Download User's manual

Transcript

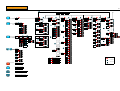

PC-2200 User’s manual Advanced Electronic/Air Column PC-2200 BOWERS METROLOGY page 1 /32 version 2.06 -E PC-2200 BOWERS METROLOGY page 2 /32 version 2.06 -E PC-2200 CONTENTS 1. INTRODUCTION 4 1.1 1.2 1.3 1.4 1.5 GENERAL INFORMATIONS TECHNICAL SPECIFICATIONS COLUMN DESCRIPTION KEYPAD CONFIGURATION STATUS PANEL 4 5 6 7 8 2. INSTALLATION 9 2.1 2.2 MECANICAL INSTALLATION ELECTRICAL INSTALLATION 9 10 3. HOW TO USE IT 11 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 SWITCHING ON THE COLUMN PROGRAMMING A SIMPLE MEASURE PROGRAMMING A PART (EXAMPLE 1) PROGRAMMING A DIAMETER PROGRAMMING A PART (EXAMPLE 2) THE CLASSIFICATION MENU THE RS232 INTERFACE LAYOUT OF IN/OUTPUT 11 12 13 14 15-16 17 18 19 4. FUNCTIONS 20 4.1 4.2 4.3 4.4 4.5 THE MEASURING MODE FUNCTIONS THE PROGRAMMING MODE FUNCTIONS CH-BUS APPLICATIONS CH-BUS MECANICAL INSTALLATION PROGRAMMING THE CH-BUS 20 21-22 23 23 24 5. PNEUMATIC INSTALLATION 25 5.1 5.2 THE A/E CONVERTER HOW TO SETUP FOR A/E CONVERTER 26 27 6. GENERAL INITIALIZATION 28 6.1 6.2 6.3 6.4 TABLE OF DEFAULT VALUES APPLICATION EXAMPLES DIAMETER/THICKNESS BLANK SETTING SHEET 28 29 29 30 7. GENERAL 31 7.1 7.2 TROUBLESHOOTING MAINTENANCE 31 32 APPENDIX A. REPLACING EPROM & CPU APPENDIX B. MENU MAP BOWERS METROLOGY page 3 /32 version 2.06 -E PC-2200 CHAPTER 1. INTRODUCTION 1.1 GENERAL INFORMATIONS - The column PC-2200 is an instrument system that measures and displays “ID, OD, Length related measurements such as misalignment, and others” in automotives, machines, electrical and electronic parts, and determines whether the measured results are acceptable or not. - The user can identify the measurement values correctly and easily as the display is made on a 3-Color LED Bar (green, orange, red) and a DOT MATRIX LED (8 characters) mounted in the front side. - The Status panel, positioned on the front bottom side, shows the current operating status in regards to the unit system (mm/inch) and operating sets (M1, M2, M3, M4) using 12 LED’s (green). - The Keypad, consists of 9 membrane switches mounted below the Status panel, performs the user program such as the system setup. The user can build the program environment that can satisfy the user’s requirements to the maximum through the Keypad operation such as selecting the menu in easy and free way and setting up the required variables. - The rear upper side is configured as the AC power switch, Fuse holder, AC power inlet and Aux. power supply, and therefore, it can use several units of PC-2200 through connecting with only one unit of power supply. The AC power of AC 110/230 V and 50/60 Hz is applied. You can select the power source of 110V/230V (default : 110V) by inserting the connector on the DC power PC board that is fixed on the upper side of the system inside. - With the 5 external interfaces on the rear center side, the column can be connected to another column, PC, Printer, PLC or CNC. - You can use the HBT, LVDT and CAPACITIVE probes as electronic system or AIR probes through the analog board on the rear bottom side. You should install the analog board (PCB) dedicated by the type of probe. - The PC-2200 is an integrated high quality measurement system that performs various measurements and display functions such as inter-channel operations up to 4 channels and dynamic mode in addition to the simple displays of measurement values. BOWERS METROLOGY page 4 /32 version 2.06 -E PC-2200 1.2 TECHNICAL SPECIFICATIONS General : Storage temperature Operational temperature Power supply Max. consumption Fuse MTBF (Mean Time between Failure) Average life of display : -40°C to 60°C /- 40°F to 140°F : 0°C to 50°C / 32°F to 122°F : 110/230V (AC) 50/60Hz : 40VA : 2A delayed : >100'000 hours : > 50'000 hours Performance : Time for stabilization after switching ON Measurement thermal drift Measuring thermal drift between channels : 5 minutes : 100PPM/°C : 30PPM/°C PC-2200 equiped with HBT-LVDT-CAP probes Measuring accuracy at 20°C / 68°F Resolution = 0.1 µm / .00001’’ : ± 0.5% ± Resolution PC-2200 equiped with Air System in the nominal conditions Working range : ± 50µm / .002’’ Interfaces : Analog OUTPUT Range : ± 5.0V F.S. Full scale accuracy: : 2% of