Download SERVICE MANUAL

Transcript

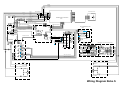

SERVICE MANUAL Chairman Robo PG8 US SERVICE MANUAL Chairman Robo PG8 Produced and published by Permobil AB, Sweden Edition no. 1, 9905 Order no.: 201019-US-0 PAB no.: 1019:1 Contents Introduction .....................................................................................................5 Technical support.........................................................................................5 Spare parts ..................................................................................................5 Warranties....................................................................................................5 Maintenance ................................................................................................5 Rating plates ...................................................................................................6 Chairman Robo............................................................................................6 Panel............................................................................................................6 Raising the seat lift.........................................................................................7 Covers..............................................................................................................8 Removal.......................................................................................................8 Fitting ...........................................................................................................8 Changing the batteries...................................................................................9 Removal.......................................................................................................9 Fitting ...........................................................................................................9 Changing the drive wheel ..............................................................................10 Removal.......................................................................................................10 Fitting ...........................................................................................................10 Changing the brake release wires ................................................................11 Changing the magnetic brake .......................................................................12 Removal.......................................................................................................12 Fitting ...........................................................................................................13 Changing the drive motor..............................................................................15 Removal.......................................................................................................15 Fitting ...........................................................................................................17 Changing the carbon-brush in the drive motor...........................................19 Removal of the carbon-brush ......................................................................19 Fitting the carbon-brush...............................................................................20 Changing the seat lift adjustment device ....................................................21 Removal.......................................................................................................21 Fitting ...........................................................................................................23 Changing the control unit..............................................................................25 Removal.......................................................................................................25 Fitting ...........................................................................................................26 Changing the control panel ...........................................................................27 Changing the joystick ....................................................................................28 Changing the printed circuit board...............................................................29 Changing the fuses ........................................................................................30 Main