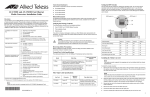

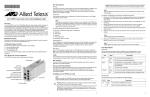

Download Allied Telesis AT-CV5001DC

Transcript