full scale Serial OUTPUT (RS 232) Type Transmission speed (Baud rate) Word length Parity control : RS 232 C : 4800, 9600, 19200 : 7 or 8 : NONE, EVEN, ODD DC-OUT Photo couplers Maximal Voltage Maximal Tension : 50V : 60mA Weight and Dimensions : Dimensions (height * width * depth) Weight BOWERS METROLOGY : 450 * 57 * 215mm / 17.7’’*2.16’’*8.66’’ : 4.12 kg page 5 /32 version 2.06 -E PC-2200 1.3 COLUMN DESCRIPTION Rear View Front View ON-OFF Switch Fuse 2A AC power line input Bar scale 3-color LED-bar(103ea) Green, orange, red Auxiliary power line (for other column) Identification and serial numbers RS 232 C Interface External Control Interface OUTPUT Interface (class) Display (LED) (8 chr.) DC OUT Interface (V) CH-BUS Interface (signal transfer) Identification analog board Status panel 12 (LED) Analog board for (HBT, LVDT,CAPACITIVE,AIR) Keypad 9 Keys Internal View Top DC Power PCB Noise filter module Display (PCB) Main board PCB Rear Front Analog board PCB Bottom BOWERS METROLOGY page 6 /32 version 2.06 -E PC-2200 1.4 KEYPAD CONFIGURATION Program Measuring mode Access to the programming mode Programming mode No function Move upward Measuring mode Select M1, M2, M3, M4 Programming mode Used to move from a specific menu to other menu, or to increase the values when setting the values of variables. Escape Measuring mode Initialization of dynamic mode Programming mode Escape to previous menu. Move left Measuring mode Send data Programming mode Used to move from a specific menu to other or move the selected LED to the next left LED Calibration Measuring mode Calibration functions Programming mode No functions Move right Measuring mode No function Programming mode Used to move from a specific menu to other or move the selected LED to the next right LED Move downward Measuring mode No function Programming mode Preset Measuring mode Used to set the current measured values to 0 or pre-selected values (See page 20) Programming mode No function BOWERS METROLOGY page 7 /32 Enter Measuring mode Instrument OFF Enter + ON = Reset Programming mode Used to move from a specific menu to other menu, or to decrease the values when setting the values of variables. Used to select the current menu or to set values of variables version 2.06 -E PC-2200 1.5 STATUS PANEL Metric display (mm) Inch display Range ±1000µm / ±1 mm Range Range ±500µm / ±0.5 mm Range Range ±100µm / ±0.1 mm Range Range Range ±50µm / ±0.050 mm Range ± 0.001 inch Range ± 0.0005 inch ± 0.05 inch ± 0.01 inch ± 0.005 inch ±10µm / ±0.01 mm Range Range ± 0.0001 inch ±5µm / ±0.005 mm Measure number BOWERS METROLOGY page 8 /32 version 2.06 -E PC-2200 Chapter 2. Installation 2.1 MECHANICAL INSTALLATION Fix the column on the aluminum base and lock it with the 2 screws (M6 x16) Connect the power supply cable (A) . Connect the probe cable to the analog board (B) Switch (ON) I. A B BOWERS METROLOGY page 9 /32 version 2.06 -E PC-2200 2.4 ELECTRICAL INSTALLATION Switching the Voltage from 230V(110V) to 110V(230V). Remove the cover by unscrewing the 8 screws. Move the connector A on 110V or 230V. A Power supply (PCB) 3PMale Transformer (Default) 220V 0V 110V to noise filter module 2P-female BOWERS METROLOGY page 10 /32 version 2.06 -E PC-2200 Chapter 3. HOW TO USE IT 3.3 SWITCHING ON THE COLUMN To start the first time, we advise to make a general RESET . Press Enter + ON simultaneously, ▓ B O W E R S ▓ Do not release your pressure on program will start. Enter R ES E T . . . - 1 . 0 4 0 0 before the message RESET appears on the display, then a test The default parameters are : CHANNEL : Source : Ext. - CH-A Ratio :1.000 Direc. + MEASURE : M1 – Bar :Bottom B.fact. 1.00 – Range : ± 0.05” Sens : 1.000 Resol.:0.00005” – Func: A – Mode: STATIC SPEC. : M1 – NOMI. 000.0000 - -TOLER –0.0500 - +TOLER +0.0500 –APPROCH –0.0500 + APPROCH : +0.0500 MASTER : M1 - -MASTER +0.00000 +MASTER +0.00000 CLASS : OFF RS232 : SPEED 9600, DATA 8, PARITY N, TERM CRLF, RTS ON, PRINT BRIEF, RSMODE PRINT ID NO. 000 ETC : GENERAL UNIT INCH, DISPLAY mm, INPUT HBT, P/W PROGRAM 0000, CALIBR OFF AVERAGE BAR 005, DIGIT 005, A/D 20 VERSION V2.xx The above parameters are the default values, so it is necessary to modify the values according to your application. Description of functions