Download BENDIX BW2786 User's Manual

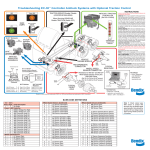

Transcript

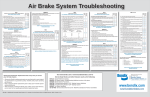

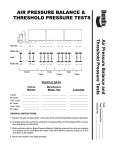

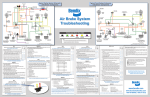

Troubleshooting Bendix ESP Stability System ® DIAGNOSTIC MODES In order to communicate with the ECU, the controller has several modes that the technician can select, allowing information to be retrieved, or other ECU functions to be accessed. To enter the various diagnostic modes: No. of Times to Press the Blink Code Switch Active diagnostic trouble code retrieval 2 Inactive diagnostic trouble code retrieval 3 Clear active diagnostic trouble codes 4 System configuration check Active Diagnostic Trouble Code Mode For troubleshooting, typically the Active and Inactive Diagnostic Trouble Retrieval Modes are used. The technician presses the blink code switch once and the ABS indicator lamp flashes a first group of two codes, and if there are more trouble codes recorded, this is followed by a second set of codes, etc. (See this page for a brief directory of these codes.) Clearing Diagnostic Trouble Codes To clear active diagnostic trouble codes (as problems are fixed), simply clear (or “self-heal”) by removing and re-applying ignition power. The only exception is for wheel speed sensor trouble codes, which clear when power is removed, re-applied, and the ECU detects valid wheel speed from all wheel speed sensors. Alternately, codes may be cleared by pressing the diagnostic blink code switch 3 times (to enter the Clear Active Diagnostic Trouble Code Mode) or by using a hand-held or PC-based diagnostic tool. Hand-held or PC-based diagnostic tools are able to clear wheel speed sensor trouble codes without the vehicle being driven. System Mode Entered 1 ® 5 Dynamometer Test Mode 7* Reconfigure ECU (See SD sheet for details.) BW1114 Quick Reference Catalog BW1231 Tractor & Truck Air Brake System Troubleshooting Wallchart BW1396 Tractor & Truck Air Brake System Troubleshooting BW1555 Brake Balance Procedure BW2780 Troubleshooting Bendix® ESP® Stability System Wallchart version of this piece BW5057 Air Brake Handbook SD-13-4869 Service Data Sheet for EC-60™ ABS/ATC Advanced Controllers EXAMPLE OF BLINK CODE MESSAGE Bendix Blink Code to Description and Other Electronic Messaging Standards (J1587 SID, J1939 SPN & FMI) 2 3 4 5 14 15 2 3 4 5 14 15 2 3 4 5 14 15 2 3 4 5 14 15 2 3 4 5 14 15 2 3 4 5 14 15 2 3 4 5 14 15 2 3 4 5 14 15 14 15 1 1 1 1 1 1 2 2 2 2 2 2 3 3 3 3 3 3 4 4 4 4 4 4 5 5 5 5 5 5 6 6 6 6 6 6 7 7 7 7 7 7 8 8 8 8 8 8 10 10 6 6 6 6 6 6 6 6 6 1 2 3 4 5 6 7 8 9 7 8 9 10 16 17 20 7 8 9 1 1 1 1 1 1 1 2 2 2 DTC Description No DTCs Wheel Speed Sensor DTCs SA Left WSS Excessive Air Gap SA Right WSS Excessive Air Gap DA Left WSS Excessive Air Gap DA Right WSS Excessive Air Gap AA Left WSS Excessive Air Gap AA Right WSS Excessive Air Gap SA Left WSS Output Low @ Drive-Off SA Right WSS Output Low @ Drive-Off DA Left WSS Output Low @ Drive-Off DA Right WSS Output Low @ Drive-Off AA Left WSS Output Low @ Drive-Off AA Right WSS Output Low @ Drive-Off SA Left WSS Open or Shorted SA Right WSS Open or Shorted DA Left WSS Open or Shorted DA Right WSS Open or Shorted AA Left WSS Open or Shorted AA Right WSS Open or Shorted SA Left WSS Loss of Sensor Signal SA Right WSS Loss of Sensor Signal DA Left WSS Loss of Sensor Signal DA Right WSS Loss of Sensor Signal AA Left