fuse .....................................................................................................30 Fuses in the fuse box ..................................................................................30 Charging fuse ..............................................................................................31 Cable fuse....................................................................................................31 DP1c programming unit .................................................................................32 Error codes......................................................................................................36 Wiring diagram................................................................................................37 4 Inledning Introduction The Service Manual is intended for technical personnel who maintain and repair electric wheelchairs. It is important that anyone who performs maintenance and repairs described in this manual reads and understands the content of this manual so that the work is performed professionally. Always state the chassis number when contacting Permobil to ensure that the correct information is provided. Technical Support In the event of Technical Problems, you should contact your dealer, or Pemobil Inc at 800-736-0925 Spare parts Spare parts must be ordered through your dealer. The spare parts catalogue for the Chairman Basic chassis is PAB 1212 and is available from Permobil Inc. Warranties Contact your nearest dealer or Permobil Inc. for information on the current warranties. Maintenance See the information in the Owner’s Manual. Reconditioning Contact Permobil Inc. for Reconditioning Instructions. 5 Rating plates Rating plates Chairman Robo Identity marking Chassis no. Panel Identity marking Art. no. Serial no. Modification no. 6 Raising the seat lift Raising the seat lift manually If the seat lift cannot be raised in the normal manner because the batteries are discharged or the adjustment device is defective, the seat can be raised manually. 1. Remove the plug on the left side of the cover. 2. Unscrew the adjustment device with the enclosed special key. NB. Block up the seat at the front before the screw is unscrewed. The seat is heavy and may fall forwards. 3. Carefully fold the seat forwards. NB. Check that the cables are not too taut. 4. Remove the upper cover. 5. Refit the adjustment device screw. 7 Covers Covers Removal 1. 2. 3. 4. Raise the seat to its highest position, se page 7. Remove the top cover. It is held in place by Velcro tape, so it just needs to be pulled upwards. Then remove the chassis cover. It is held in place by four screws. Open the electronics box and disconnect the contact for the rear light. Contact for rear light 5. Finally, remove the two front covers. They are each held in place by two screws. Fitting 1. 2. 3. 4. First fit the two front covers. Then reconnect the cable for the rear light and close the electronics box. Fit the chassis cover. Refit the top cover. Press the Velcro tape firmly in place. 8 Changing the batteries Changing the batteries NB. Use protective goggles when working with batteries. Removal 1. 2. 3. 4. 5. Raise the seat to its highest position., se page 7. Remove the covers. See removing the covers, page 7. Remove the rear cover and the battery covers. See page 8. Disconnect all battery connections, the positive poles first and then the negative poles. Lift out the batteries. Use lifting straps. Fitting 1. Insert two new batteries. The battery poles must be at the back. 2. Connect the battery connections, first the negative poles and then the positive poles. NB. The cables must be connected correctly. 3. Refit the covers. 4. Charge the batteries. Plus + Front Minus - Plus + Minus - rear Battery connections 9 Changing the drive wheel Changing the drive wheel Removal 1. 2. 3. Raise and block up the wheelchair's chassis so that the wheel does not reach the ground. Loosen and remove the center screw C, the washer B and the rim locking washer A (see the figure at the bottom of the page). Pull the wheel off the axle. Use the removal tool 304103-99-0 if the wheel cannot be removed by hand. Removal tool 304103-99-0 Fitting 1. 