Download SHARP SERVICE MANUAL - The Sharp MZ

Transcript

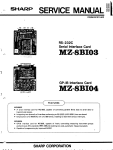

SERVICE MANUAL

SHARP

PDSM281 007-MZ

t_

----

-

------=:::::::----..,

Dot Printer

MODEL

.

MZ-80P5 (~AeL~

~~

11-HS

e. . bH P

M.()D~L l'H-t:

i~

~Mb ~~

~~}~:)

i"-1.

I c 2'2 (

1C tG,

·~

~ AQ'"f'f([

w~Ut M.A.Y ~-.toT Bf:. 1ltf

'1l+t

\\..1

~ fo

U,..TE.~

f'~l)...l'Te ':;..)

----------------~

FEATURES

•

Printing paper

Can use fanfold paper 4-10 inches wide.

•

Character printing

Four character sizes are possible.

•

Bit image printing

Printing is possible with dot units.

•

Paging

Number of lines printed on 1 page can be determined.

•

Tabulation

Both vertical and horizontal tabulation control is possible.

•

Feed

Switch for line by line paper feed and paper feed in page units.

Control is also possible through software.

•

Copies

Simultaneous copies, up

•

Alarm bell

Alarm bell sounds to warn the user of mechanical trouble, lack of printing

paper, etc.

•

Bi-directional printing Along with bi -directional printing, there is very effective printing thanks to

the use of logical seeking. (Only 80 characters/line, 40 characters/line)

•

Printing ribbon

io 3

pages in eluding the original, are possible.

lt can be easily put in and taken out because a special cartridge ribbon

is used.

