Download 1492 & 2092 Service Manual

Transcript

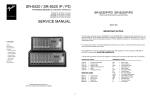

Models1492 and 2092

SERVICE MANUAL

2 YEAR LIMITED WARRANTY

This product is warranted by CERONIX to be free of defects in material

and workmanship for a period of two years from the date of purchase.

In case of a fault, developed during this time, it is the customer's

responsibility to transport the defective unit to CERONIX or

one of the authorized service centers for repair.

Please attach a note describing the problem.

All parts and labor are free of charge during the warranty period.

CERONIX

12265 Locksley Lane

Auburn, CA. 95602-2055

(530) 888-1044

This warranty does not cover mechanical breakage due to physical abuse.

CERONIX shall not be liable for any consequential damages, including

without limitation damages resulting from loss of use.

Some states do not allow limitation of incidental or consequential

damages, so the limitation or exclusion may not apply to you.

This warranty gives you specific rights and you may also have

other rights which vary from state to state.

®

®

Recognized under the Component Program

of Underwriters Laboratories Inc. and

the Canadian Standards Association.

COPYRIGHT

© 1988, 1990, 1998

CERONIX

All rights reserved.

The information contained in this manual

is subject to change without prior notice.

ABOUT THIS MANUAL

This manual is specifically written to aid the service technician, repairing

CERONIX Models 1492 and 2092 color monitors.

There are three main sections:

1. General Description.

2. Circuit Description.

3. Solutions to Problems.

INTRODUCTION

Block

Diagram

Description

BLOCK

Diagram

Schematic

Circuit

Description

Problem

Solving

Tools &

Examples

Appendix

A

Video

Interface

programs

To understand how the Monitor works, it is best to know what each

circuit does and how each circuit relates to the other circuits.

The Block Diagram is presented in a simplified view and a comprehensive

view to accomplish the goal of understanding the whole unit.

Once the general picture is clear, the complexity of each circuit will be easier

to understand.

The Circuit Description is also written in two views, a simplified view

and a detailed view to help give the reader a clear understanding of

what each component does. This understanding is most helpful for the more

complex problems or multiple problems that sometimes occur.

The Trouble Finder section is made up of an index, which lists

symptoms of problems, and a list of possible solutions. Part of this section

also deals with setting up conditions which make it easier to trouble shoot

specific circuits such as the power supply.

1

TABLE OF CONTENTS

About This Manual. 1

CERONIX Models 1492 and 2092 Electrical Specification. 3 & 4

Drive Signals to the Monitor Input voltage and waveforms, work sheet. 5

1492 and 2092 Simplified Block Diagram. 6

Video Section Description. - - - - - - - Blocks

Auto Bias and Socket Board. - - - - - - Blocks

Blanking, Sync, & Vertical. - - - - - - - Blocks

Horizontal Deflection & Remote. - - - Blocks

Horizontal Size & Power Supply. - - - Blocks

Power Supply Continued. - - - - - - - - Blocks

A-D

E-G

H-L

M-Q

R-U

V-Y

7

8

9

10

11

12

Block

Diagram

Description

1492 and 2092 Monitor BLOCK DIAGRAM. 13

1492 and 2092 Monitor SCHEMATIC

14 & 15

Video Interface Circuit Description. 16 & 17

Video Interface Schematic. 18

Video Amplifier Circuit, Function, Description. 19

Video Amplifier Circuit Description.

19 & 20

Socket Board, Degaussing Circuit, and Legend Description. 21

Blanking and Master Gain Circuit, Function, Description. 22

Blanking and Master Gain Circuit Description. 23

Blanking and Master Gain Schematic. 24

Video

Socket Board

Blanking

Master Gain

Circuit &

Function

Description

Replacement PARTS LIST. 25 & 28

1492 and 2092 Main Board ASSEMBLY DRAWING. 29 & 30

Block Diagram Review. 31

Auto Bias and Auto Bright Circuit, Function, Description. 32

Auto Bias and Auto Bright Circuit Description. 33

Auto Bias and Auto Bright Schematic. 34

Vertical and Horizontal Sync Circuit Description. 35

Vertical Deflection Circuit, Function, Description. 36

Vertical Deflection Circuit Description. 37 & 38

Horizontal Deflection Circuit Description. 39 & 40

Horizontal Raster Width Control Circuit Description. 41

Horizontal Raster Width and Position Control Schematic. 42

Simplified Power Supply Circuit, Function, Description. 43

Simplified Power Supply Circuit Description. 44

Switch Mode Power Supply Circuit Description. 45

Switch Mode Power Supply Schematic. 46

Auto Bias

Auto Bright

Sync

Vertical

Horizontal

Power Supply

Circuit &

Function

Description

Equipment setup for repairing the Model 1492 Monitor. 47

Problem Solving Tools. 48

Appendix A --- Setup and Convergence Procedure. 49

Appendix B --- Video Interface Programs. 50 to 55

Appendix C --- Resistor Array Layout for; B, C, G, H, I, & J.

57 & 58

2

CERONIX

MODELS 1492 and 2092 Electrical Specification

INPUTS

1. Standard Video Configurations, available, are:

A. Positive Analog

Source

Video

.6mA To Amp.

only

Video

Source

Source

D-A 301Ω

301Ω

Gnd

Monitor and

Monitor

{

{

Black level

Saturated color

Black level

Saturated color

1492 & 2092

Min.

Typ.

Max

.05V

0V

0V

3.1V 3.2V 3.3V

.06V

.09V .15V

1.61V 1.69V 1.75V

B. Negative Analog

Video

Source

D-A

To Amp.

Video

905 Ω

Gnd

R IN

V Blk.+.7 V

Monitor

C. 4 Line TTL

R,G,B

Video

Video

Source

*

Intensity

To Amp.

BIAS

Gnd

+12V

VB

Monitor

Red & Green Black level

Blue Black level

Saturated color

Black level

Color on

Low intensity

Full intensity

5.4V

5.6V

4.85V 5.05V

.7V

.9V

0V

2.7V

0V

4.5V

.2V

3.5V

.2V

4.6V

5.8V

5.25V

1.1V

.5V

6.0V

.4V

4.8V

* No pullup resistor on intensity line.

Note: RS170 and other voltage combinations optional for analog video.

2. The Sync signals may be of either polarity and separate or composite.

Hs

1.8K

Sync

High input voltage 2.2V

Source

.15V

Vs

Low input voltage -2.7V

1.8K

Ω,

2

PL

220

Gnd

Horizontal sync pulse 1.5uS

Monitor

Vertical sync pulse 120uS

For composite sync, vertical and horizontal

Horizontal frequency 15.3KHz

sync lines are connected together.

Vertical frequency

45Hz

3. The Power to the monitor is to be

supplied by a secondary winding

of an isolation transformer.

Model 1492

Min.

Typ.

Max.

3.5V

20V

.30V

.80V

4.5uS 31uS

.5mS 1.5mS

15.6KHz 15.9KHz

60Hz

50Hz

65Hz

Model 2092

Min.

Typ.

Max.

115VAC 50Hz or 60Hz 85VAC 115VAC 145VAC 90VAC 115VAC 145VAC

230VAC 50HZ or 60Hz 170VAC 230VAC 290VAC 180VAC 230VAC 290VAC

32W

44W

60W

30W

50W

67W

Power

3

4. The remote Controls are located on

a separate PCB for easy access.

H SIZE--------------Horizontal raster size

V SIZE---------------Vertical raster size

V RAS. POS.-----Vertical raster position

H POS-------Horizontal picture position*

M GAIN---------------------Master gain

Model 1492

Min.

Max.

9.9"

11.4"

6.3"

10.3"

0"

.44"

.9" Right

Dark

Screen

2" Left

Light

Screen

Model 2092

Min.

Max.

14.8"

16.3"

10.0"

14.0"

0"

.60"

1.2 right

Dark

Screen

2.8" left

Light

Screen

The board Controls are located on the main PCB, and are:

Focus on the flyback transformer and an optional Horizontal hold control.

* For start of horizontal sync 1.7uS after end of picture.

5.

Picture

Model 1492

Min. Typ

Max.

.

Rise time 35nS 44nS

49nS

Fall time 32nS 42nS 47nS

Overshoot

0%

0%

2%

Video response is measured at the

tube socket, using low capacitance

coupling. The input signal should

be fully damped and faster than

the expected response.

Band width

Model 2092

Min. Typ

Max.

.

