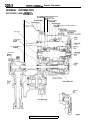

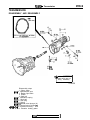

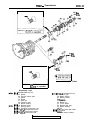

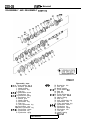

Download 1990-1996 M/T Overhaul - 3SX Performance Automotive

Transcript