SHARP CORPORATION

~~~·-HS 2.A1"LH~

PS ?en..rrf~~

Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Precautions before servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Explanation of MZ-80P5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Troubleshooting CPU board & drive PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Adjustment of head driving coil energizing pulse width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

1/0 card repair procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

Power supply section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

Functions of printer parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

Replacing of main printer parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

Replacing ink ribbon from cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

Repair procedure for printer mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44

Circuit diagram and printed wiring board

. . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .. .

57

Disasse·mbled views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66

Packing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71

Replacement parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

72

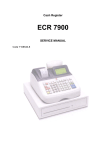

SPECIFICATIONS

• General

Item

Item

Specification

Specifications

Printing method

Impact dot matrix

Printing paper

Fanfold paper (4-10 inch wide)

Feed methos

Variable sprocket feed

Copies

Max. of 3 copies (including

original)

Kinds of characters

230 kinds (95 ASCII characters

+95 reverse characters of the 95

ASCII character +40 other

characters

Printing paper

thickness

With in 0.3mm

Character make-up

Line-to-line space

No. of digits

Ink ribbon

Special cartridge ribbon

8(H) x 9(W) dot matrix (normal

size character)

Head life

Approx. 50 million characters (14

dot character printing)

1/6 inch or determined by program

Standard interface

80 digits, 40 digits, 136 digits, 68

digits or determined by software

Power supply

8 bit parallel interface (special for

Sharp personal computer

MZ-808)

AC 220V ±1 0% 50Hz

AC 240V ±1 0% 50Hz (for UK)

Page

66 lines/page (line space mode)

or determined by program .

Printing speed

80 cps (characters per second)

(ordinary size characters)

Power consumption

75W

Working temperature 5 to 35°C

Printing direction

Storage

Si-direction (with logical seeking)

for normal size character printing

(80 characters/line) and its double

size character printing (40 characters!l-ine). For bit image printing

and other printing; u'n i-direction

(left to right).

temperatur~

External dimensions

Weight

-20 to 50°C

Approx.

377(W)

X

318(D)

Approx. 6.4 kg

Item

Specifications

Item

Specifications

CPU

Z-80A.

Timer IC

NE555

ROM

Program TMM 2732 (4K Bytes)

Head driver TR

2$D986 X 9

Character TMM 2732 (4K Bytes)

Step motor T R

2$D986 X 8

Others

Diodes, transistors

TMM 314APL-1 (2114L-1) (1K Bytes)

1/0

TMM 8255AC

Counter

Other IC's

105(H)mm

• Driver PWB Section

• CPU Board Section

RAM

X

8253AC

22 pes

• Power Supply Unit

Item

Specifications

Input

AC 220V ±10% 50Hz

AC 240V ±1 0% 50Hz (for UK)

DC 26V (21.5 to 26.5V)

DC 15V

DC 5V

Output

NOTE

-1-

Specifications and appearance are subject

to change without prior notice for improvement. In such a case, the explanation here may be a little different from

the product.

IPRECAUTIONS BEFORE SERVICING

• The printer mechanism is fixed to the chassis with two screws to keep it from being

damaged by vibration, etc. during transport. Remove these screws when using, maintaining or repairing the printer.

Fix the mechanism again with these screws when transporting the printer.

Remove the fastening screws

•

•

•

•

•

•

•

Do not apply external force to the print head, such as by touching it when it is

operating.

The print head becomes very hot so do not touch it with your hand until it cools

down sufficiently.

Do not turn the paper feeding knob (manual feed knob) when the power is on or you

will damage the paper feeding mechanism.

Do not print when the ink ribbon is loose.

When servicing and checking a printer that has been used for a long time, remove dirt,

fuzz and dust from th~ inside, and oil the mechanism.

There are two types of oil, G2 and 02. Use the proper oil for each oil point. (Refer

to page 39, 40 for oi I points.)

There are screws and nuts which are fixed and then locked with paint for vibrationproof etc. during transport. Paint the screws to lock them after disassembling and

replacing new parts. (Refer to page 39, 40 for the points to be painted to lock the

screws.)

-2-

MZ-80P5 NAMES OF PARTS AND EXPLANATION OF . FUNCTI.ONS

• Names of parts

Control panel

Power switch

Appliance inlet--

----'

L-------Signal terminal (1/0 POR1

Specification panel

L...---- - - - - F G (Frame ground) term i nal

Drive PWB unit - - - - - - - - - .

r-- - - - -- - - - - - - - - CPU board unit

Switch PWB unit

-3-

• Printer Control Flow

• Print Character Transfer Flow

When the printer receives

the character code, it raises

the signal to a high level.

• Status Check Flow

(Print character transfer routine)

(Print character transfer routine)

• Explanation of Signal

RDA . . . . . . . . . . . . The printer outputs this signal under the following conditions. (Negative logic)

1) When the power is ON.

2) When the printer is READY.

RDP . . . . . . . . . . . . Outputs from the controller to the printer. (Positive logic)

Data(RD1 ,._, RD8)strobe

STATUS . . . . . . . . . Responds in the following conditions according to STATUS demands from the controller.

(Negative logic)

1) PAPER EMPTY (1 BH + 03H)

2) Printer machanical trouble (1 BH + 04H)

-4-

I

I

0'1

I

I

IRT . . _

1

Circuit

r----Reset

Clock

~cuit

· 4MHz

CPU

Z-BOA

D

f--

PIO

8255AC

I

>

~!l ~ :2;,:e,

"1.-~

!

D

I

§I ~>I

() -1111

Circu1t

Select

Chip

Memory Circuit

(ROM, RAM)

V

Data B!us

Add,ess Bus

Control Bus

1\ 1\ 1\

Optionla Terminal

~

r--

I

Data

>I

and Buzzer Circuit

Control SW, Indicator

Circuits

Stopping Motor

0

3

C)

~

c.c

c.;·

;::'

RDP

RQ1,..._. ROB

,------->. Head Drive and

r_

I I

Circuit f - - -

Circuit

Latch

I

OJ

0

n

a.

~

C)

0

OJ

"

STATUS

RDA

Interface Circuit

•

n

c

• Driver Board Block Diagram

Head drive

CPU

>

.>

circuit

Printer

mechanism

board

'"""!\

I

Timer

circuit

*CR step

motor and

':::>

drive circuits

'>

FEED step

motor and

drive circuits

* CR Step motor= Carriage driving step motor = Timing belt motor

-6-

!\

TROUBLESHOOTING CPU BOARD & DRIVE PWB

+ 5V

+15V

+26V (21.5 to 26.5V)

Check power circuit.

Check printer

mechanism

FEED, TOF SW circuit

Check FEED drive circuit

Push FEED SW

and turn power

on again .

Check CR step motor drive

circuit & printing head drive circuit

Check printing head drive

circuit & FEED circuit

Check printer interface

circuit & 1/0 card

*TOF: Top of Form

-7-

FEED, DRIVE CIRCUIT

FEED, TOF SW CIRCUIT

Connect switch PWB.

Check FEED, TOF switches

19.

>-----... and R 5, 6, 20,

for

CPU board

Check select circuit (1)

Check latch circuit

for

DRIVE PWB

Check 023, 039, 022.

2SC 1815

2SB 743

S5277B

Check connecting line &

latch circuit

Check 011, 12, 13, 14.

Check IC2

YES

Check step motor

for FEED.

-8-

2SD 986

7406

(for DRIVE PWB check)

Check TIMING circuit

Check latch circuit

555

Check IC1 and adj<;)cent

circuit

Check 020, 21 and adjacent

•I circuit

':::>

Check 019 and adjacent

circuit

I

25A 1015

25C1815

1 25C1815

Check latch circuit

Check +26V power circuit.

Check

Check printer head

-9-

01 to 8

0 1 to 8

010 to 17

RA 1

250986

1 51555

15953

CIRCUIT CONNECTED WITH.

CR STEP MOTOR DRIVE

2SC1815

Check latch circuit.

2SB743

Check +26V power circuit.

for

DRIVE PWB

Check 025, 27, 041.

~------------------~

2SC1815

2SB743

S52778

7406

Check connecting line and

latch circuit

2SD986

Check 015, 16, 17, 18

IC3

2SD986

7406

74LS14

8253

for

CPU board

IC4, 03

R10, 14, 15

2SC1815

74LS14

Check IC15, 19, 5, 17,

R17, C10.

74LS04

74LS08

74LS10

74LS74

74LS125

Check select circuit (1)

Z-80A

Check IC23

Check CR step

motor.

-10 -

8253

PRINTER INTERFACE CIRCUI"!J (For CPU board check)

'

Connect cable.

Check IC1, 3

Check IC2

74LS125

75189

Check latch circuit.

CheckiC16

I 7406

Check latch circuit.

Check IC16

Check IC11

- 11-

7406

(For CPU board check)

...__ _ _ _ _ __, Check chip select circuit.

Check IC 26

Z-80A

Check IC13

74LS02

Check IC12

74LS04

Check I C 11

8255

Check IC11

8255

(For CPU board check)

Check reset circuit.

Check I CS, 9, 10

- 12-

(For CPW board check)

Check oscillator circuit.

2MHz

Check IC26

Z-80A

Check chip select circuit.

Check IC26

Check I C23

I 8253

(For CPU board check)

Check oscillator circuit.

Check reset circuit.

Check R30.

Check each BUS line

Check EP-ROM, RAM

circuits.

-13-

Z-80A

(For CPU board Check)

Check IC26

Z-80A

Check IC16

7406

Check IC27

74LS32

Check IC26

Z-80A

Check IC24

74LS42

Check IC17

74LS08

(For CPU board Check)

Check chip select circuit

Check reset circuit.

-14-

Check IC26

Z-80A

Check IC11

8255

(For CPU board check)

Check IC26

Z-80A

Check chip select circuit.

Check IC27

74LS32

Check IC26

Z-80A

Check IC26

Z-80A

(IC22 : ROM 1)

(IC25: ROM 2)

(For CPU board Check)

Check chip select circuit.

(IC14 : RAM 1)

(IC18: RAM 2)

-15-

Check IC26

Z-80A

Check IC27

74LS32

Check IC26

Z-80A

Check IC26

Z-80A

ADJUSTMENT OF HEAD DRIVING COIL ENERGIZING PULSE WIDTH

This concerns the printing energy force for the head wire to print a dot and its length in time as well. The shorter

the energizing pulse width (time) is, the smaller the printing energy is, thus · weakening printed letters. To the

contrary, the larger pulse width prolongs the printing time of head wire, thereby feeding the head with the head

wire clacking out. In most cases, the head wire is caught by the ink ribbon, and what is worse, the tip of head

wire is broken.

This adjustment is required to give an appropriate printing energy to the head wire. Make an adjustment in the

following manner.

1) Remove cabinet B. (Do not disconnect the connector of feed switch circuit.)

2) Take out the head cord PWB connector from the connector of terminal PWB. Be careful not to damage the

head cord PWB.

3) Turn on the paper end sensor. (Put a piece of paper in the paper sensor lever located at printing paper

insertion area.)

4) Draw out the power supply socket (N0504) with 5-pin lead from the CPU board.

5) Connect 3 units of D.C. power supply to the 5-pin connector (N0504) of CPU board as shown below:

24V D.C. (current capacity: 1.5A or more), 15V D.C. and SV D.C..

6) While pushing the line feed switch of the set, turn on the power switches of the three D.C. power supply

units. (The head is shifted right and left.)

7) Connect the synchroscope to the collector of the transistor 019 (2SC1815) on the drive PWB to check to

see if the pulse width on the synchroscope is 400±1 0 J.J.sec. If the width is out of standard value, rotate the

semi-variable resistor at the drive PWB to adjust the width.

(The semi-variable resistor is to be fixed with lacquer after adjustment.)

Note: Before checking pulse width, calibrate the synchroscope to eliminate error in time base.

Head driving coil energizing pulse signal

For pulse width adjustment

0

©

Sy nch rose ope to be

connected here

(Collector of 019)

0

Drive PWB unit

0

0

0

CPU Board Un it

Connecting diagram for power supply and synchroscope

-16-

1/0 CARD REPAIR PROCEDURE

• Procedural steps

START

(

MZ-808

MZ-80P5

Mechanical

trouble

Family

check

(

Empty of paper

J

STATUS information

Check IC1, 4,

5, 7

Check IC1,

4, 6, 7, 8, 9

Check IC2,

3, 8,9

Check IC1, 2

3, 4, 7, 8, 9

YES

(

•

END

)

Checking method of printer interface circuit

1) Press insulated part of IC with finger to check

•

if it is abnormally heated . . . . . . . . . . . . . . . . . . . . . . .

•

if there is an unappropriate change . . . . . . . . . . . . . . . . .

IC improper, too large load in IC, touching

between circuits

faulty soldering, improper printed wiring

2) Use a synchroscope to check

• if input and output logics of TTL-IC do not match

• if TTL-IC voltages· are within the TTL level

Note) TTLievel: High: 2.4Vormore

Low: 0.5V or less

- 17-

Defective I C gate

POWER SUPPLY SECTION

• Block Diagram of Power Supply Circuit

~

Smoothing

section

Rectifier

section

Smoothing

section

-

Regulator

section

Rectifier

section

Smoothing

section

--

Regulator

section

1--

AC 220V

o--

AC24 ov

(for UK)

Filter

section

Power

transformer

Regulator

section

Rectifier

section

0

+26V

(21 .5 ""26.5V)

<> +5V

~

....

-18-

--

+15V

• Troubleshooting

':>