2. Fit the wheel onto the axle. Fit the rim locking washer A, the washer B and the center screw C and tighten to secure the wheel. NB. The screw has a locking coating which is sufficient for refitting 3-4 times. Then the screw must be replaced with a new one. 10 Changing the brake release wires 2 1 Brake release mechanism Changing the brake release wires 5. The upper wire controls the left brake unit and the lower wire controls the right brake unit. Fitting Removal 1. 2. Raise the seat lift to its highest position (use the crank provided for chairs without a seat lift), see page 7. Remove the cover, see page 8. Move the brake release lever forwards to its front position to facilitate removal. Loosen the wire at the magnetic brake and at the brake release mechanism. 1. Fit the wire first at the magnetic brake and then at the release lever. 2. Adjust the length of the wire sleeve using the adjusting screw (2) so that the wire is tensioned but does not pull on the release clamp. 3. Check that the brake works. Release the brake with the release lever and check that the wheel can turn. 3. Loosen the locking nut (1). 4. Tighten the locking nut. 4. Screw the adjusting screw (2) all the way in. 5. Refit the cover. 11 Changing the magnetic brake Changing the magnetic brake Removal 1. 2. 3. Raise the seat to its highest position. Remove the covers. See page 8. Disconnect the electrical connection of the magnetic brake. Electrical connection of the magnetic brake 4. Detach the brake release wire from the brake. 5. Unscrew the three screws which hold the brake and remove the brake with the extensible cover, brake disc and cover. Note the position of the brake release arm. 6. 12 Changing the magnetic brake Fitting 1. Check the setting of the brake. Follow the instructions on the decal on how the two Allen screws are adjusted. 2. Place the magnetic brake's brake disc in the brake assembly. 3. Put on the cover. 13 Changing the magnetic brake 4. Insert a screw to align the parts and screw the magnetic brake in place using all three screws. 5. Attach the magnetic brake's electrical connection. Fit the chassis cover. See Covers, page 8. 6. The magnetic brake's electrical connection 14 Changing the drive motor Changing the drive motor Removal 1. 2. Raise the seat to its highest position. Remove all the covers. See page 8. 3. 4. Remove the positive pole from one battery. Block up the appropriate side of the wheelchair. Remove the wheel. See Changing the drive wheel, page 10. 5. 6. Detach the electrical connections for the motor and magnetic brake. Magnetic brake 7. Detach the brake release wire from the magnetic brake. 15 Motor Changing the drive motor 8. To remove the motors, the chassis reinforcement must be removed. Take off the little plastic cover to reach the nuts on the rear. The reinforcement is held in place by four screws. 9. Remove the three screws which hold the motor. 10. Turn the motor sideways so that the wheel axle turns freely. Pull the motor straight forwards. NB. To facilitate removal, press the battery as far back as possible. 16 Changing the drive motor Fitting 1. Lift the motor into place. Turn it a little so that the wheel axle can turn freely without being obstructed by the chassis. 2. Screw the motor in place with the three screws. 3. Refit the chassis support. Press the cover in place. 17 Changing the drive motor 4. Attach the brake release wire. 5. Attach the electrical connections for the motor and magnetic brake. NB. Ensure that the contacts are fully interlocking. Magnetic brake 6. Fit the wheel. See page 10. 7. Remove the blocks. 8. Connect the battery poles. 9. Fit the covers. See page 8. 18 Motor Changing the carbon-brush in the drive motor Changing the carbon-brush in the drive motor Removal 1. 2. Remove the drive motor. See page 15. Remove the motor's cables from the coupling box. 3. 4. Remove the magnetic brake. Mark the stator's position against both ends with a small mark before loosening the nuts. It is important for the function of the motor that the parts are assembled precisely without being moved away from the original position. Loosen two nuts and pull off the motor end. Press the cable gland off the motor end. 5. 6. Remove the brush holder completely. Do not divide here 19 Marking Changing the carbon-brush in the drive motor Fitting 1. Fit a new brush holder using the fitting ring provided with the new brush holder. Ensure that you turn the cables in the same direction as the outgoing shaft of the gear. 2. Fit the end with two nuts. Remember the wave washer between the bearing and the end. Ensure that you assemble the parts according to the marking made earlier. It is important for the function of the motor that the parts are assembled precisely without being moved away from the original position. 