Download SSB SERVICE MANUAL 147423D_6

Transcript

SERVICE MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

MODELS SSB-3E/5E/10EF,

(2)SSB-3E/5E/10EF,

SSB-3G/5G/10GF &

(2)SSB-3G/5G/10GF

· Self Contained

· Electric or Gas Heated

· Capacity:

3, 5 or 10 Steamer Pans Per Cavity

· Pans:

12” x 20” x 2 2/1”

PART NUMBER 147423, REV. D (6/06)

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

unifiedbrands.net

5BCMF PG $POUFOUT

*/530%6$5*0/

5)& (30&/ 4&37*$& $0/$&15

(30&/ $&35*'*&% 4&37*$&

8"33"/5: "/% /0/8"33"/5: 3&1"*34

4"'&5:

(-044"3: 0' 5&3.4

500-4 "/% 4611-*&4

3FRVJSFE 5PPMT

3FDPNNFOEFE *OTUSVNFOUT

)FMQGVM )BSEXBSF

3FDPNNFOEFE 4VQQMJFT

)08 50 64& 5)*4 ."/6"-

$0/530-4

01&3"5*/( 130$&%63&

5:1*$"- 01&3"5*0/4

01&3"5*0/

$PPLJOH 'PPE

8BUFS &OUSZ *OUP 4UFBN 3FTFSWPJS

4FSWJDF &SSPST

)FBUFS $POUSPM

%SBJOJOH 8BUFS 'SPN 5IF 4UFBN (FOFSBUPS

-PX 8BUFS -FWFM %FUFDUJPO

*/45"--"5*0/ $-&"/*/( "/% 5&45*/(

&-&$53*$ .0%&- */45"--"5*0/

("4 .0%&- */45"--"5*0/

*/45"--"5*0/

*/45"--"5*0/ $)&$,-*45

45&". 3&4&370*3 $-&"/*/(

(&/&3"- $-&"/*/(

&-&.&/5 8*3*/(

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

).42/$5#4)/.

4HE 'ROEN 3ERVICE #ONCEPT

7ARRANTY AND .ON7ARRANTY 2EPAIR

3INCE 'ROEN HAS BEEN IN THE BUSINESS OF DESIGNING AND

MANUFACTURING THE FINEST COMMERCIAL APPLIANCES FOR THE FOOD

SERVICE INDUSTRY #HEFS COOKS AND KITCHEN SUPPORT PERSONNEL

HAVE COME TO DEPEND UPON THE QUALITY OF CONSTRUCTION AND

THE RELIABILITY OF OPERATION

'ROEN 7ARRANTY PROVISIONS ARE CLEARLY PRESENTED IN THE

CUSTOMERS /PERATOR -ANUAL

'ROEN IN TURN DEPENDS UPON OUR SERVICE CENTERS AND THEIR FIELD

SERVICE PERSONNEL TO KEEP THE EQUIPMENT IN TOP OPERATING CONDI

TION )N ORDER TO DO THIS OUR DESIGNS ARE MADE WITH SERVICE AND

RELIABILITY IN MIND

/NCE THE 'ROEN EQUIPMENT IS SOLD MANUFACTURED DELIVERED AND

INSTALLED OUR REPUTATION IS CLEARLY IN YOUR HANDS !S PART OF OUR

TEAM WE VALUE YOUR EFFORTS AND INPUT TO OUR PRODUCT DESIGN

7E WILL DO ALL WE CAN TO MAKE YOUR JOB OF KEEPING THE EQUIP

MENT IN PERFECT WORKING ORDER AS EASY AS WE CAN 4OGETHER WE

WILL KEEP OUR CUSTOMERS SATISFIED

'ROEN #ERTIFIED 3ERVICE

4HE 3MART3TEAM "OILERLESS 3TEAMER HAS BEEN CAREFULLY DESIGNED

TO PROVIDE MANY YEARS OF EFFICIENT AND RELIABLE SERVICE 0ART OF THE

QUALITY PROGRAM IS 'ROEN #ERTIFIED 3ERVICE 4HIS INCLUDES

s 'ROEN CERTIFIES THAT ALL EQUIPMENT DELIVERED TO OUR CUSTOMERS

HAS BEEN INSPECTED AND TESTED FOR COMPLIANCE WITH THE

SPECIFICATIONS

s 'ROEN CERTIFIES THAT ALL PARTS REQUIRED FOR SERVICE AND

MAINTENANCE WILL BE READILY AVAILABLE

s 'ROEN CERTIFIES THAT THIS MANUAL WILL BE UPDATED BY MEANS OF

PERIODIC SERVICE BULLETINS TO PROVIDE THE MOST UPTODATE

INFORMATION FOR FIELD MAINTENANCE AND SERVICE PERSONNEL

#ALLFOR4ECHNICAL3UPPORT

#ERTAIN PROCEDURES FOR THE CLEANING ANDOR ADJUSTMENT

OF THE 3MART3TEAM "OILERLESS 3TEAMER ARE PRESENTED IN THIS MAN

UAL FOR REFERENCE BUT NOT WARRANTY RELATED

3AFETY

4HE 'ROEN 3MART3TEAM "OILERLESS 3TEAMER HAS BEEN DESIGNED

WITH SAFETY IN MIND 4HIS INCLUDES SAFETY TO THE OPERATING AND

MAINTENANCE PERSONNEL SAFETY TO THE FACILITY IN WHICH THE EQUIP

MENT IS INSTALLED AND SAFETY TO THE EQUIPMENT ITSELF

4HE STEAMER HAS BEEN DESIGNED TO THE HIGHEST INDUSTRY STANDARDS

AND HAS BEEN CERTIFIED BY THE .ATIONAL 3ANITATION &OUNDATION

4ESTING ,ABORATORY .3& 5NDERWRITERS ,ABORATORY 5, ANDOR

#3! GAS

4HE STEAMER CONTAINS SEVERAL DEVICES WHICH ARE SPECIFICALLY USED

TO PREVENT UNSAFE CONDITIONS )F THEY ARE DISCONNECTED DURING

SERVICE MAKE SURE THEY ARE REINSTALLED PROPERLY AND TESTED BEFORE

THE STEAMER IS OPERATED

4HE SAFETY PRECAUTIONS IN THIS MANUAL ARE IN ACCORDANCE WITH

!.3) 3TANDARD 4HREE DIFFERENT SIGNAL WORDS ALERT YOU TO A

HAZARDOUS SITUATION $!.'%2 7!2.).' !.$ #!54)/.

$!.'%2 4HE SIGNAL WORD $!.'%2 INDICATES THAT A

HAZARDOUS SITUATION EXISTS AND COULD RESULT IN SERIOUS INJURY

OR DEATH

s $O NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

s 7HEN YOU OPEN THE STEAMER DOOR BE VERY CAREFUL TO AVOID

ESCAPING STEAM 3TEAM CAN CAUSE BURNS

s !FTER REMOVING THE FAN BAFFLE PARTITION DO NOT PUT YOUR

HANDS OR OTHER OBJECT INTO THE COOKING CAVITY UNTIL THE FAN

COMES TO A COMPLETE STOP 2OTATING FAN BLADES CAN CAUSE

SEVERE INJURY

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

).42/$5#4)/.

2ECOMMENDED 3UPPLIES

s 0IPE 4HREAD #OMPOUND "RAND ,!#/ 0IPE4ITE 3TIK

.O OR EQUIVALENT

s -OTOR 3EALANT 'REASE "EL2AY

s v !LUMINUM $UCT 4APE

s 2EMOVABLE 4HREAD ,OCKER

,OCKTITE 4YPE $OOR

,OCKTITE 4YPE %XTERIOR

s #LEAR 3ILICONE 3EALANT

$OW #ORNING 4YPE s 3ILICONE (EAT 3INK #OMPOUND

.ON&LUID /IL #ORP #HEMPLEX s (IGH 4EMPERATURE !NTI3EIZE AND ,UBRICATING #OMPOUND

"OSTIX .%6%2 3%%: .3"4

(OW 4O 5SE 4HIS -ANUAL

2EAD THIS MANUAL COMPLETELY BEFORE ATTEMPTING ANY DISASSEMBLY

OR REPAIRS

0LEASE NOTE THE SIMILARITIES AND DIFFERENCES BETWEEN THE VARIOUS

MODELS DESCRIBED IN THE MANUAL

"EFORE MAKING REPAIRS YOU SHOULD HAVE KNOWLEDGE OF THE

STEAMER OPERATION AS DESCRIBED IN THE /PERATIONS 3ECTION OF THIS

MANUAL AND A GOOD UNDERSTANDING OF SERVICE TECHNIQUES AS

PRESENTED BY THE 'ROEN 3ERVICE 3CHOOL

4HIS SERVICE MANUAL SHOULD BE TAKEN WITH YOU ON ALL SERVICE CALLS

5SE THE CORRECT TOOLS IN ACCORDANCE WITH THE PROCEDURES SHOWN

AND USE ONLY 'ROEN #ERTIFIED 2EPLACEMENT 0ARTS WHEN PERFORMING

STEAMER REPAIRS

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

FAN Symbol or

White Service Light

The White Service Light or Fan symbol indicator light shows

when the control cooling fan is not functioning properly or

the Snap-Disc T-Stat on the drain box has been tripped. The

steamer will still function, but if the service light stays on

for more than 30 minutes service should be called because

continued use for prolonged periods could result in

component damage due to excessive temperatures.

or Fan Light

4YPICAL/PERATIONS

4HEFOLLOWINGISASEQUENCEOFEVENTSTYPICALTO3MART3TEAM

"OILERLESS3TEAMER

#OOKING&OOD

4OUSETHESTEAMERTHECAVITYDOORISCLOSEDTHE#/.42/,

0/7%2ROCKERSWITCHANDTHE/./&&TOUCHPADISSETTO/.

4HEUNITPERFORMSAQUICKDIAGNOSTICSSEQUENCELIGHTINGALL

,%$SEXCEPTTHE()4%-0,%$ONTHEFRONTPANELANDTHE

0/7%2INDICATORLIGHTREMAINSILLUMINATED4HEUNITVERIlES

THEmOATSPROBESANDDRAINBYTHESEQUENCEBELOW4HEDRAIN

VALVEISCLOSEDANDTHEWATERENTERSTHESTEAMRESERVOIRTOTHE

hlLLvPOINT7HENTHEWATERLEVELREACHESTHE,/7LEVELmOAT

PROBETHEMUFlNFANWILLRUN7HENTHEWATERLEVELREACHESTHE

()'(LEVELmOATPROBETHEWATERlLLVALVECLOSESANDTHEDRAIN

VALVEOPENSUNTILWATERDROPSOFFTHEHIGHmOATPROBE!TTHIS

POINTTHEDRAINVALVECLOSESANDTHEWATERVALVEOPENSTORElLL

THE()'(mOATPROBE7HENTHEWATERREACHESTHE()'(mOAT

PROBETHEWATERlLLVALVECLOSESSTOPPINGTHEENTRYOFWATER

INTOTHESTEAMRESERVOIR

!RELAYENERGIZESANDPROVIDESPOWERTOTHEHEATINGCIRCUIT

FORTHESTEAMRESERVOIR4HISHEATSTHESTEAMRESERVOIRTOBOIL

THEWATERCREATINGTHEREQUIREDSTEAM7HENTHECAVITYIS

HEATEDTOABOUTDEGREES&THE2%!$9INDICATORLIGHT

COMESONINDICATINGTHATTHECOOKINGCANSTART7HENITIS

DESIREDTOCOOKFOODINTHECAVITYTHEPANSAREINSERTED

INTOTHECAVITYANDTHEDOORISCLOSED

(EATUPTIMEISABOUTMINUTESAFTERTHE/./&&TOUCH

PADISPRESSEDIFALLOFTHEABOVECONDITIONSAREMET

5SINGTHETIMERCONTROLTHEKNOBISROTATEDAROUNDTHEDIAL

TOTHEDESIREDTIMEFROMTOMINUTESORPLACEDINTHE

TIMEDPOSITIONANDTHE'REEN4)-).'LIGHTBELOWTHEKNOBWILL

ILLUMINATE)NTHETIMEDPOSITIONA2ED$/.%LIGHTONTHELEFT

SIDEOFTHEDIALWILLGOONWHENCOOKINGTIMEISCOMPLETEDAND

THEhBEEPERvWILLSOUND)NTHEhONvPOSITIONA'REEN/.LIGHT

ONTHERIGHTSIDEOFTHEDIALWILLGOONTOINDICATETHAT

THESTEAMERISBEINGSETTOCONSTANT/.