NO

I Check power

.., transformer and input

circuit.

NO

Check 80103, F1 03,

C103, C104.

NO

CheckR101,

ZD102, Q102.

YES

Check Q101,

output connector

NO

YES

Check 80102,

F104,C105

YES

Check IC1 02,

output

connector

NO

Check 80101,

F105, C106.

Check IC101

output

connector

-19-

I FUNCTIONS OF PRINTER PARTS

• Exterior of Mechanism and Names of Parts

Paper sensor

Sprocket unit

Ribbon driving gear

Paper feeding motor

Print head

Timing belt motor

•

Sensing Mechanisms

Sensing mechanisms consist of HP sensor, PTS sensor and PE sensor. The HP sensor is attached to determine the

Home Position of the carriage and generates the reference signal for printing.

The PTS sensor generates the timing signal used to determine printing position. lt detects this signal and adjusts

carriage speed. The PE sensor detects the presence or absence of paper.

1.

HP Sensor (Home Position Sensor)

The HP sensor consists of the home position sensor assembly and sensor board on the lower part of the carriage.

The signal is High when the sensor board interrupts the light shaft of the photo coupler . .lt is an open collector

output)

-20-

2. PTS Sensor (Print Timing Signal Sensor)

The PTS sensor consists of the PTS sensor board assembly and the sensor board on the timing belt motor shaft.

The signal is Low when the slit of the sensor board appears. (lt is an open collector output.)

3. Paper Sensor

The paper sensor consists of the reed switch attached to paper sensor board and the permanent magnet attached

to the paper sensor lever. The permanent magnet approaches the reed switch and the signal passes when there is

no paper.

4. Sensor Circuit

To+5V

HP signal

~

Paper sensor

Reed switch

o------o~

~Permanent magnet

PTS signal

~

ToGND

• Printing Mechanism

The main elements of the printing mechanism are print head unit, carriage, timing belt, timing belt motor and

platen. The print head unit on the carriage is moved to the right and left by the timing belt on shafts A and B of the

carriage guide. The timing belt is driven by the timing belt motor through the belt driving pulley and belt driving

pulley.

Printing performs when the dot wire springs out toward the platen due to the flow of c1,.1rrent in the head driving

coil. The current flows when the PTS signal is generated by the belt motor rotation.

~--------------------~$

Carriage drive signal

HP signal

~--------------2~.5~4~m-m~(-1/-10_"_)--------------~$f

PTS signal

H d d

ea

nve coi I signal

~ C 0.4ms

---=-----

Dot wire tip

.

f

-

--~~-

1. Principle of Carriage Movement

The carriage is moved to the right and left by the drive of the timing belt motor with the timing belt inserted in

the carriage.

Carriage

Junction

Right

Timing belt

-21-

Drive for the timing belt motor is basically 2-2 phase excitation.

Sequence of the belt motor drive to move the carriage is as follows.

Carriage

From left to right

From right to left

Step

A phase

B phase

C phase

D phase

1

ON

OFF

OFF

ON

2

ON

OFF

ON

OFF

3

OFF

ON

ON

OFF

4

OFF

ON

OFF

ON

1

ON

OFF

ON

OFF

2

ON

OFF

OFF

ON

3

OFF

ON

OFF

ON

4

OFF

ON

ON

OFF

2. Printing function of the Print Head

This explanation is for the wire movement of one dot when one character is formed.

1) The function plate is pulled in to the core when current flows in the driving coil and thus the dot wire springs

toward the platen since it is connected with the function plate.

2) The forced dot wire springs out till it strikes the platen and one dot is printed on the paper through the ribbon

when it strikes the platen.

3) The function plate is reset to its former position by the force of the function plate spring when current no

longer passes through the driving coil.

The dot wire, after it strikes the platen, returnes to its position, which is connected with function plate, by its

striking force and the wire return spring and maintains itself in a waiting condition.

Dot wire

Function plate

Function plate spring

-22-

Ribbon mask Platen

•

Paper Feeding Mechanism

The paper feeding mechanism has ordinary feed, fast feed. Paper is fed by the sprocket shaft using the sprocket

transmission gear driven by the paper feeding motor and the sprocket driving gear. Paper is fed by pulling the paper

up with the sprocket pins. The drive method for the paper feeding motor is the same as the carriage motor rnoves

the carriage from right to left.

The printing position on the paper can be adjusted with a knob, but the adjustable minimum width is about 0.5mm

because of the resolution precision of the pulse motor .

..::.....::-------Paper

Sprocket drive gear

Sprocket transmission gear

Paper feeding motor

•

Ribbon Feeding Mechanism

The ribbon mechanism consists of the cartridge ribbon and ribbon feeding mechanism. The ribbon feeding mechanism is attached to the belt tension plate assembly. Movement of the timing belt to the right and left is through

the following arrangement of wheels. The ribbon driving gear normally turns counterclockwise.

Carriage movement

Arrangement of wheels

1

Left --* Right

(In direction of arrow-+)

• Belt driven pulley --* Planetary pinion ( 1) --*

Planetary pinion (2) --* Ribbon driving gear

2.

Right --* Left

(In direction of arrow

• Belt driven pulley --* Planetary pinion (1) --*

Planetary pinion (3)--* Planetary pinion (4)--*

Ribbon driving gear

L _ __ _

~)

The ink ribbon is stored endlessly in the cartridge case. This ink ribbon, pinched between the ribbon feeding knob

and ribbon pressure roller, is wound UJ3 by the ribbon feeding knob set on the ribbon driving gear.

Furthermore, there is a ribbon braking spring at the outlet of the cartridge case to. prevent the ribbon from becoming

loose as it is wound. A ribbon mask is attached to prevent the paper from becoming dirty.

-23-

Ribbon feeding knob

Ribbon pressure roller

Ribbon braking spring

Ribbon planetary gear ( 1)

Ribbon planetary gear (2)

Ribbon planetary

Ribbon driving gear

Ribbon planetary gear (4)

•

gear (3)

Connector Diagram

Connector terminal No.

Connector terminal No.

Connection

15

Print solenoid

Connection

R, T sensor (GND)

Paper sensor

11

2

2

~16

11

3

3

0 17

11

4

4

L18

11

5

5

19

Timing signal

11

6

6

20

Reset signal

11

7

7

21

CR motor A phase

11

8

8

22

" B "

11

9

9

23

" c "

10

24

.. D "

11

25

VLED (+5V)

12

26

" B "

CR motor common

line( +)

13

27

" c "

PF motor common line

14

28

" D"

Print solenoid

Common line(+)

11

Paper sensor

PF motor A phase

Note: Print solenoids are counted 1, 2 ..... 9 from the upper side of the characters.

-24-

IREPLACING

OF MAIN PRINTER PARTS

1. Sprocket Unit

. 1-1 Disassembly

(1) Remove fastener for sprocket guide shaft. (4N x 2,4W x 2)

(2} Remove sprocket bearing from frame LA side of the sprocket shaft. (E ring)

(3) Remove the sprocket unit and disassemble.

1) Pull the sprocket shaft in the direction of the arrow and remove the sprocket bearing from frame RA.

2) Lift the sprocket unit up and out.

Frame RA

94V F 303003000

-+

Sprocket shaft

94VF303013010

Sprocket guide shaft

94VF303010010

Sprocket shaft

94VF30301301 0

-25-

(4) Disassemble the sprocket unit

1) Pull out sprocket LA assembly

2) Pull out the paper guide roller.

3) Pull out sprocket RA assembly.

4) Disassembly sprocket LA and RA assemblies (Remove the sprocket lock lever, sprocket wheel, paper

holding cover spring, G pin and paper holding cover.)

5) Pull out the sprocket gear (Spring pin)

Sprocket lc;>ck lever

94VF303011050

Sprocket frame

94VF303011 01 ~

1

Sprocketwh~

94VF303011020

Sprocket gear

94 V F 303013020

SP(if>2X 14)

?VB130103216

1-2 Assembly

(1) Assemble the sprocket unit in the reverse order used for disassembly.

• Note the direction for inserting LS (leaf spring).

SP(<P2X 14)

94VB130103216

Sprocket bearing

Sprocket gear

94VC601302050

94VF303013020

-26-

• Attach the sprocket wheels to have the sprocket numbers be in the same direction and same angle in

relation to the sprocket shaft.

• Note the direction for inserting the paper guide roller

Sprocket lock lever

Sprocket LA Assembly

Paper guide roller

94VF30301 0020

Sprocket gear

,-[h

Tee~cket

Sp,ocket wheel numbe,

RA assembly side

Direction for inserting paper guide roller

• Parts used for sprocket LA and sprocket RA are the same but the direction attaching the sprocket lever

and paper holding cover is different.

2. Print Head Unit

2-1 Disassembly

( 1) Pull the head cable from the head connector.

·When inserting or pulling out the head cable, hold the place marked with arrows ( 9 ) and move the

head cable horizontally in the direction of the arrow(~), while pushing the head connector.

Print head unit

94VF4011 00000

Head cable

Head connector

0

iJ

• •

94VA260112001

(2) Turn the head lock lever clockwise.

(3) Remove the print head unit.

2-2 Assembly

(1) Set the print head unit on the carriage.

(2) Insert the head cable into the head connector.

-27-

3. Paper Sensor

3-1 Disassembly

(1)

(2)

(3)

(4)

(5)

Remove the soldered lead wire from the terminal board ..

Stretch the bend in the outer paper guide [In the direction of the arrow.]

Remove the paper sensor lever spring.

Remove the paper sensor board assembly.

Remove the soldering of the reed switch.

Sensor board assembly

94 V F303009000

. Outer paper guide

94VF303007010

Paper sensor lever spring

94VF303007020

3-2 Assembly

(1) Assemble in the reverse order used for disassembly.

4. PTS Sensor

4-1 Disassembly

(1) Remove the sold_ered lead wire from the PTS sensor board.

(2) Remove the PTS sensor board assembly (2.5mm screw x 1 ).

-28-

4-2 Assembly and Adjustment

(1) Temporarily fasten the PTS board assembly.

(2) Solder the lead wire.

(3) Adjust the period of the PTS signal.

1) Check T period while printing.

• Check the wave form with a synchroscope.

• Check that the print head has been fitted.

T

~

•

]-J

2) Adjust the PTS sensor board in the direction shown by the arrow in the figure so that the going and

return T periods are almost equal.

3) After adjusting, fix the screw lock and paint the screw to lock it.

5. HP Sensor

5-1 Disassembly

( 1) Remove the soldered lead wire of the HP sensor board from the terminal board .

• Do not touch the timing belt the soldering iron.

(2) Remove the HP sensor board assembly (2 .5mm screw. E ring) .

t

~

~~----~

~~

- 29-

HP sensor board assembly

----- 94VF303030000

5-2 Assembly and Adjustment

(1) Attach the HP sensor board assembly

• Put in the screws temporarily.

(2) Solder the lead wire to the terminal board.

(3) Check the relation between the PTS signal and HP signal.

• Check the wave form with a synchroscope.

• Check that the print head has been set.

(4) When the phase is not right, adjust it by moving the HP sensor board in the direction of the arrow.

(5) After adjusting, fix the screw lock and paint the screw to lock it.

HP Signal

PTS Signal

I

I

0.9 - 1.2ms

6. Motor Assembly (Timing belt motor assembly, paper feeding motor assembly, belt driving pulley)

& 1 Disassembly

(1) Remove lead wires of the timing belt motor assembly from the terminal board.

(2) Remove lead wires of the paper feeding motor assembly from the terminal board.

(3) Remove the PTS sensor lead wires from the terminal board.

(4) Take off the wire band.

Wire band

motor assembly

0

0

0

0

0

0

Green Green Red White Black Yellow

For timing belt motor assembly

- 30-

Timing belt motor assembly lead cable

(5) Remove the paper feeding motor assembly. (2.5mm screw x 2)

·When removing it, only take out the two screws shown in the figure so that the motor heat sinker and

HP sensor board assembly come out together.

(6) Remove the timing belt motor assembly. (2.5mm screw x 2)

-......

Paper feeding motor assembly

94VF303031000

·~

~

'-....._~

Belt motor heat sink

94VF303026010

(7) Remove the timing belt motor assembly from the timing belt motor heat sink.

(8) Remove the PTS sensor board assembly.

(9) Remove the belt driving pulley ( E ring).

• When removing the belt driviog pulley; frrst loosen the timing belt. (Refer to page 34)

(1 0) Remove the ball bearing from the belt driving pulley.

t

Timing belt motor assembly

94 VF303027000

PTS sensor board

94 V F303029000

Belt motor heat sink

94VF303026010

- 31-

6-2 Assembly and Adjustment

(1) Attach the timing belt motor assembly to the timing belt motor heat sink.

(2) Attach the PTS sensors board.

(3) Place the ball bearing in the belt driving pulley.

(4) Put in the belt driving pulley.

(5) Attach the timing belt motor assembly and timing belt motor heat sink to the frame.

·Check the gear backlash. (C should be minimum.)

(6) Attach the paper feeding motor assembly to the frame.

·Check the gear backlash. (C should be minimum.)

''Gl