3. 4. 5. Marking Insert the mounting plate, cover and brake disc. Ensure that you position the holes correctly for fitting the brake. Turn the brake so that the brake arm is in the correct position. Screw the motor cables to the plinth. Fit the drive motor. See page 17. 20 Changing the seat lift Changing the seat lift adjustment device The procedure is the same for both adjustment devices for the seat lift. Removal 1. Raise the seat lift to its highest position. 2. Remove all covers. See page 8. Lower the seat lift again. 3. Cut off the cable ties which hold the cables to the adjustment device. 4. Disconnect the connections to the adjustment device. Note how the cables are attached. 5. Unscrew the rear bolt of the adjustment device. 6. Unscrew the front bolt of the adjustment device. NB. Work on the left adjustment device is facilitated if you manually push the chair forwards. Check that no cables are too taut. 21 Changing the seat lift 7. Remove the clamping ring of the limit switch. 8. Loosen the screws which hold the limit switch. Pull away the adjustment device. 22 Changing the seat lift Fitting 1. Fit the limit sleeve on the new adjustment device. Press it as far back as possible before the sleeve is fastened on the adjustment device. NB. Check that the clamping ring of the limit sleeve clamps against the frame. 2. Fit the clamping ring of the limit sleeve. 3. Tighten the front screw of the adjustment device. 23 Changing the seat lift 4. Fit the rear screw of the adjustment device. 5. Reattach the cables of the adjustment device. 6. Fit the covers. See page 8. 24 Changing the electronics Changing the control unit Removal 1. 2. 3. 4. 5. Raise the seat to its highest position. Connect the DP1c programming unit. Read off and note the drive parameters. See page 32. Remove the top cover and rear cover. Disconnect the power connections from the electronics unit. Disconnect these three cable connections Unscrew the two screws which hold the electronics unit in place. The electronics unit is held in place by two screws 25 Changing the electronics Fitting 1. 2. Remove the mounting plate from the old electronics and mount it on the new electronics. Screw the electronics unit to the frame with the two screws. The electronics unit is held in place by two screws 3. 4. 5. 6. Connect the three cable to the electronics unit. Fit the wheelchair's rear cover and top cover. Connect the DP1c programming unit and switch the chair on. See page 32 Check and compare the drive parameters. Adjust as required. See page 32. Connect these three cable connections 26 Control panel Control panel CAUTION! Anyone opening the panel must be ESDprotected (with a wristband connected to earth). Changing the panel 1. Remove the upper cables from the electronics. 2. Unscrew and remove the control panel from the panel bracket (two Allen screws under the panel). 3. Unscrew and remove the upper part of the control panel (four screws). 4. Disconnect the upper cables in the panel. 5. Open the new panel and connect the upper cables. 6. Assemble the panel and screw it to the panel bracket. NB! The panel cover and base cover are marked with ID numbers and modification numbers and belong together 7. Connect the upper cables to the electronics. 27 Control panel CAUTION! Anyone opening the panel must be ESDprotected (with a wristband connected to earth). Changing the joystick 1. 2. 3. 4. 5. 6. 7. 8. Remove the upper cables from the electronics. Unscrew and remove the upper part of the control panel (four screws). Disconnect the joystick connection from the electronics. Unscrew the two mounting screws of the joystick. Pull out the joystick ball and then remove the whole mechanism. Screw the new joystick in place and connect it to the printed circuit board. Turn the joystick so that the pointed side is to the left. Assemble the control panel using the screws. Connect the upper cables to the electronics. 28 Printed circuit board CAUTION! Anyone opening the panel must be ESDprotected (with a wristband connected to earth). Changing the printed circuit board 1. 2. 3. 4. 5. 6. 7. 