7HENTHETIMEDCOOKINGPERIODISCOMPLETEABUZZERWILLSOUND

ANDTHE2ED$/.%LIGHTONTHETIMERDIALWILLGOONUNTILTHE

TIMEKNOBPOINTERISROTATEDTOTHE/&&OCLOCKPOSITION

BETWEENTHETWOLIGHTS

7HENTHETIMERISSETTOTHE/&&POSITIONTHEUNITWILLCONTINUE

TOOPERATEFORMINUTESTHENPERFORMADUTYCYCLEOFMINUTE

/.MINUTES/&&

)FTHEDOORISOPENEDDURINGTHECOOKINGPROCESSTHEDOORINTER

LOCKSWITCHCAUSESTHEDOORLIGHTTOILLUMINATECAUSINGPOWER

TOBEREMOVEDFROMTHECONVECTIONMOTORANDTHESPRAYVALVE

CLOSES4HERELAYOPENSTHECIRCUITTOTHESOURCEOFHEATINSTANTLY

REDUCINGTHEHEATFROMTHESTEAMRESERVOIR

7ATER%NTRY)NTO3TEAM2ESERVOIR

/NPOWERUPTHEBOILERGOESTHROUGHAlLLDRAINDIAGNOSTICTO

VERIFYTHECONDITIONOFTHEWATERLEVELPROBEANDDRAIN

>°Ê )FTHEDRAINISBLOCKEDASERVICEERRORISGENERATED

L°Ê )FEITHERPROBEISNOTRESPONDINGASERVICEERRORISGENERATED

#!54)/.ÊÊ!SCALEDRESERVOIRORDEBRISWILLCAUSESERVICEERRORS

7HENABUTTONORmOATPROBEHAVEEXCESSIVESCALETHEYWILLNOT

FUNCTIONPROPERLY

./4)#%ÊÊ7HENPOWEREDOFFTHECONTROLSEMPTYTHESTEAM

RESERVOIR

4HE()'(7!4%2mOATPROBEDETERMINESIFTHEREISAFULLAND

PROPERLEVELOFWATERINTHESTEAMRESERVOIR)FTHEWATERLEVEL

GOESDOWNTHEmOATPROBEISOPENEDBYTHEWATERLEVELGETTING

LOW4HISCAUSESTHEWATERlLLVALVEFORTHATSTEAMRESERVOIRTO

TURNONTOPERMITWATERTOENTERTHESTEAMRESERVOIR

7ATERWILLCONTINUETOENTERTHESTEAMRESERVOIRUNTILTHELEVELOF

WATERISHIGHENOUGHTOCLOSETHE()'(7!4%2mOATPROBE4HIS

DETERMINESTHATTHESTEAMRESERVOIRISFULLANDTHENTHEWATER

SUPPLYSOLENOIDVALVEISTURNEDOFFSTOPPINGTHEWATERmOWTOTHE

STEAMRESERVOIR

7HENTHE()'(7!4%2mOATPROBEISOPENTHEREISATO

SECONDDELAYBEFORETHEWATERlLLVALVEOPENS4HISISTOTAKEINTO

7HENTHEUNITISATREADYTEMPERATUREANDTHETIMERISSETTOTHE ACCOUNTTHERISINGANDLOWERINGOFTHEWATERLEVELDUETOTHE

TIMEDPOSITIONTOMINUTESORPLACEDINTHEMANUALPOSITION BUBBLINGACTIONOFTHEBOILINGWATERINTHESTEAMRESERVOIR)FTHE

mOATPROBEISOPENFORMORETHANAPPROXIMATELYSECONDSTHEN

THEMOTORANDFANINTHECAVITYSTARTSTHECONDENSATESPRAY

THEWATERlLLVALVEISACTIVATED

COMESONANDTHESTEAMENTERSTHECAVITYANDISDISTRIBUTED

THROUGHOUTTHECAVITY

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

The Water Level Control Board and Low Probe or K4 Relay & Low

Float monitors and shuts the unit down if reservoir water level is

below the low float/probe.

.OTES

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

-/ ] /-/ 'AS -ODEL )NSTALLATION

7!2.).'

4HEUNITMUSTBEINSTALLEDBY

PERSONNELWHOAREQUALIFIEDTOWORK

WITHGAS ELECTRICITYANDPLUMBING

)MPROPERINSTALLATIONCANCAUSE

INJURYTOPERSONNELANDORDAMAGE

TOTHEEQUIPMENT 4HEUNITMUSTBE

INSTALLEDINACCORDANCEWITH

APPLICABLECODES

#!54)/.

$O NOT INSTALL THE UNIT WITH THE REAR

VENTS BLOCKED OR WITHIN INCHES OF

A HEAT SOURCE SUCH AS A BRAISING PAN

DEEP FAT FRYER CHARBROILER OR KETTLE

4O AVOID DRAINAGE PROBLEMS

LEVEL THE UNIT FRONT TO BACK

OR PITCH IT SLIGHTLY TO THE REAR

!LTHOUGH 'ROEN RECOMMENDS THE 3MART3TEAM "OILERLESS 3TEAMER IS

INSTALLED NEAR NONCOMBUSTIBLE SURFACES THE FOLLOWING Õ

CLEARANCES ARE TO ANY SURFACE COMBUSTIBLE OR NONCOMBUSTIBLE

2IGHT 3IDE INCHES

,EFT 3IDE INCHES

2EAR INCHES

(OWEVER FOR EASY SERVICE AT LEAST A INCH CLEARANCE SHOULD EXIST

FOR RIGHT SIDE ACCESS TO GAS SHUTOFF VALVE

4HE UNIT MUST BE INSTALLED IN A WELLVENTILATED ROOM WITH AN

ADEQUATE AIR SUPPLY 4HE STEAMER MUST BE INSTALLED BENEATH A

VENTILATION HOOD SINCE GAS COMBUSTION PRODUCTS EXIT THE APPLIANCE

!NY ITEM WHICH MIGHT OBSTRUCT OR RESTRICT THE FLOW OF AIR FOR

COMBUSTION AND VENTILATION MUST BE REMOVED $O NOT OBSTRUCT

THE FLUE COVER OR REAR VENTS AFTER INSTALLATION

4HE AREA DIRECTLY AROUND THE APPLIANCE MUST BE CLEARED OF ALL

COMBUSTIBLE MATERIAL 4HE INSTALLATION MUST CONFORM WITH LOCAL

CODES OR IN THE ABSENCE OF LOCAL CODES WITH THE .ATIONAL &UEL

'AS #ODE !.3) :.&0! OR THE .ATURAL 'AS AND

0ROPANE )NSTALLATION #ODE #3! "

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

4HE UNIT AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED

FROM THE GAS SUPPLY SYSTEM DURING ANY PRESSURE TESTING OF THAT

SYSTEM WHICH HAS TEST PRESSURES IN EXCESS OF 03) K0A

)T MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING

ITS INDIVIDUAL MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF

THE GAS SUPPLY PIPING SYSTEM WHICH HAS TEST PRESSURES EQUAL TO

OR LESS THAN 03) K0A

%LECTRICAL 3UPPLY #ONNECTION

0ROVIDE 6!# (: 0( !-0 SERVICE "RING WIRE IN

THROUGH HOLE ON THE BACK PANEL %ACH CAVITY REQUIRES A

SEPARATE CORD FOR CONNECTION ,OCAL CODES ANDOR THE .ATIONAL

%LECTRICAL #ODE SHOULD BE OBSERVED IN ACCORDANCE WITH

!.3).&0! !. %,%#42)#!, '2/5.$ )3 2%15)2%$

4HE WIRING DIAGRAM LOCATED IN THE SERVICE COMPARTMENT AND IN

THIS MANUAL -AXIMUM LOAD IS !-0S )N #ANADA PROVIDE

ELECTRICAL SERVICE IN ACCORDANCE WITH THE #ANADIAN %LECTRICAL

#ODE #3! # 0ART ANDOR LOCAL CODES

'AS 3UPPLY #ONNECTION

#ONNECTION TO THE GAS SUPPLY SHALL BE IN ACCORDANCE WITH THE

CHART BELOW 3UPPLY PRESSURE MUST BE AT LEAST v 7# MAXIMUM

v 7# FOR NATURAL GAS OR v 7# MAXIMUM v 7# FOR

,0 GAS )N #ANADA THE INSTALLATION MUST CONFORM TO THE

#ANADIAN 'AS #ODE #!. " )NSTALLATION #ODES FOR 'AS

"URNING !PPLIANCES AND %QUIPMENT ANDOR LOCAL CODES #HECK ALL

GAS CONNECTIONS FOR LEAKS PRIOR TO UNIT OPERATION

2!4).'3 &/2 '!3 3-!2434%!).#/-).' '!3

&%%$ 2!4%

-).)-5- -!8)-5-

"45

/0%2!4).'

02%3352%

' .ATURAL

v 7#

v 7#

v 7#

' 0ROPANE

v 7#

v 7#

v 7#

' .ATURAL

v 7#

v 7#

v 7#

' 0ROPANE

v 7#

v 7#

v 7#

' .ATURAL

v 7#

v 7#

v 7#

' 0ROPANE v 7#

v 7#

v 7#

-/$%,

3EE PAGE FOR FURTHER INSTALLATION INSTRUCTIONS

#ALLFOR4ECHNICAL3UPPORT

”

24

0]

[61

UNITS WITH VENTS

CURRENT PRODUCTION

STEAM FREE ZONE

Refer to page 3.3 for proper clearances.

If unit has a code, turn off at Touch Pad. Open the steamer door.

WARNING

DO NOT DISASSEMBLE FLOAT PROBES DURING CLEANING, BREAKAGE WILL RESULT. USE HOT WATER TO

WASH OUT PIVOT JOINTS OF FLOAT.

-/ ]Ê

Ê Ê/-/ %LEMENT7IRING

33"%

*52(166%((/(0(17:,5,1*3+$6(

$

% $

% $

% $

% $

% $

% $

0HASE

$

$

% $

% $

% $

% $

% $

%

$ $

$ $

% % %

%

127(:+(1&219(57,1*

)5203+$6(723+$6(

$''$-803(5:,5()520$72

&217(50,1$/%/2&.7%$6

6+2:1217+(:,5,1*

',$*5$0

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

+($7(5(/(0(176

%

$

$

%

%

%

$

$

$

$

/

/

/

%

%

(/(0(177(50,1$/

%/2&.

