runa separate

line from

from the

the gas

meterto

to the

the

separategas

valve installed

installedat

meter.

burner

burnerwith

with a shut

shut off

off valve

at the

the meter.

proper line

Use

line size

size according

accordingto

the charts

charts

Use the

the proper

to the

piping,and

new piping,

locate itit

shown

Alwaysuse

use new

and locate

shownbelow.

below.Always

pipe is

later. Black

Black pipe

is

conveniently

for easy

easy servicing

servicinglater.

convenientlyfor

gas because

practicalfor

for natural

naturalgas

becauseof

of the

the

the

the most

most practical

required;copper

tubingwith

with an

internal

large

largesizes

sizesrequired;

coppertubing

an internal

Pip

recommendedwith

with L.P.

L.P.Gases.

coating

coatingof

of tin

tin is

is recommended

Gases.Pipfrom cutting

ing

ing rnust

must be

clean, free

free from

cutting burrs,

burrs, and

and

be clean,

in structure

The line

line must

must be

be

defects

defectsin

structureor

or threading.

threading.The

gas tight.

durable,

and

durable,substantial,

substantial,

and gas

tight.

2.

2.

Installa tee

f ittingwith

witha sediment

sedimenttrap

trapat

at the

the bottom

bottom

Install

tee fitting

riser to

foreign matter

matter in

in the

the fuel

fuel

of

of the

the riser

to catch

catch any

any foreign

gas valve

line.Install

Installa main

manualgas

valveon

the outside

outside

line.

mainmanual

on the

requiredby

by local

localcodes

of

thefurnace

furnacewhen

whenrequired

codesor

or utility

utility

of the

requirements.

requirements.

3.

3.

gas leaks

for gas

leakswith

with a soapy

soapysolution

solution

Carefully

Carefullycheck

checkfor

brushed

NEVER

NEVERUSE

FLAME.

brushedon

on the

theconnection.

connection.

USEA FLAME.

A.

OF

A. GAS

BURNER

GAS BURNER

BURNERREPLACEMENT

REPLACEMENT

OF OIL

OIL BURNER

1.

1.

CONTENTS

OF

C ON T E N T S

OFCARTON

C A R T ON

Burner

a.

a. Gas

Gas Burner

b.

b. Installation

Installationand

Manual

and Service

ServiceManual

c.

c. Gas

Gas Burner

BurnerGasket

Gasket

2.

2.

BURNER

REMOVING

THE

R EMOV IN G

T H E PRESENT

PR ES EN TBURNER

gas

Before installing

installingthe

Model AMS-1

AMS-'10/TMS-10

Before

OfTMS-1 0 gas

the Model

performing

presentburner

by performing

burner,

burner,remove

removethe

the present

burnerby

the

the following:

following:

powerand

and fuel

fuel supply.

supply"

a.

a. Shut

Shut off

off electric

electricpower

fuel line;

b.

Disconnectand

and remove

removefuel

line; disconnect

disconnect

b. Disconnect

thermostat

thermostatleads

leadsand

and burner

burnercord.

cord.

(3) hexagon

nutsholding

holdingburner

c.

Removethree

hexagonnuts

burner

c. Remove

three(3)

placeand

in

in place

and remove

removeburner.

burner.

Inspectcombustion

replaceifif

d.

d. Inspect

combustionchamber

chamber and

and replace

pipe

furnace and

vent pipe

damaged.

damaged.Also

Also inspect

inspectfurnace

and vent

furnacefor

for corrosion,

loosenedfiton

on top

top of

of the

the furnace

corrosion,loosened

littings,

tings,soot,

soot, etc.

etc.

3.

3.

THE GAS

BURNER

INSTALLING

THE

INSTALLING

GAS BURNER

gasketon

in furnace,

furnace,

Place

Placenew

new burner

burnergasket

on three

three studs

studsin

place with

(3) hexin place

with three

three (3)

mount

burner, fasten

fasten in

hexmount burner,

leadsto

to T.T.

T.T.of

agon

nuts, connect

thermostatleads

of terteragon nuts,

connectthermostat

gaspiping.

piping.

and connect

connectgas

minal

minalboard

boardon

on control

controlbox

boxand

4.

4.

GAS

PIPINGTO

TO FURNACE

FURNACE

GAS PIPING

Pipingand

and Section

SectionC

C Piping

Piping

See

See Section

SectionB

B Gas

Gas Piping

piping.

Charts

about

Chartsfor

for information

information

aboutpiping.

5.

5.

THERMOSTAT

THERMOSTAT

ItIt is

is necessary

necessaryto

heatanticipator

anticipatorsetting

setting

to change

changethe

the heat

gasburner

replacesan

of

of the

thethermostat

thermostatwhen

whenthe

the gas

burnerreplaces

an oil

oil

Failingto

burner.

burner.Reset

Resetthe

to .4

.4 amps.

amps. Failing

to

the anticipator

anticipatorto

make this

in a wide

make

will result

wide temperature

this change

changewill

resultin

temperature

rangein

in the

range

the mobile

mobilehome.

home.

C.

PIPINGCHARTS

CHARTS

c. PIPING

lor Natural

Black

Black Pipe

Pipefor

NaturalGas

Gas

1/2"when

lessthan

20 feet.

feet.

Use

when length

lengthrequired

requiredis

is less

than 20

Use '12"

s/t"

when length

lengthrequired

requiredis

is less

lessthan

feet.

Use

Use 3/

than 60

60 feet.

4 " when

lengthrequired

requiredis

is less

lessthan

100feet.

feet.

Use

1" when

whenlength

than 100

Use 1"

Aluminum or Copper

Copper Tubing

Tubing for Natural

Natural Gas

Gas

Aluminum

th" 0.0.

lessthan

10feet.

Use

feet.

whenlength

lengthrequired

requiredis

is less

than 10

Use'12"

O.D.when

s/a"

requiredis

is less

feet.

Use

whenlength

lengthrequired

lessthan

than 30

30 feet.

4 " 0.0

Use 3/

O.D when

Aluminum

Aluminumor Copper

Tubingfor L.P.

L.P.Gas

Gas

CopperTubing

feet.

lengthrequired

requiredis

is less

lessthan

40 feet.