WSS Loss of Sensor Signal AA Right WSS Loss of Sensor Signal SA Left WSS Wheel End SA Right WSS Wheel End DA Left WSS Wheel End DA Right WSS Wheel End AA Left WSS Wheel End AA Right WSS Wheel End SA Left WSS Erratic Sensor Signal SA Right WSS Erratic Sensor Signal DA Left WSS Erratic Sensor Signal DA Right WSS Erratic Sensor Signal AA Left WSS Erratic Sensor Signal AA Right WSS Erratic Sensor Signal SA Left WSS Tire Size Calibration SA Right WSS Tire Size Calibration DA Left WSS Tire Size Calibration DA Right WSS Tire Size Calibration AA Left WSS Tire Size Calibration AA Right WSS Tire Size Calibration SA Left Poor Brake Performance SA Right Poor Brake Performance DA Left Poor Brake Performance DA Right Poor Brake Performance AA Left Poor Brake Performance AA Right Poor Brake Performance AA Left WSS Configuration Error AA Right WSS Configuration Error Power Supply DTCs Battery Voltage Too Low Battery Voltage Too High Battery Voltage Too Low During ABS Battery Voltage Input Open Circuit Ignition Voltage Too Low Ignition Voltage Too High Ignition Voltage Too Low During ABS Input Voltage Excessive Noise (Temp.) Input Voltage Excessive Noise (Latched) Pressure Modulator Valve DTCs SA Left PMV REL Solenoid Shorted to Ground SA Right PMV REL Solenoid Shorted to Ground DA Left PMV REL Solenoid Shorted to Ground DA Right PMV REL Solenoid Shorted to Ground AA Left PMV REL Solenoid Shorted to Ground AA Right PMV REL Solenoid Shorted to Ground Trailer PMV REL Solenoid Shorted to Ground SA Left PMV REL Solenoid Shorted to Voltage SA Right PMV REL Solenoid Shorted to Voltage DA Left PMV REL Solenoid Shorted to Voltage Clearing Active Diagnostic Trouble Codes The ECU will clear active trouble codes when the diagnostic blink code switch is depressed and released three times. Visit www.bendix.com or www.foundationbrakes.com for Service Data Sheets and other literature such as the following: * To enter the Reconfiguration Mode, the switch must be held in before the application of ignition power. Once the power is supplied, the switch is released and then pressed seven times. Bendix Blink Code 1st digit 2nd digit 1 1 Inactive Diagnostic Trouble Code Mode The ECU stores past trouble codes and comments (such as configuration changes) in its memory. This record is commonly referred to as “event history.” When an active trouble code is cleared, the ECU stores it in the event history memory as an inactive trouble code. Using blink codes, the technician may review all inactive trouble codes stored on the ECU. The ABS indicator lamp will display inactive diagnostic blink codes when the diagnostic blink code switch is depressed and released two times. Inactive trouble codes, and event history, may be retrieved and cleared by using a hand-held or PC-based diagnostic tool, such as the Bendix® ACom™ Diagnostics software. J1587 J1939 FMI SID SPN N/A N/A 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 82 83 84 85 86 87 5 6 789 790 791 792 793 794 789 790 791 792 793 794 789 790 791 792 793 794 789 790 791 792 793 794 789 790 791 792 793 794 789 790 791 792 793 794 789 790 791 792 793 794 3534 3535 3536 3537 3538 3539 793 794 1 1 1 1 1 1 14 14 14 14 14 14 2 2 2 2 2 2 10 10 10 10 10 10 7 7 7 7 7 7 8 8 8 8 8 8 13 13 13 13 13 13 7 7 7 7 7 7 13 13 251 251 251 251 251 251 251 251 251 627 627 627 627 627 627 627 627 627 4 3 4 5 4 3 4 2 14 48 49 50 51 52 53 66 48 49 50 795 796 797 798 799 