%

%

*52(166%((/(0(17:,5,1* RU3+$6(

$

% $

% $

% $

% $

% $

% %

$

$

$

$

$

$

$

% $

% $

% $

% % $ $

$

% $

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

(/(0(17

0HASE

(/(0(17

+($7(5(/(0(176

% $

% $

%

$

%

$

%

%

%

/

/

/

%

%

%

%

7(50,1$/%/2&.

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

-/ ]Ê

Ê Ê/-/ %LEMENT7IRING

33"%

£ Ó

ÊÊ,

ÊÊ7/

È

Î { n £ä

È

6OR6 x

{

0HASE

0HASE Î

Ó

Î

/ÊÊÓ£

/ÊÊÓä

/ÊÊ£

/ÊÊ£n

/ÊÊ£Ç

£Î £{ £ Óä Ó£

£x

£È

£Ç

£n

£

Óä

Ó£

£n

£Ç

£È

£x

£{

£Î

£Ó

Ç

n

£ä

££

/ÊÊ£È

/ÊÊ£x

£Ó

x

£

££

Ç

Ó

£

/ÊÊ£{

/ÊÊ£Î

/ÊÊ£Ó

/ÊÊ££

/ÊÊ£ä

/ÊÊ

/ÊÊn

/ÊÊÇ

/ÊÊÈ

/ÊÊx

/ÊÊ{

/ÊÊÎ

/ÊÊÓ

/ÊÊ£

/,Ê /-

£

/Ê/, Ê"

Ê

Ó

Î

,/Ê/, Ê"

Ç

n £ä ££

/ÊÊÓ£

/ÊÊÓä

/ÊÊ£

/ÊÊ£n

/ÊÊ£Ç

/ÊÊ£È

/ÊÊ£x

/ÊÊ£{

/ÊÊ£Î

/ÊÊ£Ó

/ÊÊ££

/ÊÊ£ä

/ÊÊ

/ÊÊn

/ÊÊÇ

/ÊÊÈ

/ÊÊx

/ÊÊ{

/ÊÊÎ

/ÊÊÓ

/ÊÊ£

/,Ê /-

£n £ Óä Ó£

£Ç

ÊÊ,

ÊÊ7/

0HASE

£

È

x

{

Î

Ó

£

Î

{

x

È

Ç

£

£

/Ê/, Ê"

Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

£Ó

£Î

£{

£x

£È

Ó

Ó

n

£ä

££

£È

£x

£{

£Î

£Ó

£Ç

£n

£

£

Ó

£

,/Ê/, Ê"

Óä

Ó£

#ALLFOR4ECHNICAL3UPPORT

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

-/ ]Ê

Ê Ê/-/ %LEMENT7IRING

33"%

/ÊÊ

/ÊÊn

/ÊÊÇ

/ÊÊÈ

/ÊÊx

/ÊÊ{

/ÊÊÎ

/ÊÊÓ

/ÊÊ£

/,Ê /-

£ Ó Î Ç n

6OR6

0HASE

0HASE

ÊÊ,

ÊÊ7/

{

È

x

{

Î

Ó

£

x

£

Ó

È

Ç

n

Î

/, Ê"

0HASE

ÊÊ,

ÊÊ7/

"/\ÊÊ7 Ê

" 6,/ Ê

,"ÊÊÎÊ*-Ê/"Ê£Ê*-]Ê

ÊÊ1*,Ê7,Ê,"ÊÊ

/"Ê

Ê" Ê/, Ê"

Ê

/£Ê-Ê-"7 Ê" Ê/Ê

7, Ê,

È

Ç

/ÊÊ

/ÊÊn

/ÊÊÇ

/ÊÊÈ

/ÊÊx

/ÊÊ{

/ÊÊÓ

/ÊÊ£

/ÊÊÎ

/,Ê /-

n

£ Ó Î

x

{

Î

Ó

£

{

x

È

Ç

n

£

£

Ó

/Ê/, Ê

"

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

42/5",%3(//4).' %LECTRIC 'AS -ODELS

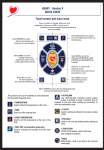

0ROCEDURE TO !CCESS 3ERVICE #ODES

4URN UNIT OFF USING THE /./&& BUTTON ON THE TOUCH PAD CONTROL

4URN UNIT

USING

/./&&

BUTTON

ON THE

TOUCH $OOR,ID

PAD CONTROL

0RESS

AND OFF

HOLD

THE THE

HIDDEN

BUTTON

LOCATED

BETWEEN

AND (ITEMP LIGHTS FOR SECONDS

0RESS

AND

HOLD

THE

HIDDEN

BUTTON

LOCATED

BETWEEN

$OOR,ID

AND (ITEMP LIGHTS FOR SECONDS

/BSERVE 2EADY LIGHT FLASH TO START

/BSERVENUMBER

2EADY OF

LIGHT

FLASH

TO START

#OUNT

TIMES

3ERVICE

LIGHT FLASHES

#OUNT

NUMBER

OF

TIMES

3ERVICE

#ORRELATE WITH NUMBER IN COLUMLIGHT

OFFLASHES

%RROR #ODE 4ABLE

#ORRELATE WITH NUMBER IN COLUM OF %RROR #ODE 4ABLE

3MART3TEAM %RROR #ODES

3MART3TEAM %RROR #ODES

%22/2

%22/2

#/--%.4

#/--%.4

3(54$/7.

3(54$/7.

&ATAL %RROR

"%%0%2

"%%0%2

,%$

,%$

).$)#!4)/.

).$)#!4)/.

&ATAL %RROR

&ILL TO ,OW FLOATPROBE TIME

&ILL

TO ,OW PROBE

TIME

EXCEEDED

BAD LOW

PROBE

EXCEEDED BAD LOW PROBE

#HIRP

#HIRP

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE

,IGHT

ONCE EVERY

SECONDS

ONCE EVERY SECONDS

#LOGGED FILTER

#LOGGED

FILTER

,OW WATER

PRESSURE

,OW

WATER

PRESSURE

"AD FLOATPROBE

"AD

"AD PROBE

FILL DRAIN

"AD

DRAIN

/PENFILLDRAIN

/PEN DRAIN

&ILL TO (IGH FLOATPROBETIME

$RAIN THEN REFILL

&ILL

TO (IGH BAD

PROBE

TIME

EXCEEDED

LOW

FLOATPROBE $RAIN THEN REFILL

EXCEEDED BAD LOW PROBE

#HIRP

#HIRP

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE

,IGHT

ONCE EVERY

SECONDS

ONCE EVERY SECONDS

#LOGGED FILTER

#LOGGED

FILTER

,OW WATER

PRESSURE

,OW

WATER

"AD PROBE PRESSURE

"AD

"AD PROBE

FILL DRAIN

"AD

DRAIN

/PENFILLDRAIN

/PEN DRAIN

2EFILL -AKEUP WATER TIME

2EFILL

-AKEUP

WATER

EXCEEDED

RECOVERY

FILL TIME

TIME

EXCEEDED

RECOVERY

FILL TIME

OR BOIL OFF RATE

OR BOIL OFF RATE

#HIRP

#HIRP

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE

,IGHT

ONCE EVERY

SECONDS

ONCE EVERY SECONDS

#LOGGED FILTER

#LOGGED

FILTER

,OW WATER

PRESSURE

,OW

WATER

PRESSURE

"AD FLOATPROBE

"AD

"AD PROBE

FILL DRAIN

"AD

DRAIN

/PENFILLDRAIN

/PEN DRAIN

"OTH WATER FLOATSPROBES FAILED &ATAL %RROR

"OTH WATER PROBES FAILED

&ATAL %RROR

/N

/N

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE ,IGHT

X SECOND

X SECOND

,IME

,IME

"AD FILL VALVE

"AD FILL VALVE

)F ERROR OCCURRED BEFORE ERROR

)F ERROR

OCCURRED

BEFORE ERROR

2EV"hUSE

v -,

2EV" hUSE v -,

&ATAL %RROR

&ATAL %RROR

/N

/N

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE ,IGHT

X SECOND

X SECOND

(I FLOATPROBEBUTNOLOW

(I PROBE BUT NO LOW PROBE

FLOATPROBE

&ATAL %RROR

&ATAL %RROR

/N

/N

&LASH $OOR ,ID,IGHT

&LASH

$OOR ,ID,IGHT

X SECOND

X

SECOND

&LASH 3ERVICE,IGHT

&LASH

3ERVICE,IGHT

X SECOND

X SECOND

(IFLOATPROBE3ATISFIED

(IPROBE3ATISFIED

WITH

NO ,OW FLOATPROBE

WITH NO ,OW PROBE

&ATAL %RROR

&ATAL %RROR

/N

/N

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE ,IGHT

X SECOND

X

SECOND

&LASH $OOR,I,IGHT

&LASH

$OOR,I,IGHT

X SECOND

X SECOND

-AKEUP WATER FILL TIME

-AKEUP

EXCEEDED WATER FILL TIME

EXCEEDED

,IME BUILDUP

,IME BUILDUP

"ETWEEN FILL VIOLATION

"ETWEEN

VIOLATION

WATER

-AKEUP FILL

-AKEUP

WATER

.OT USED

2ECOVERY TIME

.OTFLOAT

USED

2ECOVERY TIME

WITH

WITH

FLOAT

FLOATPROBE

PROBE SOFT

SOFTWARE

WARE

$RAIN TIME EXCEEDED FAULT

$RAIN TIME EXCEEDED FAULT

&ATAL %RROR

&ATAL %RROR

#HIRP

#HIRP

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE ,IGHT

X SECOND

X SECOND

&AILED BLOCKED DRAIN

&AILED

BLOCKED DRAIN

FLOATPROBEFALSEPOSITIVE

PROBES FALSE POSITIVE

(OT FILL TIME EXCEEDED

(OT FILL TIME EXCEEDED

&ATAL %RROR

&ATAL %RROR

/N

/N

&LASH 3ERVICE ,IGHT

&LASH

3ERVICE

,IGHT

ONCE EVERY

SECONDS

ONCE EVERY SECONDS

#LOGGED FILTER

#LOGGED

FILTER

"AD FLOATPROBE

"AD

PROBE

&AILED FILL DRAIN

&AILED FILL DRAIN

&ILL6ALVE3LOW&ILL

&ILL6ALVE3LOW&ILL

7ATER0RESSURE

7ATER 0RESSURE

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

42/5",%3(//4).' %LECTRIC 'AS -ODELS

3MART3TEAM 4ROUBLESHOOTING 0ROCEDURE

%ACH TEST PROCEDURE BUILDS ON THE PRIOR ONES !LWAYS START AT THE BEGINNING OF THIS PROCEDURE AND CONTINUE UNTIL THE RESULTS INDICATE A

MALFUNCTION $O NOT SKIP STEPS

7, \ ÃViVÌÊiiVÌÀV>Ê«ÜiÀÊLivÀiÊÃiÀÛV}°

4HE INDICATOR LIGHT TABLE BELOW WILL QUICKLY POINT YOU TO THE PROBLEM AREA )F THE CODES OR LIGHTS DO NOT INDICATE THE PROBLEM USE THE

TROUBLESHOOTING PROCEDURES THAT FOLLOW

).$)#!4/2 ,)'(4 4!",%

,IGHT

,IGHT !CTION

)NDICATION

0OWER

/N

0OWER IS APPLIED AND /N/FF SWITCHES ARE SET TO /.