37nS 46nS

52nS

35nS 44nS 50nS

0%

0%

2%

DC

to

8MHz

DC

to

8MHz

Horizontal blank time 12.4uS 12.9uS 13.4uS 12.4uS 12.9uS 13.4uS

20H 1.28mS 20H

20H 1.28mS 20H

Vertical blank time

1%

2%

1%

2%

Horizontal linearity

1%

2%

1%

2%

Vertical linearity

1%

2%

1%

2%

Pincushion

Picture tube

6.

Model 1492

Model 2092

Inch

mm

Inch

mm

Useful diagonal

13

328

20

508

Useful horizontal

10.83

275

16

406.6

Useful vertical

8.13

206.5

12

304.8

86

Useful area

558

192

1,239

Spacing between dot/line trios

.015

.39

.029

.74

Horizontal resolution

680 Pixels

550 Pixels

Vertical resolution

240 Pixels

240 Pixels

Interlaced

480 Pixels

480 Pixels

Deflection angle

90°

90°

Light transmission at center of glass Approximately 46% Approximately 46%

CRT also features: Enhanced contrast, Internal magnetic shield, and

X-Ray output Less than .3mR/hour.

7.

Environmental

Operating temperature

Storage temperature

Operating humidity

Storage humidity

0° C

-20° C

20%

10%

70° C

85° C

80%

95%

0° C

-20° C

20%

10%

70° C

85° C

80%

95%

4

The "Drive Signals To The Monitor Input" form is included here for those people who have

problems interfacing their drive electronics with the Ceronix Monitor.

DRIVE SIGNALS to the MONITOR INPUT

voltage and waveforms, work sheet.

CERONIX

12265 Locksley Lane

Auburn, CA, USA 95602-2055

VIDEO:

Company name:

Date:

Drive signal source

Model number:

For the following measurements use an oscilloscope.

RED GREEN BLUE

With no load the black level voltage is:

With no load the saturated color voltage is:

With 301Ω load

the black level voltage is:

Ω load.

or other

the saturated color voltage is:

To GND, or to

voltage

V.

}

If available, sketch the video drive circuit on the back of a copy of this form.

Horizontal or composite sync:

Horizontal frequency:

Horizontal sync pulse time:

Hz

uS

"High" voltage:

"Low" voltage:

V

V

Hz

uS

"High" voltage:

"Low" voltage:

V

V

Compare your sync to

this table and check

the best fit.

For composite sync.

Sketch if different.

Vertical sync:

Vertical frequency:

Vertical sync pulse time:

Check correct polarity.

Complete form and send to:

CERONIX, 12265 Locksley Lane

If there are any questions, call (530) 888-1044.

Auburn, CA. 95602-2055

5

1492 and 2092 Simplified Block Diagram

VIDEO

Output

VIDEO

Interface

GAME

Blanking

SYNC

Output

VIDEO

Amps.

AUTO BIAS

Vertical Deflection

Horizontal Deflection

Remote

Controls

Isolated

Power

CRT

FBT

Horizontal Size

Control

POWER SUPPLY

This block diagram gives a broad view of the circuit organization of

the 1492 and 2092 monitors. The blocks with the bold outline represent

circuits that are quite different than most other monitors.

The auto bias circuit is designed to actively compensate for picture

tube and circuit drift which normally cause the color balance to become

unbalanced and also brightness variation. This circuit eliminates the need

for the color setup procedure.

The horizontal size control circuit permits the horizontal size to be

adjusted from a remote control board instead of a coil on the main board.

It is also used to compensate for pincushion distortion and acts as an

anti-blooming circuit by correcting for horizontal size variations which

are caused by the additional load on the flyback transformer under high beam

current conditions.

The 1492 and 2092 power supplies differ from most other monitors

because of their high efficiency switching mode power supply. It is not

difficult to troubleshoot if the techniques presented in this manual are

clearly understood. Careful reading of all the information presented in this

manual will make trouble shooting of the CERONIX monitor no more difficult

than any other monitor and maybe even easier.

6

Refer to the block diagram on page 13 (foldout) when reading this description.

A

The Video Interface is designed around a custom IC and will accept positive

or negative analog video signals and also 4 line TTL. This IC also has a

built in multiplier circuit for the master gain control and blanking.

Resistors are used to protect the IC and to set the gain. The programmed gain

is dependent on the input signal amplitude except on TTL. Solder jumpers are

used to program the Video Interface for the type of input signal to be received.

The output of the IC drives the video amplifiers. This drive is a current where

0 mA is black and 4.5 mA is a satur`ted color.

B

The Video Amplifiers are of the push pull type. They are built partly on

thick films and partly on the PCB. Spreading out the amplifier reduces the

component heat and improves the life of the unit. The bandwidth is 8 MHz

with 60Vp-p output. The rise and fall times are .04uS.

C

The Beam Current Feedback circuit directs most of the beam current of each

amplifier to the beam current buffer. The only time this current is measured by

the auto bias circuit is during the time of the three faint lines at the top of the

screen and three lines thereafter. The auto bias circuit is designed to adjust the

video amplifier bias voltage such that the beam current of each of the three guns is

set (programmed), at this time.

D

The Beam Current Buffer converts the, high impedance low current, beam

current signal into a low impedance voltage. This voltage is applied to the

auto bias IC through a 200 ohm resistor. After the three lines of beam

current are measured, the program pulse from the auto bias IC, produces a

voltage drop across this 200 ohm resistor that equals the amplitude of the

beam current voltage.

7

E

The Auto Bias IC is a combination of digital and analog circuitry.

The digital part is a counter and control logic which steps the analog

circuits through a sequence of sample and hold conditions.

The analog part uses a transconductance amplifier to control the voltage on

a 10uF capacitor (one per gun). This voltage is buffered and sent to the

video amplifhers as the bias voltage. In monitors without auto bias, this

voltage has to be set manually using a setup procedure to set the color

balance. With the auto bias, the color balance is set during the end of each

vertical blanking time.

The control sequence is:

1. Grid pulse on G1 causes cathode current (3 lines top of screen)

which is transmitted by the beam current feedback to the

beam current buffer where it is converted to a voltage and

applied to the auto bias input pin.

2.

Auto bias IC outputs a reference voltage at its input pin which

sets the voltage across the coupling capacitor. This coupling

capacitor voltage is directly dependent on beam current.

3.

After the grid pulse is over, the program pulse matches the

voltage from the beam current buffer. If the voltage from the

beam current buffer, during the grid pulse, is the same as the

voltage from the program pulse, the bias is correct and no bias

adjustment is made for that vertical cycle.

F

The aging of the picture tube (CRT) not only affects the balance of the

cathode cutoff voltage, which is corrected by the auto bias circuit, but

it also affects the gain of the CRT. The Auto Bright circuit actively

corrects for CRT gain changes by sensing any common bias change from

the auto bias circuit and adjusts the screen voltage to hold the average

bias voltage constant. The lower adjustment on the flyback

transformer is used to set the auto bright voltage to the center of

its range. This sets up a second control feedback loop to eliminate

picture variation due to the aging of the picture tube.

G

The CRT is a 90° deflection type color picture tube with a 25KV EHT

and has integral implosion protection.

8

H

Blanking is accomplished by setting the gain of the interface IC to zero during

blank time. The Horizontal Blanking pulse is generated by amplifying the flyback

pulse. The Vertical Blanking pulse is started by the vertical oscillator and ended

by the counter in the auto bias IC via the "bias out" pulse. The Master Gain control,

located on the remote PCB, sets the gain of the video signal when blanking is not

active. The Beam Current Limiter circuit, which is designed to keep the FBT from

overloading, will reduce the video gain if the average beam current exceeds .75mA.

I

The Sync Interface can be made to accept separate or composite sync. Two

comparators are used to receive sync, one for vertical sync and the other for

horizontal sync. Resistor dividers are used to protect the comparator IC from

over voltage damage.

J

The Vertical Control circuit consists of:

1.

2.

3.

4.

Vertical sync circuit.

Vertical oscillator.

Linear ramp generator.

Output control and bias circuits for controlling the power driver.

The active components that make up these circuits, except for part of the bias circuit,

are located in the deflection control IC (LA7851). The vertical sync circuit is capable

of accepting either positive or negative going sync pulses without adjustment.