per menu CHANNEL : Select the source and the probes used with ratio and measuring direction. MEASURE : Select the starting position of the bar, Bar factor, Range of the Bar, Resolution of the digital display, Combination of probes, Static or Dynamic measuring mode. SPEC. : Store the nominal size, the upper tolerance, the lower tolerance, the upper warning limit, the lower warning limit of the component to be measured. MASTER : Store the lower master value and the upper master value used. CLASS : Active the classification mode, class number, starting value, class range. RS232 : Select the transmission speed, word length, parity control, end of characters, request to send signal, printing mode, simplex or duplex mode, identity number. ETC GENERAL : Select the unit (mm or inch), type of display (mm or um), type of probes used, program and calibration password. AVERAGE : Select the bar sensitivity , the display sensitivity, the analog board sensitivity. VERSION : Show the software version. BOWERS METROLOGY page 11 /32 version 2.06 -E PC-2200 3.2 PROGRAMMING A SIMPLE MEASURE Example N°1 Measure a component with a HBT probe connected to channel A. Component 20.000mm ± 0.005 USING a HBT probe, we do not use the calibration, this mode will be explained in a subsequent chapter. Master 20.0000mm Step n°1 is to place the probe into a correct position to be able to get the maximum range and the minimum deviation. Place the master 20.0000 mm on the stand, place the probe into position. Press simultaneously Enter S Enter 1 . 0 5 0 0 C H - A A D J U S T Move the probe down to the electro-mechanical zero, zero, lock the probe . Press Esc 0 . 0 0 1 0 , then approximately stop around to escape to the measuring mode. Parameters to be changed for example number 1 MEASURE : M1 –Range : ± 0.01mm Resol.:0.0002mm – SPEC. : M1 – NOMI. 020.0000 - -TOLER –0.0050 - +TOLER +0.0050 –APPROCH –0.0040 + APPROCH : +0.0040 BOWERS METROLOGY page 12 /32 version 2.06 -E PC-2200 3.3 PROGRAMMING A PART (EXAMPLE 1) Press Prog (2 sec.) P / W 0 0 0 0 Enter M 1 Enter S E L E CT B AR R ANG E Enter ± 1 . 0 ± 0 . 5 ± 0 . 0 1 ± 0 . 0 0 5 ± 0 . 0 5 S EN S . R ESO L . Enter Esc 0 . 0 0 0 2 Enter R ESO L . S PE C . Enter M 1 S - M 0 . 8 0 0 0 + TO L ER S M Enter + + TO L ER S Esc 0 . 0 0 4 0 M Enter 0 2 0 . 0 0 0 0 Enter 0 . 8 0 0 0 - AP P RO Enter + S A V E ? S Enter Enter Esc N OM I . Enter Esc R ANG E MEA S URE 0 0 0 . 0 0 0 0 - TO L ER Enter 0 . 0 0 5 0 0 . 8 0 0 0 M 1 Enter - TO L ER + M - 0 . 1 0 . 0 0 0 5 M 1 + AP P RO Enter ± 0 . 0 0 1 0 . 0 0 5 0 Enter B . F A CT N OM I . - AP P RO 0 . 0 0 4 0 MEA S URE C HAN NE L S Enter Esc Enter M + 0 . 8 0 0 0 S PEC . Enter Place the master 20.0000mm in contact with the probe, then press Preset P RE S ET Enter Upper tolerance Upper approach limit The approach limit should be within the tolerance. Nominal value Lower approach limit Lower tolerance BOWERS METROLOGY page 13 /32 version 2.06 -E PC-2200 3.4 PROGRAMMING A DIAMETER Measurement of a diameter with a HBT probe connected to channel A. Component 15.000 mm ± 0.002 Min master 14.9988mm Max. master. 15.0026mm Step n°1 is to place the probe into a location to be able to get the maximum range and the minimum deviation. Place the measuring head of 15.0000 mm in the master, Press simultaneously Enter S Enter 1 . 0 5 0 0 C H - A A D J U S T Move the probe down to the electro-mechanical zero. zero, lock the probe . Press Esc 0 . 0 0 1 0 , then approximately stop around to escape to the measuring mode. Parameters to be changed for example number 2 CHANNEL : Direc. MEASURE : M1 –Range : ± 0.005 mm Resol.: 0.0001mm – SPEC. MASTER : M1 – NOMI. 015.0000 - -TOLER –0.0020 - +TOLER +0.0020 –APPROCH –0.0016 + APPROCH : +0.0016 : M1 - -Master : 14.9988mm - +Master : 15.0026mm BOWERS METROLOGY page 14 /32 version 2.06 -E PC-2200 3.5 PROGRAMMING A PART (EXAMPLE 2) Press Prog (2 sec.) P / W 0 0 0 0 C HA N NE L Enter S OUR CE Enter D I R E C + Enter R A T I O Enter D I R E C Esc Enter M 1 Enter S E L E CT B AR B . F A CT R ANG E Enter ± 1 . 0 ± 0 . 5 ± ± ± 0 . 0 1 ± 0 . 0 0 5 C H - A - MEA S URE 0 . 1 Enter C H - A 0 . 0 5 C HAN NE L Esc R ANG E S EN S . R ESO L . Enter 0 . 0 0 1 0 . 0 0 0 5 0 . 0 0 0 2 0 . 0 0 0 1 Enter R ESO L . M 1 Esc S PEC . S - M 0 . 