Use

%" 0.0.

when length

O.D.when

than40

Usels"

3/q"

requiredis

is less

less than

100

when length

Use

lengthrequired

than 100

4 " 0.0.

Use 3/

O.D. when

feet.

feet.

higherthan

roomtemperature

temperature

10.

10. Set

roomthermostat

thermostathigher

than room

Setthe

the room

(centrifugal

so

will start.

start. A safety

safety control

control (centrifugal

so the

the burner

burner will

preventsthe

gas valve

motor)prevents

the gas

valvefrom

from openswitch

in the

the motor)

openswitchin

is supplying

sufficientcombustion

combustion

ing

ing until

the blower

bloweris

supplyingsufficient

until the

air.

air.

INPUT

D.

GAS INPUT

D. CHECKING

NATURALGAS

CHECKINGNATURAL

the burner

burner is

is

Check

label on

the burner

burner to

to be

be sure

sure the

the label

on the

Check the

gas is

is to

used.AlterAlterequipped

whichever gas

withorifices

for whichever

to be

be used.

equippedwith

orificesfor

lnstrucnate

in cloth

cloth bag

attachedto

lo burner.

burner. Instrucnate orifices

orilices are

are in

bag attached

To check

tions

for changing

orifices are

on Page

Page 2.

2. To

check the

the

tions for

changing orifices

are on

the meter

meterfor

for one

revolution

whilethe

the

input,

while

input,time

timethe

the dial

dialon

on the

onerevolution

varies more

more than

50/ofrom

from

burner

is operating.

operating.Iflf the

the time

time varies

than 5%

burner is

gas pressure

pressureaccordthe

the chart,

accordthe times

times shown

shown on

on the

chart,check

check gas

procedurestated

"Pressure

ing

ing to

the procedure

stated on

Page 2 under

to the

on Page

under "Pressure

pressure

pressure reading

Regulator:'

reading matches

matches the

Regulatori' Iflf pressure

the pressure

proper burner

shown

the proper

burner

shown on

on the

the chart,

chart, check

check to

to be

be sure

sure the

problemsshould

gas problems

reis being

Furthergas

be reorifice

orifice is

being used.

used. Further

should be

gas supplier.

gas varies

in BTU

ferred to

local gas

supplier.Natural

Naturalgas

variesin

BTU

ferred

to the

the local

1.050 BTU

foot. The

The chart

chart is

is

value

from 950

value from

950 to

to 1,050

BTU per

oer cubic

cubic foot.

per cubic

based

on an

an average

of 1,000

1,000BTU

BTU per

foot.

based on

averageof

cubic foot.

Btu!

Btu/

I NP UT

INPUT

PRESSURE

PRESSURE

80,000

3. 5' W . C.

80,000 3.5"W.C.

3.5'W.C.

100,000 3.5"W.C.

100,000

TYPE

TYPE

OF

OF

GAS

GAS

THE BURNER

BURNER

H.

ADJUSTINGTHE

H . ADJUSTING

left side

the burner

burnerhousing

housingto

to

1.

Rotatethe

the disc

disc at

at the

the left

side of the

1. Rotate

Rotatethe

air. Rotate

the disc

disc clockwise

clockwiseto

to

adjust

combustionair.

adjustthe

the combustion

increase

combustion air,

air, counter-clockwise

counter-clockwiseto

to dedeincrease c.ombustion

crease

combustionair.

air.

creasecombustion

2.

combustionflame

flame through

through observation

observationdoor

door

2. Observe

Observecombustion

placed in

is placed

immediately

immediatelyafter

after the

the burner

burner is

in operation.

operation.

in color.

color.After

Afterthe

the burner

burnerhas

has

The

The flame

flameshould

shouldbe

be blue

blue in

operated

minutes, flame

flame color

will

operated for

for two

two or

or three

three minutes,

color will

change

changeto

to light

lightorange.

orange.

BURNER

BURNER

ORIFICE

ORIFICE

DIAL

DIAL

SIZE

SIZE

TIME

TIME

PER

PER

REV.

REV.

pulsates or

quietly. Iflf burner

3.

run qUietly.

burner pulsates

or

Burner should

should run

3. Burner

rumbles,

rumbles,rotate

rotatedisc

decreaseair

air supply.

supply.

disc to

to decrease

No.

N o .'19

19

'13

No. 13

No.

11 cu.

ft.

c u . ft.

1 cu.

ft.

cu. ft.

4 5 sec.

45

sec

37

37 sec.

sec

patternand

noiselevel,

level,lock

lockdisc

4.

Afterchecking

flamepattern

and noise

disc

4. After

checkingflame

positionby

Phillipshead

headscrew.

in

in position

by tightening

tighteningPhillips

screw.

Natural

N a tu ra l

Natural

Natural

importantthat

NOTE:

is very

very important

that air

air supply

supply be

be ample

ample

NOTE: Itlt is

An inadequate

without

withoutdecreasing

efficiencyof

of burner.

burner.An

inadequate

decreasingefficiency

(CO).The

monoxide(CO).

amount

The

of air

air can

can cause

cause carbon

carbon monoxide

amountof

products

(COj

carbon

content of

of the

the flue

flue products

carbon dioxide

dioxide (C0

2 ) content

per cent

gas

should

7.0 to

to 8.0

8.0 per

cent for

for natural

naturalgas

shouldapproximate

approximate7.0

per cent

gases.

and

for L.P.

L.P. gases.

and 8.0

8.0 to

to 9.0

9.0 per

cent for

E.

E. CHECKING

L.P. GAS

GAS INPUT

INPUT

CHECKINGL.P.

gas installations

L.P. gas

installationsare

not usually

with meters

meters

L.P.

are not

usuallysuppHed

suppliedwith

gas used.

for

for determining

determiningthe

the amount

amount of

of gas

used.The

The chart

chart shows

shows

per dial

requiredper

revolutionifif a meter

meter is

is used

used that

is

time

time required

dial revolution

that is

cubic feet

feet delivery.

calibrated

for cubic

calibratedfor

deliverv.

Btu!

Bru/

INPUT

INPUT

PRESSURE

PRESSURE

TYPE

t5?t

OF

GAS

GAS

BURNER

BURNER DIAL

D'AL

ORIFICE

SIZE

ORIFICE

SIZE

TIME

T3"t

PER

REV.