$OOR ,ID

/N

$OOR OPEN BAD DOOR SWITCH OR MISSING ACTUATING MAGNET

2EADY

/N

5NIT IS AT READY TEMPERATURE

(I4EMP

/N

(EATER OR STEAM RESERVOIR AREA OVERHEATED

/N

-UFFIN FAN MAY HAVE FAILED CONDENSATE NOT OPERATING HOT WATER EXITING

&AN7HITE3ERVICE

3ERVICE AND $OOR

2APID FLASH

AND ALARM

(IGHFLOATPROBEGROUNDED,OWFLOATPROBE

BOTH PROBES OPEN FILL TIME EXCEEDED

.ONE EXCEPT 0OWER

2APID FLASH

AND ALARM

)F UNIT WILL NOT FILL LOW FLOATPROBEGROUNDED

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

42/5",%3(//4).' %LECTRIC -ODELS

3%450

%80%#4%$ 2%35,43

02/"!",% $%&%#4

4%34 OR #/--%.43

-EASURE INPUT VOLTAGE AND

COMPARE TO RATING PLATE

)NPUT VOLTAGE IS WITHIN OF RATED VOLTAGE

7RONG MODEL VOLTAGE INSTALLED

.OTIFY CUSTOMER

#HECK INPUT POWER TO DETERMINE

IF IT IS THREE PHASE OR SINGLE

PHASE

3TEAMER WIRING MATCHES

INCOMING POWER

7RONG MODEL ORDERED #HANGE

WIRING AT TERMINAL BLOCK TO

MATCH INCOMING POWER

7HEN CONVERTING FROM THREE

PHASE TO SINGLE PHASE DO NOT

EXCEED AMPERAGE OF BREAKER OR

POWER CORD PLUG

$ISCONNECT OR TURN OFF WATER

SUPPLY OPEN DOOR SET BOTTOM

/./&& SWITCH TO /. AND TOUCH

PAD /./&& SWITCH TO /&&

.O LINE VOLTAGE

VDC VDC (IGH PROBE

AND

FLOATPROBEAND

,OW PROBE

LIGHTS ON CIRCUIT

FLOATPROBELIGHTSONCIRCUIT

BOARD ARE ILLUMINATED

0RESS /./&& TOUCHPAD TO /.

2ECONNECT OR TURN ON WATER

SUPPLY

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

VAC ,%$ LIGHT ON CONTROL

BOARD ILLUMINATES

4HE LOW WATER PROBE

LIGHT ON

FLOATPROBELIGHT

THE

CONTROL BOARD GOES OUT

ONTHECONTROLBOARDGOESOUT

AFTER ABOUT SECONDS

-UFFIN FAN OPERATES

3TANDARD TEST

"LOWN AMP FUSE & OR &

3TANDARD TEST

"OTTOM /./&& SWITCH

3TANDARD TEST

{näÛ ÕÌ ÞÌÀ`

VÀVÕÌ LÀi>iÀ

,iÃiÌ LÀi>iÀ

{näÛ ÕÌ ÞÌÀ`

ÌÀ>ÃvÀiÀ

i>ÃÕÀi {näÛ>V >`

£ÓÛ>V ³É Óä¯Û>V ÕÌ

£Ó ÛÌ ÌÀ>ÃvÀiÀ /Ó

i>ÃÕÀi ÓänÛ>V >`

£ÓÛ>V ³É Óä¯Û>V ÕÌ

#ONTROL BOARD

3UBSTITUTE TO TEST

)NCORRECT WIRING

#HECK WIRING DIAGRAM

"REAKER ON VOLT TRANSFORMER

2ESET BREAKER

VOLT TRANSFORMER 4

-EASURE OR VAC IN AND

VAC OUT

/VERTEMP SHUTDOWN CONTROL +

-EASURE ACROSS + COIL TERMINALS

TO )F VDC AND RELAY DOES

NOT ENERGIZE + IS BAD

(I,IMIT AUTORESET

(ITEMP LIGHT WILL COME ON

-EASURE FOR CONTINUITY

NORMALLY CLOSED

#ONTROL BOARD

3UBSTITUTE TO TEST

)NCORRECT WIRING

#HECK PER WIRING DIAGRAM

,OW WATER PROBE

FLOATPROBE

0ROBE MEASURES OPEN TO GROUND

&LOATPROBEMEASURESOPENTO

WITHOUT WATER 3HORT PROBE WIRE

GROUNDWITHOUTWATER3HORT

TO GROUND TO SIMULATE WATER

FLOATPROBEWIRETOGROUNDTO

SIMULATEWATER

7ATER LEVEL BOARD

2ED LIGHT INDICATES POWER TO

BOARD "YPASS TO TEST $ISCONNECT

WIRE TO , MOVE WIRE FROM ./

TO .# REMOVE WIRE FROM ( AND

./ AND JUMPER THESE TWO

WIRES TOGETHER

#ALLFOR4ECHNICAL3UPPORT

42/5",%3(//4).'%LECTRIC-ODELS

3%450

%80%#4%$2%35,43

!BOUTSECONDSAFTERTHELOW

PROBELIGHTGOESOUT THEHIGH

FLOATPROBELIGHTGOESOUT

THE

PROBELIGHTGOESOUT

HIGHFLOATPROBELIGHTGOESOUT

#AUTION )FCONTROLDOESNOTSEE

HIGHPROBE THECAVITYWILLFILLFOR

HIGHFLOATPROBE

THECAVITYWILL

MINUTES ERRORWILLOCCURAND

FILLFORMINUTES

ERRORWILLOCCUR

UNITWILLSHUTOFF

ANDUNITWILLSHUTOFF

3ETTIMERTO/&& ANDCLOSEDOOR

!UDIBLECLICKASCONTACTOR

PULLSIN

!BOUTMINUTESAFTERCLOSING

THEDOOR THEREADYLIGHTCOMESON

#ALLFOR4ECHNICAL3UPPORT

02/"!",%$%&%#4

4%34OR#/--%.43

&ILL6ALVE

&ILLVALVEISNORMALLYCLOSEDWHEN

WATERISBELOWHIPROBE 6!#6!#

WATERISBELOWHIFLOATPROBE

ISAPPLIEDTOCOILORVALVEANDIT

OPENS 7HENWATERREACHESHI

PROBE THECOILDEENERGIZES

FLOATPROBE

THECOILDEENERGIZES

$RAINVALVE

7ITHOUTPOWER THEVALVEISOPEN

WHEN6$#ISAPPLIEDTOTHECOIL

ORTHEVALVE ITENERGIZESTOPREVENT

DRAINING

-UFFINFAN

6ERIFYVACACROSSMUFFINFANCOIL

#ONTROLBOARD

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

4HEHIGHPROBELIGHTGOESOUTBUT 4HECONTROLSAREVERIFYINGPROBE

4HEHIGHFLOATPROBELIGHTGOESOUT

4HECONTROLSAREVERIFYINGFLOATPROBE

MOMENTARILYCOMESONAGAIN

BUTMOMENTARILYCOMESONAGAIN

OPERATION 4HISISNORMAL

(IGHWATERPROBE

(IGHWATERFLOATPROBE

0ROBEMEASURESOPENTOGROUND

&LOATPROBEMEASURESOPENTOGROUND

WITHOUTWATER 3HORTPROBEWIRE

TOGROUNDTOSIMULATEWATER

#ONTROLBOARD

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

$OORSWITCH

-EASUREFROM*PINTO

VDCWITHDOOROPEN ZERO

LOWVOLTAGEWITHDOORCLOSED

)FVOLTAGEISNOTZERO CHECKDOOR

SWITCH DOORMAGNET LIGHTAND

TIMERBOARD WIRING

#ONTROL"OARD

-EASUREFOR6$#OUT

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

7ATERLEVELBOARD

2EDLIGHTINDICATESPOWERTO

BOARD "YPASSTOTEST $ISCONNECT

WIRETO, MOVEWIREFROM./

TO.# REMOVEWIREFROM(AND

./ANDJUMPERTHESETWO

WIRESTOGETHER

#ONTACTOR+

6ERIFY6!#ACROSS+COIL

,IGHTANDTIMERBOARD

3UBSTITUTETOTEST

2EADYTHERMOSTAT

.ORMALLYCLOSED OPENSATABOUT

ª &

#ONTACTOR+

6ERIFY6!#ACROSS+COIL

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°ÊÊ

42/5",%3(//4).'%LECTRIC-ODELS

3%450

%80%#4%$2%35,43

7ITHREADYLIGHTON CONDENSATE

WATERFLOWS

3ETTIMERTO/.

/.LIGHTILLUMINATES

3ETTIMERTOMINUTE

4IMERTIMESOUT DONELIGHT

ILLUMINATES MOTORSTOPS

CONDENSATESTOPSANDUNITBEEPS

UNTILDOORISOPENEDORTIMERIS

CHANGEDTOANOTHERSETTING

3ETTIMEONTIMERANDLETRUNFOR

ABOUTSECONDS

4URN/./&&TOUCHPADTO/&&

/PENDOORANDVERIFYFANIS

ROTATINGFANWILLGRADUALLYSTOP

WHENDOORISOPENED

#AVITYDOESNOTDRAINUNTILPOWER

ISTURNEDOFF

.ODEFECTFOUNDBUTCUSTOMER

COMPLAINTISTHATUNITISSLOWTO

HEAT

02/"!",%$%&%#4

4%34OR#/--%.43

(EATERELEMENT

-EASUREAMPERAGEFOREACHLEG

ANDCOMPARETOCHARTONPAGE

)FAMPERAGEISINCORRECT DISCON

NECTPOWER DISCONNECTLEADSTHEN

MEASUREHEATERRESISTANCECOLD

ANDCOMPARETOCHARTONPAGE

)FRESISTANCEISNOTWITHIN

SPECIFIED REPLACEHEATERELEMENT

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

#ONDENSATESPRAYVALVE

.ORMALLYCLOSED /PENSWHEN

VACISAPPLIED

#ONTROLBOARD

#HECKFOR6!#OUTPUT

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

4IMER

3UBSTITUTETOTEST

#ONTROLBOARD

3UBSTITUTETOTEST

,IGHTANDTIMERBOARD

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

#ONTROLBOARD

3UBSTITUTETOTEST

,IGHTANDTIMERBOARD

3UBSTITUTETOTEST

4IMER

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

3TARTCAPACITOR

3TANDARDTEST

)NTERNALTHERMALPROTECTORON

FANMOTOR

-EASUREBLACKTOWHITEMOTOR

LEADS OHMS

&ANMOTOR

-EASUREORANGETOBROWNMOTOR

LEADS OHMS 2EDTO

BLUEOHMS

#ONTROLBOARD

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

$RAINVALVE

$RAINVALVEISNORMALLYOPENUNTIL

VDCISAPPLIED THENITCLOSES

#ONTROLBOARD

-EASUREFORVDCOUT

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

#USTOMERMAYBEOPENINGDOOR

FREQUENTLYTOADDORREMOVEFOOD

4ALKTOCUSTOMER

" ,/1/" -tÊ/

iÊÕÌÊÃÊ«iÀ>Ì}ÊVÀÀiVÌÞ°

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

42/5",%3(//4).' 'AS -ODELS

3%450

%80%#4%$ 2%35,43

%80%#4%$2%35,43

02/"!",%

$%&%#4

02/"!",%$%&%#4

4%34

OR #/--%.43

4%34OR#/--%.43

#HECK INCOMING GAS SUPPLY AND

#HECKINCOMINGGASSUPPLYAND

MEASURE INPUT VOLTAGE

MEASUREINPUTVOLTAGE

VAC INCOMING POWER

VACINCOMINGPOWER

2ECOMMENDED

INCOMING GAS

2ECOMMENDEDINCOMINGGAS

PRESSURE

)NSUFFICIENT

GAS PRESSURE OR

)NSUFFICIENTGASPRESSUREOR

WRONG

VOLTAGE

WRONGVOLTAGE

3EE

CHART ON PAGE 3EECHARTONPAGE

6ERIFY

DATA PLATE FOR TYPE GAS

6ERIFYDATAPLATEFORTYPEGAS

SUPPLIED .ATURAL

OR 0ROPANE

.ATURALOR0ROPANE

.OTIFY

CUSTOMER IF INCORRECT

.OTIFYCUSTOMERIFINCORRECT

'AS

INLET HOSE TOO SMALL

'ASINLETHOSETOOSMALL

$ISCONNECT OR TURN OFF WATER

$ISCONNECTORTURNOFFWATER

DOOR SET

BOTTOM

SUPPLY OPEN

OPENDOOR

SETBOTTOM

TO /. ANDTOUCH

AND TOUCH

/./&& SWITCH

SWITCHTO/.

