Download 2 - PlayKom.Ru

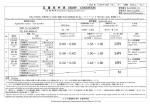

Transcript