REV.

I.

ADJUSTING

ADJUSTINGHEAT

HEATDISTRIBUTION

DISTRIBUTION

"ON"

1.

1. The

The lower

lowerblower

controlshould

should be

be set

set at

at FAN

FAN "ON"

blowercontrol

"OFF" 90.

110: FAN

110?

FAN "OFF"

90.

'l12 sec.

11"W.C- L.P.

Propane No.

80,000

41 1 cu.

80,000 11"W.C.

L.P.Propane

No.41

cu- ft.

ft. 112

sec.

100,000 11"W.C.

11"W.C. L.P.

L.P.Propane

Propane No.

No.36

36 1 cu.

100,000

cu. ft.

ft. 91

91 sec.

sec.

room thermostat

for desired

desiredroom

room temperature.

2.

2. Set

Set room

thermostatfor

temperature.

F.

F. PURGING

PURGINGUNBURNED

UNBURNEDGAS

FROMFURNACE

FURNACE

GAS FROM

heat distribution

3.

Balance the

the heat

distribution by

by adjusting

adjusting register

register

3. Balance

openings.

openings.

'l - Turn

gas valve

"PILOT;' depress

Turn gas

valve control

1.

controlknob

knob to

to "PILOT;'

depressand

and

"OFF:'

turn

turn to

to "OFF:'

J.

room temperature.

2.

2. Set

Set thermostat

thermostatabove

above room

temperature.

FOR SEALED

COMBUSTION

AIR

AIR SUPPLY

SUPPLYFOR

SEALEDCOMBUSTION

1.

1. Replace

Replaceburner

accessdoor

door to

to complete

completethe

the outdoor

outdoor

burner access

passage.

combustion

combustionair

air passage.

powercord.

gas burner

Plug in

in gas

3.

3. Plug

burnerpower

cord.

is enclosed,

homeis

enclosed,be

be sure

vent

2.

the space

spacebelow

belowthe

the home

surea vent

2. Iflf the

or

least18

18square

inchesis

is made

madeto

out

or duct

duct of

of at

at least

squareinches

to free

freeoutfor combustion.

door

door air

air to

to provide

sufficientair

air for

combustion,

Drovidesufficient

gas burner

motorand

4.

4. The

The gas

burnermotor

and blower

blowerwill

willstart,

start,drawing

drawingair

air

gas out

the burner

burner and

forcingunburned

out the

through

through the

and forcing

unburnedgas

the

MU ST RUN

flue.

f lue. BURNER

B URNE RMUST

R U N A MINIMUM

MIN IM U MOF

OF FIVE

FIV E

MINUTESFOR

FORANY

ANY PURGING

MINUTES

PURGINGOPERATION.

OPERATION.

K.

TO PUT

PUT BURNER

BURNEROUT

K. TO

OUT OF

OF OPERATION

OPERATION

THE BURNER

BURNER

G.

G. STARTING

STARTINGTHE

pilotlighter

gasvalve

Turngas

valvecontrol

controlknob

knoband

lightermain

valve

1.

and pilot

mainvalve

1. Turn

"OFFI'

to

to "OFF:'

gas valve

gas

valvecontrol

1. Depress

Depressthe

the gas

1.

controlknob

knob on

on the

the electric

electricgas

"OFFI'

valveand

valve

and turn

turn to

to "OFF:'

room thermostat

2. Set

Set room

thermostatabove

room temperature

2.

aboveroom

temperatureand

and let

let

purge the

gas

run five

five minutes

minutesto

burner

burner run

to purge

the unburned

unburnedgas

from

from the

the furnace.

furnace.

thermostatbelow

below room

room temperature.

temperature.

3.

3. Set

Set thermostat

pilotlighter

"ON:' Depress

lightermain

mainvalve

4.

4. Turn

Turnpilot

valveto

to "ON:'

Depressand

andturn

turn

gas valve

"PILOT:'

knob on

on gas

valveto

control

controlknob

to "PILOT:'

pilot observation

5.

5. Open

Open pilot

observationdoor.

door.

pilotlighter

to pilot

lightertube

6.

Hold match

matchto

tube and

and depress

red button

button

6. Hold

depressred

pilot lighter

lighter valve.

valve. Hold

on pilot

Hold button

on

button down

down 3 seconds

seconds

gas valve.

while depressing

depressingknob

knobon

valve.Hold

while

on gas

Holdcontrol

controlknob

knob

pilot stays

about 60

60 seconds

lightedafter

down

down about

secondsuntil

until pilot

stays lighted

after

releasing

releasingknob.

knob.

pilot- ifif not

7. Observe

Observepilot7.

not lighted

lightedrepeat

repeatsteps

steps 1 through

through6.

6.

pilotobservation

8. Close

Closepilot

8.

door.

observation

door.

"ONl'

gas valve

9. Turn

Turngas

valvecontrol

9

controlknob

knobto

to "ON:'

AMS,t0.'TMS-10

62693-001REV

Al\.lSJ.-rvS-1':"'I £:2593-001

PAGE

FEV 03/05-01-96

03/05-01_96

PAGE22

2.

Turn off

off electric

electricsupply.

supply.

2. Turn

L.

L.

GAS

GAS BURNER

BURNERCONTROLS

CONTROLS

PILOTLIGHTER

1. PILOT

LIGHTERMAIN

MAINVALVE

VALVE

gas to

The Pilot

LighterMain

MainValve

Valvecontrols

controlsthe

flowof

The

PilotLighter

the flow

ot gas

to

pilot lighter

lightervalve.

valve.

the

the pilot

2. COMBINATION

E LE C TR IC GAS

V A LVE AND

C OMB IN A TIONELECTRIC

GA S VALVE

AND

PRESSURE

PRESSUREREGULATOR

REGULATOR

The Combination

Electric Gas

Valve and

The

CombinationElectric

Gas Valve

and Pressure

Pressure

with several

Regulator

Regulatoris

is equipped

equippedwith

severalcomponents.

components.

positions.The

The Gas

ValveControl

Knob has

has three

The

Gas Valve

ControlKnob

three positions.