PAD /./&& SWITCH TO /&&

PAD/./&&SWITCHTO/&&

0RESS /./&& TOUCHPAD TO /.

0RESS/./&&TOUCHPADTO/.

2ECONNECT OR TURN ON WATER

2ECONNECTORTURNONWATER

SUPPLY

6$#

AND 6$# ,%$ LIGHT

6$#AND6$#,%$LIGHT

AND

HIPROBE AND LOW PROBE

ANDHIPROBEANDLOWPROBE

LIGHTS

ON CIRCUIT BOARD

LIGHTSONCIRCUITBOARD

ARE

ILLUMINATED

AREILLUMINATED

6!#

,%$ ON CONTROL BOARD

6!#,%$ONCONTROLBOARD

ILLUMINATES

4HE

LOW WATER PROBE LIGHT ON

4HELOWWATERFLOATPROBELIGHT

THE

CONTROL BOARD GOES OUT

ONTHECONTROLBOARDGOESOUT

AFTER

ABOUT SECONDS AND

AFTERABOUTSECONDSAND

MUFFIN

FAN OPERATES

MUFFINFANOPERATES

#ALLFOR4ECHNICAL3UPPORT

.O

LINE VOLTAGE

.OLINEVOLTAGE

3TANDARD

TEST

3TANDARDTEST

"LOWN

AMP FUSE & OR &

"LOWNAMPFUSE&OR&

3TANDARD

TEST

3TANDARDTEST

"OTTOM

/./&& SWITCH

"OTTOM/./&&SWITCH

3TANDARD

TEST

3TANDARDTEST

VOLT TRANSFORMER 4

VOLTTRANSFORMER4

i>ÃÕÀi £ÓäÛ>V >`

i>ÃÕÀiÊ£ÓäÛ>VÊÊ>`Ê

£ÓÛ>V ³É Óä¯Û>V ÕÌ

£ÓÛ>VʳÉÊÓä¯Û>VÊÕÌ

#ONTROL

BOARD

#ONTROLBOARD

3UBSTITUTE TO TEST

3UBSTITUTETOTEST

)NCORRECT

WIRING

)NCORRECTWIRING

#HECK WIRING DIAGRAM

#HECKWIRINGDIAGRAM

2ELAY

+

2ELAY+

3UBSTITUTE TO TEST

3UBSTITUTETOTEST

VOLT TRANSFORMER 4

VOLTTRANSFORMER4

2ESET BREAKER ON TRANSFORMER

2ESETBREAKERONTRANSFORMER

OR SUBSTITUTE TO TEST

ORSUBSTITUTETOTEST

(I,IMIT

AUTORESET

(I,IMITAUTORESET

(I,IMIT LIGHT COMES ON

(I,IMITLIGHTCOMESON

-EASURE FOR CONTINUITY

-EASUREFORCONTINUITY

NORMALLY CLOSED

NORMALLYCLOSED

/VERTEMP

SHUTDOWN CONTROL +

/VERTEMPSHUTDOWNCONTROL+

-EASURE ACROSS + COIL TERMINALS

-EASUREACROSS+COILTERMINALS

TO )FVDCANDRELAYDOES

)F VDC AND RELAY DOES

TO

NOT ENERGIZE +

IS BAD

NOTENERGIZE

+ISBAD

#ONTROL

BOARD

#ONTROLBOARD

3UBSTITUTE TO TEST

3UBSTITUTETOTEST

)NCORRECT

WIRING

)NCORRECTWIRING

#HECK PER WIRING DIAGRAM

#HECKPERWIRINGDIAGRAM

,OW

WATER PROBE

,OWWATERFLOATPROBE

0ROBE MEASURES OPEN TO GROUND

&LOATPROBEMEASURESOPENTO

WITHOUT WATER 3HORT PROBE WIRE

GROUNDWITHOUTWATER3HORTFLOAT

TO GROUND TO SIMULATE WATER

PROBEWIRETOGROUNDTOSIMULATE

WATER

7ATER

LEVEL BOARD

7ATERLEVELBOARD

2ED LIGHT INDICATES POWER TO

2EDLIGHTINDICATESPOWERTO

TO TEST $ISCONNECT

BOARD "YPASS

"YPASSTOTEST

WIRE TO , MOVE

WIRE FROM ./

WIRETO,

MOVEWIREFROM./

TO .# REMOVE

WIRE FROM (

TO.#

REMOVEWIREFROM(

AND ./ AND JUMPER THESE TWO

AND./ANDJUMPERTHESETWO

WIRES TOGETHER

WIRESTOGETHER

&ILL

VALVE

&ILLVALVE

&ILL VALVE IS NORMALLY CLOSED

&ILLVALVEISNORMALLYCLOSED

7HEN WATER IS BELOW HIGH PROBE

7HENWATERISBELOWHIGHPROBE

VAC IS APPLIES TO COIL OF VALVE

VACISAPPLIESTOCOILOFVALVE

AN IT OPENS 7HEN

WATER REACHES

ANITOPENS

7HENWATERREACHES

HIGH PROBE THE COIL DEENERGIZES

HIGHPROBETHECOILDEENERGIZES

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

42/5",%3(//4).''AS-ODELS

3%450

%80%#4%$2%35,43

!BOUTSECONDSAFTERTHELOW

PROBELIGHTGOESOUT THEHIGH

FLOATPROBELIGHTGOESOUT

THE

PROBELIGHTGOESOUT

HIGHFLOATPROBELIGHTGOESOUT

#AUTION )FCONTROLDOESNOTSEE

HIGHPROBE REFERTOTIMEERROR

HIGHFLOATPROBE

REFERTOTIME

ERRORCHARTONPAGE

CHARTONPAGE

3ETTIMERTO/&&ANDCLOSEDOOR

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

!UDIBLECLICK

02/"!",%$%&%#4

4%34OR#/--%.43

$RAINVALVE

7ITHOUTPOWER THEDRAINVALVEIS

OPEN 7HEN6$#ISAPPLIEDTO

THECOILOFTHEVALVE ITENERGIZES

TOPREVENTDRAINING

-UFFINFAN

6ERIFY6!#ACROSSMUFFINFAN

#HECKPERWIRINGDIAGRAM

#ONTROLBOARD

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

4HEHIGHFLOATPROBELIGHTGOES

4HEHIGHPROBELIGHTGOESOUTBUT

OUTBUTMOMENTARILYCOMESON

MOMENTARILYCOMESONAGAIN

AGAIN

4HECONTROLSAREVERIFYINGFLOATPROBE

4HECONTROLSAREVERIFYINGPROBE

OPERATION 4HISISNORMAL

(IGHWATERFLOATPROBE

(IGHWATERPROBE

&LOATPROBEMEASURESOPENTOGROUND

0ROBEMEASURESOPENTOGROUND

WITHOUTWATER 3HORTPROBEWIRE

3HORTFLOATPROBEWIRE

TOGROUNDTOSIMULATEWATER

#ONTROLBOARD

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

$OORSWITCH

-EASUREFROM*PINTO

VDCWITHDOOROPEN ZERO

LOWVOLTAGEWITHDOORCLOSED

)FVOLTAGEISNOTZERO CHECKDOOR

SWITCH DOORMAGNET LIGHTAND

TIMERBOARD WIRING

7ATERLEVELBOARD

2EDLIGHTINDICATESPOWERTO

BOARD "YPASSTOTEST $ISCONNECT

WIRETO, MOVEWIREFROM./

TO.# REMOVEWIREFROM(

AND./ANDJUMPERTHESETWO

WIRESTOGETHER

+2ELAY

6ERIFYVACACROSS+COIL

,IGHTTIMERBOARD

3UBSTITUTETOTEST

#ONTROL"OARD

3UBSTITUTETOTEST

)NCORRECTWIRING

#HECKPERWIRINGDIAGRAM

(OTSURFACEIGNITOR

)F+DROPSOUTAFTERSECONDS

MEASUREVOLTAGETOHOTSURFACE

IGNITOR )TSHOULDGLOWRED )FNOT

ITISDEFECTIVE

#ALLFOR4ECHNICAL3UPPORT

Switch position has no function when Rev D chip is used

42/5",%3(//4).'

!-0%2!'% 2%3)34!.#% #(!24

-ODEL 6OLTAGE 0HASE

!MPERAGE

2ESISTANCE

33"%

4HREE 0HASE

33"%

4HREE 0HASE

33"%

4HREE 0HASE

33"%

3INGLE 0HASE

33"%

3INGLE 0HASE

33"%

4HREE 0HASE

33"%

4HREE 0HASE

33"%

4HREE 0HASE

33"%

3INGLE 0HASE

33"%

3INGLE 0HASE

33"%

4HREE 0HASE

33"%

4HREE 0HASE

33"%

4HREE 0HASE

'!3 /2)&)#% 3):% #(!24 !,4)45$% !"/6% 3%! ,%6%, ). &%%4

>ÌÕÀ>

x -âi

"LANK

x *É

£ä -âi

£ä *É

Î -âi

Î *É

"LANK

"LANK

"LANK

MM MM MM MM MM MM *À«>i

x -âi

x *É

£ä -âi

£ä *É

Î -âi

Î *É

-- MM MM MM MM MM MM #ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

!33%-",9 $)3!33%-",9

'ENERAL )NFORMATION

4OP #OVER

&OR 0ART .UMBER SEE SECTION ON THE 3TEAMER -ODEL

4HIS SECTION PROVIDES COMMON REMOVAL AND INSTALLATION PROCEDURES

FOR PARTS USED IN MORE THAN ONE MODEL OF 3MART3TEAM "OILERLESS

3TEAMERS 7HEN 0ART .UMBERS DIFFER BY 3TEAMER -ODEL THE 0ART

.UMBERS ARE NOT GIVEN IN THIS SECTION

4HE FOLLOWING PROCEDURES ARE BASED UPON HAVING ACCESS TO THE

STEAMER ON ALL FOUR SIDES )F THE STEAMER IS INSTALLED BETWEEN

OTHER APPLIANCES AND THERE IS NOT ENOUGH ROOM ON THE SIDES FOR

ACCESS THE STEAMER MUST BE PULLED OUT FROM ITS POSITION TO GAIN

PROPER ACCESS

#ARE SHOULD BE TAKEN IN MOVING THE STEAMER SO AS NOT TO STRESS

OR PULL ON THE ELECTRICAL GAS AND WATER CONNECTIONS

.OTE 5NDER NORMAL CONDITIONS THE TOP COVER SHOULD NEVER HAVE

TO BE REMOVED 4HE MOST LIKELY REASON FOR REMOVING IT IS IF THE

PANEL ITSELF HAS BEEN DAMAGED BY A FALLING OBJECT

2EMOVE RIGHT SIDE AND LEFT SIDE PANELS

!T THE FRONT ON EACH SIDE REMOVE THE SCREW HOLDING A TOP

COVER RETAINER SEE ILLUSTRATION TO THE TOP COVER 4HEN SLIDE

THE COVER FORWARD UNTIL CLEAR OF THE REAR CLIPS AND LIFT OFF

!33%-",9 4)0 )N REPLACING THE TOP COVER MAKE SURE THAT BOTH

RETAINERS ARE REPLACED AND SCREWED DOWN TIGHT

3TEAMER #ONTROL 0# "OARD 0. 7!2.).'