800 1056 795 796 797 4 4 4 4 4 4 4 3 3 3 Bendix Blink Code 1st digit 2nd digit 10 2 16 2 17 2 20 2 7 3 8 3 9 3 10 3 16 3 17 3 20 3 7 4 8 4 9 4 10 4 16 4 17 4 20 4 7 5 8 5 9 5 10 5 16 5 17 5 20 5 7 6 8 6 9 6 10 6 16 6 17 6 20 6 7 7 8 7 9 7 10 7 16 7 17 7 20 7 7 8 8 8 9 8 10 8 16 8 17 8 20 8 11 11 11 11 11 11 1 2 3 4 5 6 11 7 11 12 12 12 12 1 2 3 12 4 12 5 12 12 12 12 12 12 6 7 8 9 10 11 12 12 12 12 12 12 12 12 12 13 14 15-21 22 23 24 25 13 13 1 2 DTC Description DA Right PMV REL Solenoid Shorted to Voltage AA Left PMV REL Solenoid Shorted to Voltage AA Right PMV REL Solenoid Shorted to Voltage Trailer PMV REL Solenoid Shorted to Voltage SA Left PMV REL Solenoid Open Circuit SA Right PMV REL Solenoid Open Circuit DA Left PMV REL Solenoid Open Circuit DA Right PMV REL Solenoid Open Circuit AA Left PMV REL Solenoid Open Circuit AA Right PMV REL Solenoid Open Circuit Trailer PMV REL Solenoid Open Circuit SA Left PMV HLD Solenoid Shorted to Ground SA Right PMV HLD Solenoid Shorted to Ground DA Left PMV HLD Solenoid Shorted to Ground DA Right PMV HLD Solenoid Shorted to Ground AA Left PMV HLD Solenoid Shorted to Ground AA Right PMV HLD Solenoid Shorted to Ground Trailer PMV HLD Solenoid Shorted to Ground SA Left PMV HLD Solenoid Shorted to Voltage SA Right PMV HLD Solenoid Shorted to Voltage DA Left PMV HLD Solenoid Shorted to Voltage DA Right PMV HLD Solenoid Shorted to Voltage AA Left PMV HLD Solenoid Shorted to Voltage AA Right PMV HLD Solenoid Shorted to Voltage Trailer PMV HLD Solenoid Shorted to Voltage SA Left PMV HLD Solenoid Open Circuit SA Right PMV HLD Solenoid Open Circuit DA Left PMV HLD Solenoid Open Circuit DA Right PMV HLD Solenoid Open Circuit AA Left PMV HLD Solenoid Open Circuit AA Right PMV HLD Solenoid Open Circuit Trailer PMV HLD Solenoid Open Circuit SA Left PMV CMN Open Circuit SA Right PMV CMN Open Circuit DA Left PMV CMN Open Circuit DA Right PMV CMN Open Circuit AA Left PMV CMN Open Circuit AA Right PMV CMN Open Circuit Trailer PMV CMN Open Circuit SA Left PMV Configuration Error SA Right PMV Configuration Error DA Left PMV Configuration Error DA Right PMV Configuration Error AA Left PMV Configuration Error AA Right PMV Configuration Error Trailer PMV Chuff Test/Configuration Error J1939 DTCs J1939 Serial Link J1939 Retarder J1939 Engine Communications J1939 Invalid Data (Engine/Retarder) J1939 Supply Pressure J1939 ESP Messages Invalid Data Miscellaneous DTCs Time-Out or Invalid Data on ETC7/VP15 (for HSA-Function) J1939 HSA Switch Error or Unavailable Stop Lamp Switch Not Detected Stop Lamp Switch Always On Dynamometer Test Mode Retarder Relay or HSA Lamp Open Circuit or Shorted to Ground Retarder Relay Circuit or HSA Lamp Shorted to Voltage ABS Dash Indicator Circuit DTC PMV Common Shorted to Ground PMV Common Shorted to Voltage ATC Disabled to Prevent Brake Fade Tire Size Out of Range (Front to Rear) Wheel Speed Sensors Reversed on an Axle Diff Lock Solenoid Shorted to Ground or Open Circuit Diff Lock Solenoid Shorted to Voltage Sensor CAN Supply Voltage Error Reserved ESP Sensor Voltage Out of Range I/O2 or I/O3 Shorted High HSA Solenoid Shorted to Voltage HSA Solenoid Open or Shorted to Ground ECU DTCs ECU (02) ECU (10) J1587 SID 51 52 53 66 48 49 50 51 52 53 66 42 43 44 45 46 47 66 42 43 44 45 46 47 66 42 43 44 45 46 47 66 7 8 9 10 11 12 66 7 8 9 10 11 12 66 J1939 SPN 798 799 800 1056 795 796 797 798 799 800 1056 795 796 797 798 799 