The

positioncompletely

gas supply.

"OFF" position

completelyshuts

shuts off

off the

the gas

supply.

positionreleases

gas to

"PILOT" position

pilot burner

The

The "PILOT"

releasesgas

to the

the pilot

burner

positionreleases

gas to

pilot

releasesgas

only.

only. The

The "ON" position

to the

the pilot

longas

lighted,and

and to

to the

the main

mainburner

burner

burneras

as long

as itit is

is lighted,

burner

w heniti t is

i s energized

electrically.

when

energi zed

el ectri cal l y.

gas

locatedin

in the

valve,filters

filtersthe

the gas

The

The Pilot

PilotGas

Filter,located

the valve,

Gas Filter,

p i l o tburner.

supply

t o the

th e pilot

b u rn e r.

s upplyto

provides100%

Valveprovides

1000/o

shut-offof

of

safety

The

The Pilot

PilotSafety

SafetyValve

safetyshut-off

pilotis

pilotgas

gas whenever

wheneverthe

is extinguished.

pilot

the pilot

extinguished.

pressurefor

for natural

The

The Pressure

PressureRegulator

Regulatorregulates

regulatespressure

natural

gases.

The

regulator

L.P.

gases.

The

screwdriver

slot

on

and

L.P.

screwdriver

slot

on the

the regulator

and

"NAT:' ifif the

po,intto the

fired

must

the word

word "NAT'

the burner

is to

to be

be fired

must point

burneris

"L.P." ifif itit is

gas.

gasand

with

firedon

L.P.gas.

withnaural

nauralgas

and "L.P."

is to

to be

be fired

on L.P.

pressure,remove

pressuretap

plug

gas pressure,

To check

removethe

tap plug

To

check gas

the pressure

gas valve.

the

combinationelectric

valve. Insert

Insert the

of

of the

the combination

electric gas

pressuretap

the

pressure

fittingof

of the

the manometer

manometerand

connectthe

tap fitting

and connect

rubbertube

from the

fitting to

manometer.Refer

Referto

to

rubber

tube from

the fitting

to the

the manometer.

pressure

manometer instructions

instructions for

lor taking

taking pressure

the

the manometer

pilotburner

readings.

readings.Be

Be sure

the main

mainburner

are

surethe

burnerand

and pilot

burnerare

readings.

both

when making

makingreadings.

both burning,

burning,when

Pressureshould

3.5"W.C.

for natural

natural gas

and

W.C. for

Pressure

should be

be 3.5"

oas and

11.0"

11. 0"W.C.

W . C .for

fo r L.P.

L .P .Gas.

Ga s .

3.

CENTRIFUGALSWITCH

3. CENTRIFUGAL

SWITCH

for the

The

The electric

motor for

the blower

blowerwhich

which supplies

comelectricmotor

suppliescomwitha Centrifugal

bustion

air to

the burner

is equipped

Centrifugal

bustionair

to the

burneris

equippedwith

gas

with the

Switch

wired in

in series

the combination

combinationelectric

electricgas

Switchwired

serieswith

valve.

valve.This

This switch

is normally

normallyopen

open until

until the

the speed

speed of

switch is

the

the blower

blower motor

motor closes

thus opens

opens the

the electric

electric

closes itit and

and thus

gas valve.

valve. The

The valve

valve will

will not

not open

open until

is

gas

until the

the blower

blower is

operating

operatingat

at full

full speed.

speed.

REMOVINGCOMPONENTS

M. REMOVING

M.

COMPONENTS

1.

1. TO

T O REMOVE

RE M O VEBURNER

BU R N ERASSEMBLY

AS SE M BL Y

a.

a. Set

thermostatat lowest

lowest setting.

Set thermostat

setting.

gas supply

meter.

b.

b. Shut

off gas

supplyat

at the

the meter.

Shut off

gas burner

gas supply

c.

burnerelectric

electriccord,

cord,gas

supplyto

to

c. Disconnect

Disconnectgas

leads.

burner,

thermostatleads.

burner,and

and thermostat

hexagon nuts

nuts holding

holding burner

burner in

in

d.

d. Loosen

Loosen three

three hexagon

place. Rotate

10" and

place.

Rotate burner

burner clockwise

clockwise about

about 10°

and

remove

removeburner.

Durner.

TO CHANGE

2.

2. TO

C H A N GEMAIN

MA IN BURNER

B U R N E RORIFICE

OB IFI CE

gas

valve at

meter or

a.

tank.

a. Shut

Shut off

off gas valve

at meter

or storage

storage tank.

pipe union,

power cord,

b.

fuel pipe

b. Disconnect

Disconnectfuel

union, burner

cord,

burner power

plate

aluminum

fittings on

the burner

front plate

aluminumtube

tube fittings

on the

burner front

gas valve.

lead on

and

the gas

and thermocouple

thermocouplelead

on the

valve.

c.

Removetwo

two bolts

the orifice

orifice holder.

holder. Pullout

Pull out

c. Remove

bolts on

on the

holder,and

the holder,

the

and change

changethe

the burner

burnerorifice.

orifice.

procedurefor

Reversethe

for re-assembly.

re-assembly.

d.

the above

d. Reverse

above procedure

purge the

gas line

NOTE:

from the

NOTE: Be

Be sure

to purge

the gas

line

sure to

the air

air from

(See Page

restartingthe

Page 2)

2)

before

the burner.

before restarting

burner. (See

PILOTORIFICE

3.

3. TO

TO CHANGE

CHANGEPILOT

ORIFICEOR

OR THERMOCOUPLE

THERMOCOUPLE

(see steps

holderremoved

removed(see

a.

With orifice

steps a through

through d

a. With

orificeholder

pull out

remove four

four screws,

burner

above)

the burner

above) remove

screws, pull

out the

tube assembly.

tube

assembly.

pilot and

pilot

b.

b. Remove

Removescrews

holding the

the pilot

change pilot

screws holding

and change

orifice

thermocouple.

orifice and/or

and/or thermocouple.

procedure lor

c.

for re-assembly,

Reverse the

above procedure

re-assembly,

c. Reverse

the above

making sure

tight.

making

that all

fittings are

sure that

all the

the tube

tube fittings

are tight.

purge the

gas line

line

NOTE:

the air

from the

the gas

NOTE: Be

Be sure

to purge

sure to

air from

before

restartingthe

before restarting

the burner.

burner.