~~~

i ~ @)' \I

I

I

I

.o J

'":~

\,_>

/

·~

"0r___v

\ ./r~I

--

'~c-~

(Timing belt motor backlash)

(Paper feed motor backlash)

7. Timing Belt

7-1 Disassembly

(1) Remove the timing belt motor assembly and motor heat sinker. (2.5mm screw x 2)

Do not mix up the screws. (Refer to * mark in the figure.)

(2) Pull the timing belt from carriage assembly A.

(3) Loosen the lock screw on the belttension plate and remove the timing belt. (2.5mm screw)

Belt tension plate

94VF303019000

Timing belt

94VF303014010

Timing belt motor assembly

94VF303027000

Motor heat sinker

94 V F30302601 0

-32-

7-2 Assembly and Adjustment

(1) Hang the timing belt on the belt driving pulley and belt driven pulley.

(2) Insert the timing belt into the carriage.

(3) Temporarily fasten the belt tension plate while gently stretching the timing belt. (2.5mm screw x 2)

(4) Adjust the tension of the timing belt.

• Using the hole in the belt tension plate, adjust it to its rating on the spring scale.

[Standard value]

1300gr ±50gr

(5) Tighten the lock screw after the adjustment and paint the screw to lock it.

Belt tension plate

94VF303019000

2.5mm screw

- 33-

8. Belt Tension Plate Assembly {Including ribbon driving gear)

8·1 Disassembly

(1) Remove carriage guide side A.

1) Remove E ring on frame LA.

2) Remove the nuts on carriage shaft A. (4N x. 2)

3) Move the carriage to frame LA side and pull carriage shaft A out to the right

Frame LA

94 V F303002000

Frame RA

94 V F303003000

(2) Move the carriage to the center between frame LA and RA

(3) Remove the home position sensor assembiy. (2.5mm screw, E ring)

·There is no need to remove the soldered lead wire.

(4) Remove the lock screw for the belt tension assembly and remove the timing belt. (2.5mm screw)

(5) Pull out the belt tension plate assembly and ribbon driving gear.

-34-

(6) Disassemble the belt tension plate assembly.

1) Remove the belt driven pulley flange. (E ring)

2) Pull out the belt driven pulley.

3) Pull out the planetary lever assembly.

4) Remove the planetary pinion. (E ring x 3)

~

®

Planetary lever assembly

94VF303020000

p-~

~~lt driven pulley flange

F30301802t ·8020

all bearing

94VB210151490

Belt driven pulley

94VF303018010

"""- ,..1

e.

<!?

V

LS(3-0.07-6)

94VB101252190

~~

Planetary pinion

94 V F303020020

8-2 Assembly and Adjustment

( 1) Assemble the belt tension plate assembly.

1) Put in the planetary pinion. (E ring x 3)

• Do not make a mistake about the direction and position of LS (leaf spring).

2) Put in the planetary lever assembly.

3) Put in the belt driven pulley.

~LS(3-0. 07-6)

4) Put in the belt driven pulley flange.

_rr_

Planetary pinion

(2) Put in the ribbon driving gear and ribbon tension plate and attach the timing belt (Temporarily fasten

with 2.5mm screw.)

(3) Attach the home position sensor assembly. ( E ring)

(4) Assemble carriage shaft A in the reverse order used for disassembly.

(5) Adjust the belt tension properly. (Refer to section 7.2 on page 33.)

(6) Check the HP signal and PTS signal. (Refer to section 4.2 on page 29 and section 5.2 on page 30.

9. Platen (Including sprocket transmission gear)

9-1 Disassembly

(1) Remove the sprocket unit. (Refer to section 1-1 on page 25.)

(2) Remove the paper feeding motor. (Refer to section 6-1 on page 30.)

·There is no need to remove the soldered lead wire.

(3) Remove the sprocket transmission gear. (E ring)

(4) Remove platen A. (3mm screw x 4)

-35-

Platen A

94 V F303004000

Sprocket transmission gear

Paper feeding

motor assembly

94 V F303031 000

9-2 Assembly and Adjustment

(1) Temporarily fasten platen A to assembly LA and RA. (3mm screw x 4)

(2) Determine the position of platen A and paint the screws to lock them after fastening them.

·Determine the position of the platen then push in the direction of the arrow so there is no space

between the platen and positioning pins and then tighten the lock screws.

(3) Attach the sprocket transmission gear. (E ring)

(4) Attach the paper feeding motor. (Refer to section 6-2 on page 32.)

(5) Attach the sprocket assembly. (Refer to section 1·2 on page 26.)

Positioning pin

-36-

10. Adjusting Lever (Including adjustment of basic space between platen and print head)

10-1 Disassembly

( 1) Move the adjusting lever to the middle step in the hole in frame LA ..

(2) Remove the print head unit. (Refer to section 2-1 on page 27.)

(3) Insert a screwdriver or similar tool into the hole in carriage shaft B to stop it from turning and remove

the nuts holding it (4 N).