!FTERSERVICINGGASPIPINGON

GASMODELS CHECKFORGASLEAKS

BEFOREPUTTINGUNITBACKINSERVICE

7!2.).'

$ISCONNECTTHESTEAMERFROM

ELECTRICPOWERBEFOREBEGINNING

ANYSERVICEPROCEDURES

#AVITY #OMPARTMENT 3IDE 0ANELS

&OR 0ART .UMBER SEE SECTION ON THE 3TEAMER -ODEL

2EMOVAL

7ITH A FLAT BLADE SCREW DRIVER REMOVE THE TWO SCREWS

ON THE LOWER EDGE OF THE PANEL AND ONE AT THE TOP EDGE AT

THE CENTER OF THE TOP PANEL OVERHANG 4HE PANEL IS RETAINED

TO THE STEAMER BY THESE THREE SCREWS AND THREE SPRINGLIKE

CLIPS AT THE REAR EDGE

/NCE THE SCREWS ARE REMOVED THE PANEL CAN BE PULLED

FORWARD ABOUT INCH THEN LOWERED FROM BEHIND THE TOP

PANEL OVERHANG

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

2EMOVAL

5NPLUG THE FOLLOWING CONNECTORS * * * *! * AND *

5SING A v SOCKET REMOVE FIVE v LOCK NUTS AND

REMOVE THE BOARD FROM FIVE STUDS ON THE FRONT PANEL "E

CAREFUL NOT TO LOSE THE PLASTIC WASHERS BELOW EACH NUT

2EMOVE VOLTAGE SELECT JUMPER * AND SAVE FOR INSTALLATION

ON NEW BOARD

#ALLFOR4ECHNICAL3UPPORT

!33%-",9 $)3!33%-",9

)NSTALLATION

/N THE NEW CIRCUIT BOARD SET STEAMER SELECT SWITCH 3 AND

3 FOR THE MODEL OF STEAMER THE BOARD IS BEING INSTALLED IN

37)4#( 6:,7&+

37)4#( 0RGHO

6:,7&+

66%(

2))

2))

66%*

21

2))

-ODEL

33"%

33"'

66%(

33"%

66%*

33"'

66%(

33"%

66%*

33"'

$//:)/2$76

/&&

/.

2))

/&&

2))

21 /&&

21 /.

2)) /.

/&&

/&&

21

/.

2))

21/&&

21/.

2))/.

3WITCH /RIENTATION

/.