8. Remove the upper cables from the electronics. Unscrew and remove the upper part of the control panel (four screws). Disconnect the upper cables in the panel. Unscrew the printed circuit board from the panel (four screws). Remove the old printed circuit board and fit a new one. Screw the new printed circuit board in place and reconnect the cables. Assemble the control panel using the screws. Connect the upper cables to the electronics. 29 Changing the fuses Changing the fuses In order to be able to change the fuses, you must remove the rear cover. Unscrew the five screws and lift off the cover. Ensure that the rear light cables in the rear cover are firmly attached to the electronics (connector). Main fuse The main fuse must only be changed by persons with good knowledge of the wheelchair. NB. If the main fuse blows, it often means that there is a major electrical fault. The cause should be investigated carefully before a new fuse is inserted. 80 A main fuse Change the main fuse and refit the rear cover. Fuse box Remove the lid of the fuse box. Replace any blown fuses. Refit the lid of the fuse box, refit the rear cover and screw it in place. Fuse box The fuses in the fuse box have the following functions: 1 2 3 1. Seat lift/lights/24 V switched 15 A 2. 24 V direct 15 A 3. This fuse has various functions depending on the cable in the chassis. Charging fuse 15 A (cable 306858-00-0) Loop (cable 308737-00-0) NB. The loop must not be removed. Fuses 30 Changing the fuses Charging fuse on cable 308737-00-0 The fuse holder for the charging fuse is placed on the narrow red cable which goes to the positive pole of the battery. 15 A charging fuse Cable fuse on cable 308737-00-0 The cable fuse protects the cable in the event of a short-circuit in the contact. If this fuse blows, there is a faulty connection in the contact in the card in the fuse box. 20 A cable fuse 31 DP1c programming unit Connection 1. Switch off the chair. 2. Connect the DP1c to the socket beside the charging socket on the left side of the chair. 3. Switch on the chair. NB. The seat lift must be in its lowest position for the instrument to work. The instrument DP1c The arrow keys are used to step to the various programming positions and to make the necessary changes in these positions. Custom Programmer (For use with Permobil wheelchairs only) The ? key can be used to obtain help in the respective programming positions. Enter is used to confirm programming and to jump to programming positions from the menu. ? The Traffic Light is used to prepare the chair for driving/testing. Yes No Enter Penny+Giles 32 DP1c programming unit Root Menu When the chair is switched on and the DP1c is connected, driving is blocked. "DP1c Vn.n" is displayed in the text window of the DP1c, where n.n is the version number of the program in the DP1c in question. Then the Chairman 8 LS menu position is displayed. It is now possible to step through the various menus by pressing on either of the arrow keys. The menus in the root menu are: To go from the menu to the respective program positions, press Enter. Chairman Robo 8 LS Downloads all the parameters which a Chairman with Leroy Somer motors had on delivery. Answer Yes or No and press Enter. These parameters will now be the new basic settings. Chairman Robo 8 GS Downloads all the parameters which a Chairman with Grosshop motors had on delivery. Answer Yes or No and press Enter. These parameters will now be the new basic settings. Reserved 2 reserve positions for any future chair models. Service Menu? Jump to the service menu. Service Menu To enter the service menu, step to Service Menu? with the arrow keys and press Enter. It is possible to step through the service menu using the arrow keys as in the root menu. The service menu is used to set special drive parameters for a user and to read/erase the fault log. The following positions are available in the service menu: To go from the menu to the respective program positions, press Enter. Read Fault Log In the fault log it is possible to read off the alarms which have occurred in the chair. For example, this may appear as follows: 1:Code 3B00#5. This means that fault 3B00 has occurred 5 times in the chair and the most recent type of fault was 3B00 = Cable break left drive motor. To return to the menu, press Enter. Erase Fault Logg It is possible to erase the fault log here. Answer Yes or No and press Enter. Acceleration Here it is possible to set how fast/slowly the chair is to accelerate. Set the desired value with the arrow keys, up = increase in value, down = reduction, between 0 and 100. Then press Enter. See the table for the normal value. Deceleration Here it is possible to set how fast/slowly the chair is to brake. Set the desired value with the arrow keys, up = increase in value, down = reduction, between 0 and 100. Then press Enter. See the table for the normal value. 