8 0 0 0 + TO L ER Enter S 0 . 0 0 1 6 M MAS T ER S M M 1 S M Enter + Enter Enter 0 . 8 0 0 0 - AP P RO Enter Enter 0 1 5 . 0 0 0 0 S M 1 Esc BOWERS METROLOGY Enter 0 . 0 0 2 0 S M Enter - M MAS T ER Esc Enter Enter Enter Enter 0 1 5 . 0 0 2 6 S Enter Esc - MA S T ER Enter S A V E ? page 15 /32 0 . 0 0 2 0 0 . 8 0 0 0 M 1 Enter - TO L ER + - MA S T ER Esc 0 0 0 . 0 0 0 0 - TO L ER + AP P RO M 1 0 1 4 . 9 9 8 8 N OM I . N OM I . - AP P RO 0 . 0 0 1 6 + Esc MEA S URE 0 1 5 . 0 0 0 0 + TO L ER Enter Enter Enter M + 0 . 8 0 0 0 S PE C . 0 1 5 . 0 0 0 0 + MA S T ER + MA S T ER Enter Esc Enter version 2.06 -E PC-2200 The Calibration Example N°2 The parameters are now stored. The automatic calibration can be started. Min. master 14.9988mm Cal C A L . . M1 Enter Max.master 15.0026mm C A L . place the measuring head in the lower master. place the measuring head in the upper master. C A L . Enter Enter 0 . 9 8 1 The sensitivity is calculated automatically. If the message M I N then the calculated value. Cal C A L . . M1 V A L U E Enter O V E R appears, that means that the value between the two masters is bigger MODU L E Enter M 1 Enter C A L % 0 0 0 % NONE : All sensitivity values are allowed. 000% : The sensitivity value will not be accepted if the calculated value during the calibration is different from the stored value. XXX% : The sensitivity value will not be accepted if the calculated value during the calibration is different from XXX% of the stored value. After the calibration the measurement can be started. BOWERS METROLOGY page 16 /32 version 2.06 -E PC-2200 3.6 THE CLASSIFICATION MENU CLASS The class menu is used separately. Example : Pin dia. 10mm - 0 +0.100mm to be classified by steps of 0.005mm , in 20 classes, starting from 10.0000 mm. Prog (2 sec) P / W Enter S PE C . C L A S S MAS T ER O F F 0 1 0 S T A R T S Enter S T A R T 0 0 0 . 0 0 5 0 ON M Enter OK MEA S URE C HA N NE L Enter S E L E CT 0 2 0 M 0 0 0 . 0 0 0 0 S S T E P Enter S T E P Esc C Enter Enter M S E L E CT Enter N UMB ER Enter N UMB ER 0 1 0 . 0 0 0 0 0 0 0 . 0 1 0 0 C L A S S measure the first pin S Esc Enter M S AV E ? C Enter 5 The first pin will be classified into class 5, and the printed value will be between 10.025 and 10.030 mm To escape from the Class menu, SELECT. OFF BOWERS METROLOGY page 17 /32 version 2.06 -E PC-2200 3.2 THE RS232 INTERFACE The RS 232 Interface allows to send the data to a printer, as well to a PC, also allows to modify the stored parameters in the column with the help of the communicator software. How to connect a PC-2200 to a serial printer. The most important to connect a column to a printer or a computer is the adjustment of parameters. The first values to be known are the serial printer parameters. e.g. : 4800 bauds, 7 bits, parity even. adjustment How to setup the column ? Prog (2 sec.) P / W 0 0 0 0 MAS T ER S PE C . C LA S S 9 60 0 S PE E D Enter D AT A Enter P AR I T Y Enter N ON E M T ERM Enter C R M R TS Enter P R I N T Enter B R I E F R SMO D E Enter P R I N T I D N O . S AV E ? Press S ID NO :000 MEA S URE C HA N NE L Enter M 8 R S2 3 2 4 80 0 Enter S PE E D Enter D AT A E VE N Enter P AR I T Y C RL F Enter T ERM Enter R TS Enter P R I N T Esc R S2 3 2 7 M ON O F F F U L L Enter Enter 0 0 0 Enter 2 . 0 0 0 0 Enter R SMO D E Enter I D N O . Esc S END . . . M1 :+ 2.000mm OK ID NO :000 BOWERS METROLOGY page 18 /32 M1 :+ 2.000mm OK version 2.06 -E PC-2200 3.1 LAYOUT OF IN/OUTPUT 6 7 RS-232 C 8 9 Pin# 1 2 3 4 5 6 7 8 9 Functions * (not connected) Rxd Txd Vcc Gnd * (not connected) Rts Cts Gnd 1 2 3 4 5 6 7 EXT.CON 8 9 Pin# 1 2 3 4 5 6 7 8 9 Functions RS 232 sortie (0.5 sec.) Current value display Dynamic/Static M1->M2->M3->M4 Hold measure * (not connected) * (not connected) * (not connected) Gnd 1 2 3 4 5 6 7 OUTPUT 8 9 Pin# Functions 1 2 3 4 5 1 2 3 4 5 6 7 DC OUT 8 9 1 2 3 4 5 6 7 CH-BUS 8 9 1 2 3 4 5 6 7 8 9 O.K (Green) * (not connected) Approch + (Orange) +N.G (Red) * (not connected) Approch – (Orange) -N.G (Red) Drive Voltage Gnd Pin# 1 2 3 4 5 6 7 8 9 Functions D/A sortie * (not connected) * (not connected) * (not connected) * (not connected) * (not connected) * (not connected) * (not connected) Gnd Pin# 1 2 3 4 5 6 7 8 9 Functions Ex-A Ex-B Ex-C Ex-D Gnd * (not