(4) Remove the ribbon mask and head sitting plate. (2.5mm screw x 2)

Adjusting lever

94VF303001030

Ribbon mask

94VF303001092

Screwdriver

Head sitting plate

94VF303001100

@, ~

10-2 Assembly and Adjustment

(1) Temporarily fasten the adjusting lever. (4N)

·Set it in the middle step of the adjusting hole.

(2) Attach the print head unit to the carriage.

·There is no need to insert the head cable into the head connector.

(3) Turn carriage shaft B so the hole is up.

• lt is eccentric so pay attention to the top and bottom of the eccentric part.

: :!If!~! 1 ~ -

Screwddver

I

Carriage shaft B

"vff-k-fa

I

Up

\.. \. ;1 I ,; / /

a> b

b

-37-

(4) Move the carriage to the 1 side on the scale graduation.

(5) Insert a narrow screwdriver or similar tool into the carriage shaft B hole and adjust the clearance between the dot head tip and platen by moving it forward and back.

• [Standard clearance] 0.65mm

• Position the carriage shaft where the platen and platen head tip lightly touch both sides of a thickness

gauge.

(6) Fix the adjusting lever

·Tighten it so the clearance does not change.

(7) Remove the print head unit.

(8) Temporarily fasten the head sitting plate and ribbon mask. (2.5mm screw x 2)

(9) Attach the print head unit.

• Insert the head cable into the connector.

(10) Fasten the ribbon mask and head sitting plate.

1) Adjust the adjusting lever to its uppermost step.

·Adjust it all-the way to the side marked (-).

2) Adjust the relative position of the platen, ribbon mask

and print head tip as shown in the figure.

·Check that the ribbon mask is at a right angle.

a-+-*i-b

about 0.65nm

a> b

Print head unit

Within ±0.3mm

of C (standard)

Ribbon mask

3) Put the head sitting plate approximatel y parallel to the side surface of the carriage and in contact

with the bearing. In addition, position it so it satisfies the conditions in (2) and fasten it with screws.

(11) Do not touch the home position sensor assembly and carriage sensor plate when setting the adjusting

lever to the uppermost and lowermost steps.

f

9

>0

>0

Home position sensor assembly

Sensor pi ate

-38-

A

I

B

I

c

I

I

• Points for Oiling and Painting (To lock screws)

3

/ .-·

'"---. . .

~

L

"~l!

.

~'' 0101!~;JP

~ ""~

~ ~l

~@ I

'

(LS) ·~t~

~

~'

. ,. '. "i

' !'ili

t~"'

........:.., "-

·,

·

~

.

'

"

.

~·~~

~.. . . . . 'Jr~~ ""~

G2

~t,

~

-39-

"

-40-

~(LSI

·~

REPLACING INK RIBBON FROM CARTRIDGE

1. Remove the cartridge ribbon from the printer.

2. Remove the cartridge case lid from the cartridge case frame.

Note: There are catches ( - ) in 6 places. When removing the lid, push the catches to the outside so they aren't

bent and remove the cartridge case lid.

Cartridge case frame

Fig. 2

-41-

3. Remove the used ink ribbon

Cart ridge case lid

Used ribbon

Cartridge case frame

Fig. 3

Note:

Fig. 3 is an illustration and there is no need to remove everything as shown. If you do remove everything, the

relative positions are as shown in the figure.

4. Remove the new ribbon with the ribbon package from its cellophane case.

New ribbon

94VER-04-1/ //

Ribbon package

Cellophane case

Fig. 4

5. Put the new ribbon ~nto the cartridge.

(1) Leave the ribbon in the package and put it into the cartridge as shown in Fig. 5.

(2) Pass the ink ribbon through the path as shown in Fig. 6.

(3) Hold the top of the package with your hand and pull out the bottom of the package in the direction of the

arrow (Fig. 5).

(4) Remove the top of the package. (Note: The ink ribbon is not removed from the cartridge.)

-42-

Cartridge case lid

Ribbon

Ribbon package

Bottom of package

Fig, 6

Cartridge case frame

Fig. 5

6. Put in the cartridge case.

7. Turn the ribbon feeding rooler in the direction marked on the cartridge and check that the ribbon is not pinched

between the ribbon case.

Ribbon feeding rollwer

Fig. 7

Note: After replacing the ink ribbon, make a check on the cartridge label that indicats number of times the

cartridge ribbon has been replaced. After 5 checks, use a riew cartridge ribbon.

Example

PLATEN

INKED RIBBON

PRINT HEAD

-43-

REPAIR PROCEDURE FOR PRINTER MECHANISM

• Flow Chart to Check Cause of Defective

Phenomenon 1.

Mechanism does not function

Is it connected

to the system?

NO

Is there

printing paper?

NO

YES

Does the

mechanism function?

YES

To check of power

and control circuits.

Phenomenon 2.

Carriage does not move.

Is it connected

to the system?

Does the

carriage move?

NO

NO

YES

Does the timing belt

motor revolve?

YES

NO

NO

Is the timing belt

motor wired?

YES

Does the carriage move

when you move the timing

belt by hand?

NO

~----t-..4

To check parts

connected with power

supply.

Only timing belt moves.

Timing belt also doesn't move.

NO

NO

Belt driving pulley.

Belt driven pulley.

Is the timing belt

motor driving signal

normal?

YES

NO

1----+--_..,""'

To check of things

related with control.

Timing belt motor.

Does it move when

removing the cartridge

ribbon?

Note:

NO

Only timing belt moves.

Timing belt also doesn't move.

Active the paper to print even if there is no need to print while checking.

-44-

Phenomenon 3.

Does not print at all.

NO

Is it connected

to the system?

YES

Connect the

connector.

NO

YES

NO

Is printing command

outpu_t?

OK

Does it print?

J

-

To check parts

connected with

control.

YES

NO

Is there printing

paper?

YES

Does paper sensor

function normally?

~

.

*

NO

To Phenomenon 7.

~epla~eas

YES

Does carriage move?

NO

n sect1on 2-2.

To Phenomenon 2.

'

YES

Is print head unit

connector connected?

NO

Connect the

connector.

YES

YES

YES

Is print head driving

waveform normal?

r

Does it make any

function noise?

YES

NO

To check of things

connected with

control.

Is +26V supplied

to print head?

NO

NO

To check the parts

related

with power supply.

NO

~

@

Is printing done

on copy paper?

NO

Move the

adjusting lever to the

lowest step.

YES

YES

Is the cartridge ribbon

put in correctly?

Does it print by merely

adjusting the

adjusting lever?

NO

~

Repai,as

section 10-2.

J

Put the

cartridge ribbon in

correctly.

~*Remove the paper and check if there is a "clicking" sound when the sensor lever approaches the reed switch.

-45-

Phenomenon 4.

Ribbon does not feed.

Does carriage move?

NO

Is ribbon fed?

To Phenomen on 2.

NO

YES

Is cartridge put

in correctly?

NO

-

YES

OK

l

Put cartridge

in correctly.

YES

Does cartridge knob

turn by hand?

NO

YES

Is ribbon fed when knob

turns?

Remove cartridge.

Does knob move with

only the cartridge?

YES

~

NO

J

NO

YES

Does knob turn when

ribbon moves.

NO

YES

YES

Does knob turn only

when cartridge moves

from left to right?

Does ribbon driving gear

turn when cartridge is

removed?

I

YES

NO

Does knob turn only

when cartridge moves

from right to left?

YES

-46-

NO

I

To Repair

3

Phenomenon 5.

Paper does not feed.

NO

Is it connected to

the system?

-

YES

Connect

the connector.

Does paper feed?

NO

YES

Are paper holes out

of sprocket pins?

<§>-

YES

.

NO

YES

j

'

*1

Is there an abnormal

load at the paper feedin inlet?

YES

Has paper run out?

1---

NO

Alright for a time but

paper feed ends soon?

NO

To Repair

4.

""'

..,

YES

NO

*2

Is paper sensor

functioning properly?

NO

To Phenomenon 7.

Lighten load.

YES

Is paper fed

after printing?

-

Check parts related

with control.

NO

Is paper fed when

sprocket gear is

tu med by hand?

~

Does motor heat up

when electric signal

is sent?

YES

"""'

To Repair 5

~

I

YES

NO

Does the paper feeding

motor shaft gear also

turn at the same time?

YES

Wire

according to

section 6. ~

Is the paper feeding

motor wired?