SERVICE

CHECKS

FURNACES

SERVICE

FORGAS

CHECKSFOR

GAS GUN

GUN FURNACES

A.

Burnerwill

will not

not start

Burner

start when

when thermostat

thermostatcalls

callsfor

for heat

heat

gassupply

1. Be

Be sure

valveis

is turned

1.

suregas

supplyvalve

turnedon

on at

at the

the meter

meterso

so

fuelis

fuel

is being

beingsupplied

to the

the burner.

suppliedto

burner.

gasvalve

2.

k~ob on

2. Be

Besure

valvecontrol

controlkhob

on the

theburner

suregas

burneris

isturned

turned

"oN:'

to

to "ON:'

Be sure

sure the

the electric

electriccurrent

currentis

is on

no

3.

3. Be

on and

and there

thereare

are no

blown

fusesin

in the

furnacecircuit.

blownfuses

the furnace

circuit.

pilotis

4. Be

Be sure

4.

relight

surethe

the pilot

is lighted.

lighted.Iflf extinguished,

relightacacextinguished,

cording

for

cordingto

to Instructions

lnstructions

forStarting

StartingGas

GasBurner,

Burner,Steps

Steps11

(SeeBand

through6.

furtherinstructions

through

6. (See

B andC

C below

belowfor

for further

instructions

pilots.).

on

on pilots.).

it.

12.

12. Iflf burner

motorstill

stilldoes

doesnot

notoperate,

operate,replace

replaceit.

burnermotor

willnot

notlight,

light,check

checkthe

the

13.

13. Iflf burner

burnermotor

motorruns

runsbut

butburner

burnerwill

removing

theend

end

operation

of

switch

the

operation

ofthe

thecentrifugal

centrifugal

switchby

by removing

not enenbell

of the

burnermotor.

motor.Iflf the

the contacts

contactsare

are not

bell of

the burner

closed,

motorhas

has enclosed

enclosedconconclosed.clean

cleanthem.

them.Iflf the

the motor

replacethe

motor.

tacts,

tacts,replace

the motor.

problemsor pilot

pilot outage

B. Pilot

Pilot ignition

ignitionproblems

B.

outagebetween

betweenburner

burner

cycles

cycles

pilotorifice.

1.

1. Check

Checkthe

the pilot

orifice.Iflf dirty,

or replace.

replace.

dirty,clean

cleanor

5. Check

Checkthe

mainburner

5.

the main

orifice. If

or plugged, clean

burnerorifice.

lf dirty

dirtyorplugged,

clean

replaceit.

itit or

or replace

it.

propersize

(See

2.

2. Be

Be sure

sure the

size orifice

is being

used.(See

orificeis

being used.

the proper

"OrificeChart:'

Page1.)

1.)

"Orifice

Chart:'Page

place wires

5. Disconnect

Disconnectwires

wires

6.

wires at

at thermostat

thermostatand

and place

together.

together.Iflf burner

burnerstarts

startsthen

thenthermostat

thermostatis

is defective

defective

and

andshould

shouldbe

be replaced.

replaced.

pilotgas

gasline.

restrictions

3.

in

3. Check

Checkfor

for restrictions

in the

the pilot

line.Blowout

Blowoutthe

the

pilotline.

pilot

line.

7. Check

lighttester

7.

Checkthe

thecontrol

controlcircuit

circuitwith

withaa light

testeror

volt-ohm

or volt-ohm

meterfor

for loose

looseconnections

meter

or

wires.

connections

or broken

brokenwires.

gas

the current

8. Check

Checkthe

currentto

to the

the combination

8.

combinationelectric

electricgas

valve.Iflf circuit

valve.

circuitis

is closed

closed.a'nd

vatvedoes

ihO valve

does not

not open,

open,

replacevalve.

replace

valve.

pressureregulator.

9. Check

the pressure

regulator.Iflf regulator

9.

Checkthe

regulatorwill

not adwill not

adjust

hold to

gas

and hold

to 3112"

just and

31/2"Water

WalerColumn

for natural

naturalgas

Columnfor

(L.P.gases

gasesare

operation,

replaceregulator.

regulator.

operation,

replace

(L.P.

regulated

areregulated

at

at the

thetank.

tank.Be

Besure

regulatoron

on the

theburner

is open

lor

sureregulator

burneris

openfor

gasoperation.)

L.P.

L.P.gas

operation.)

gasline.

gasline

4. Be

4.

Besure

surethere

thereis

isno

noair

airin

inthe

thegas

line.Purge

Purgethe

thegas

line

instructionson

Page2.

according

accordingto

to the

the instructions

on Page

2.

pressure.Iflf too

gaspressure.

highor

low,check

with

5.

5. Check

Checkgas

too high

or too

too low,

checkwith

gaspilot

pilotpressure

pressurenormally

(Nat.gas

thefuel

fuelsupplier.

normallyis

is7"

the

(Nat.

supplier.

pressurenormally

gaspilot

pilotpressure

WaterColumn;

Water

Column;L.P.

L.P.gas

normallyis

is 11"

11"

WaterColumn.)

Water

Column.)

gas valve

6.

6. Be

Be sure

sure the

the connection

connectionbetween

betweenthe

valve and

and

the gas

thermocoupleis

is tight

thermocouple

tight to

to ensure

ensurecontact.

contact.

10. Check

tor 24

10.

transformerfor

24 volt

volt output.

no

Checkburner

burnertransformer

output.Iflf no

voltage,replace

replacetransformer.

voltage,

transtormer.

7. Check

with millivoltmeter.

7.

Check thermocouple

thermocouplewith

millivoltmeter. Voltage

Voltage

no less

lessthan

than88 millivolts

millivoltsclosed

should

shouldbe

be no

closedcircuit

circuitand

and

from18

18to

millivolts

open

range

rangefrom

to 32

32 millivolts

opencircuit.