connected) * (not connected) * (not connected) Gnd (Connection of a serial printer or a PC) In the case of RS232-RS mode is set as “PRINT”, the display value is printed via the RS232 by connecting the pins #1,9 of external control.. If the RS 232-RS mode is set as « HOST », the communication becomes (duplex) and allows to use the communicator software. The external control functions can be activated by connecting the pins #1 to 5 to the pin #9(GND) according to the required function. The following functions can be activated by connecting the pin #9 to pin # (foot pedal, box) #1)Print the display value. #2) Change dynamic mode to static mode #3) Reset the dynamic mode (min., max.) #4) Move the measurement mode (M1) to M2,…… M2,M3,M4 should be active. (ON) #5) Freeze the displayed value. Active the preset mode by connecting the pin #3 and #5 simultaneously Class Mode (Binary) Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Active the contact with GND pin#9 when the value of the bar is positioned in the corresponding range pins #1, 3, 4, 6, 7) . This application shows if the product is acceptable or not with an external unit such as lamps, relays, by powering the pins #8,9. If the Class mode is turned on, the judgement mode(OK, +/-NG, etc.) is automatically turned off and the data is output with BCD code through the same port(each pin).(Refer to the chapter 3.6 for setting up.) Analog output of the display (Signal Voltage (pin #1 and #9). The voltage range is : Approx. ±4.3V with ±1 mm, or ±0.05 inch This function is used when the signal of a probe should be shifted to a second column. Application : Example : Display a maximum value on 1 column and a minimum value to the other column with only one probe.. The analog board of the column which is receiving the data should be disconnected,. Circuit connection diagram (OUTPUT) CH-Bus diagram E #4 #3 #1 #6 #7 #9 Red (bigger value than TOLER+) Probe input Analog board PCB A B C D Orange (Value between APPRO+ and TOLER+) EX-A (pin #1) EX-B (pin #2) EX-C (pin #3) EX-D (pin #4) Green (Value between APPRO- and APPRO+) Orange (Value between APPRO- and TOLER-) Red (smaller value than TOLER-) GND A/E-Converter E=External voltage Display controller BOWERS METROLOGY page 19 /32 version 2.06 -E PC-2200 Chapter 4. Functions Definition of keypad functions per menu 4.1 THE MEASURING MODE FUNCTIONS Functions Functions Access to programming mode Prog “M” Change the measure number (M1-M2) only if M2,M3,M4 (ON) M M1-M2-M3-M4 Esc “S” send the displayed value to RS232 S No function in measuring mode No function in measuring mode Enter Preset Cal Preset Value M1 00.0000 Calibration Module M1, M2, M3,M4 CAL% Simultaneously when switching (ON) RESET Access to preset mode Value = Norm. value + Meas. range. PRESET Maximum +/- 0.05” Cal. Min__ and Max Cal. by measure M1, M2, M3, M4 NONE, Value XXX% 4.2 THE PROGRAMMING MODE FUNCTIONS Prog Menu CHANNEL Sub-menu SOURCE CH-A CH-B CH-C CH-D Functions EXT. CH-BUS RATIO RATIO RATIO RATIO Functions Functions Functions 1.000 1.000 1.000 1.000 DIRECT DIRECT DIRECT DIRECT +/+/+/+/- SOURCE : EXT. Select the source of the probe on the analog board on this column. CH-BUS. Select the source of the probe from another column thru the CH-BUS. CH-A : Select the ratio value and measuring direction for the channel A. CH-B : Select the ratio value and measuring direction for the channel B. CH-C : Select the ratio value and measuring direction for the channel C. CH-D : Select the ratio value and measuring direction for the channel D. BOWERS METROLOGY page 20 /32 version 2.06 -E PC-2200 Prog Menu MEASURE Sub-menu M1 Functions ON Functions BAR B. FACT RANGE SENS. RESOL. FUNC MODE M2, M3, M4 ON/OFF ………. Functions BOTTOM,CENTER,-10->0 1.00 ± 0.05, ±0.01, ±0.005, ± 0.001, ± 0.0005, ±0.0001 1.000 0.005,0.001,0.0005,0.0001,0.00005, 0.00002, 0.00001” A,B,C,D,A+B,A-B,C+D,(A+B)-C, (A+B+C)/3,(A+B+C+D)/4, (A+B)-(C+D) STATIC,MAXIMUM,MINIMUM, (M+m)/2,(M-m)/2,M-m. M1,M… : Select the characteristics of the measuring result M1, it is possible to store 4 different measuring results (M1, M2, M3, M4). M2, M3, M4 should be (ON) BAR : Select the starting position of the LED-bar, (BOTTOM) start from bottom, (CENTER) start from center, (-10->0) start from an