The vertical oscillator in the LA7851 is set at 45 Hz and will sync up to 65 Hz

without adjustment. The deflection yoke is driven with a linear current ramp which

produces evenly spaced horizontal lines on the raster. This linear ramp is generated

by supplying a 1uF capacitor with a constant current. The vertical output voltage is

held within range (biased) by a timer which partly discharges the 1uF ramp capacitor

at the start of vertical retrace. The duration of the timer is controlled by the vertical

output voltage and the vertical auto bias circuit.

K

The Vertical Auto Bias circuit greatly increases the range of the bias circuit built

into the LA7851. It is made up of a negative peak detector and an amplifier which

outputs current to the normal bias circuit, but with a much lower frequency response.

This then eliminates the need for adjustments during production and permits the use

of 50Hz and 60Hz vertical sync with only a size adjustment on the remote control board.

K

The aging of the picture tube (CRT) not only affects the balance of the cathode

cutoff voltage, which is corrected by the auto bias circuit, but it also affects

the gain of the CRT. The Auto Bright circuit actively corrects for CRT gain changes

by sensing any common bias change from the auto bias circuit and adjusts the scre

en voltage to hold the

9

M

The Horizontal Control incorporates a variable sync delay and a phase

locked loop to generate the horizontal timing. The H POS. adjustment on the

remote control board sets the sync delay time which controls the picture position.

The phase locked loop uses the flyback pulse to generate a sawtooth wave

which is gated with the delayed sync pulse to control the horizontal oscillator.

N

The Horizontal Driver supplies the high base current necessary to drive the

horizontal output transistor which has a beta as low as three.

It also protects the horizontal output transistor since it is a transformer and

cannot keep the base turned on for longer than its inductive time constant.

O

The Horizontal Output transistor is mounted to the rear frame which acts as

a heat sink. The collector conducts 1,000 volt flyback pulses which should

not be measured unless the equipment is specifically designed to withstand

this type of stress. A linear ramp current is produced in the horizontal

yoke by the conduction of the horizontal output transistor (trace time).

A fast current reversal (retrace time) is achieved by the high voltage pulse

that follows the turn off of the horizontal output transistor. This pulse is due

to the inductive action of the yoke and flyback transformer.

P

The main function of the Flyback Transformer (FBT) is to generate a

25,000 volt (EHT) potential for the anode of the picture tube. This voltage

times the beam current is the power that lights up the phosphor on the face

of the picture tube. At .75mA beam current the FBT is producing almost 19

watts of high voltage power. The FBT also sources the focus voltage and the

filament power. The FBT has a built in high voltage load resistor which

stabilizes the EHT, for the low beam current condition. This resistor also

discharges the EHT, when the monitor is turned off, which improves the

safety of handling the monitor.

Q

The Remote Control PCB houses the:

CONTROL

1.

2.

3.

4.

5.

DESCRIPTION

CIRCUIT

H SIZE ----------- Horizontal raster size --------- Diode modulator

V SIZE ----------- Vertical raster size ------------- Vertical drive

V RAS. POS. --- Vertical raster position ------- DC current to V. yoke

H POS ------------ Horizontal picture position -- H. sync delay

M GAIN ---------- Master gain ---------------------- Video interface

10

R

The Horizontal Size Control circuit has four inputs:

#

1.

2.

3.

4.

SIGNAL

FUNCTION

Horizontal size ---------------------- Horizontal size control

Beam current ----------------------- Blooming control

Vertical linear ramp ---------------- (#4)-(#3)=Vertical parabolic

Vertical parabolic + V. linear ramp

(Pincushion)

The horizontal size control circuit sums the four signals at one node to

produce the diode modulator control voltage.

S

The Diode Modulator is a series element of the horizontal tuned circuit.

It forms a node between GND and the normal yoke return circuit.

If this node is shorted to GND, maximum horizontal size is present.

A diode is used to control the starting time of the retrace pulse at this node.

The reverse conduction time is dependent on the forward current because the

current waveform at this node has to exceed the forward current in the diode.

A diode, placed in series with the yoke, is then used to control the retrace

pulse amplitude across the yoke. The horizontal size, therefore, is controlled by

controlling the current to this diode via the horizontal size control circuit.

T

A Voltage Doubler is used in the power supply for two reasons:

1. To improve the efficiency of the power supply.

2. To permit 120 volt and 220 volt operation. For the 220 volt

operation the voltage doubler is replaced with a bridge rectifier.

U

The Switching Regulator is synchronized to the horizontal pulse and drives

a power MOSFET. Unlike most regulators that have a common GND, this

power supply has a common V+ and current is supplied from V- to GND.

The MOSFET is connected to V- and signal ground (GND) through a

transformer which is used as an inductor for series switchmode regulation.

An operational amplifier, voltage reference, comparator, and oscillator

in the power supply controller IC are used to accomplished regulation by

means of pulse width modulation.

11

The transformer has two taps on the main winding which are used to

generate the +16 volt and +24 volt supplies. It also has a secondary which is

referenced to V- and supplies the power supply. Since the power supply is

generating its own power, a special start up circuit is built into the power

supply controller IC that delays start up until its supply capacitor is

charged up enough to furnish the current to start the power supply.

This capacitor is charged with current through a high value resistor

from the raw dc supply. This is why the power supply chirps when

an overload or underload occurs.

V

The Load consists of the video amplifiers and the horizontal flyback circuit.

The power supply will not operate without the load since the voltage that

sustains the power supply comes from a secondary in the power transformer

and depends on some primary current to generate secondary current.

W & X

A separate +12V regulator for the video and the deflection circuits are used in this

monitor to minimize raster and video interactions. This also simplifies PCB layout,

since the video GND loops are separate from the deflection GND loops.

Y

The Over Voltage Protect circuit is built into the power supply and monitors the

flyback transformer peak pulse voltage. This circuit will turn off the power

supply and hold it off if the EHT exceeds its rated value. This circuit not only

provides assurance that the X-ray specifications are met but also protects the

monitor from catastrophic failure due to a minor component failure.

12

1492 & 2092 Monitor Block Diagram

GAME

VIDEO

VIDEO

3

VIDEO

AMPS.

3

Interface

Bias

A

SYNC

F.B.P.

V retrace

Beam limit

M. gain

H

AUTO BIAS

IC

SYNC

Interface

I

Vs

G

VDY

H DY

3

F

D

Beam current

buffer

Program pulse

Grid pulse

H. blank

V. blank

2

CRT

Feedback

C

Auto

Bright

3

3

Current

B

3

3

BLANKING

Beam

3

E

VERTICAL

CONTROL

VERTICAL

OUTPUT

I. V. Feedback

High Efficiency

L

J

VERTICAL

AUTO BIAS

K

EHT

Hs

HORIZONTAL

CONTROL

Sync delay

H. Pos.

H.

H.

Driver

Output

FBT

O

N

P

M

V. Size &

V. Ras. Pos.

PINCUSHION

2

REMOTE

CONTROLS

(PCB)

DIODE

HORIZONTAL

Size Control

Q

Modulator

R

S

Beam Current

+127V

ISOLATION

Transformer

(IN GAME)

VOLTAGE

DOUBLER

Raw DC

320V

T

V-

LOAD

-200V

(VIDEO & DEFLECTION)

SWITCHING +16V

REGULATOR +27V

Sync U

OVER

VOLTAGE

PROTECT

Y

V

+12V

Video

Regulator Supply

W

+12V Deflection

Zener

Supply

X

13

BB

CC

DD

EE

FF

GG

HH

II

JJ

KK

LL

MM

13

0

6

11

3

7

7

8

+12V

392Ω

1.65K

B5

B11

1

B8

82B

7

12

14

8

B2

B19

096

3.3pF

B9

B10

89B

FDH400

83B

WITH GRID

B12

3.32K

B7

GND

VERTICAL BLANKING

129

6.8K

136

138

2

PN2907

1

139

+

155

124

134

3

1N4148

102

1.8K

135

133

8

1/2

LM393

7

1.8K

HORIZONTAL

6.4-7.5VDC BLANKING

8V

63uS

1N4148

4

0Ω

1N4148

1/2

LM393

+

6

1.92.3V

RC7

Master

Gain

RC2

5

1.8K

4

097

.1uF

GND

187

OUT

20

224

+16V

IN

V+

2.7K

2

Hs 56pF

137

132

7.2-8.1VDC

5V 63uS

104

6.8K

1K

.01uF

107

112

197

7

+12V

I2

I1

-9Hz

200K

B

22K

C

TC

4

H7

100K

4.75K

17

RETRACE &

BIAS O/S

DELAYED

SYNC O/S

15

16

V Ref.