)NSTALL VOLTAGE SELECT JUMPER *

0OSITION THE BOARD ON FIVE STUDS BELOW THE TIMER

)NSTALL v LOCK NUTS WITH WASHERS 5SE A SOCKET TO TIGHTEN THEM IN PLACE

)NSERT JACKS * * * *! * AND * IN THE SAME

CONNECTOR LOCATIONS AS PER REMOVAL 0RESS FIRMLY TO MAKE

SURE THE JACK IS FULLY SEATED ON THE BOARD

,IGHT AND 4IMER 0# "OARD

0. 2EMOVAL

5NPLUG THE FOLLOWING CONNECTORS *" * AND *

5SING A v SOCKET REMOVE TWO v LOCK NUTS

AND REMOVE THE BOARD FROM THREE STUDS ON THE FRONT

PANEL

#ALLFOR4ECHNICAL3UPPORT

)NSTALLATION

0OSITION THE BOARD ON THREE STUDS ABOVE THE TIMER

)NSTALL v LOCK NUTS ONTO THE AND WASHERS STUDS AND

TIGHTEN IN PLACE USING A v SOCKET

)NSERT JACKS *" * AND * IN THE SAME CONNECTOR LOCATIONS

AS PER REMOVAL 0RESS FIRMLY TO MAKE SURE THE JACK IS FULLY

SEATED ON THE BOARD

3TEAM 2ESERVOIR $RAIN 6ALVE 0. .OTE 7HENTHESTEAMRESERVOIRDRAINVALVEISDEENERGIZEDOR

/0%.THESILICONEHOSECANFREELYSLIDETHROUGHTHEVALVE

HOUSING4HESTEAMRESERVOIRDRAINVALVEISLOCATEDTOTHERIGHT

OFTHESTEAMERCAVITY

2EMOVAL

4URN OFF POWER AND DISCONNECT STEAMER FROM BRANCH CIRCUIT

2EMOVE RIGHT SIDE PANEL ,ET STEAMER DRAIN COMPLETELY

5SING SPRING CLAMP PLIERS DISCONNECT /.% %.$ OF THE SILICONE

DRAIN HOSE BY LOOSENING THE DRAIN HOSE CLAMP FROM THE DRAIN

FITTING COMING FROM THE CAVITY DRAIN 2EMOVE CLAMP

5NPLUG THE VALVE ELECTRICAL WIRES

7ITH A INCH NUTDRIVER REMOVE THE TWO SCREWS

HOLDING THE DRAIN VALVE TO THE BRACKET ON THE STEAMER BASE

2EMOVE THE TWO SCREWS AND REMOVE THE VALVE FROM

THE BRACKET

,OOSEN THE CLAMP AND REMOVE THE OTHER END OF THE SILICONE

HOSE FROM THE DRAIN BOX )NSPECT THE HOSE FOR ANY DAMAGE OR

LIME BUILDUP #LEAN OR REPLACE THE HOSE IF REQUIRED THEN

REATTACH TO THE STEAM RESERVOIR DRAIN FITTING

)NSTALLATION

!TTACH NEW DRAIN VALVE TO VALVE BRACKET 3LIDE THE SILICONE

HOSE THROUGH THE DRAIN VALVE HOUSING AND INSTALL HOSE CLAMP

OVER THE EXPOSED END OF THE HOSE #HECK THAT THE HOSE IS

STRAIGHT AND NOT TWISTED

&IT THE EXPOSED END OF THE SILICONE HOSE ONTO THE ELBOW OF

THE CAVITY DRAIN 5SING SPRING CLAMP PLIERS POSITION AND

TIGHTEN THE HOSE CLAMP

0LUG THE ELECTRICAL LEADS OF THE VALVE INTO THE WIRING HARNESS

#ONNECT STEAMER TO BRANCH CIRCUIT AND TURN ON POWER

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

!33%-",9$)3!33%-",9

4ESTING

/PERATESTEAMERANDALLOWSTEAMRESERVOIRTOFILL #HECKFOR

LEAKSANDOBSERVEIFDRAINVALVEFULLYCLOSES 4URNOFFSTEAMER

ANDOBSERVETHATDRAINVALVEOPENSANDTHESTEAMRESERVOIR

DRAINS

2EINSTALLRIGHTSIDEPANEL

4IMER!SSEMBLY

4IMER&ASTENER.UT

4IMER+NOB

2EMOVAL

3HUTOFFPOWERTOSTEAMER

&ROMTHEFRONTOFTHESTEAMER REMOVETHEKNOBFROMTHE

TIMER 5NDERTHEKNOBISAHEXAGONALNUTWHICHHOLDSTHE

TIMEMECHANISMTOTHESTEAMER .OTETHATTHEREISAFLATON

THETIMERSHAFTWHICHCORRESPONDSTOAFRICTIONALMOUNTING

HOLEONTHEKNOB

5NPLUGWIRESFROMTHEFIVETIMERMECHANISMTERMINALSAND

THETWOBLACKTIMERMOTORLEADS

7ITHAv OPENENDEDWRENCH REMOVETHEHEXNUT

HOLDINGTHETIMERINPLACE 4HETIMERMAYTHENBEREMOVED

FROMINSIDETHECOMPARTMENT

./4% 2IGHTBELOWTHETIMERSHAFT THETIMERHASASMALL

PLASTICDISKMOLDEDONTOTHECASE 4HEREISACORRESPONDING

HOLEPUNCHEDINTOTHEFRONTPANELOFTHESTEAMER 4HISHOLE

MAYBESEENFROMTHEINSIDEOFTHECOMPARTMENTONLYWHEN

THETIMERISREMOVED

)NSTALLATION

&ITTHETIMERINPLACEMAKINGSURETHATITISPROPERLYPLACED

SOTHATTHEDISKONTHETIMERFITSINTOTHEPUNCHEDHOLEIN

THEFRONTPANEL

/NCETHETIMERISPROPERLYLOCATED INSTALLANDTIGHTENTHE

HEXNUTSOTHATTHETIMERDOESNOTSLIPORROTATE $ONOT

OVERTIGHTENTHENUT

!LIGNTHEFLATOFTHEKNOBHOLEWITHTHEFLATONTHETIMER

SHAFT 0RESSTHEKNOBFIRMLYONTOTHETIMERSHAFT

0LUGINTHEWIRESIDENTIFIEDABOVEANDCONNECTTHETWOBLACK

WIRESFROMTHEMOTORLEADS

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

$OOR2EMOVAL)NSTALLATION!LIGNMENT

&OR0ART.UMBER REFERTOSECTIONON3TEAMER-ODEL

2EMOVAL

4OREMOVETHEDOOR TURNOFFTHESTEAMERPOWERANDALLOWTHE

STEAMERTOCOOL 4HENOPENTHEDOORAND WHILESUPPORTING

THEWEIGHTOFTHEDOOR REMOVEHINGEPINORREMOVEDOORTO

HINGEBOLTS

0LACETHEDOORONAFLAT CLEANTABLEORSIMILARSUPPORT WITH

GASKETFACINGUP "ECAREFULNOTTOSCRATCHDOORSURFACE

)NSPECTDOORGASKETFORSIGNSOFCUTS OROTHERDEFECTSWHICH

MAYIMPAIRITSFUNCTION 2EPLACEIFNECESSARY

./4% 'ASKETNOTCOVEREDUNDERTERMSOFWARRANTY

)NSTALLATION

4OINSTALLTHEDOOR APPLY.%6%23%%:LUBRICANTTOHINGEPIN

!LIGNDOORWITHHINGEANDINSERTHINGEPIN ORAPPLY,OCKTITE

TOTHEDOORTOHINGEBOLTS THENINSTALLDOORAND

MOUNTINGBOLTS 3NUGBOLTSONLY $O./4TIGHTENMOUNTING

BOLTSATTHISTIME

!LIGNMENT

0LACEAPIECEOFMASKINGTAPEOVERTHEDOORLATCHPIN

BULLETHOLEINTHEDOOR

#LOSETHEDOORUNTILTHEDOORLATCHPINJUSTPENETRATESTHE

MASKINGTAPE -AKESURETHEDOORPINCONTACTSONLYTHE

DOORLATCHSPRING

)FDOORPINDOESNOTSTRIKETHECENTEROFTHEMASKINGTAPEOR

SPRINGHOLEINHE5CHANNEL LOOSENTHEHINGETOOVENBOLTS

ANDALIGNTHEDOORTOTHEDOORPIN 4IGHTENHINGETOOVEN

MOUNTINGBOLTS

9OUSHOULDBEABLETOPULLADOLLARBILLORCOMPARABLEPIECE

OFPAPERWITHSOMEEFFORT FROMBETWEENTHEGASKETAND

STEAMERCAVITYWITHTHEDOORCLOSED 4OADJUSTTHEHINGE

SIDE LOOSENTHEDOORTOHINGEBOLTSANDALIGNTHEDOOR

GASKETWITHTHEOVENCAVITY 4IGHTENTHEDOORTOHINGE

MOUNTINGBOLTS

/PERATESTEAMERANDCHECKFORLEAKS

#ALLFOR4ECHNICAL3UPPORT

!33%-",9$)3!33%-",9

$OOR2EVERSAL0ROCEDURES

4URNOFFSTEAMERPOWERANDALLOWSTEAMERTOCOOL

4OREMOVEDOOR SUPPORTDOORWHILEREMOVINGHINGETO

STEAMERBOLTS

0LACEDOORWITHHINGEONAFLAT CLEANTABLEORSIMILAR

SUPPORT WITHTHEGASKETFACINGUP "ECAREFULNOTTOSCRATCH

DOORSURFACE

./4% $ONOTREMOVETHEHINGEFROMTHEDOOR

.OTEANDRECORDDISTANCEBETWEENJAMNUTANDENDOFDOOR

LOCKINGPINBULLET 4HISINFORMATIONWILLBENEEDEDDURING

BULLETINSTALLATIONIN3TEP

,OOSENJAMNUTWITHAINCHWRENCH REMOVEDOORLATCH

PINANDJAMNUT

#OATLATCHPINTHREADSWITH.%6%23%%:HIGHTEMPERATURE

DEGREE&ANTISEIZEANDLUBRICATINGCOMPOUND )NSTALL

DOORLATCHPINANDJAMNUTDIRECTLYACROSSSTEAMERCAVITY

FROMOLDBULLETLOCATION )NSTALLTHESETWOITEMSSOTHATJAM

NUTTOENDOFBULLETDISTANCEISAPPROXIMATELYTHESAMEAS

MEASUREDIN3TEP

2EMOVETHETWOTRUSSHEADSCREWSFROMABOVEAND

BELOWTHEOLDBULLETLOCATIONANDINSTALLTHEMABOVEAND

BELOWTHENEWBULLETLOCATION

2EMOVESCREWSAND5CHANNELFROMTHEDOOR 4AKEMAGNET

ANDBLOCKASSEMBLYFROMPRESENTLOCATIONANDPLACEITATTHE

OPPOSITEENDOFTHEDOORCHANNEL WITHMAGNETFACING

OUTWARDFROMTHEDOOR

2EMOVESCREWS 2EMOVEDOORHANDLEFROMCAM

!PPLY.%6%23%%:HIGHTEMPERATUREDEGREES&

ANTISEIZEANDLUBRICATINGCOMPOUNDTOTHECAMAND

,OCKTITETOSCREWTHREADS

4URNHANDLEANDCAMDEGREESFROMTHEIRORIGINAL

POSITIONSANDINSTALLTHEMONTHEDOORWITHSCREWS "ESURE

HANDLEANDCAMMOVESMOOTHLY

"ESUREDOORHANDLEISINTHE$/7.POSITION 4URN5CHANNEL

DEGREESFROMITSORIGINALPOSITION HOLDDOORSPRINGIN

5CHANNELOPENWITHASCREWDRIVERORSIMILARTOOL AND

INSTALL5CHANNEL

#HECKOPERATIONOFTHECAM 0USHUPONTHEDOORHANDLE

ANDCHECKIFTHESPRINGOPENS )FTHESPRINGDOESNOTOPEN

CAMANDSPRINGARE./4CORRECTLYALIGNEDANDPROBLEMMUST

BECORRECTED

!PPLYALIGHTAMOUNTOF,OCKTITETOSCREWS THENINSTALL

SCREWS

#ALLFOR4ECHNICAL3UPPORT

!PPLY,OCKTITETOTHEHINGETOSTEAMERBOLTS THEN

INSTALLDOORANDHINGEMOUNTINGBOLTS $O./4TIGHTEN

MOUNTINGBOLTSATTHISTIME

!LIGNDOORTOSTEAMER 2EFERTO !LIGNMENTPROCEDURE

./4% 4HEREISADOORSWITCHINSIDETHEFRONTPANELOFTHE

STEAMER ONEACHSIDEOFTHECAVITY )TISPREWIREDINPARALLEL SO

NOWIRINGCHANGEISNECESSARYWHENTHEDOORISREVERSED

#LOSESTEAMERDOORANDOPERATESTEAMER )FSTEAMERFAN

DOESNOTOPERATE CHECKLOCATIONOFDOORMAGNETANDTRY

OPERATIONAGAIN )FFANOPERATIONPROBLEMSTILLEXISTS REFERTO

THE4ROUBLESHOOTING3ECTION

!LLOWSTEAMERTOOPERATEFORAPPROXIMATELYMINUTES AND

THENCHECKFORLEAKS )FTHEREARENOLEAKS THESTEAMERIS

READYFOROPERATION )FTHEREARELEAKSAROUNDTHEDOOR

RECHECKDOORALIGNMENT ANDIFNECESSARY DOORGASKET

INSTALLATION

$OOR3WITCH0.