excentred position in case of being out of range with the LED – bar. B.FACT : Bar multiplication factor, giving the possibility of adjusting several column at the same level. RANGE : Select the measuring range. SENS : Calculated sensitivity value after calibration. RESOL : Select the measuring resolution.. FUNC : Select the setting of measurement. MODE : Select the dynamic or static mode Prog Menu SPEC. Sub-menu M1 Functions M2 M1,M.. NOMI. -TOLER +TOLER -APPRO +APPRO Prog Functions NOMI. -TOLER +TOLER -APPRO +APPRO …… Functions 0.00000” -0.05” +0.05” -0.05” +0.05” …… Functions Functions +0.00000” +0.00000” ……… : Store in measurement number 1, 2, 3, 4. : Store the nominal size : Store the lower tolerance. : Store the upper tolerance. : Store the lower warning limit. : Store the upper warning limit. Menu MASTER Sub-menu M1 Functions -MASTER +MASTER M2 ….. M1,M… : Store in measurement number 1, 2, 3, 4. -MASTER : Store the lower master value. +MASTER : Store the upper master value. BOWERS METROLOGY page 21 /32 version 2.06 -E PC-2200 Prog Menu CLASS Sub-menu Select Functions ON/OFF Functions NUMBER START STEP Functions 000 +0.0000” 0.0000 Functions Functions 4800,9600,19200 BAUD RATE 7,8 Bits NONE, ODD,EVEN CRLF / CR ON / OFF BRIEF / FULL PRINT /HOST 000 CLASS : Switch ON or OFF the class menu. NUMBER : Store the number of classes to be used. START : Store the starting nominal value STEP : Store the step value of the class. Prog Menu RS232 SPEED DATA PARITY TERM RTS PRINT RS232 ID NO Prog Sub-menu SPEED DATA PARITY TERM RTS PRINT RSMODE ID NO. Functions : Select the transmission speed . : Select the word length. : Select the parity control : none, even, odd : Select the end characters : CR, CRLF : (Request to Send) request to send a signal : Select the printing mode, (BRIEF) send the minimum data, (FULL) send a complete protocol. : Select the RS232 Interface in mode PRINT(Simplex) or HOST (Duplex) : Store an identity number. Menu ETC Sub-menu GENERAL Functions UNIT DISPLAY INPUT P/W AVERAGE BAR DIGIT A/D VERSION Functions Functions METRIC, INCH mm or um HBT,LVDT,CAP_1,CAP_5,AIR PROGRAM 0000 CALIBR. ON/OFF 0000 005 005 20 v 2.xx BMI GENERAL : Select the measuring unit, select the display (mm or um), select the analog board used, store a PROGRAM password and a CALIBRATION password. AVERAGE : BAR, Store a filter for the bar. DIGIT, Store a filter for the digital display. A/D, Store a filter for analog/digital converter. VERSION : Show the software version. ※ When changing the unit(metric to inch or inch to metric) it will be automatically out of the program without saving or confirming. The user should check the specification input after going into the program again. BOWERS METROLOGY page 22 /32 version 2.06 -E PC-2200 4.3 CH-BUS APPLICATIONS The CH-BUS channel transfers a data signal to another column. Application. Component 0.002 15.000mm ± 0.007 1 probe We need to see 2 values simultaneously. 1. Diameter 15.0000mm 2. max T.I.R 0.002mm Dia. Max-min Min.master. 14.9988mm Max.master 15.0026mm 4.4 CH-BUS MECHANICAL INSTALLATION Column n°2 Column n°1 Power supply cable Cable PC-2302 The receptive column should have the analog board removed. Cable PC-2352 Probe cable Analog board Column without analog board (Blank back cover PC-2009) BOWERS METROLOGY page 23 /32 version 2.06 -E PC-2200 4.5 PROGRAMMING THE CH-BUS The column n°1 should be programmed like example n°2 on page n°15 Programming column n°2 P / W Prog 0 0 0 0 C H - B US E X T . C HAN NE L Enter Enter S OUR CE Enter S OUR CE Enter C HA N NE L Esc M 1 Enter S E L E CT B AR B . F A CT R ANG E Enter ± 1 . 0 ± 0 . 5 ± ± ± 0 . 0 1 ± 0 . 0 0 5 MEA S URE Enter 0 . 1 0 . 0 5 R ANG E S EN S . R ESO L . Enter 0 . 0 0 1 0 . 0 0 0 5 0 . 0 0 0 2 0 . 0 0 0 1 Enter R ESO L . F UNC . MOD E Enter MOD E Esc M - m S PE C . S - M 0 . 0 0 0 0 + TO L ER Enter Enter S 0 . 0 0 1 6 M S AV E ? Enter 0 0 0 . 0 0 0 0 S M Enter + + TO L ER - M 1 Enter 0 . 0 0 0 0 - AP P RO Enter + Enter M 1 N OM I . Enter Esc Enter 0 0 0 . 0 0 0 0 Enter 0 . 8 0 0 0 M 1 0 . 0 0 2 0 S Enter Esc Enter M + 0 . 8 0 0 0 S PEC . Esc 0 . 0 0 0 0 Column n°2 Column n°1 15 . 0 0 0 0 Diameter 15.0000 mm BOWERS METROLOGY + + AP P RO Enter MEA S URE - TO L ER Enter M - Esc - TO L ER 0 . 