"""

YES

Is +26V su pp I ied to

paper feeding motor?

NO

~

Check parts related

with power supply.

YES

Is paper feeding motor

driving signal normal?

NO

--

Check parts related

with control.

YES

Paper feeding motor.

""'

Replace as

in section 6 .

......_

~

* 1 Check if there is a load on the paper when it is in the paper box, system case, etc.

*2

Remove the paper and check if there is a "clicking" sound when the sensor lever approaches the reed switch.

-47-

Phenomenon 6.

Prints on the same line.

Has paper run out?

NO

Alright for a time but

soon prints on same Iine? t-- -- - - - - - 4

YES

YES

NO

Are paper holes out

of sprocket pins?

Is there an abnormal

load at the paper

feed-in inlet?

YES

YES

NO

Check parts related

with control.

Is there LF, FF

paper feeding?

NO

To check

Phenomemon 5.

Phenomenon 7.

Prints even without paper.

Is paper sensor attached?

Attach paper sensor.

NO

YES

~

Is paper sensor

lead wire wired?

Lead wire soldering.

NO

YES

Is reed switch moved

by paper sensor lever?

NO

YES

Check parts related

with control.

-48-

Section 3-2.

Phenomenon 8.

Paper feed pitch is abnormal.

Is there an abnormal

load on the paper

feed-in inlet?

YES

YES

NO

Check Phenomenon 6.

Phenomenon 9.

Density of characters varies across line.

NO

Is PTS signal

period regular?

Is PTS signal output

level normal?

YES

NO

YES

Does cartridge move

smoothly by hand?

YES

a

Is +5V supplied

to PTS sensor?

NO

Check parts related

with power supply.

YES

Check parts related

with control.

YES

Is it normal if PTS

waveform amp is

changed?

Check parts related

with control.

NO

NO

Is contact of PTS

sensor lead wire

alright?

Check

Phenomenon 2.

YES

Wire as

in section 4-2.

NO

PTS sensor.

Replace as

section 4 .

in

....._

Phenomenon 10.

Fast digit characters of printing shifts.

YES

Is position of

paper correct?

After a ~ime i_t slips ~ith

no relat1on With prev1ous

correction.

I N01

1 N~

YES

---

---

A re both right and left

sprocket lock levers

securely locked?

INO

YES

Is HP sensor securely

fastened?

Check that it has

same period as PTS.

I NO

YES

Does it have same

period as PTS?

I NO

YES

Check Phenomenon 9.

-49-

-I.O

~

Phenomenon 11.

Printing paper is dirtied by ink ribbon.

After a time does

it get dirty again?

Is ink ribbon

loose?

NO

YES

NO

Is ink ribbon

path correc t?

NO

YES

Is ribbon mask

attach ed correc tly?

NO

YES

Is scale pressing

paper firmly ?

NO

._...._c

YES

Is clearance correc t after

adjust ing with adjust ing

lever?

Is clearance betwe en

print head and platen

correc t?

YES

YES

Is it correc ted when

cartr idge ribbon is

changed?

NO

YES

NO

Is paper guide plate

A put in correc tly?

NO

1-- --- --- --- --- --- +- --- ---

YES

Is paper put i n

correc tly?

NO

YES

Is paper within

standards?

-50 -

--- --- --- --t

Phenomenon 12.

Printing is light.

Is ink ribbon almost

used up?

YES

Does it immediately

become light again?

NO

NO

YES

Is the cartridge ribbon

put in correctly?

NO

YES

Is ribbon fed when

carriage moves left

and right?

NO

Check

Phenomenon 4.

YES

Is clearance between

tip of print head and

platen correct?

Is clearance correct

after adjusting with

adjusting lever?

NO

~

YES

YES

INO

Is paper within

'standards?

Phenomenon 13.

I

•

<::.

Printing is light and dark.

Is clearance between

tip of print head and

platen correct?

Is clearance correct after

adjusting with adjusting

lever?

NO

YES

YES

Does light and dark

printing disappear?

NO

-51-

~

1 YES

•

Phenomenon 14.

Same dots only are usually (sometimes) omitted.

Is contact of head

connecto r alrigh t ?

NO

Head cable side.

YES

Terminal board side.

Is correct head driv ing

signal outputted ?

NO

Check head connecto r

and 3210 cable A .

Check things related

with control.

'YES

lsdotw i re

bent?

YES

NO

Is driving coil inside

head disconnec ted?

YES

1----+ ----.<

NO

- 52 -

Phenomenon 15.

The ribbon winds but becomes loose.

Is printing paper

within standards?

Does ribbon

feed correctly?

NO

YES

NO

YES

Is clearance between

tip of print head and

platen correct?

Is clearance corrected

by adjusting with

adjusting lever?

NO

NO

YES

Phenomenon 16.

Go/return time for the carriage varies.

Does carriage move

smoothly by hand?

NO

Check

Phenomenon 2.

YES

Do phase of HP signal

and PTS signal match?

1NO

..::"

• Practical Method of Repair

Repair 1

PTS signal is bad, HP signal is bad

(1) Check points and method

1) Check +5V. [Standard] +5V ±5%

2) Test whether LEDs are normal or not.

+5V ± 5 %

,- --------,

I

1

I

I

<

~

PTS signal

I

I

I

I

I

PTS sensor

l

_j

~._ -

I

__ _j

-53-

the light shaft to the sensor plate.

3) Check the wavefor m output by opening and intercep ting

'---.

~l

I

PTS sensor side

HP sensor side

:::~--'----....,....11

(2) Method of Repair

1) Check the parts related with the +5V power supply.

sensor board assembl y.

2) If there is no continu ity between a-b, exchang e the PTS

board assembl y.

sensor

HP

the

e

exchang

b-e,

3) If there is no continu ity between

Repair 2

Timing belt does not move

(1) Check points and method

and timing belt motor shaft.

1) Check the backlash of the gears on the belt driving pulley

ry pinion and ribbon driving gear.

planeta

pulley,

driven

belt

2) Check meshing of gears between

(2) Method of Repair

1) Adjust the backlash . (Refer to page 32.)

parts and readjust .

2) If damage , or wear, to the gears, etc. are found, replace the

Repair 3

Ribbon driving gear does not turn

(1) Check points and method

1) When ribbon driving gear does not turn by hand

ry pinion and ribbon driving gear.

(a) Check meshing of gears of ribbon driven pulley, planeta

to right or right to left.

left

either

moves

2) When ribbon driving gear turns when carriage

pinion.

ry

planeta

and

y

(a) Check meshing of planeta ry lever assembl

(b) Check the reversed revoluti on of the planeta ry lever.

(2) Method of repair

the parts and readjust .

1 ), 2): If damage , or wear to the gears, ·etc. are found, replace

Repair 4

Paper feeding path is normal but paper does not feed

(1) Check Points and Method

are fixed correctl y.

1) Check if the right and left position s of the sprocke t wheel

y.

correctl

2) Check if the paper holding cover is holding the paper

-54-

3) Check if the paper holding cover spring is damaged or fallen off.

4) Check if the sprocket lock lever is securely locked.

(2) Method of repair

1) Correct sprocket wheel positions. (Refer to se·c tion 27 .)

2), 3), 4): Replace the parts if transformation, wear, etc. are found in any parts.

Repair 5

Paper feed motor gets hot and paper does not feed

(1) Check Points and Method

1) Check the backlash of the gear on the paper feeding motor and the sprocket transmission gear.

(Refer to section 32.)

(2) Method of repair

1) If damage, or wear, to the gears, etc. are found, replace the parts and readjust.

Repair 6

Scale does not hold paper correctly.

(1) Check Points and Method

1) Check if scale springs Land R are off and if there is wear, etc.

(2) Method of repair

1) If damage, etc, to scale spring Land R is found, change them.

Repair 7

Paper guide plate A is bad.

(1) Check .Points and Method

1) Check if paper guide plate A is twisted and if there is a space between it and the platen.

(2) Method of repair

1) If paper guide plate A is deformed or if there is a space between the platen and it, change paper

guide plate A.