./4% /NENORMALLYOPENDOORSWITCHISFACTORYINSTALLEDON

EACHSIDEOFTHESTEAMERCAVITY !CTIVATEDTHATIS CLOSEDBYTHE

PROXIMITYOFTHEDOORMAGNET THEYAREWIREDINPARALLELSOTHAT

ONLYONESWITCHATATIMEWILLAFFECTSTEAMEROPERATION

2EMOVETHESIDEPANELFORACCESSTOTHEDOORSWITCHTHATIS

TOBEREPLACED

5NPLUGTHEDOORSWITCHLEADSFROMTHESTEAMERHARNESS

4HESWITCHISHELDINPLACEWITHTWOSMALLSCREWS 7ITH

ASLOTTEDSCREWDRIVER REMOVETHESESCREWSANDTHESWITCH

MAYBEREMOVED

4OINSTALLTHESWITCHUSETHETWOSCREWSANDA

SCREWDRIVERWITHASCREWSTARTERFEATURES

#ONNECTSWITCHLEADSTOSTEAMERHARNESS

4ESTSTEAMEROPERATION

2EPLACESIDEPANEL

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

!33%-",9 $)3!33%-",9

$OOR 'ASKET

&OR 0ART .UMBER REFER TO SECTION ON 3TEAMER -ODEL

./4% $OOR 'ASKET NOT COVERED UNDER TERMS OF WARRANTY

2EMOVAL

4URN OFF STEAMER POWER AND ALLOW TO COOL

2EMOVE THE DOOR USING ONE OF THE FOLLOWING TWO METHODS

A 3UPPORT DOOR WEIGHT AND REMOVE HINGE PIN OR

B 3UPPORT WEIGHT OF THE DOOR AND REMOVE THE TWO DOORTO

HINGE BOLTS

0LACE THE DOOR ON A FLAT CLEAN SMOOTH TABLE OR SIMILAR

SUPPORT WITH HANDLE HANGING OVER EDGE "E CAREFUL NOT TO

SCRATCH THE DOOR

2EMOVE FOUR OR EIGHT TRUSS HEAD SCREWS AND REMOVE

INNER DOOR PANEL

2EMOVE AND DISCARD DOOR GASKET

#LEAN BACK OF THE INNER DOOR PANEL "E SURE OLD SEALANT IS

COMPLETELY REMOVED

)NSTALLATION

)NSTALL NEW DOOR GASKET AROUND INNER PANEL AS SHOWN IN THE

ILLUSTRATION "E SURE THE INNER DOOR PANEL FLANGE IS FULLY

INSERTED INTO THE DOOR GASKET GROOVE

!PPLY A HIGH TEMPERATURE SILICONE SEALANT SUCH AS '% 246

OR EQUIVALENT TO THE FOUR DOOR SPACERS

!PPLY ,OCKTITE TO INNER DOOR PANEL MOUNTING SCREWS

)NSTALL INNER DOOR PANEL AND DOOR GASKET ON THE DOOR

SPACERS AND TIGHTEN MOUNTING SCREWS

!LIGN DOOR WITH HINGE AND INSERT HINGE PIN /2 APPLY ,OCKTITE

TO THE DOORTOHINGE BOLTS THEN INSTALL DOOR AND MOUNTING

BOLTS $O ./4 TIGHTEN MOUNTING BOLTS AT THIS TIME

!LIGN DOOR TO STEAMER AND TIGHTEN BOLTS

0LEASE REFER TO FOR ALIGNMENT PROCEDURE

&LOAT 0ROBES

2EMOVAL

4URN OFF THE STEAMER POWER AND DISCONNECT THE STEAMER

FROM THE BRANCH CIRCUIT

2EMOVE THE RIGHT SIDE COVER FROM THE STEAMER

$ISCONNECT THE WATER LEVEL PROBE HARNESS WIRE

,OOSEN AND REMOVE THE HEX LOCKING NUT AND WASHER

2EMOVE THE FLOAT PROBE FROM INSIDE THE CAVITY

./4% 0ROBE ORIENTATION PRIOR TO REMOVAL ,OW

PROBE ROTATES DOWN AND HIGH PROBE ROTATES UP

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

)NSTALLATION

)NSERT THE NEW WATER LEVEL PROBE THROUGH THE OPENING FROM

INSIDE THE STEAMER CAVITY BE SURE THE ORING SEAL IS IN PLACE

FOR A BUTTON PROBE OR THAT THE SOFT WHITE WASHER IS INSIDE THE

CAVITY FOR A FLOAT PROBE

&ROMTHEOUTSIDEPUTONANYWASHERANDLOCKINGNUT4IGHT

ENNUTFINGERTIGHTANDTHENANOTHERTURNTOPREVENTANY

WATERLEAKS

!TTACH THE HARNESS WIRE

4URN ON THE BRANCH CIRCUIT POWER SUPPLY

4URN /. THE STEAMER AND TEST

%LEMENT

2EMOVAL

4URN OFF THE STEAMER POWER AND DISCONNECT THE STEAMER

FROM THE BRANCH CIRCUIT

5SING A SCREWDRIVER REMOVE BOTH LEFT AND RIGHT SIDE PANELS

2EMOVE REAR ELEMENT ACCESS PANEL

&OLD INSULATION OUT OF THE WAY

2EMOVE ELEMENT INSULATION COVER BY REMOVING THE EA

v X NUTS USING A RATCHET AND v SOCKET

2EMOVE ELEMENT INSULATION

,OOSEN BUT DO NOT REMOVE THE ELEMENT BRACKETS USING THE REMAINING v X NUTS USING A RATCHET AND v SOCKET

4RACE THE WIRES OF THE ELEMENT BACK TO THE ELEMENT TERMINAL

BLOCK AND REMOVE THE WIRES WITH A FLAT BLADE SCREWDRIVER

3LIDE THE ELEMENT OUT FROM THE BACK OF THE UNIT THROUGH THE

ELEMENT ACCESS AREA TO REPLACE

)NSTALLATION

3LIDE THE NEW THROUGH THE ELEMENT BRACKET FROM THE REAR

ACCESS PANEL

)NSTALL THE ELEMENT WIRES INTO THE ELEMENT TERMINAL BLOCK

FROM WHICH THE ORIGINAL ELEMENT WAS INSTALLED USING A FLAT BLADE SCREWDRIVER

4IGHTEN THE v X NUTS SUPPORTING THE ELEMENT

BRACKETS USING A RATCHET AND v SOCKET

2EPLACE ELEMENT INSULATION

2EPLACE ELEMENT INSULATION COVER AND SECURE USING A RATCHET

AND THE REMAINING v X NUTS

2EPLACE AND SECURE REAR ELEMENT ACCESS PANEL USING A FLAT BLADE SCREWDRIVER AND THE v SCREWS

2ECHECK ALL WIRE CONNECTIONS AND SCREWS

5SING A SCREWDRIVER REPLACE BOTH LEFT AND RIGHT SIDE PANELS

2ECONNECT POWER SUPPLY

#ALLFOR4ECHNICAL3UPPORT

!33%-",9$)3!33%-",9

"URNER

2EMOVAL

$ISCONNECTPOWERANDGASSUPPLIEDTOTHEUNIT

2EMOVETHELEFTSIDEPANELBYREMOVINGTHETHREEEXTERIOR

SCREWS

2EMOVETHESIDEACCESSPLATEBYREMOVINGTHETWOXNUTS

5NPLUGTHE(3)ANDFLAMESENSOR

2EMOVETHEv SCREWSONTHEHOLDINGPLATENEARTHE

IGNITIONTUBEANDTHETWOONTHEBOTTOMOFTHEHOLDINGPLATE

,OOSENTHEv COMPRESSIONFITTINGONTHEIGNITIONTUBE

ANDMOVEITTOWARDTHEBASE

3LIDETHEBURNEROUTTHELEFTSIDEOFTHEUNIT

)NSTALLATION

3LIDETHENEWBURNERINTOTHELEFTSIDEOFTHEUNIT

!TTACHTHEIGNITIONTUBEANDTIGHTENTHEv COMPRESSION

FITTING

)NSTALLTHEv SCREWSINTOTHEHOLDINGPLATE

0LUGINTHE(3)ANDFLAMESENSOR

4URNONGASSUPPLYANDPOWERTOTHEUNIT

È° "/\Ê4HEIGNITIONTUBEDOESNOTRECEIVEGASUNTILTHE

BURNERSAREACTIVE

)NSTALLTHESIDEACCESSPLATEWITHTHEXNUTS

2EINSTALLTHELEFTSIDEPANELWITHTHETHREEEXTERIORSCREWS

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

.OTES

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

#ALLFOR4ECHNICAL3UPPORT

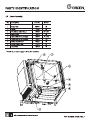

*,/- /

/"

33" 'AS #AVITY !SSEMBLY

.O $ESCRIPTION

0ART .O

-ODEL

!LL

!LL

!LL

!LL

!LL

!LL

!LL

'

'

'

'

'

'

!LL

!LL

!LL

!LL

!LL

!LL

!LL

,IGHT AND 4IMER "OARD

4IMER

#ONTROL "OARD

$OOR 3WITCH

3ERVICE LIGHT 7HITE MUFFIN FAN

/./&& 4OGGLE 3WITCH

'AS 6ALVE .ATURAL

.ATURAL TO 0ROPANE #ONVERSION +IT

0ROPANE TO .ATURAL #ONVERSION +IT

.ATURAL TO 0ROPANE #ONVERSION +IT

0ROPANE TO .ATURAL #ONVERSION +IT

.ATURAL TO 0ROPANE #ONVERSION +IT

0ROPANE TO .ATURAL #ONVERSION +IT

(I &LOAT0ROBE

,O &LOAT0ROBE

$RAIN #UP

$RAIN #UP 'ASKET

$RAIN 6ALVE

$RAIN 4STAT

&LOAT 0ROBE +IT

.O $ESCRIPTION

0ART .O

-ODEL

!LL

/LD3TYLE

''

''

!LL

'

'

'

!LL

'

'

'

!LL

!LL

!LL

!LL

!LL

!LL

!LL

!LL

'AS h4v FOR $OUBLE 3TACK 5NITS

#ONDENSATE !SSEMBLY

#ONDENSATE !SSEMBLY

#ONDENSATE !SSEMBLY

#OOLING &AN

&LUE

&LUE

&LUE

7ATER 6ALVE

&LUE 0ROTECTOR

&LUE 0ROTECTOR

&LUE 0ROTECTOR

&USE (OLDER

&USE

"LOWER &AN -OTOR

-OTOR 3HAFT 3EAL

/IL 3LINGER 7ASHER

4IMER -OUNTING .UT

4IMER +NOB

#LEAN 7ATER +IT

.OT SHOWN

#ALLFOR4ECHNICAL3UPPORT

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

2

3

3

6

4

6

1

3

3

2

2

2

4

5

3

5

1

ITEM NO.

1

2

3

4

5

6

ITEM NO.

1

2

3

4

5

6

150659

142549

138457

150662

150628

150672

142549

138457

150662

150628

150661

150672

PART NUMBER

PART NUMBER

DESCRIPTION

WELDMENT, DRAIN MANIFOLD ASSY, SSB-3/5E&G

ELBOW 3/4" HOSE BARB

CLAMP, CONSTANT TENSION CTB-27

HOSE, CONDENSATE DRIP

DRAIN, CONDENSATE

HOSE, CONDENSATE DRAIN SSB

DESCRIPTION

ELBOW 3/4" HOSE BARB

CLAMP, CONSTANT TENSION CTB-27

HOSE, CONDENSATE DRIP

DRAIN, CONDENSATE

WELDMENT, DRAIN MANIFOLD ASSY

HOSE, CONDENSATE DRAIN SSB

QTY.

1

4

1

1

1

1

QTY.

1

4

1

1

1

1

3

4

2

1

2

5

SSB-3, 5 & 10E

ITEM

NO.

6

6

5

5

4

3

2

1

QTY.

USED

PART OR

IDENTIFYING NO.

150665

150663

150661

150659

142549

150662

138457

150672

NOMENCLATURE OR DESCRIPTION

FIELD REPLACE CONDENSATE DRIP CUP AND DRAIN SSB-10E & G

FIELD REPLACE CONDENSATE DRIP CUP AND DRAIN SSB-3/5E & G

WELDMENT, DRAIN BOX SSB-10E & G

WELDMENT, DRAIN BOX SSB-3/5E & G

3/4" HOSE BARB, 90 DEG. ELBOW

HOSE, CONDENSATE DRIP

CLAMP, CONSTANT TENSION CTB-27

HOSE, CONDENSATE DRAIN SSB

2

3

3

6

4

6

1

3

3

2

2

2

4

5

3

5

1

ITEM NO.

1

2

3

4

5

6

ITEM NO.

1

2

3

4

5

6

150659

142549

138457

150662

150628

150672

142549

138457

150662

150628

150661

150672

PART NUMBER

PART NUMBER

DESCRIPTION

WELDMENT, DRAIN MANIFOLD ASSY, SSB-3/5E&G

ELBOW 3/4" HOSE BARB

CLAMP, CONSTANT TENSION CTB-27

HOSE, CONDENSATE DRIP

DRAIN, CONDENSATE

HOSE, CONDENSATE DRAIN SSB

DESCRIPTION

ELBOW 3/4" HOSE BARB

CLAMP, CONSTANT TENSION CTB-27

HOSE, CONDENSATE DRIP

DRAIN, CONDENSATE

WELDMENT, DRAIN MANIFOLD ASSY

HOSE, CONDENSATE DRAIN SSB

QTY.

1

4

1

1

1

1

QTY.

1

4

1

1

1

1

3

4

2

1

2

SSB-3, 5, & 10G

ITEM

NO.

6

6

5

5

4

3

2

1

QTY.

USED

PART OR

IDENTIFYING NO.

150665

150663

150661

150659

142549

150662

138457

150672

NOMENCLATURE OR DESCRIPTION

FIELD REPLACE CONDENSATE DRIP CUP AND DRAIN SSB-10E & G

FIELD REPLACE CONDENSATE DRIP CUP AND DRAIN SSB-3/5E & G

WELDMENT, DRAIN BOX SSB-10E & G

WELDMENT, DRAIN BOX SSB-3/5E & G

3/4" HOSE BARB, 90 DEG. ELBOW

HOSE, CONDENSATE DRIP

CLAMP, CONSTANT TENSION CTB-27

HOSE, CONDENSATE DRAIN SSB

5

-iÀÛViÊÕiÌÊÊ£{

6"Ê-*1/Ê-,6

Ê

-\

2EMIND#USTOMERSTHAT3MART3TEAM2EQUIRES$AILY0ROBE7IPE$OWN

-ODELS!FFECTED !LL3MART3TEAM4- "OILERLESS3TEAMER-ODELS

3MART3TEAMNEVERNEEDSDELIMINGANDONLYREQUIRESMINIMALMAINTENANCETODELIVERHIGHPERFORMANCE /URMUTUAL

CUSTOMERSARESODELIGHTEDWITHNOTHAVINGTODELIME THEYAREOVERLOOKINGTHENEEDFORTHEDAILYCLEANINGREGIMENWITH

WIPEDOWNOFTHEWATERLEVELPROBES

)FCUSTOMERSDONTDOTHISFORAWHILE AFTERAFEWDAYSTOAFEWWEEKS ONEOFTHEFOLLOWINGMAYOCCUR

4HEh$OOR,IDv !JAR,IGHTANDh3ERVICEv ,IGHTFLASHONTHECONTROLPANEL

5NITMAYOVERFILLWITHWATER

7HENYOURECEIVEACALLTOSERVICEA3MART3TEAMUNITWITHTHESYMPTOMSABOVE SUGGESTTOTHECUSTOMERTHATTHEYPERFORM

THEDAILYWIPEDOWN WITHANEMPHASISONWIPINGTHEPROBESCLEAN )NMOSTCASES THEMALFUNCTIONWILLGOAWAYENTIRELY

%XPLAINTOTHEMTHATIFYOUCOMEANDFINDTHEPROBLEMISDIRTYPROBES YOUMUSTCHARGETHEMFORTHESERVICECALL SINCEA

DAILYCLEANINGREGIMENWITHWIPEDOWNOFTHEWATERLEVELPROBESISACUSTOMERRESPONSIBILITYANDISNOTCOVEREDUNDER

WARRANTY

-ENDELL$AVIS$RIVE

*ACKSON -ISSISSIPPI

WWWGROENCOM

4OLLFREE 0HONE &AX 3EPTEMBER *,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

!)-$ !,%%!+$&

.PEFMT"GGFDUFE "MM4NBSU4UFBN5. #PJMFSMFTT4UFBNFS.PEFMT

0O4NBSU4UFBN#PJMFSMFTT4UFBNFST TPNFDVTUPNFSTEPOUSFBMJ[FUIBUUIFSFBSFUXP0/0''TXJUDIFT 5IFZQSFTTUIF

CPUUPNSPDLFSTXJUDI CVUGBJMUPQSFTTUIFUPQNFNCSBOFTXJUDI 8IFOUIJTPDDVST UIFVOJUXJMMCFJOPQFSBUJWF

/PMJHIUTPOUIFGSPOUQBOFMXJMMMJHIU

8IFOZPVSFDFJWFBDBMMUPTFSWJDFB4NBSU4UFBNVOJUXJUIUIFBCPWFTZNQUPNT BTLUIFDVTUPNFSUPWFSJGZUIBUCPUI

0/0''TXJUDIFTBSFPO

.FOEFMM%BWJT%SJWF

+BDLTPO .JTTJTTJQQJ

XXXHSPFODPN

5PMMGSFF 1IPOF 'BY %FDFNCFS *,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

*,/Ê 1,Ê£{Ç{ÓÎ]Ê,6°Ê

0HQGHOO'DYLV'ULYH

-DFNVRQ06 7HOHSKRQH

)D[

JURHQFRP

6066%

((()

***)

3DUW1XPEHU5HY'