0 0 0 0 - AP P RO 0 . 0 0 1 6 S T A T I C N OM I . S Enter 0 . 0 0 0 0 T.I.R 0.0020 mm page 24 /32 version 2.06 -E PC-2200 Chapter 5. PNEUMATIC INSTALLATION 1. Fix the column and the converter on the aluminum base. 2. Fix the hose of the air probe to nipple of converter. Hose nipple for the air probe 3. Connect the cable PC-2332 between the converter and the analog board. 4. Connect the air supply hose to the hose nipple on the converter. Air supply hose nipple Connection cable PC-2332. Not less than 3 bar of air should be supplied. BOWERS METROLOGY page 25 /32 version 2.06 -E PC-2200 5.1 THE A/E CONVERTER < Front View> <Rear View> (View) <Internal View> (Diagram) The programming procedure is similar to an electronic probe. BOWERS METROLOGY page 26 /32 version 2.06 -E PC-2200 5.2 HOW TO SETUP FOR A/E CONVERTER A. BALANCE B. PRESSURE E. SIGNAL C. GAGE D. AIR IN It is necessary to adjust the A/E CONVERTER in order to use this Column optimally. 1) Pressure Adjustment(STANDARD : 2 ± 0.1bar) - Connect PRESSURE GAUGE to “C”. Connect AIR(Min. 3 bar) to “D”. Adjust pressure by turning “B” with screw driver. ♦ Default pressure is 2 bar(Factory setting). 2) Balance adjustment - Connect the A/E converter and the Column with cable(PC-2332). Connect the air gauge to “C”. Stop supplying “D” with air. Preset the Column to “0” with the “PRESET” key. Place the air gauge into the Min. Master. Supply “D” with air. Adjust “A” with screw driver. 예) Example) Min. Master value : -0.020mm DISPLAY VALUE : -0.020mm ♦ In case of unbalance, measuring range could be narrow. BOWERS METROLOGY page 27 /32 version 2.06 -E PC-2200 Chapter 6. GENERAL INITIALIZATION (1) Function: Initialize all stored data to the default values. CAUTION : All your stored data will be erased. Press Enter + ON 6.1 TABLE OF DEFAULT VALUES Menu CHANNEL Sub-menu SOURCE Selection EXT. CH-BUS CH-A CH-B CH-C CH-D MEASURE M1 SELECT Functions Choice Default value EXT. RATIO DIREC. RATIO DIREC. RATIO DIREC. RATIO 0 - 5.000 +/0 - 5.000 +/0 - 5.000 +/0 - 5.000 1.000 + 1.000 + 1.000 + 1.000 DIREC. ON BAR +/- + ON BOTTOM B.FACT RANGE BOTTOM CENTER -10->0 -5.00 / +5.00 1.00 ± 0.05” ± 0.01” ± 0.005” ± 0.001” ± 0.0005” ± 0.0001” ± 0.01 ~ 5.000 ± 0.05” RESOL. 0.005, 0.001, 0.0005, 0.0001, 0.00005, 0.00002, 0.00001 0.00005” FUNC A, B, C, D, A+B, A-B, C+D, (A+B)-C, (A+B+C)/3, (A+B+C+D)/4 (A+B)-(C+D) STATIC, MAXIMUM, MINIMUM,(M+m)/2, (M-m)/2, M-m A SENS. MODE 1.000 STATIC SPEC. M1 NOMI. -TOLER. +TOLER -APPRO +APPRO 000.0000 -0.0000 +0.0000 -0.0000 +0.0000 0.00000 -0.05 +0.05 -0.05 +0.05 MASTER M1 +0.0000 +0.0000 CLASS SELECT -MASTER +MASTER OFF / ON NUMBER START STEP SPEED 1 - 100 +0.0000 0.0000 19200, 9600, 4800 +0.0000 +0.0000 OFF 010 +0.00000 0.001 9600 DATA PARITY TERM RTS PRINT RSMODE 7, 8 None,even,Odd CR,CRLF ON / OFF BRIEF, FULL PRINT,HOST 8 None CRLF ON BRIEF PRINT ID NO. UNIT DISPLAY INPUT P/W BAR 000 METRIC,INCH Mm, um HBT,LVDT,CAP,AIR PROGRAM CALIBR. 000 000 INCH mm HBT 0000 OFF 005 DIGIT A/D 000 00 RS232 ETC GENERAL AVERAGE VERSION BOWERS METROLOGY page 28 /32 ON/OFF 005 20 V2.xx version 2.06 -E PC-2200 6.2 APPLICATION EXAMPLES 6.3 DIAMETER/THICKNESS <Specification of the measure> External diameter : 10.000 mm Lower tolerance : - 20µm Upper tolerance: +20µm Lower warning limit: - 15µm Upper warning limit: +15µm Lower master : 9.980 mm Upper master : 10.020 mm Unit : mm A B <Initialisation> Menu CHANNEL Sub-menu SOURCE Selection EXT. CH-BUS CH-A CH-B CH-C CH-D MEASURE M1 SELECT Function RATIO DIREC. RATIO DIREC. 0 - 5.000 +/0 - 5.000 +/- 1.000 + 1.000 + RATIO DIREC. RATIO DIREC. 0 - 5.000 +/0 - 5.000 +/- 1.000 + 1.000 + ON BAR SENS. RESOL. FUNC MODE M1 MASTER M1 CLASS SELECT RS232 ETC GENERAL AVERAGE ON BOTTOM CENTER -10->0 CENTER -5.00 / +5.00 1.00 ± 1.0mm ± 0.5mm ± 0.1mm ± 0.05mm ± 0.01mm ± 0.005mm ± 0.01 ~ 5.000 ± 0.05mm 0.01, 0.005, 0.001, 0.0005, 0.0002, 0.0001 A, B, C, D, A+B, A-B, C+D, (A+B)-C, (A+B+C)/3, (A+B+C+D)/4 (A+B)-(C+D) STATIC, MAXIMUM, MINIMUM,(M+m)/2, (M-m)/2, M-m 1.000 0.001 A+B STATIC NOMI. -TOLER. +TOLER 000.0000 -0.8000 +0.0000 010.000 -0.0200 +0.0200 -APPRO +APPRO -MASTER +MASTER OFF / ON NUMBER START -0.0000 +0.0000 +00.0000 +00.0000 1 - 100 +00.0000 -0.0150 +0.0150 +9.9800 +10.0200 OFF 010 +00.0000 STEP SPEED DATA PARITY TERM RTS 0.0000 19200, 9600, 4800 7, 8 None,even,Odd CR,CRLF ON / OFF 0.0100 9600 8 None CRLF ON PRINT RSMODE ID NO. UNIT DISPLAY INPUT P/W BRIEF, FULL PRINT,HOST 000 METRIC,INCH mm, um HBT,LVDT,CAP,AIR PROGRAM BRIEF PRINT 000 METRIC mm HBT 0000 BAR DIGIT A/D CALIBR. 