33 DP1c programming unit Turn Accel´n Here it is possible to set how fast/slowly the chair is to reach the maximum turn speed. Set the desired value with the arrow keys, up = increase in value, down = reduction, between 0 and 100. Then press Enter. See the table for the normal value. Turn Decel´n Here it is possible to set how fast/slowly the chair is to stop turning. Set the desired value with the arrow keys, up = increase in value, down = reduction, between 0 and 100. Then press Enter. See the table for the normal value. Forward Speed Here it is possible to set the maximum and minimum forward speeds. Set the desired value with the arrow keys, up = increase in value, down = reduction, between 0 and 100. Then press Enter. See the table for the normal value. Reverse Speed Here it is possible to set the maximum reverse speed. The minimum speed is calculated from the forward speed. Set the desired value with the arrow keys, up = increase in value, down = reduction, between 0 and 100. Then press Enter. See the table for the normal value. Turning Speed Here it is possible to set the maximum and minimum turning speeds. Set the desired value with the arrow keys, up = increase in value, down = reduction, between 0 and 100. Then press Enter. See the table for the normal value. NB. Adjust with great care. Speed State States whether the maximum speed setting is possible. Answer Yes or No and press Enter. Normal setting = Yes. Response State Possible future parameters. Answer Yes or No and press Enter. Normal setting = No. Present Unit Resets all parameters to the most recent basic settings. Answer Yes or No and press Enter. Set Inhibit Here it is possible to set how inhibit (stop driving) is to function. First answer Yes or No to the question about whether the chair is to stop in the event of a short-circuit and press Enter, then answer Yes or No to whether there is be an alternate function for inhibit and press Enter. Normal setting = No/No. Set Sleep Mode Here it is possible to determine whether the chair is to switch itself off if it is inactive for more than 5 minutes. Answer Yes or No and press Enter. Normal setting = No. Park Brake Trip Here it is possible to set whether the chair is to sense the magnetic brakes. Answer Yes or No and press Enter. Normal setting = Yes. Set Steering Straight trim. Trim with the arrow keys: arrow up (+) = trim to the right, arrow down (-) = trim to the left. Press Enter to confirm the trim. Applies from V4 of the electronics. Show Settings Shows all settings which have been made. Press Enter again to exit the display. Back to Root Return to the root menu. 34 DP1c programming unit Preprogrammed values Value Chairman Robo 8 LS Chairman Robo 8 GS Acceleration 50 50 Deceleration 70 70 Turn Accel´n 15 20 Turn Deccel´n 28 25 Forward Speed 90/30 100/30 Reverse Speed 42 60 Turning Speed 25/10 25/8 Speed State Yes Yes Response State No No Set Inhibit No/No No/No Set Sleep Mode No No Part Brake Trip Yes Yes Enter Dp1c V1.2 var0 entering menu... Back to root Show Settings Set Steering Part brake Trip Set Sleep Mode ? Enter Chairman 8 LS Service Menu? Read Fault Log Set Inhibit Chairman 8 GS Reserved Erase Fault Log Present Unit Hexior 8 LS Reserved Acceleration ? Response State Deceleration ? Speed State? Turn Accel´n ? Turn Decel´n ? 35 Forward Speed Reverse Speed Turning Speed Battery indicator Battery indicator – Battery indicator flashes fast.. A fault has occurred and the wheelchair will not work. The number of flashing lights indicates the nature of the fault. – Note the number of flashing lights. – Switch off the wheelchair. – Switch the wheelchair back on. – Check whether the fault is still present. The battery indicator indicates the status of the wheelchair. – Battery indicator lights permanently This indicates that everything is OK. – Battery indicator flashes slowly. This indicates that the battery should be charged as soon as possible. Troubleshooting If a fault occurs in the wheelchair, a number of lights flash on the battery voltage indicator. Count the number of lights, starting from the joystick, and check in the list what the fault is and what you can do. Number of lights Cause Remedy 1 The charge level of the battery is much too low. It requires immediate charging Check the condition of the battery to see whether it needs replacing. Check the contact between the battery and the control unit. 2 There is an interruption to the left motor. Check the connection to the left drive motor. Check whether the drive motor's carbon-brush is worn. 3 Short-circuit between the battery and the drive motor. Check the contacts and cables of the motor. 