800 1056 795 796 797 798 799 800 1056 795 796 797 798 799 800 1056 795 796 797 798 799 800 1056 795 796 797 798 799 800 1056 231 231 231 231 231 231 639 639 639 639 639 639 FMI 3 3 3 3 5 5 5 5 5 5 5 4 4 4 4 4 4 4 3 3 3 3 3 3 3 5 5 5 5 5 5 5 5 5 5 5 5 5 5 13 13 13 13 13 13 7 12 14 2 2 2 2 231 639 2 231 55 231 17 639 1045 639 576 2 7 2 14 13 801 2 13 801 3 23 93 93 17 79 22 811 802 802 614 1069 810 2 4 3 14 13 7 102 564 5 102 103 N/A 103 154 94 94 564 3 1808 2 N/A N/A 1808 2 614 3 2622 3 2622 5 254 254 629 629 Bendix Blink Code 1st digit 2nd digit 13 3 13 4 13 5 13 6 13 7 13 8 13 9 13 10 13 11 13 12 13 13 13 14 13 15 13 16 13 17 13 18 13 19 13 20 13 21 13 22 13 23 13 24 13 25 18 18 18 18 19 19 19 19 1 2 3 4 1 2 3 4 21 21 21 21 21 21 21 21 21 21 1 2 3 4 5 6 7 8 9 10 22 22 22 22 22 22 22 22 22 22 22 22 1 2 3 4 5 6 7 8 9 10 11 12 22 13 22 14 22 22 15 16 23 23 23 23 23 1 2 3 4 5 23 6 23 7 24 24 24 24 24 24 1 2 3 4 5 6 DTC Description ECU (11) ECU (12) ECU (13) ECU (14) ECU (15) ECU (16) ECU (17) ECU (18) ECU (1A) ECU (1B) ECU (80) ECU (04) ECU (06) ECU (0E) ECU (0D) ECU (19) ECU (1C) ECU (27) ECU (1D) ECU (1E) ECU (28) ECU (37) VIN / Chassis Mis-Match TCV DTCs TCV DA Solenoid Shorted to Ground TCV DA Solenoid Shorted to Voltage TCV DA Solenoid Open Circuit TCV DA Configuration Error TCV SA Solenoid Shorted to Ground TCV SA Solenoid Shorted to Voltage TCV SA Solenoid Open Circuit TCV SA Configuration Error Steering Angle Sensor DTCs SAS Not Calibrated SAS Calibration in Progress SAS Static Signal SAS Signal Out of Range SAS Signal Reversed SAS Invalid Signal SAS Gradient Error SAS CAN Timeout SAS Long Term Calibration Error SAS Plausibility Check (Ref Yaw Rate) Yaw Rate Sensor DTCs YRS Signal Out of Range YRS Sensor Reversed Signal YRS Invalid Signal YRS Gradient Error YRS CAN Timeout YRS Static BITE Error YRS Dynamic BITE Error YRS Fast Calibration Error YRS Static Calibration Error YRS Normal Calibration Error YRS Sensitivity Calibration Error YRS Plausibility Check (Ref Yaw Rate) YRS Plausibility Error (Inside Model Based Limits) YRS Plausibility Error (Outside Model Based Limits) YRS Sign Check Not Completed YRS Vibration Detected Lateral Acceleration Sensor DTCs LAS Signal Out of Range LAS Calibration in Progress LAS Static Calibration Error LAS Long Term Calibration Error LAS Plausibility Error (Inside Model Based Limits) LAS Plausibility Error (Outside Model Based Limits) Erratic ESP Sensor Signal Pressure Sensor DTCs PS1 Open or Shorted PS2 Open or Shorted PS3 Open or Shorted PS1/PS2 Plausibility Error PS Supply Voltage Error PS Not Calibrated J1587 J1939 FMI SID SPN 254 629 12 254 629 2 254 629 2 254 629 12 254 629 2 254 630 13 254 630 13 254 630 12 254 802 12 254 802 12 254 629 12 254 629 12 254 629 12 254 629 12 254 629 2 254 629 2 253 630 12 253 630 12 253 630 13 253 630 13 253 630 13 254 629 12 254 629 12 18 18 18 18 19 19 19 19 806 806 806 806 807 807 807 807 4 3 5 13 4 3 5 13 89 89 89 89 89 89 89 89 89 89 1807 1807 1807 1807 1807 1807 1807 1807 1807 1807 13 13 2 2 2 12 2 9 2 2 103 103 103 103 103 103 103 103 103 103 103 103 1808 1808 1808 1808 1808 1808 1808 1808 1808 1808 1808 1808 2 2 2 2 9 2 2 2 2 2 2 2 103 1808 2 103 1808 2 89 103 1808 1808 13 2 99 99 99 99 99 1809 1809 1809 1809 1809 2 13 2 2 2 99 1809 2 99 1809 14 77 78 69 77 77 77 1067 1068 1059 1067 1067 1067 2 2 2 11 2 7 12 12 See the Service Data sheet for full test and repair procedures: SD-13-4869 Bendix® EC-60™ Advanced ABS Controllers Troubleshooting Bendix ESP Stability System ® ® Typical Tractor System Schematic with ESP® Stability PP-5™ Control Valve TP-3DC™ Tractor Protection Valve MV-3® Control Valve Typical Truck System Schematic with ESP® Stability Control WS-24™ Wheel Speed Sensor C WS-24™ Wheel Speed Sensor S WS-24™ Wheel Speed Sensor Hose Couplings Stop Light Switch ADB-22X™ Disc Brake M-32™ / M-32QR™ Modulator DC-4® Double Check Valve EC-60™ Electronic Controller Advanced ADB-22X™ Disc Brake Supply ADB-22X™ Disc Brake M-32™ / M-32QR™ Modulator (4 places) TCS-9000™ Valve M-32™ / M-32QR™ Modulator (4 places) Antilock Traction Relay Valve E-8P® / E-6® Brake Valve with BVA-85™ Brake Valve Actuator SAS-60™ Steering Angle Sensor AD-IS® Air Dryer Rear Axle Module (RAM) with ATR-6™ Traction Relay Valve YAS-60™ Yaw Rate & Lateral Acceleration Sensor PP-DC® Park Control Valve YAS-60™ Yaw Rate & Lateral Acceleration Sensor SAS-60™ Steering Angle Sensor Antilock Traction Relay Valve Orifice Check Valve To Accessories PR-3™/ PR-4™ Valve AD-9®/ AD-IP® Air Dryer Low Pressure Indicator Safety Valve Front Axle Reservoir Supply Reservoir ® ES™ Drum Brake w/ ASA-5® Automatic Slack Adjuster and Service Chamber Tu-Flo 550/ Tu-Flo® 750 BA-921® / BA-922® Air Compressor Rear Axle Reservoir To Accessories WS-24™ Wheel Speed Sensor ES™ Drum Brake w/ ASA-5® Automatic Slack Adjuster and SB-4™ Spring Brake Chamber ES™ Drum Brake w/ ASA-5® Automatic Slack Adjuster and Service Chamber Primary Secondary Park (Supply) Antilock Traction Relay Valve SR-7® Spring Brake Modulating Valve Low Pressure Indicator Front Axle Reservoir Rear Axle Reservoir WS-24™ Wheel Speed Sensor ES™ Drum Brake w/ ASA-5® Automatic Slack Adjuster and SB-4™ Spring Brake Chamber Tu-Flo® 550/Tu-Flo® 750/ BA-921®/ BA-922® Air Compressor Notes: The color coding of the brake system schematic follows TMC Recommended Practice #423. Air disc & drum brake actuation combined on a single axle are shown for pictorial purposes only. TRUCKS AND TRUCK TRACTORS: Charging ADB-22X™ Disc Brake E-8P®/ E-6® Brake Valve Stop Light Switch QR-1C® Quick Release Valve EC-60™ Electronic Controller Advanced Parking Accessories (Control) Troubleshooting: PC-based Troubleshooting, Blink Codes and Diagnostic Tools & Modes The information presented here is condensed from the troubleshooting section of the Bendix® EC-60™ Advanced ABS Controller Service Data Sheet, SD-13-4869 available for download on www.bendix.com. Whenever possible, use a PC-based diagnostic tool, such as the Bendix® ACom™ Software (free download from www.bendix.com) or hand-held Bendix® Remote Diagnostic Unit (RDU). The Bendix® ACom™ Software uses on-screen troubleshooting steps to help correct any DTCs. The Bendix® ACom™ Software (BW2329) may also be ordered on CD from the Literature Center at www.bendix.com. Below: Bendix® Remote Diagnostic Unit (RDU), Right: Bendix® ACom™ Diagnostics Software for ABS BLINK CODES Blink codes allow a technician to troubleshoot ABS problems in situations where a hand-held or PC-based diagnostic tool is not available. Instead, information about the ABS system is communicated by the ECU, using the ABS indicator lamp to display sequences of blinks. Note: The ECU will not enter the diagnostic blink code mode if the wheel speed sensors show that the vehicle is in motion. If the ECU is in the diagnostic blink code mode and