14

GND

13

LA7851

RAS. POS.

0 TO 7 VDC

6

7

8

3.6-4.1VDC

1.6V 63uS

3.2VDC

2.9-3.4VDC

0V

5.9VDC

5.7-6.3VDC

.2V 63uS

6.3VDC

5.9-6.4VDC

4V 63uS

11

226

9

25K

330pF

I5

6,10

227

1

10K

230

I13

18

6,800pF

45K

+

228

I6

236

218

9

5.3-6VDC

7.5V 63uS

33K

13

I7

14

I8

1uF

.01uF

233

231

1K

17

2.05K

15

6800pF

I10

232

054

2,200pF

032

6.8K

15.8K

030

033

1.82K

Y

C7

094

+12V

GND

Z

*

62K

016

3.92K

3.92K

013

003

017

R

GIN

14

14

11

5

15

BR

8

340Ω

340Ω

340Ω

038

035

031

L

N

18

13

4K

O

12.1K

023

340Ω

12.1K

024

034

12.1K

340Ω

037

008

340Ω

GND

007

121

120

C2

+

.047uF

14

1/4

LM324

6,800pF

111

.1uF

5

68.1K

C12

118

20

.1uF

4

117

68.1K

C15

C1

1

V. RETRACE

604Ω

604Ω

464Ω

018

044

014

G

8

H

2.7K

052

I

1N4148

1N4148

1N4148

020

042

012

+12V

.1uF

.1uF

025

060

GND

11.5-12.5V

022

041

4.42K

021

043

D 301Ω

E

004

A

9

046

B

005

14

GND

AA

C

027

VC RED VC

4 INPUT 3

GND

P

G

VC GREEN

5 INPUT

270Ω

301Ω

001

75Ω

053

FG

B

VC BLUE

6 INPUT

1.8K

1K

047

048

FRAME

GND

080

8

1

33K

1/2

LM393

4

8

12K

20K

176

C5

2,9

67

HB

5 +

6

116

078

6.8K

1/2

LM393

270Ω

7

+10V

1.8K

VC 4 LINE

0 TTL INPUT

s

VC

1

CC

3

1.22.5V

4

Red

hold

cap.

sw.

normal

Green

hold

cap.

5

1.22.5V

10.6K

18

6

Blue input

5.86.4V

Blue

hold

cap.

303

7

1.22.5V

8

.1.3V

9

10

6.37.7V

PN2222

.5-.8VDC

.7V 17mS

J15

11K

125

16

33K

254A

GND

5V Ref.

PROGRAM

14

246

13

Inrush

Current

Limit

2.2nF

275

275

274

254A

276

279

150uF

250V

100K

1/2W

247

7

8,14

239

3

4

CONTROL &

FAULT SENSE

.1-.5VDC

5

277

5.7-6.3VDC

330pF

288

J6

FR205

248A

248

4uS

DELAY

COMP.

+

.022uF

296

GG

6 Rx

Osc.

7 Cx

285

3.6-4.4VDC

6V 63uS

12

13

5.3-5.7VDC

.10-.17VDC

1V 63uS

OUTPUT

Current

SENSE

DRIVE

38.3K

1,000

pF

J9

291

1.8K

169

271

9

G4

8

2092

22K

166 H. Pincushion

167

Parabolic

62K

50K

163

166A

G9

J11

8.87K

10K

J8

2SK1446LS

D

270

1N4005

283

284

3

13

18Ω

MPSA64

2

HEAT

SINK

10K

G1

GND

267

268

+6V LINE 19 6.8K

6.8K

171

2, 12

GND

G16

.1uF

300

.01uF

1.5KV

306

1N4005

.47uF

250V

8VDC 22V

4V 12Vp-p 17mS

MAX. MIN. H. Size

310

305

2092

.33uF

305

7

750uH

13

18

161

1/4

LM324

G13

316

2SC4159E

0Ω

14 2.2K

278

G14

15 16

HEAT

SINK

16K 17 .01uF

G15

14

185

186

1N4937

311

2.7uF

.022uF

630V

315

8

307

168

CC1

265

150Ω

292

264

CC2

BF5ROM

125

No.

Optional LTR.No.

V-

255

KK

11

2092

8.2nF

306

3,300pF

302

8VDC 23V

70V 250V 63uS

MAX. MIN. H. Size

12 +

164

1

308

200pF

1.2Ω

POWER SUPPLY VOLTAGES REFERENCED FROM VSCOPE GND MUST NOT BE CONNECTED TO GND AND V- AT THE SAME TIME.

3

4

1/4

LM324

6

1N4005

1/2W

298

301

44.2K

*

510Ω

H. Size

2.2K

220uH

167

Linear

13

G11

4

G2

10

38.3K

+12V

J12

2.4-3.6VDC

14V 63uS

1

H.

Width

H. Lin.

68uH

Adj.

.01uF 100K

G10

5

YC4

127VDC

150V 300V

MAX. MIN.

G5

12K

H SIZE

15.8K

14.7K

12

JJ

+6V

18

2,200pF

II

2092

68uH

301

1.00M

1.00M

282

5K

28K Blooming correction.

H. Width

G12

+ 100uF

162

YC3

6VDC

3V 17mS

G17

20

159

.047uF

17

11

J PRA PINS: 3,10,15, & 19

290

20

J10

8 +7.5V REF. V- 9

XRC5184 280

V-

HH

2092

36K

166

1.82K

179

287

V-

0VDC

48V 63uS

NOTES:

5

3.3K

1N4148

191K

16

.1uF

286

238

10K

8

266

244

PC 115VAC PC

2 INPUT 1

FF

FR205

8

1/4

LM324

165

G6

066

433

6VDC

4V

17mS

220K

258

2

1

6-7VDC

+127V

9

6,800pF

90K

18Ω

070

10uF

069 GND

172

10

7

.1uF

7.15K

9

10

184

1/4

LM324

6

6

SMXFR 5

9

4

3

241

Vs

EE

064

HORIZONTAL YOKE

G3

10K

Pincushion correction.

10K 7 5

261

14.8-16.3VDC

INPUT

Output

3.5-4.1VDC

3-4V 63uS

100uF

254

220Vo

131

62K

+

065

10K

178

260

19

J7

FR205

240

245

J3

+15V 16

+17V 15

INPUT Over

Voltage 14

COMP. Protect }

INPUT

3.4-4.2VDC

33.2K

257

3A

FUSE

1.9-2.3VDC

4V

17mS

5

56pF

273

253

150uF

CUT

250V

FOR

256

220Vo

25-.5Ω

C-200

12

PULSE

8.0-9.0VDC

8.4V 17mS

.5-.8VDC

J4

1.8K

252

220Vo

4.6-5.2VDC

EN

21 H. Line Auto

Counter

Bias

CL

Active

Decoder

sw. control

GRID

PULSE

15

.1uF

2

6,800pF 56pF

23.2K

2

FR205

6V Ref.

BIAS

56K

4

J2

2.2nF

143

CL

Start

Counter

FF Q

ERROR

AMP.

6.5-7.5VDC

A

+1.5V

130Ω

2.56.7V

2.7K

154

33K

comp.

VC VERTICAL

2 SYNC

DD

750Ω

4

1K

201

+

1

275

281

17 10uF

sw.

6.5-7.5VDC

.01uF

J16

142

262

183

+ 1,000uF

G7

B

+3V

260Ω

comp.

.1uF

.33uF

GND

INPUT

126

+ 1,000uF

10uF

+

2092

28K

203

203

FR205

+16V

16.3-17.8VDC

J5

2.56.7V

263

251

6

19 10uF

sw.

295

250

33K

141

Green input

250V

294

250V

317

215

249

147

2.56.7V

TZ160B-T3

160V Zener

100K

*

22K

127

20

J14

J1

1 2SA1371E

21 10uF

.1uF

150uF

289

65A

36K

FR205

+27V

20

4.67K

J13

193K

8

+127V

0Ω

297

Beam current limiter circuit.

MPSA64

+6V 270Ω

PN2222

62K

071

D

+12V

GND

+127V

D -3V

2.33K

146

1/4

LM324

comp.

5.86.4V

11

153

GND

5.86.4V

77

061

HORIZONTAL

SYNC H

TH

2

+

.14-.16V

050

75Ω

002

BB

270 Ω

045

PN2907

011

F

301Ω

026

75Ω

R

010

301Ω

301Ω

3

1.8K

.047uF

152

22K

062

051

301Ω

1K

148

10 +

9

Red input

200Ω

C16

5K

2

C -1.5V

sw. in grid pls. pos.