A reading

readingof

circuil.A

of

lessthan

18millivolts

millivoltsindicates

indicatesaa weak

less

than18

weakthermocouple

thermocouple

replaced.

be replaced.

and

and itit should

shouldbe

11. Check

check the

relayoutput.

output.Iflf less

lessthan

11.

the burner

burnerrelay

than 110

110volts,

volts,

replacerelay.

replace

relay.

pilotoutage.

(See

8.

combustion

air

8. Excessive

Excessive

combustion

aircan

cancause

causepilot

outage.(See

Adjustingthe

Page

Page22 Adjusting

the Burner.)

Bumer.)

AMS-10/TM910 62693-001

PAGE 3

AMs-l0rrMS-l0

62693-001 REV.

REV. 03105-01-96

03/05{1-96 PAGE

palotis

Burner motor

c. Burner

motor runs,

runs, pilot

is lighted,

lighted, but

but no

no burner

burner flame

llame

C.

gas

1.

Be

sure

valve

control

knob

on

the

is

burner

turned

1. Be sure gas valve control knob on the burner is turned

" O Nl'

t o "ON:'

to

gas pressure

pressureand

2. Check

Check gas

and thermocouple

thermocoupleas

as outlined

outlinedin

in

2.

B

5.

6and7ab

ove.

B-5, 6 and 7 above.

3. Check

gas valve

Check combination

combinationelectric

electricgas

valve as

as outlined

outlinedin

in

3.

A-6 above.

above.

A-6

4. Check

Check the

the contacts

contacts of

of the

the centrifugal

centrifugalswitch

switch as

as outout4.

linedunder

underA-12

A-12above.

above.

lined

D. Burner

Burner flame

flame without motor

motor running

running

D.

Dirt on

on the

the valve

valve seat,

seat, or

gas

or an

an obstruction

obstructionin

in the

the main

main gas

Dirt

permittinggas

valve is

gas to

is permitting

leak to

to leak

to the

the burner.

burner.Replace

Replacecomcomvalve

gas valve.

binationelectric

electricgas

valve.

bination

E. Intermittent

Intermittent burner

burner operation

operation

E.

1. Be

room thermostat

Be sure

sure room

thermostat is

is not

not located

located near

near another

another

1.

heat or

or cold

coldsource,

source,i.e.,

i.e.,lamps,

lamps,kitchen

kitchenrange,

range,over

overaa

heat

register,in

in sunlight,

sunlight,near

nearan

an outside

outsidedoor,

door,etc.

etc.

register,

2. Be

Be sure

sure the

the return-air

return-airfilter

filter is

is clean.

clean.

2.

3. Be

Be sure

sure the

the lower

lower blower

blower switch

switch setting

is at

seiling is

at 85°

85o or

or

3.

below.

below.

F. Noisy

Noisyfire

fire

F.

Re-adjust

combustion

discto

to reduce

reducethe

thevolume

volumeof

airdisc

of air

air

Re-adjust

combustion

air

(SeePage

drawninto

intothe

theburner.

Page2.)

2.)

beingdrawn

burner.

being

(See

gasbills

Highgas

bills

G. High

G.

Checkcombustion

combustion

adjustment.

airadjustment.

1'l Check

air

propersize

(See"Orifice

"Orifice

Besure

2. Be

sureproper

sizeorifice

orificeisisbeing

beingused.

used.(See

2.

Page1.)

1.)

Chartl'Page

Chart;'

Besure

return-air

filterisisclean.

3. Be

surereturn-air

clean.

3.

filter

4. Be

Besure

homeisisinsulated,

insulated,

windows

anddoor

fittightly,

surehome

doorfit

tightly,

4.

windows

and

no air

leaksin

in the

heatingducts.

andthere

thereare

areno

air leaks

the heating

ducts.

and

roomthermostat

to be

5. Check

Checkroom

thermostatto

be sure

surethe

the setting

settingis

is not

not

5.

higherthan

necessary.Low

Low humidity

humidityrequires

requireshigh

than necessary.

high

higher

temperatures

lor comfort.

comfort.Perhaps

Perhapshumidity

humidityshould

shouldbe

be

temperatures

for

increased.

increased.

H . Circulation

will not

Girculationblower

blower will

not operate,

operate,even

even though

though the

the

H.

burneroperates

operates

burner

1. Check

Checkupper

upperblower

blowerand

and burner

burnerswitch

switchand

and lower

lower

1.

blowerswitch.

switch.

blower

2. Check

theelectrical

Checkthe

electrical

connections

to the

theblower

motor.

blowermotor.

2.

connections

to

outthe

3. Check

Checkout

the blower

blowermotor.

motor.

3.

4. Check

Check the

the control

(See A-5

control circuit.

circuit. (See

A-5 above.)

above.)

4.

5. Check

Check the

the thermocouple.

(See B-6

thermocouple.(See

8-6 and

and 7 above.)

above.)

5.

AMS-IO

GA S BURNER

W IR IN G

B U R N E R WIRING

GAS

T hllrmoslal

Gas Valve

BK

24 V T r o n s

Trmc Dcloy Rcloy

AMS-10/TMS-10

AMS-l0fTMS·10 62693-001

62693-001 REV.

REV. 0305-01-96

03105-01·96 PAGE

PAGE 44

BK

REF.

REF.

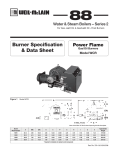

NO.

NO .

1I

2

2

3

4

PART

NO.

PARTNO.

DESCRIPTION

DESCRIPTION

60151

ro.t:''

..

60154

60,1.54

*•

60155

601

55

61455

61455

61428

61428

60160

60160

60161

601

61

61407

61407

60359

60359

61637

61637

60171

60171

14

14

15

15

60172

60172

60353

603s3

PART NO.

PART

NO.

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

24

24

25

25

26

26

27

27

601n

60177

60178

60178

100018

100018

60356

60356

60186

60186

61444

61444

't2946

12946

62503-021

62503021

60192

60192

60193

60193

60194

60194

60198

60198

60728

60728

29

29

30

30

31

31

32

32

'33

*33

60239

60239

61430

614it0

60196

60196

60196

60196

60006

60006

Pipe Union

Pipe

Union

Nipple

Off Set Nipple

Valve

Gas Valve

Gas

Elbow

Elbow

**

60150

60150

6

7

8

9

10

10

10

10

10

10

10

10

11

1' 1

12

12

13

13

REF.