000 000 00 VERSION BOWERS METROLOGY Values EXT. B.FACT RANGE SPEC. Choice page 29 /32 ON/OFF OFF 003 003 10 V2.00 version 2.06 -E PC-2200 6.4 BLANK SETTING SHEET <Specification of the measure> Nominal size : Lower tolerance: Upper tolerance: Lower warning limit: Upper warning limit: Lower master : Upper master: Unit : mm <Initialisation> Menu CHANNEL Sub-menu SOURCE Selection EXT. CH-BUS CH-A CH-B CH-C CH-D MEASURE M1 SELECT Function RATIO DIREC. RATIO DIREC. 0 - 5.000 +/0 - 5.000 +/- RATIO DIREC. RATIO DIREC. ON BAR 0 - 5.000 +/0 - 5.000 +/- B.FACT RANGE SENS. RESOL. FUNC MODE SPEC. M1 MASTER M1 CLASS SELECT RS232 ETC GENERAL AVERAGE NOMI. -TOLER. +TOLER 000.0000 -0.8000 +0.0000 -APPRO +APPRO -MASTER +MASTER OFF / ON NUMBER -0.0000 +0.0000 +00.0000 +00.0000 1 - 100 START STEP SPEED DATA PARITY TERM RTS +00.0000 0.0000 19200, 9600, 4800 7, 8 None,even,Odd CR,CRLF ON / OFF PRINT RSMODE ID NO. UNIT DISPLAY INPUT BRIEF, FULL PRINT,HOST 000 METRIC,INCH mm, um HBT,LVDT,CAP,AIR P/W PROGRAM CALIBR. 000 000 00 BAR DIGIT A/D Choice Values BOTTOM CENTER -10->0 -5.00 / +5.00 ± 1.0mm ± 0.5mm ± 0.1mm ± 0.05mm ± 0.01mm ± 0.005mm ± 0.01 ~ 5.000 0.01, 0.005, 0.001, 0.0005, 0.0002, 0.0001 A, B, C, D, A+B, A-B, C+D, (A+B)-C, (A+B+C)/3, (A+B+C+D)/4 (A+B)-(C+D) STATIC, MAXIMUM, MINIMUM,(M+m)/2, (M-m)/2, M-m ON/OFF VERSION BOWERS METROLOGY page 30 /32 version 2.06 -E PC-2200 Chapter 7. General 7.1 TROUBLE SHOOTING Default The digital display & LED display are off. The digital display is off. The digital display & LED display are not moving. The function M2, M3, M4 do not work The calibration is refused “OVER MINIMUM” BOWERS METROLOGY Actions Check the power(AC 110) Check the fuse(2A) Check the power switch(ON) position Reset the column.(“Enter” key + Power ON) Check the probe position Check the connection of probe & column. Check the connection of main board & analog board. The functions M2, M3, M4 must be turned ON at MEASURE menu. One or a few data are not compatible between the specification values and the master values. page 31 /32 version 2.06 -E PC-2200 7.2 MAINTENANCE Please do not forget that this measuring instrument must be treated with care. Take notice that this “User’s manual” is in relation with the software version V.2.00. Please do not hesitate to contact us if you need further assistance. BOWERS METROLOGY page 32 /32 version 2.06 -E Menu Map for PC2200(V2.xx) BN20914 YES(ENTER) Prog P/W > 2 sec CHANNEL MEASURE SPEC EXT. M1 SELECT CH-BUS PRESET VALUE CH-A M1 ⓐ M2 ⓐ M3 ⓐ M4 ⓐ ON M1 CLASS RS232C RATIO= 0 ~ 5.000 DIREC.= + BAR RATIO= DIREC.= CAL..M(X) MOUDLE CH-EA (xxxx) RATIO= B.FACT 0.1 ~ 5.00 RANGE ⓑ SENS. ±0.010~5.000 RESOL ⓒ FUNC A 0 ~ 5.000 M1 CAL ̄ M2 xxxx M3 xxxx M4 NONE + M2 VALUE 000% 0 ~ 5.000 + C - D " CH-ED - MASTER ⓓ SELECT OFF SPEED ETC. + TOLER ⓕ + MASTER ⓓ M2 - MASTER ⓓ NOMI. ⓕ ⓕ + MASTER M3 ⓔ - MASTER + MASTER - TOLER ⓕ + TOLER ⓕ M4 4800 GENERAL UNIT 9600 INCH CLASS_No 4~100 START ⓖ STEP ⓗ DISPLAY DATA INPUT PARITY ⓓ + MASTER ⓓ HBT LVDT NONE ODD CAP_1 EVEN CAP_5 ⓓ ⓓ ㎜ ㎛ 7 8 ⓓ - MASTER METRIC 19200 AIR TERM CRLF CRLF RTS P/W ON PROGRAM **** CAL.P/W OFF OFF B DIREC.= ⓕ +APPRO " CAL_ - TOLER -APPRO - CAL% M1 -10 → 0 OR P/W ⓔ BOTTOM CENTER " CH-D NOMI. ON - >0.5 sec MASTER OFF " >0.5 sec Cal NO(ESC) (xxxx) SOURCE Preset SAVE? -APPRO ⓕ +APPRO ⓕ NOMI. ⓔ ON AVERAGE PRINT BAR 2~50 FULL DIGIT 2~50 PRINT A/D 2~20 BRIEF A+B RATIO= 0 ~ 5.000 A–B M3 RSMODE HOST C+D DIREC.= + (A+B)-C - - TOLER ⓕ (A+B+C)/3 VERSION ID_NO (A+B+C+D)/4 + TOLER ⓕ -APPRO ⓕ +APPRO ⓕ NOMI. ⓔ - TOLER ⓕ V 2.xx 0~255 (A+B)-(C+D) + ADJUST >0.5 sec MODE CH-A xxxx STATIC MAXIMUM " MINIMUM " (M+m)/2 CH-D xxxx CH-EA xxxx M-m " M4 (M-m)/2 M2 Same as M1 map + TOLER ⓕ Enter Key M3 Same as M1 map -APPRO ⓕ Left/Right Key M4 Same as M1 map +APPRO ⓕ Up/Down Key " CH-ED Enter + Power S/W xxxx Initialization of setup data Retun to upper menu in setup mode Esc Reset in dynamic mode S M Data sending(Digital display Value) M1~M2~M3~M4 Transfer (Toggle key) ****