4 There is an interruption to the right motor. Check the connection to the right drive motor. Check whether the drive motor's carbon-brush is worn. 5 Short-circuit between the battery and the drive motor. Check the contacts and cables of the motor. 6 Charger connected to charging socket. Remove the charging contact from the chair. Joystick fault. Ensure that the joystick is not affected by operation. Check the contact between the joystick and the control unit. Replace the joystick unit. Replace the joystick cables. If the fault is still present, replace the control unit. 8 Control unit fault. Check the contacts of the control unit. If the fault is still present, replace the control unit. 9 Interruption in brake circuit. Check the contacts of the magnetic brake. Too high voltage in the battery Check the battery and the contacts between the battery and the control unit. 2 3 4 5 6 7 7 8 9 10 10 36 Green RK 4,0 White RK 4,0 Yellow RK 0,5 Brown RK 0,5 Battery pos +24V 0 Red RK 6,0 Black RK 6,0 1 2 2 3 3 5 5 6 6 Red RK 6,0 7 7 8 8 9 9 Battery neg 24V Output 15A 20A 1 1 2 2 3 3 10 PG8 REMOTE DIGITAL CONTROLLER Red RK 2,5 Green UL1569 AWG24 Black RK 2,5 2 3 4 5 6 2 16 Red RK 1,5 Green UL1061 0.56 Black RK 1.0 Red RK 1,5 Green UL1061 0.56 Black RK 1.0 - N 24V 1 2 Black RK 0.75 Violet RK 0.75 1 PCB SLS REDUCED 7192 CABLE CHARGE CONNECTOR 8737 INH D 1 2 15A 6 5 4 3 2 1 J4 3 2 0V SEAT POS INHIBIT DATA SER.OUT +12 1 2 3 4 1 2 3 4 5 6 5 6 5 6 34 5 7 8 6 7 8 Brown Red Orange Yellow Green Black ACTU CONTROL SEAT LIFT 6422 1 1 15A J10 2 1 Grey 0.75 Black RK 0.75 Orange RK 0.75 Blue 0.75 Red 0.75 J11 15A Black 0.75 2 1 Blue RKKB 4x0.75 C Grey RKKB 4x0.75 2 No Nc 1 Black Elcu mini 2x0,22 2 Brown Elcu mini 2x0,22 Actuator 1 2 1 2 3 4 +24V No Nc CABLE BRAKE TERRA 7135 Brown SKX 0.75 Blue SKX 0.75 CABLE BREAKPO SEAT FUNC 6127 J7 1 C 1 2 1 2 J9 InhibitLow Speed J5 2 1 +24V 0V J4 J3 2 3 4 5 6 7 8 SW3 1 SW1 2 Red RKKB 4x0.75 Nc No Green Elcuflex 0.22 No Nc Blue FKUX 0.25 SW2 M End Plug 4 7 8 SW3 C Orange FKUX 0.25 1 2 3 SW2 C Black RKKB 4x0.75 Orange Elcuflex 0.22 5 6 C Red Elcuflex 0.22 No Nc Yellow Elcuflex 0.22 Brown Elcuflex 0.22 No Nc SEAT LIFT ACTU 6422 SW3 ACTU TERRA C Black Elcuflex 0.22 M SW4 6429 MEMBRANSWITCH 6061-3 RE2 SW1 C 3 T2 SW3 Brown RKKB 0.75 Yellow RKKB 0.75 Actuator SW1 C Nc No +24V CABLE ACTU CTR 24V 6319 Nc No 4 SW3 MEMBRANSWITCH ACTUATOR CONTROLLER 5954-10 +24V SW4 SW2 SW5 PIN RE1 4 1 2 2 3 4 3 4 K5 K7 3 4 K2 K4 K6 K8 5 6 5 6 5 7 8 9 7 8 9 7 8 9 10 10 (SW1) RE4 5 1 2 RE3 Brown SKX 0.75 Blue SKX 0.75 4 J5 3 6 5 T3 5 K3 4 8 7 3 2 1 2 1 6 10 SIL1 CABLE ACTUATOR CONTR. 6743 CABLE ACTUATOR CONTR. 6743 (SW2) 4 K1 J2 2 3 T4 9 ACTU CONTROL TERRA 7134 +24V IC1 1 5 PIN 10 Brown SKX 0.75 Blue SKX 0.75 J6 3 T1 +24V 1 1 2 J1 SIL2 1 5 SW1 2 2 3 4 CABLE PCB-ELECTRONIC 6851 12 3 4 5 6 5 4 J6 CABLE 24V OUTLET 7044 1 2 3 4 5 6 J3 6 1 2 Relay C 13 15 1 2 + P Charge plug Brown RKKB 0.75 Blue RKKB 0.75 HA Black RK 2.5 Red RK 2,5 1 12 Black UL1569 AWG24 Green UL1569 AWG24 CABLE PROGR SIDE PANEL 6852 Prog 11 7777 14 1 Brake switch JOYSTICK 4 4 Fuse 80A CONTROL PANEL L8 7199 1 1 2 Blue RK 4,0 Brown RK 4,0 Left motor 24V CABLE LOWER 7699 Brown RK 0,5 Yellow RK 0,5 Left parkbrake Brown Elcuflex 0.22 Black Elcuflex 0.22 RITHA ACTUATOR CONTROLLER BOARD 7131-10 Blue Rk 0.75 Blue Rk 0.75 Black Rk 0.75 1 Black Rk 0.75 Red2.5 Black 2.5 1 M M Black 2.5 Red 2.5 2 RIGHT MOTOR 2 LEFT MOTOR Wiring Diagram Robo S SW4 K7 K8 SW2 K5 K6 SW3 K3 K4 SW1 K1 K2 Blue RKKB 4x0.75 Grey RKKB 4x0.75 Grey 0.75 Blue 0.75 Red 0.75 Black 0.75 Black Elcu mini 2x0,22 Brown Elcu mini 2x0,22 Black RKKB 4x0.75 Red RKKB 4x0.75 Orange Elcuflex 0.22 Orange FKUX 0.25 Green Elcuflex 0.22 Blue FKUX 0.25 Red Elcuflex 0.22 Yellow Elcuflex 0.22 Brown Elcuflex 0.22 Black Elcuflex 0.22 Brown Red Orange Yellow Green Blue Violett Grey Blue Violett Green Orange Brown Elcuflex 0.22 Black Elcuflex 0.22 Blue Orange Yellow Green Grey Violett Blue Green Orange Violett Wiring Diagram Robo CS