Download Bunn SINGLE CWF Technical data

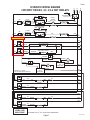

Transcript