REF.

NO.

NO.

Thermocouple

Thermocouple

Elbow

Elbow

Orifice Holder

Holder

Orifice

Bulkhead

Union

Bulkhead Union

'100

Orifice

Orifice - Nat.

Nat. 100

Orilice- Nat.

Nat. 80

80

Orifice

LP 80

80

Orifice

Orifice- LP

100

Orifice

LP 100

Orifice - LP

Coverplate

Coverplate

Mixer Tube

Tube

Mixer

Fasco

Centrifugal

Centrifugal Switch

Switch Fasco

Micro Switch

SwitchFranklin

Micro

Franklin

Blower,Motor

Motor&

& Wheel

Wheel

Blower,

Air Shutter

Shutter

Air

ControlBox

Control

Box

TerminalBoard

Terminal

Board

Power

Power Cord

Cord

Control Cover

Control

Cover

Transformer

Transformer

Relay

Relay

Burner

Gasket

Burner Gasket

Housing

Burner Housing

Burner

Pilot

Pilot Orifice

Orifice - Nat.

Nat.

Pilot

Orifice - LP

LP

Pilot Orifice

Pilot

Pilot

Pilot

Shield

Pilot Shield

Pilot

Tube

Pilot Tube

Pilot

Tube

Pilot Lighter

Lighter Tube

Pilot

Pilot Valve

Valve

Lighter Tube

Lighter

Tube

Feeder

Tube

Feeder Tube

Valve

Shut-Off

Shut-Off Valve

purchasedat

local hardware

hardwarestore.

store.

be purchased

at local

*-'May

• May be

'Not Shown

*Not

Shown

\

DESCRIPTION

DESCRIPTION

p

15

13'-'

1./

l?

-.-

?'i

4

Q28'\

4

1.

30

Tz

\\--A

1..

--.-Y

i \o^

6;"

t-I

31

AMS-10/TMS-1062693-001

62693{01 REV.

REV.03/05-01-96

PAGE5

03/05{1-96 PAGE

AMS·l0rrMS·10

The

The

Burner

BurnerModel

ModelNo.

No.

----,:-:-;---:(Make)

(Make)

i nsta lledat

at

installed

,, Serial

No.

Serial No.

_

Bears

1978

B earsa label

l abelevidencing

w i th ANSZ21.17b

A N S Z21.17b

197 8and

has

evi denci ngcompliance

compl i ancewith

and has

,...,--,,...,.---_---;-;-----:---::---:-;--,--(Addressof Installation)

(Address

Installation)

beeninstalled

installed

in accordance

accordance

with the

the instructions

instructions

in the

the manufacturer's

been

in

with

in

installation

manual

with

manufacturer's

installation

manualand

in conformity

conformity

withlocal

local

andin

regulations,

ordinances.

regulations,

codes,

codes,and

and ordinances.

No. ,and

No.

the Input

lnput

, andthe

The

The Furnace

Furnace

(Make)

(Make)

of

of unit

unit consists

consistsof

of

BTUH

BTUH

CO

CO, In

l n Flue

F lue

o

%

Flue

Flue Gas

Gas Temperature

Temperature

OF

oF

CO

In Flue

F lue

CO In

%

%

Ambient

AmbientTemperature

Temperature

OF

of

Net

Net Flue

FlueGas

Gas Temperature

Temperature

OF

oF

2

Overfire

Overfire

Draft

DraftIn

In Flue

Flue

_

(inchesH

(inches

0)

HrO)

2

Firing

Fi ri ngRate

B ate

BTU/HR

BTU/HR

properinstallation

lim it i n gdevices

h a v ebeen

All

Al l controls

co nt r olsand

and limiting

d e v i c e shave

b e e nchecked

c h e c k e dfor

for proper

i nstal l ati on

Gas

Gas

Fuel

Fuel used,

us ed,

"w.c.

"W.C.

Manifold

ManifoldPressure

Pressure

_

Gas

Pressure

GasSupply

SupplyPressure

Inches

l nchesW.C.

W. C.

The above

test results

results are

are certified

certified to be

true: - - - - - - - - : - ; - ; - - - - ; - ; : : - - - - - - ; - - ; - : - - - - - - : - ; - - - : - ; - ; - - : - 7 . , . - , - - - - - - - - - - - - above test

be true:

The

Per

Per

--:=_-,----,--( Sig n a tu r e )

(Signature)

(N ameof

(Name

of Company

Maki ngInstallation)

Instal l ati on)

C ompanyMaking

Address:

Address:

Phone:

Phone:

_

FOR

FOR SERVICE

SE RV I CECALL:

CA LL:

Name:

Name :

Phone:

P hone:

Address:

Address:

Date:

Date:

_

_

!-WAYNE\

,

I

WAYNEHOME

HOT'EEQUIPMENT

WAYNE

EOUIPMENT

A SCOTT

SCOTT FETZER

FETZERCOMPANY

COMPANY

801 Glasgow

801

GlasgowAvenue

Avenue

Forl Wayne.

Wayne, Indiana

Indiana 46803

46803

Fort

LIMITEDWARRANTY

LIMITED

WARRANTY

products and

(Wayne)warrants

faulty workmanworkmanWayne

f rom defects

defects due

due to faulty

Home Equipment

warrantsits

its products

and components

f ree from

Wayne Home

Equipment(Wayne)

componentsto be

be free

(' t2)months

monthsfrom

from the

the date

d at e of

of ininship

m at e ri a l sat

ti m e of

o f shipment

a n d under

u ndernormal

normaluse

for twelve

tw el ve(12)

sh i p or

or defective

def ec t iv emate~ials

a t time

s h i p me n tand

use and

and service

servi cefor

qualifie d installer

(1 8 )months

f ir st .This

This

months from

date occurs

occursfirst.

stallation

i n s ta l l e ror

o r eighteen

e i g h te e n(18)

f rom the

the date

manufacture,which

w hi ch ever

everdate

sta l l at ionby

by a qualified

date of

of manufacture,

products,or

has been

m isused,

n o t extend

o r apply

W ayne' sproducts,

w hi ch has

beenmisused,

LIMITED

L IMITE DWARRANTY

W A RRA NT Ydoes

d o e s not

e x te n dor

a p p l y to Wayne's

thereof,which

or any

any component

componentthereof,

w orkmanshi pand

which is

is

neglected,

n egl e c t ed,improperly

im pr oper l yinstalled

i n s ta l l e dor

o r otherwise

o th e rw i s eabused.

