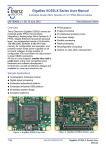

Download TE0720 User Manual

Transcript