200Ω

C13

5K

19

C14

.047uF

1

17

12

122

C3

1/4

LM324

16

.1uF

7

68.1K

+

2

110

C8

AUTO BIAS IC

1 GND

Vcc 22

CA3224E

123

200Ω

5K

C9

3

C11

6,800pF

7

12

13

4K

144

1/4

LM324

22K

150

.1uF

146

+

6

C10

6,800pF

108

8

4

.1uF

+4.2V

4K

015

GR B IN

15

7

K

312

314

4

1 FIL.

CPT1500

GND

VERTICAL LINEARITY

+10V

145

1.82K

1.8K

M

J

7

103

C4

GND

RR

1

101

Beam

4 Current

5 FIL.

2

V-

063

2.74K

16 13 9 6 11

3

10

5 12

TTL M GAIN

+A EN +12V - A BL

R o G o Bo

BBL

Controls XRC5346A 036

R IN

2

10

C6

Q

X

6

057

2.7K

1.62K

055

.1uF

SCREEN

HL

HR

293

3

FOCUS

7

3

GND

1N4005

1.62K

040

+127V

HORIZONTAL RASTER ADJ. FR205

FR205

E

GND

9

6

8

304

470Ω,1/2W 270Ω, 2W

FBP

1N4005 1N4005

4.2-8.2VDC

5-10 17mS

9

U

056

3

4

309

200Ω 412Ω

909Ω

1

16

F

EHT

2SD1651

GND

+

5

T

237

V-

+200Hz

I16

I15

+800Hz +400Hz

FLYBACK

TRANSFORMER

10

234

157

GND

+127V

2

I11

390Ω, 2W

+27V

H.Fo ADJ. 170Ω

680Ω 340Ω I14

I9 9.31K

2

NO DVM

1KV 63uS

100Ω

20

105

S

TC1

Transformer

2SC4159E

H. V+

10

G

GND

421

182

Hs

GND

423

12.7VDC

33V 63uS Horizontal Drive

235

I12

180

150Ω 1/2W

HORIZONTAL

OSCILLATOR DISCHARGE

5

+ 1uF

418

4,700pF

433

YC2

19

.1-.3VDC

1.4V 63uS

6.8K

1

1K 1/2W

330pF

VERTICAL

DEFLECTION

YOKE

209

19

V

+

comp.

-

4

11

422

2SC3467

16

12

X-RAY

PROTECT

MULTIPLIER

BIAS

SAW TOOTH

TR . GENERATOR

431

EHT

FIL.

.01uF

195

H8

GND

+9Hz

1

1/2W

413

1K 1/2W

1/2W

H11

.36-.4VDC

.6V

63uS

8.2-9VDC

4.4V 63uS

I3

402

7

1K

405

2092

0Ω

405

GND

1,000uF 35V

+

6-6.4VDC

3

1,000

pF

47Ω

424

200K

H3

VERTICAL

OSCILLATOR

D

417

416

415

47Ω 1/2W

5

.68Ω

YC1

H9

223

.7-1.2VDC

.9V 17mS

3.0-3.8VDC

3V 17mS

9

18

4.99K

7.9-8.5VDC

4.4V 63uS

8.8K

1/2W

403

425

15

1N4742

2

22K

470Ω

414

100K 1/2W

200Ω, 2W

11.5-12.5V

12

H6

11

.16-.23VDC

5V 17mS

10

.015uF 250V

10K 1/2W

196

330Ω

76.8K

H18

84K

18

GND

0VDC

47V 63uS

1N4148

H19

CRT

12

1K

13

14,6

500K

Reverse

Hs

12K

1.8K

3

198

1,000pF

205

200

4

410

404

BLUE 11

TC2

.047uF

220

127K

0

8

420

H17

VERTICAL

± SYNC INPUT

1

8

I4

106

PN2222

.068uF

207

15

7

PICTURE

Horizontal

POSITION

O/S

SYNC INPUT

225

0Ω

VIDEO GAIN LINE

5.7-6.6VDC

4V 17mS

19

VERTICAL

100uF

GND 130

.1uF VERT.

206 OSC.

5.8-6.5VDC

4V 17mS

or

Hp5,2

18Ω

RC1

095

1.8K

.047uF

GND

216

128

3.0-3.8VDC

3V 17mS

175

.047uF

7812

.1uF

0Ω

100uF

173

156

.01uF

H14

411

1K 1/2W

2SC3675

1N4005

470uF,50V

190

+ 191

204

Vo

12.4 TO 14V

42V 17mS

9

22K

56pF

208

H4

1.2VDC

25V 17mS

+27V

330pF

118K

7

22-25VDC

1V 16mS

.7-1.0VDC

.9V 17mS

22-25VDC

25V 17mS

210

PCB 490

+12V

GND

H23

H24 GND

068

Remote Control

1K

058

098

H16

17

H10

H22

10uF

10uF

Vs

1K

485

MPS A64

D

3906

34K

6

5

+12V

GND

+12V

93B

1.62K

H13

H5

484

3 7.4-8.4VDC

100

H25 3904

22K

4

193

Bias Control Line

1.21K

200K

301Ω 11

10

202

+10V

6.8K

H15

H20

1N4148

H2

1uF

483

RC4

1.8K

H1

8

Horizontal 20K

Position

1.8K

81B

174

18

22K

88K

330Ω

92B

91B

+12V

1K

3

432

6

408

FDH400

412

TC

3

GRID PULSE

RR

RED

1K 1/2W GREEN

*

2

H12

0Ω 1 330Ω

+12V

3

406

160

RETRACE

BOOSTER

COMP.

INPUT

Retrace

Booster

Vo

18

20

1K

1.8K

2SA1370

B3

B4

181

486

RC3

1.5-2.4V

across

85B

11

1.2K

Vertical

Raster

Position

80-112VDC

Dark screen

90B

27 Ω

2

5.62K

B00

836Ω

88B

4

8.0-9.2VDC

1-2V 4uS

.1uF

0Ω

RC6

1

3.3Ω

510 Ω

2SC3467

5

790Ω

20

180 Ω

B22

3.78K

B16

RC8

750Ω

B13

14

510 Ω

500Ω

482

84B

32 Ω

1000pF

NE592

1.27K

B6

15

19

.015uF

Vertical

Size

.1uF

87B

1

B1

5

SOT

606Ω

2

10

18

0 VDC

2-4V 17mS

GND

0Ω

VERTICAL DRIVE

VERTICAL OUTPUT

VERTICAL 192

POWER

AMPLIFIER

GND

188

481

B15

2SA

68K

1

3

Horizontal

10K

Size

RC5

HEAT

SINK

+12V

+127V

B18

66 Ω

B14

B20

LA7830

270 Ω

20 16 1N4148

1370

86B

17

539Ω

8

1K 1/2W

407

FDH400

1.8-2.3VDC

270Ω

B17

FDH400

11

124-126VDC

40.2K

PCB 428

TC

6

13

Blue Video Amplifier

WITH GRID

Socket Board

20

3

8.9-9.8VDC

1V

4uS

PP

8

13

81G

Green Video Amplifier

8

6

20

81R

Red Video Amplifier

8

NN

TC

10

+

AA

Dual Posistor Optional. 246

LEGEND

BOARD PART No.

PART No. ON PRA.

X

X

PRA PIN No.

DC VOLTAGE

XRANGE, USING

Y V X-Y VDC

A DMM.

X-Y VDC

AC VOLTS CYCLE

Vp-p TIME

Peak to Peak TIME

WAVEFORM

LL

CERONIX

SCALE:

NONE

DRAWN BY:

F. H.

DATE & REV. 1/16/88

1/8/88

5/21/88 2/12/98

9

3/11/88 11/12/90

CERONIX MODEL 1492 MONITOR CIRCUIT

DRAWING

NUMBER

Measured with scope

MM

12265 Locksley Lane

Auburn, California 95602-2055

NN

PP

2ED0114-E

RR

15

VIDEO INTERFACE CIRCUIT DESCRIPTION (+ & - Analog)

The video interface circuit is a general purpose RGB type input circuit. This circuit

connects the external video signal to the video amplifiers. It can accept positive going

analog, negative going analog, and 4 line TTL. The particular mode of operation is

selected by placing solder bridges on the foil side of the PCB. The solder bridge patterns

are given in appendix A.

