Download Mercury Bravo Three Service manual

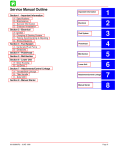

Transcript