then detects vehicle motion, it will exit the blink code mode. In addition, by operating the blink code switch as described below, one of several diagnostic modes can be entered. See Diagnostic Modes section below. Blink Code Switch Activation When activating the blink code switch: ECU DIAGNOSTICS The EC-60™ controller contains self-testing diagnostic circuitry that continuously checks for the normal operation of internal components and circuitry, as well as external ABS components and wiring. Active Diagnostic Trouble Codes (DTCs) When an erroneous system condition is detected, the EC-60™ controller: 1. Illuminates the appropriate indicator lamp(s) and disengages part or all of the ABS, ATC and ESP functions. (See Service Data Sheet.) 2. Places the appropriate trouble code information in the ECU memory. 3. Communicates the appropriate trouble code information over the serial communications diagnostic link as required. Hand-held or PC-based diagnostic tools attach to the vehicle diagnostic connector, typically located on or under the dash. When using our PC-based Bendix® ACom™ Software, follow the on-screen troubleshooting steps to correct any DTCs. A hand-held tool such as the Bendix Remote Diagnostic Unit (RDU) provides direct access to the DTCs without the need to use blink codes. 1. Wait at least two seconds after “ignition on.” (Except when entering Reconfiguration Mode - see Service Data sheet.) 2. For the ECU to recognize that the switch is activated “on,” the technician must press for at least 0.1 seconds, but less than 5 seconds. (If the switch is held for more than 5 seconds, the ECU will register a malfunctioning switch.) 3. Pauses between pressing the switch when a sequence is required, (e.g. when changing mode) must not be longer than 2 seconds. 4. After a pause of 3.5 seconds, the ECU will begin responding with output information blinks. Blink Code Timing The ECU responds with a sequence of blink codes. The overall blink code response from the ECU is called a “message.” Each message includes, depending on the mode selected by the technician, a sequence of one or more groups of blinks. Simply record the number of blinks for each sequence and then use the brief troubleshooting index shown here, or full troubleshooting information in the Service Data sheet, for active or inactive trouble codes. NOTE: 1. Sequences of blinks illuminate the ABS indicator lamp for half a second, with half-second pauses between them. 2. Pauses between blink code digits are 1.5 seconds. 3. Pauses between blink code messages are 2.5 seconds. 4. The lamp remains on for 5 seconds at the end of the messages. Once the ABS indicator lamp begins displaying a sequence of codes, it continues until all blink code messages have been displayed and then returns to the normal operating mode. During this time, the ECU will ignore any additional blink code switch activation. All trouble codes, with the exception of voltage and J1939 trouble codes, will remain in an active state for the remainder of the power cycle. Voltage trouble codes will clear automatically when the voltage returns within the required limits. All ABS functions will be re-engaged. J1939 trouble codes will clear automatically when communications are re-established. www.bendix.com BW2786 © 2009 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • All Rights Reserved • 08/09 • Printed in U.S.A. www.foundationbrakes.com