Simplified video interface circuit:

Black Level (5.6V)

1. NEGATIVE GOING ANALOG MODE.

+12V

RED channel shown

Saturated Color (1V)

16

7.5V BIAS LINE

VIDEO

AMPS

2.2V

R,G,&B

VIDEO

INPUTS 301Ω

200 Ω

20

604Ω

21

18

3

62K

6.3V

2

C5346

-Analog Black Level

3.6K

MG 12

Connections Installed

36

ALWAYS

(-A BL)

Q&Y

MASTER

GAIN&

BLANKING

NORMALLY

S&X

R

16

In the negative analog mode, the video signal has a black level which is the -A BL voltage.

This voltage is normally 5.6V and may be set to 5.1V by adding solder connection R .

The saturated color is the lowest input voltage (.9V-1.1V). To prevent input line ringing

from exceeding the saturated color voltage limit, a clamp diode 20 has been added.

The current amplitude to the video amplifiers is defined by resistors 21 & 18 and the

master gain voltage.

Saturated Color (1.6V or 3.2V)

2. POSITIVE GOING ANALOG MODE.

+12V

Black Level (.27V)

15.8K 11

16

VIDEO

AMPS

+ANALOG ENABLE

33

R,G,&B

VIDEO

INPUTS

3.6K

200Ω

301Ω

21

D

2

C5346

+12V

36

12.1K

23

A

75Ω

05

RED channel shown

7.5V BIAS LINE

301Ω

04

340Ω

24

MG 12

Connection Installed

ALWAYS NORMALLY

Y

MASTER

GAIN &

BLANKING

D,E,F,G,H,I,

J,K,L,P, & T

3

J

340Ω

38

M

In the positive analog mode, a bias current flows to the input which is set by resistor 33

at the +Analog Enable input. This current produces a voltage, across the parallel resistance

of the (game and 04 ) plus resistor 21 , at the IC pin 2. Without this bias current the black

level input voltage to the C5346 would be 0V and resistor 23 would not be needed.

With a bias resistor of 15.8K, the bias current is .6mA. If the external source resistance is

300 ohms, the black level voltage at pin 2 is .27V. A black level voltage of .3V is set by

resistor divider 23 , 24 to compensate for the bias current voltage drop.

The input termination resistor 04 reduces video line ringing and sets a dark

screen when the video input connector is disconnected. The saturated

color is the highest input voltage. There are two standard, saturated color,

16

voltages available: 1.6V J connected and 3.2V M connected.

VIDEO INTERFACE CIRCUIT DESCRIPTION (TTL)

3. 4 LINE TTL MODE.

+12V

RED channel shown

7.5V BIAS LINE

15.8K

R,G,&B

VIDEO

INPUTS

11

VIDEO

AMPS

+ANALOG EN. &TTL

33

+12V

905 Ω

18 21

200Ω

2.7V

2

C5346

1K (Optional)

04

+12V

INTENSITY

INPUT

16

36

GND

3.92K

03 1.87K

3.92K

13

3.6K

MG 12

Connections Installed

ALWAYS NORMALLY

None

MASTER

GAIN &

BLANKING

A, B, C,

P, & T

5

15

In the 4 line TTL mode the red, green, and blue video lines will pass color when high.

The intensity of the color is set by the fourth TTL line. Saturated color is displayed when

the intensity line is high or open, and when it is low, the displayed color is half intensity.

Although the R, G, and B lines are logic lines, the intensity line is an analog line.

To insure full saturated color, the TTL driver to the intensity line should have no other loads.

The, 1K to GND, input resistor on the color lines may be installed to keep the screen dark when

no video input cable is connected. The logic 0 voltage at the input is 0 to .4V @ .6mA.

The logic 1 voltage at the input is 2.7V to 5.5V @ -2.1mA with the 1K pulldown and .6mA without.

Refer to the video interface schematic to the right for the following component description.

Both the blanking and the gain control is accomplished by the Master Gain line to the video

interface IC (C5346 pin 12). Resistors 054 , 055 , 056 , 057 , & 094

94 provide five

programmable voltages for setting the max. MG voltage. The video gain is also affected by

each of the input modes. Resistors 021 , 018 , 043 , 044 , 011 , and 014 set the video

gain for the -Analog mode and provide protection to the video interface IC inputs in the

+Analog and TTL modes.

Resistors 014 and 030 modify the blue video response in the

Analog mode. The video gain, for the +Analog mode is set by resistors 023 , 024 , 038 ,

034 , 037 , 035 , 008 , 007 , and 031 . The TTL video gain is set by resistors 003 , 013 ,

and 015 . In the +Analog mode, G , H , AND I are bridged to reduce the offset voltage

caused by the bias current. Also, input termination resistors 004 , 026 , and 001 are used

to improve input line matching. In the TTL mode resistors 005 , 027 , and 002 may be 1K &

programmed in. A clamp circuit is used in the -Analog mode to reduce the effect of line ringing.

Resistors 050 and 051 provide a reference voltage which is buffered by PNP transistor 053 ,

load resistor 052 , capacitor 025 , and applied to diodes 020 , 042 , and 012 to perform

this clamping function. P is bridged to reference the clamp to GND for the +Analog and TTL

modes. Resistor 016 is used to set the -Analog black level lower than 5.6 volts.

If the -Analog black level is set below 4.9 volts, both resistors 016 & 017 are used to

override the chip resistor tolerance. The black level for the blue channel may be increased

for all modes by connecting resistor 030 . The C5346 036 has, built in, separate circuits

for each of the three input modes. These modes are selected by bridge points Q & Y .

17

VIDEO INTERFACE SCHEMATIC

P.S. Master Gain line (MG)

To

Video

Amps.

S

T

909 Ω

200 Ω

054

056

040

057

2.7K

Y

094

6.8K

15.8K

62K

030

033

016

+12V

GND

3.92K 3.92K

*

017

013

003

1.87K

Q

X

4.2-8.2VDC

5-10 17mS

1.5K

412 Ω

1.62K

055

.1uF

032

U

R

015

16 13 9 6 11

3

5 12

10

BL

A

TTL

M GAIN

+ A EN +12V

Ro G o B o

BBL

Controls

C5346

036

4

GND

R IN

2

RR

1

GIN

14

GR B IN

15

7

BR

8

340Ω

340Ω

340Ω

038

035

031

J

M

K

N

L

O

12.1K

340 Ω

12.1K

340 Ω

12.1K

340Ω

023

024

034

037

008

007

604Ω

604Ω

464Ω

018

044

014

G

H

I

2.7K

052

1N4148

1N4148

1N4148

020

042

012

+12V

.1uF

.1uF

025

060

GND

4.42K

051

022

041

010

301Ω

301Ω

301Ω

021

043

011

D 301Ω

E

004

A

F

301Ω

026

B

75 Ω

005

C

75 Ω

027

R

G

VC RED

4 INPUT

VC GREEN

5 INPUT

301Ω

053

001

FG

P

1.00K

050

75 Ω

002

B

PN2907

FRAME

GND

GND

HORIZONTAL

SYNC

VC BLUE VC 4 TH LINE

6 INPUT 0 TTL INPUT

18

VIDEO AMPLIFIER CIRCUIT, FUNCTION, DESCRIPTION

The video amplifier, is a high speed push pull amplifier, which can swing as much as 92 volts.

The maximum dynamic output swing is limited to 60 volts. The rest of the output voltage range

is reserved for bias adjustment.

+127V

SIMPLIFIED VIDEO AMPLIFIER CIRCUIT:

270Ω

B14

2SA1370

66Ω

B15

+12V

87B

40.2K

VIDEO

INTERFACE

392Ω

B5

1.65K

B11

606Ω

B6

C5346

790Ω

B9

1

B17

+

NE592

7

68K

B1

.015uF

82B 2SC3467

83B

14

836Ω

B10

27Ω

B3

5.62K

B12

From Auto Bias

control output

+7.9V line

The video amplifier's output voltage, With no input signal, is the black level

which is the picture tube cut off voltage. This voltage is set for each of the three video

amplifiers by the auto bias circuit. This black level voltage has a range of 80V to 112V.

The voltage swing at the output is 60 volts for a 4.3 mA current signal from the C5346.

For this same 4.3 mA current signal the voltage swing at the video amp. input is 1.32 volts and the

-input voltage swing at the NE592 is .75 volts. The reason for using the voltage matching resistor

B6 is that the C5346 minimum output voltage is 7.7 volts, and the bias voltage at the NE592

input is 5.3 volts.