2) Replacement procedure

1. Move the carriage to the graducation 80 side of the scale.

2. Move the scale to the print head unit side.

3. Remove lock screws (3) of paper guide plate A.

4. Remove paper guide plate A by lifting it up from the side opposite the carriage.

5. Put a new paper guide plate A in from the carriage side.

6. Tighten lock screws (3) for paper guide plate A.

-55-

Repair 8

Check abnormalities of print head unit

(1) Che~k points and Method

coil. [Stand ard] approx . 22r2/c oil

1) Measure the DC resista nce of the print head unit

3

7

I

5

9

4

8

6

2

3

7

6

2

(2) Method of repair

rd, change the print head unit.

1) If DC resista nce of the coil does not indica te standa

•.

-56 -

(

A

I

B

c

E

D

F

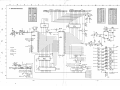

CIRCUIT DIAGRAM AND PRINTED WIRING BOARD I

Notes:

0

N

M

L

K

J

H

G

The circuit diagram and printed w iring board subject to change without prior notice.

• CPU Board Circuits (1)

To OPTION UNIT

40 P CONNECTOR

J ~,,.,_____________,

~;~g;~=?Tr-=rrrr=r=rrrrlrrr=rr=rrrrrrr=rr=r=rrrrrr=rr~

2

11!-----'

RESE T -- - - - '

f.iREQ - - - - - - '

Wlf

----,

R"O

R

~~~.

IC16

-

R!!

IK

11(

lc2a lc:n

IC24

TriT -------------~

lOOp

IC27

LS32

7

6

!I

4

11

R31

IK

~8

9

IC 16

06

0~

l

R29

330

L_j3

~

~

LS42

elll!

~

Jj

4MHz

IC 26

Z- 80A

(00801

4

~

I

~~OPTIO N

13~2R23

IORO

MI

3

~

MREO

0

~

00

ICI7

08

10

3~4

8

2 3

c

-

CS!!

CS4

CS3

CS2

C'S I

9

B

I

0

A

PAO

!I

2

I

6

CSjl!l

4IC17

08

ICII

82!1!1AC

PA 1

PA l

PA 2

PA2

PA3

PA4

T.S

PRINT

PAo

11! 1

PAl

2MHz

151~~~~

5

PAT

*

IC7

LS I2!1

"f>'-'-+- - --____z§J RESE T

PCO

16

PCI

PC I

~--+--- cse

PCI

PCS

PC4

PCo

PCe

R2

IRT

6

PCT

~

I

IC2

7!1189

C2

2200PF

;:n

iN'f

PBo

R

I

I C4

LS 14

PBI

PBI

0 1

PBa

RES182!1!11

CS3

RES

§

PB3

iiR

P94

1ili

PBo

CS

PBe

RESET

PBT

7

T

ICI6

06

2 1~~ L

1

8

csl-a-

TMM314APL - I

OATEjl!lf5

14

GATE I

OATE2

1

o

T.$

1

10

CS2

CSi

4WR

NMI~IO

E - - T.S1

;-c;;--1

NMIC

_....._ _,.R(j

11

-57-

I I 2 I

3 I 4 I

+&V

OPTION

All

!I I 6 I

A11

A 14

7 I 8 I

A11

111

9 I 10 I

A1e

04

11 I 12 I

A4

Os

131 14 I

As

De

1!11 16 I

A2

De

17 I 181

AI

AO

191201

Ao

Ae

21 122

I

Dz

Ar

231 22 I

DT

M1

2!11 26 I

Do

RESET

271281

Ae

29130

A 10

31

+!IV

9

cs.s

CONNECTOR

OPTION

8

-58-

I

Wlf

I 321

331 34 1

I

ADR

01

INT

A•

MREO

iOlfO

lflj

3!5 I 36

ONO

371 381

ONO

ONO

391 40

I

ONO

p

A

c

B

E

D

G

F

H

• CPU Board Circuits (2)

PAo

DRIVE

2

PA!

i

PA4

I

PAe

3

5

PAl

5

PA7

IC5

LS12!1

y

i

si

12

7 1

!!

8 1

2

9]

~

K

R3~

PCo----oc::!~~-~-mr--

I

10

IK

12

11

PIN2

3

4

PIN3

!I

6

PIN!!

I2!!P

I

(1/0 CONECTOR)

PINS

7

8

PIN7

I

GNO: 13'¥2!!

PINS

9

10

PIN9

IRDe

ATCP

11

12

PE

I R06

I RD7

T.SIG

13

14

R. SIG

VL

I!!

16

PMIA

PM 18

17

18

PM2A

10

IRPP

PM28

li

20

HOLD I

!..i-<>

12!-o

I RDA

HOLD 2

21

22

HOLD3

IS'TATUs

+!!V

23

24

+!IV

IIRT

+15V

2!1

26

+ 15V

+26V

27

28

GND

+26V

2i

!0

GNO

+26V

31

32

GNO

PRINT

33

~

GNO

IRT-!Q.l...o

L_

1

_j

13

-,IlD

~~

PIN I

PIN4

IC16

06

~·-------------------------

2

IRD4

CONECTOR

. rl !I ,jl

1

20

1/0 CONNECTOR

CONNECTOR

I

I

: ROe

11_

RS2

:

4

!le!!CLR

IRD•

GND

13

1

3D

1

40

11 !ID

::: r!lllll : I

1160

' 1 70

5

P87

~e

11 BD

•

1 1 I

I I

I

I

I

___ _ ________ Control Switch, LED, Buzzer ______ _ __________________________ _

CLR

p

=----;&

R~:)l""_k~WI

+26V

RIB

2.2K

270{1

01

!Gl

R4

6

120:

~

SW2

R3

3 .3K

Q2

""'

RZ

IOK

~ 1 ~~-------,

2SC I81S

IK

2SAIOI!I

11

~·I

7

IIIIIIII

~

ID

20

3D

4D

IC i

LS273

1or£-

1.l....o I PIN

=e~

~ IPIN3:

~ IPIN4~

~ 1PIN!!if

~

2o~

r!...o

.!!.!...a

i...o

60 IS

70 16

80 19

8

1

IK

1

' - - - - - - - '-'-1"-ot !I!I!!CLR

!10 12

!ID

Re

( 34·Pin connector)

hi

lol o

I

I

IPIN2:;

I PINS;

I PIN 7 : ·

I PINS::.

I PIN 9

11..:...

,...------'-'

1-o I ATCP

~

I PRINT

r-c'_j

I

RESET

I

T.S

rn

~7

CS3

R.S

Az

IC13

02

4

91

~

0

. m;

IC7

R9

I!IK

1!10

OPTION

8

2

RIO

15K

RI!!

IC12

04

T . SIG : - R. SIG I

I

10

IC12

VL I

RS

11

-59-·

ICI3

02

ICI2

04

A

8

c

E

D

F

H

G

• PWB (CPU Board Section)

Perspective View

2

D

Parts-fitted face

D

Opposite side

3

4

5

6

7

8

9

10

•

11

-60--

0)

.....

I

I

I

o-r-

0

~~

I I

I

I

I

~~~~

o-t--t------,

c>-J---+-·

0--'--t-----,

I

0--'--t---~

PRINT ! 0 I

ATEPI

I

I

PIN 91

PIN 7!

PIN 61

PIN 4lI

PIN 5 j

PIN 3!

PIN 2 1 <>-1--t--~

0

14

,.,.,

I

:

le

1 1

r1ZKi II

<.o

+26V

·~~~~T ~~~~6-4=~~

D26

5!12778

I "f"' '"I'£""

~,) I "f""" IIZ2'1 I

' -w -

I

•o I lr'\

...

00

I

06

5

1

I

6

e

7

PIN 4

PIN 6

26

29

30

ze

27

29

:51

:5:5 34

'I" !IV

+I !IV

+26V

+26V

+26V

PRINT

32

22

24

21

23

HOLD 2

2D

19

17

19

16

PM 18

14

13

15

T

VL

PM 28

12

11

10

B

4

2

I

3

PIN 2

R

PE

PIN9

PIN 7

PIN !I

PIN 3

PIN I

GND

GND

GND

GND

'I-I !IV

+!IV

HOLD:S

HOLD I

PM 2A

PM lA

CONNECTOR

5!1!1CLR

9

·

L - - _ _J

29

26

27

12

24

22

VB24 --Lo14

ATEP

I

I

I

I

I

I

I

I

I

I

-

Rl2

1.2K

HDLD2

VB24

21~r--+----~

2D0

IQQ I

VA24-+1:5

I

I

: 09

OB

r-f-oiD

I

I

I

l&o-1---

17

15=H

16

I

'U+, ": ~

PIN 8

PE

~

I

w

0

+26V

I

-

IPMIA

CN I

r--,

!'V

I

:::;·

c

;::;:

Cl

""0

~

:::·

CD

•

..,c

:HOLD 2

IHDLD:S

~J

--t-0

~IHOLDI

----to

jPM29

:PM2A

IPMIB

en

(")

r-----,-~7

,,

T

I

r<'l

'-------1--<14

I

VL R

i =?=i::f=?J

U1

(")

CN2

CNI

0>

,----1

'-------1--c :5

-....!