a b u s e d .Equipment

E qui pmentwhich

materi alor

or workmanship

and which

w hi ch is

i s defective

defecti vein

i n material

p e ri o dwill

re p ai redor

removed

re mo v edwithin

t he specific

ti m e period

w i l l be

b e repaired

or replaced

repl acedas

wit hin the

s p e c i fi ctime

as follows:

fol l ow s:

poi nt or

(1 ) Field

or distributor

di stri butorof

of Wayne

Wayne

(1)

Fi eld units,

c ont r o l s ,motors

mo to rs &

tra n s fo rm e rsshould

s h oul dbe

be returned

returnedto

to an

servi cepoint

unit s ,controls,

& transformers

an authorized

authori zedservice

point or

sai d service

or

for

o f this

th i s LIMITED

w heresaid

servi cepoint

for determination

o f applicability

a p p l i c a b i l i tyof

L IM IT EDWARRANTY

W A R R A N TYas

as to

to repair

repai ror

or replacement

repl acementwhere

det er m inat ionof

is reasonably

r eas o n a b l yavailable

l ocal i ty.

distributor

a v a i l a b l ein

i n customer's

c u s to m e r ' slocality.

d i s t r ibut oris

(2) Where

transformers,or

or where

where

not avialable

(2)

motors &

& transformers,

local service

is not

avialablefor

lor components

components involving

involvingsaid

controls, motors

Where such

such local

service is

said controls,

products should

prepaid,to Wayne's

home office.

off ice.

other

involved,such

such products

returned,freight

Wayne's home

other components

are involved,

should be

be returned,

freight prepaid,

componentsare

or replaced

replacedat

(3) Products

this LIMITED

repairedor

at

(3)

Productsdetermined

be covered

coveredunder

under this

LIMITEDWARRANTY

WARRANTYby

be either

either repaired

determinedto be

by Wayne

Wayne shall

shall be

opt i o n .

Wayne's

Way ne' ssole

s ole option.

productsand

(4) Wayne

for any

labor cost

for removal

removaland

(4)

responsiblefor

any labor

cost for

and equipment

equipmentassociated

associated

replacementof

of said

Wayne is

is rlot

not responsible

and replacement

said products

therewith.

th er ewit h.

other components

this LIMITED

LIMITEDWAR·

WAR(5) Controls,

(5)

transformers,or

or other

componentswhich

replacedwill

will carry

carry this

motois &

& transformers,

which are

repairedor

or replaced

Controls,motois

are so

so repaired

portion of

product LIMITED

of the

the original

original product

RANTY

the unexpired

unexpiredportion

RANTYequal

equal to the

LIMITEDWARRANTY.

WARRANTY.

productwill

(6) If

not disclose

repaired

discloseany

will be

be repaired

(6)

lf inspection

inspectionby

Waynedoes

does not

any defect

defect covered

coveredby

by Wayne

by this

this LIMITED

LIMITEDWARRANTY,

WARRANTY,the product

o f the

th e customer

t he expense

c u s to m e rand

a n d Wayne's

W ayne' sregular

regul archarges

or

o r replaced

r eplac edat

at the

e x p e n s eof

w i l l apply.

appl y.

chargeswill

T H E SOLE

S OL EAND

A N D EXCLUSIVE

OR FOR

FORA

N Y OTHER

O THER

THE

STATES

REMEDY

ANY

THE FOREGOING

FO RE G O I NG

EX C L U SIV E

R E ME D YFOR

FORANY

W A R R A N TYOR

S T A T E STHE

A N Y BREACH

B R E A C HOF

OF WARRANTY

IN , OR

S OU N D IN GIN

I N CONCO N.

CLAIM

ANY

N Y DEFECT

D E F EC TIN,

OR NON·PERFORMANCE

N ON -P ER FOR MA N COF,

E THE

W

C LAIM BASED

B A S E D ON

ON A

OF,

TH E PRODUCTS,

P R OD U C TSWHETHER

, H E TH E RSOUNDING

IN

ANY

N O OTHER

OR

IMP LIE DINCLUDING

, C LU DI NGANY

TRACT,

NO

N EGL IGE N C E.

OT H E RWARRANTY,

W A R R A N TYWHETHER

W

, H E TH E REXPRESSED

TR AC T ,WARRANTY

W A RRA NT YOR

O R NEGLIGENCE.

E X P R E S S E OR

D IMPLIED,

WI TH

OR

F IT N ES SFOR

IN CONNECTION

C ON N E C TI O N

WARRANTY

PURPOSE,

WITH

M E RC H A N T A BIL ITOR

Y FITNESS

FOR A PARTICULAR

P A R TIC U LA R

E X IS TIN

WARRA NT YOF

O F MERCHANTABILITY

P U R P OS ESHALL

S, H A LLEXIST

A N D IN

OR CONSECO NSE.

TH E SALE

PR OD U C T S

IN NO

FORANY

IN C ID E N TA OR

L

THE

AND

SALEOR

O R USE

US EOF

O F SUCH

S U C HPRODUCTS

N O EVENT

E V E N TWILL

A N Y INCIDENTAL

W ILLWAYNE

W A Y N EBE

B E LIABLE

LIA B LEFOR

ot her

personto

f or Wayne

W ayneany

anyother

W

n e i therassumes

QUENTIAL

to assume

assumefor

DA M A G E SOF

A N Y NATURE.

N AT U R EWayne

. a y n eneither

assumesnor

nor authorizes

QUEN T I A LDAMAGES

OF ANY

authori zesany

any person

th e sale

products.

w i th the

s a l e of

o f these

liability

l i a bi l i tyor

or obligation

obligat ionin

i n connection

c o n n e c ti o nwith

these products.

AMS-1o/TMS-10 62€rO-OC1

AMS-l0/TMS-l0

ii?693-0o1 RE:V

REV 03;05-01-96

PAGE 6

03/05-0r 96 PAGE