VIDEO AMPLIFIER CIRCUIT DESCRIPTION

The control circuit for the video amplifier is located on the B PRA (B precision resistor array).

The B PRA includes all the Bxx resistors and the NE592. All of the parts labeled xxR

Rxx ,

xxG

xxG , and xxB

xxB , are components located on the circuit board, which are part of the red,

green, and blue video amplifiers.

The video amplifier's stability and precise response to the input signal comes from a

combination of the geometric layout of the B PRA and the high frequency response of the NE592.

The NE592 stabilization capacitor B00 is an integral part of the B PRA conductor layout.

Resistor BB44 is used to boost the NE592 drive current to the PNP transistor 87B

87B .

The NE592 bias circuit, at the input side, consists of BB55 , B6 , and BB99 .

The negative feedback bias resistors are, B11

12 with B

17 as the

B11 , B10 , and BB12

B17

output feedback resistor. Resistors B19 and B20 are connected to solder pads which,

when bridged, permit the 1492 B PRA to be used on the models 1490 and 1491 monitors.

The NE592 gain is set by resistor B8 . The drive signal from the NE592, B22

B22 pin 7,

is coupled to the base of the NPN transistor 83B through an impedance matching resistor B2

B2 .

This drive is also coupled to the base of the PNP transistor 87B

87B via a coupling capacitor 82B

82B .

The NE592 output voltage range is 6V to 10V, which is the reason for the 7.9 volt NPN bias line.

The 7.9 volt bias line is generated by buffering a voltage divider, formed by resistors 097

97

and 100 , with a PNP darlington transistor 098

98 . A capacitor 095

9 5 is connected to

shunt the high current spikes to GND. This line is common to all three video amplifiers.

The AC current gain is set by resistor B3 for the NPN output transistor and by B13

B13

for the PNP output transistor which is AC coupled via a capacitor 84B

.

On

a

positive

84B

output transition of the video amplifier, the current of the PNP transistor can go

as high as 32mA and on a negative transition the current drops to 0mA

19

VIDEO AMPLIFIER SCHEMATIC

6

7

8

Blue Video Amplifier

WITH GRID

+12V

392 Ω

1.65K

B5

B11

40.2K

B17

B14

10

5

B8

12

14

.1uF

B19

3.3pF

B00

790 Ω

836 Ω

B9

B10

.015uF

096

5.62K

B12

GND

+12V

B16

4

8.0-9.2VDC

1-2V 4uS

FDH400

83B

90B

2SA

1370

27 Ω

2

WITH GRID

88B

B3

11

1.2K

3.32K

B4

B7

91B

80-112VDC

Dark screen

1.5-2.4V

across

85B

2.2K

92B

PART OF

AUTO BIAS

2.2K

93B

BIAS CONTROL LINE

3 7.4-8.4VDC

+12V

+12V

VIDEO INTERFACE

MG

G

B13

14

510 Ω

20

84B

32 Ω

19

81B

R

15

180 Ω

510 Ω

B2 2SC

85B

3467

8

5

3.78K

.1uF

87B

1000pF

NE592

B22

18

1

82B

+127V

B15

2SA

7

SOT

1.27K

B1

B18

66 Ω

20 16 1N4148

1370

86B

17

68K

1

3

B6

270 Ω

270 Ω

B20

606Ω

1.8-2.3VDC

124-126VDC

539 Ω

8

13

3

8.9-9.8VDC

1V

4uS

VERTICAL and

HORIZONTAL

BLANKING,

Master Gain, &

Beam limiter

1.21K

100

MPS A64

D

1.62K

097

GND

098

.1uF

095

GND

B

VIDEO SOURCE (external)

For low output distortion, the PNP transistor is biased with a 6 mA current. The NPN

transistor and resistor B

17 conduct the PNP bias current to GND. Diode 86B balances the

B17

PNP base to emitter voltage. Resistors B1 and B14

B14 set the voltage across B15

B 15 which

define the video amplifier output stage bias current. A quick way to check this current, is to

measure the voltage drop across the 510 ohm 85B . The permissible voltage range is

listed on the schematic as 1.5-2.4V. The PNP and NPN collector resistors B16 and 85B

help stabilize the amplifier and provide some arc protection. Resistor BB18

18 is used to decouple

the video amplifiers from the +127V line. Capacitor 096

96 is used to decouple the +12 volt line

close to the video amplifiers. If this capacitor or the 7.9V line capacitor 095 is open, the

video may be unstable and distorted. Resistor B7

B7 is the auto bias output load resistor.

If there is a problem with the video, first check the output waveform of the video amplifier,

with the oscilloscope, if ok the problem is not in the video section. If not ok, check the input

waveform at B PRA pin 8, if not ok there, check the video interface, If ok at the video amplifier

input, refer to this section to help with analyzing the video amplifier problems.

20

SOCKET BOARD , DEGAUSSING CIRCUIT, AND LEGEND DESCRIPTION

TC

10

8

PCB 428

TC

6

FDH400

1K 1/2W

407

406

FDH400

TC

3 GRID PULSE

RED

1K 1/2W GREEN

8

411

FDH400

1K 1/2W

410

404

BLUE 11

12

*

.1uF 250V

470Ω

412

414

1/2W

403

10K 1/2W

2SC3675

100K

417

416

200K

420

100K 1/2W

47Ω

424

10

6

408

425

TC

4

432

Socket Board

415

9

5

.68Ω

405

2092

0Ω

405

47Ω

402

GND

7

1

431

1K

1K 1/2W

422

EHT

1/2W

413

1K 1/2W

EHT

FOCUS

SCREEN

418

330pF

2,200pF

423

421

FIL.

FBT

TC1

TC2

FIL.

FIL.

The primary function of the socket board is to connect the main board to the CRT and to

CC1

protect the main board against arc related voltage spikes which originate in the CRT.

The tube socket has built in spark gaps which direct part of the arc energy to the

403 . The remaining high voltage

tube ground (aquadag) through a dissipation resistor 403

CC2

406 , 406

411 , and 411

404 and

from an arc is dropped across current limit resistors: Resistors 404

407 , 408

408 , & 410

410 protect the video amplifiers by directing the arc energy to

diodes 407

BF

capacitor 414

414 . Since arcing does not normally occur in rapid succession, capacitor 414

414

5ROM

is left to discharge by the leakage current of diodes 407 , 408

408 , & 410

410 and zener

125

diode 412

412 is not normally used. The grid pulse transistor is protected by a low pass filter

244

made up of resistors 422

422 & 425

425 and capacitor 423

423 . The auto bright transistor 417

417

is protected by resistors 416

416 & 420

420 and by a low pass filter comprised of

resistors 413

413 , 418

418 , & 415

415 and capacitor 421

421 . Resistors 402

402 & 424

424

3A FUSE

reduce the arc energy from the tube ground to signal GND.

245

The current gain of the auto bright control loop is set by resistor 420

420 .

The filament current is fine tuned by resistor 405

405 .

The degaussing coil 432

432 is energized when power is turned on.

It then rapidly turns off due to the heating of posistor 244

244 .

241

PC

115VAC PC

Legend Description

2 INPUT 1 238

the 1492 board part number. The parts list gives the

No.

{ Represents

CERONIX PART NUMBER which is indexed to the board part number.

LTR.No.

Part numbers of the resistors on the PRA indicated by LTR.

LEGEND

PRA

pin

number.

To

determine

which

PRA

the

pin

number

X

X

{ belongs to, look for the nearest PRA part number on that line. No.

BOARD PART No.

XYV

X-Y VDC

DC voltages are measured to GND except in the power supply

where V- is the reference. Use a DVM for DC measurements.

X-Y VDC

Vp-p TIME

WAVEFORM

TIME is the cycle time of the waveform.

waveform is normally checked with a oscilloscope.

{ The

It has a P-P voltage amplitude of Vp-p .

LTR.No.

X

X

PART No. ON PRA.

PRA PIN No.

DC VOLTAGE

XRANGE, USING

Y V X-Y VDC

A DMM.

X-Y VDC

AC VOLTS CYCLE

Vp-p TIME

Peak to Peak TIME

WAVEFORM

CAUTION: When making measurements on the power

supply be sure that the other scope probe is not connected to GND.

