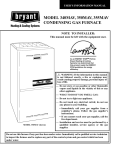

Download Bryant 355MAV Furnace User Manual

Transcript