I

G>

.,

m

0

('")

(lJ

)>

A

c

B

E

D

H

G

F

• PWB (Drive Board Section)

2

3

4

5

Perspective View

D

D

6

7

Parts-fitt ed face

Opposite side

• Power Supply Circuits

~T101

1- - - -

I

I

8

8010 3

- -

-

-

I

I

I

I I

I I

I

I

I ' - - - - - -'

I

FUSE F101

+

I

I

26V

C107

33351

I

I

,1. SW101

S4VB10

r----- 1

- 1

rr-~~~~~--~--~-c>

T. F

5V

9

I I

I

+

I

-

I

'--

C101

1001"

101

--- --·

0

10

15V

+

-

C110

100.1"

251

I

I_---- ----·

11

of the set. Be sure to replace these

Parts marked with " L!',. " are importan t for maintain ing the safety

of the set.

parts with specified ones for maintain ing the safety and performa nce

-62-

8

A

c

D

E

G

F

• Printed Wiring Board (Power Supply Section)

•

2

3

5

I

PRIMARY

6

7

8

9

10

SECONDARY

11

-63-

H

I

0)

~

9

10

Al2

All

17

18 EX RESET

19

20

21

2~

A4

A3

A2

AI

AO

GNO

--------------

l/0 CARD lor PRINTER

A : PARTS SIDE

GNO

NMI

EX WAIT

EX INT

RESET

lEO

16

A5

-

lE I

HALT

1!5

14

GNO

MREQ

WR

MI

BUSfl$

07

06

A6

A7

13

8

Al3

A8

IOREQ

7

Al4

11

6

Al5

12

RD

!5

GND

A9

D!5

4

DO

AIO

04

3

Dl

03

D2

+!5V

I

2

+!5V

B

I

CONNECTOR

0

A

I /0

__..

__..

DO

Dl

D2

D3

D4

D5

D6

D7

<0

ID

20

3D

ID

2D

5

RO

I

CLEAR

13

12

~

4

I

I

I

I

I

_1ol

-~6

~a

IC8 7416

V

V

V

V

~

--

I

I

"""'-121

I

_,.,_21

-

~

RDA

IRT

RDP

-

15 A

14 B

13 c

CO

IC4

LS42

2

IC7 LSO"'

I

I

I

~~-J

'"

220.{1

I/2W

Jio 390Jl

1/4W

...

:

)

I

lOO

p

_v__

NOTE

STATUS

2

4

3

5

5 _6

2

I

H5V

..

..

3

,

1nn

100!

~

220.{1

I/2W 56/l I/4W

3900.

"'I/4W

~

.,~

•

.

11

10

9

8

7

GNO

13

STATUS 12

RDA

IRT

RD8

RD7

RD6

6

5

4

RD2

RD3

2

I

25

24

23

22

21

20

19

18

17

16

15

14

GND

GND

GND

GND

GND

GND

GND

GND

GND

GNO

GND

GND

CONNECTOR

ROI

RDP

PRINTER

IC7

LS04

en

;:::t'

c

(")

n

::;·

3

Q.

4

~

...

0

•

'-

5

6

12

11

1\J

RESET~RST

AO

WR

RD

A3

A2

AI

A4

A!5

A6

A7

IOREQ

w

RD5

VI

VI

V

V

RDI

RD2

R03

RD4

R0!5

R06

RD7

ROB

~

R04

+!5V

L __ _j

I

....:JL :

WO

I

113

I

I

I

I

~

I

I

Ill

I

1!5

I

19

~I I

I

"

_j

,--,

L __

..., 41

I

V

V

V

(]1

tc5

ILSI25A

;a~,

I

"""'-1ol

Ill

I

I

I

I

~61

I

I !5

I

I

....._a

19

riC9 7416

--:-r

0'>

1

RST

_!_

~

3Q 6

9

CLOCK

I"SJT

I

Ill

I

I

~

9

14

403

CLEAR

IC6

LS175

3

iQ

2Q 3

3Q 11

CLOCK

IC2

LSI7!5

~

4Q6

CLEAR

9

IQ 14

2Q 3

4QII

CLOCK

IC3

LSI7!5

"'-J

4Q 6

r=--J

2

3D

~ 40

13

4

12 3D

!5 40

13

4

12

!5 4D

CO

I

G'>

,

m

0

()

lro

I:J>

D

a::>e:} pan!:}-SlJed

D

ap!s al!SOddQ

-gg-

OL

Ma!/\ 9A!l:»9dSJad

6

8

L

9

9

l

a

3

H

8

B

A

1

.c

E

D

DISASSEMBLED VIEWS

2

--[

([D

8

8

3

4

5

6

7

8

9

10

11

-66-

F

G

H

A

8

c

D

E

F

G

H

J

K

L

M

Changed to [PR DAR0043PAZZ]

(Sub Radiator) during production.

(IC102, Si3552 are attached

to Sub Ragiator.)

The secondary lead wire of main

transformer will be passed between

the transformer and the secondary

power board.

2

3

4

Ill

Ill I

IIll

5

6

7

8

9

10

1l

-67-

-68-

N

0

p

I

CJ)

I

0

I

......

I

CO

0

00

U1

•

""C

...

:r

s...

0

z

r

:c

m

.. )>

A

c

8

F

E

D

G

H

PACKING METHOD

2

~~--

d~ ~Pack;ng

3

Instruction manual

(Sometimes not packed

in same case.)

Screw ~

r&

o-~-:!S"''P<

AC .Cord

(0ACCK0050AFZZ)

(0ACCB0001 PAZZ)

(for UK, SESA)

Add. L

(SPAKA0043PAZZI

Sack

4

issAKHoo33PAzzJ A

MZ-80P5

5

•

Paper guide

(DGiD-0005PAZZ)

Packing Add.R

(SPAKA0044PAZZ)

6

7

Pack ing case

(SPAKC0125PAZZ) ..____ _ _ __

Sleeve

(SPAKS0069PAZZ)

8

9

10

11

-71-

REPLACEMENT PARTS LIST

•HoW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the following information.

1. MODEL NAME

2. REF. NO.

3. PART NO.

4. DESCRIPTION

NOTES: Be sure to use regular parts for securing the safety and reliability of the set.

portant for maintaining the safety of the set .

safety and performance of the set.

Parts marked with " .::t:. " (D) are imBe sure to replace these parts with specified ones for maintaining the

MODEL MZ-80P5

REF.

NO.

PART NO.

DESCRIPTION

CODE

* * * CPU BOARD UNIT· SECTION * * *

OPWB-0215PAZZ

REF.

NO.

PART NO.

DESCRIPTION

CODE

R21

s

VRO-SC2EF1 02J

1 Kohm, 1/4W

AA

VRO-SC2EF151J

150 ohm, 1/4W

AA

R9 }

R10

VRO -SC2EF153J

15K ohm , 1 /4W

AA

R11 }

R14

VRO-SC2EF472J

4.7K ohm, 1 /4W

AA

:~ ~}

VRO-SC2EF222J

2.2K ohm, 1 /4W

AA

R13}

Rl6

VRO-SC2EF272J

2.7K ohm, 1/4W

AA

R24}

R26

R25

R27

R29

R34

VRO-SC2EF221 J

220 ohm, 1 /4W

AA

VRO-SC2EF561 J

VRO-SC2EF182J

VRO-SC2EF331 J

VRO-SC2EF150J

560 ohm, 1/4W

1.8K ohm, 1/4W

330 ohm, 1/4W

15 ohm, 1/ 4W

AA

AA

AA

AA

R23

R28

R30

Assembled CPU Board Unit

(Not replacement item)

s

INTEGRATED CIRCUITS

R33

R35

!Cl }

IC3

IC6

IC7

IC2

IC4

RH-iX0141 PAZZ

SN74LS125N

AG