Measured with scope

21

BLANKING AND MASTER GAIN CIRCUIT, FUNCTION, DESCRIPTION

Blanking in this monitor is accomplished by reducing the video gain to zero during the

vertical and horizontal blank time. During video time, the gain is set by the master

gain control which is located on the remote control PCB. If the overall beam current

exceeds .75mA for more then ten frames, the beam current limiter circuit will reduce the

video gain to protect the FBT.

SIMPLIFIED GAIN CONTROL CIRCUIT:

GAIN SELECT

RESISTORS

+12V

1K

MASTER GAIN

1K

VIDEO INTERFACE

VIDEO GAIN LINE

C5346

Video

Amp.

36

58

485

3.6K

HORIZONTAL BLANKING

FLYBACK PULSE

0VDC

47V 63uS

To

CRT

200Ω +7.5V

PN2222

One of three input circuits.

SIGNAL

CONDITIONING

CIRCUIT

BIAS ACTIVE

LM393

6 +

155

BEAM CURRENT LIMITER

+6V

2

5

Vertical Bias O/S 1/2

104

VERTICAL BLANKING

+2V

HIGH Z

+2V

+

+12V

7

1N4148

134

.047uF

MPSA64

1/2

LM393

1

PN2222

D

3 +

65

63

Total

beam current

From FBT

10uF

66

132

The video P-P voltage amplitude at the cathodes, is the video input signal amplitude times

the master gain control setting times the video amplifier gain. The gain select resistors set

the maximum video gain via the master gain line. For a greater range of brightness,

(highlighting) the video system is allowed to supply high peak video currents which could

damage the FBT if sustained. The beam current limiter circuit insures that the long term

maximum beam current is not exceeded.

104 .

Horizontal blanking is achieved by amplifying the flyback pulse (FBP) with transistor 104

Vertical blanking starts as soon as the LA7851 starts the vertical retrace sequence and is

terminated by the auto bias, bias active signal. A comparator is used to sense the vertical bias

132

O/S, at pin 16 of the LA7851, which goes low when vertical retrace starts. Capacitor 132

holds the vertical blanking active, between the vertical bias O/S pulse, and the bias active pulse.

132 is reset and vertical blanking ends,

When the bias active line goes high, the capacitor 132

after the bias active line returns to it's high impedance state.

22

BLANKING AND MASTER GAIN CIRCUIT DESCRIPTION

The master gain control 485 is connected to the video gain line through a 1K

58 . The voltage range of the video gain line is programmable via resistor 094

resistor 58

094

54 , 55

55 , 56

56 , and

and solder bridges at S , TT , & U

U which may connect resistors 54

57

57 to the video gain line. This arrangement permits a variety of input signals and

picture tubes to be used with the same monitor PCB.

Horizontal blanking ( H B ) is added to the gain line by transistors 104 . This transistor

102 when the flyback pulse is high.

pulls down on the gain line through diode 102

105 , 106 and resistor 112

Capacitor 197 is charged by diodes 105

112 such that, as soon as

the flyback pulse starts going positive the NPN transistor 104 turns on and horizontal

blanking starts. The time constant of capacitor 197 and resistors 112

112 and 107 is

chosen such that the capacitor will lead the FBP on the downward slope and turn the

horizontal blanking transistor off just at the end of the FBP.

Vertical blank time is started when a low going pulse from the LA7851 pin 16 causes

the output, pin 7, of the dual comparator 155 to go low. Capacitor 132 is discharged

through resistor 135

135 at this time. After the end of the LA7851 pulse, the capacitor 132

holds the output, pin 1 of the comparator, low until the bias active pulse recharges the

134 . During the high time of the bias active pulse, the

capacitor 132 through diode 134

134 .

second comparator output is still low, because of the voltage drop across the diode 134

The end of vertical blank time occurs when the bias active line returns to it's high

impedance state. The capacitor 132 holds the charge from the bias active pulse until the

next vertical blank time.

The video gain line will source up to 32mA during blank time, which is the reason for

buffering the vertical blank comparator with a PNP transistor 139

139 and E-B resistor 129 .

138 supply a voltage that is midrange relative to the LA7851 pulse

Resistors 137 and 138

for maximum noise immunity. Resistors 133 and 136 also supply another midrange

voltage for the bias active pulse and the, vertical blanking, hold capacitor to work against.

Resistors 124 and 156 are used as jumpers.

The beam current limiter circuit uses the base to emitter voltage of a darlington

transistor 65 to set the maximum beam current. The beam current is converted to a

voltage across resistor G17 . This voltage is applied to a long time constant RC circuit,

70

66 , before it is sensed by the darlington transistor.

resistor 70

and capacitor 66

65A

Resistor 65

A has been added to protect the darlington transistor from arc energy.

64 and 71

71 .

The sharpness of the limiting response is set by resistors 64

63 then, reduces the video gain by pulling down on the master gain line

Transistor 63

upon excessive beam current.

23

BLANKING AND MASTER GAIN SCHEMATIC

Remote control PCB

1K

VIDEO GAIN LINE

MASTER

GAIN

RC2

1K

485

GND

058

4.2-8.2VDC

5-10 17mS

+12V

VERTICAL BLANKING

FROM AUTO BIAS SUPPLY

+10V

1.8K

136

2

MPS2907

1

1/2

LM393

139

+

155

3

63uS

5

4

1.9-2.3VDC

4V

17mS

1.92.3V

1.8K

(VERTICAL BIAS O/S)

From LA7851 pin 16

156

3.0-3.8VDC

3V 17mS

1.8K

.047uF

1N4148

137

132

GND

106

6.8K

1K

.01uF

(FLYBACK PULSE)

From FBT pin 8

107

1N4148

105

112

197

0VDC

47V 63uS

PN2222

104

+

135

133

6

1/2

LM393

1.8K

1.8K

HORIZONTAL

6.4-7.5VDC BLANKING

8

124

7

134

(BIAS ACTIVE)

From auto bias IC pin 13

138

0Ω

1N4148

1N4148

102

8V

6.8K

6.8K

129

HB

TO AUTO BIAS IC

GND

GAIN SELECT RESISTORS

S

T

U

909Ω

200Ω

412 Ω

054

056

057

M

1.62K

10K

040

094

GAIN

C5346

036

VIDEO INTERFACE IC

1.62K

055

+12V

GND

FBT

+6V

BEAM CURRENT LIMITER CIRCUIT.

+6V

PN2222

063

270Ω

071

1.8K

MPSA64

D

750Ω

065

064

GND

62K

62K

065A

070

GI7

EHT

Return

+ 10uF

066

24

BB9

BB9

CC6

AA9

AA9

A2

A2

A2

B1

B2

B1

B1

B1

CPR0132 B2

BB8

BB8

BB8

BB6

BB7

BB6

BB6

BB6

AA7

Optional input filter capacitor.

301 ohm ±1%, .25W

1N4148 10mA, 75V Diode

3.92K ohm ±1%, .25W

464 ohm ±1%, .25W

1.8K ohm ±5%, .25W

62K ohm ±5%, .25W

Optional -BL adjust resistor.

604 ohm ±1%, .25W

CPD1251 B1 AA8

CPR0128 B2 AA8

B2 AA8

CPR0144 B2 AA7

CPR0129 C2 AA7

CPC1039 C2 CC8

CPR0128 C2 BB9

CPR0124 C2 BB9

CPR0050 A2

1N4148 10mA, 75V Diode

301 ohm ±1%, .25W

Optional input filter capacitor.

12.1K ohm ±1%, .25W

340 ohm ±1%, .25W

.1uF ±5% @ 50V

301 ohm ±1%, .25W

75 ohm ±1%, .25W

0 ohm Jumper

CPR0013

CPR0129

CPC1039

CPR0145

CPR0144

CPR0129

CPI1409

CPR0129

CPR0129

CPR0128

CPD1251

CPR0140

CPR0131

CPR0011

CPR0018

301 ohm ±1%, .25W

75 ohm ±1%, .25W

3.92K ohm ±1%, .25W

301 ohm ±1%, .25W

75 ohm ±1%, .25W

6 Conductor Header.

BB7 340 ohm ±1%, .25W

BB7 12.1K ohm ±1%, .25W

A2

A2

A2

A2

B3

B2

B2

B2

B2

AA6

BB7

AA5

AA6

AA7

BB7

AA6

BB7

AA7

6.8K ohm ±5%, .25W

340 ohm ±1%, .25W

.1uF ±5% @ 50V

15.8K ohm ±1%, .25W